Butt joint connecting device and method for large-scale steel pipe columns under circumstance of vibration load

A technology for connecting device and steel pipe column, which is applied to auxiliary devices, welding equipment, welding equipment, etc., to avoid grinding and finishing work, reduce engineering construction costs, and strengthen the strength of pipeline interface positions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

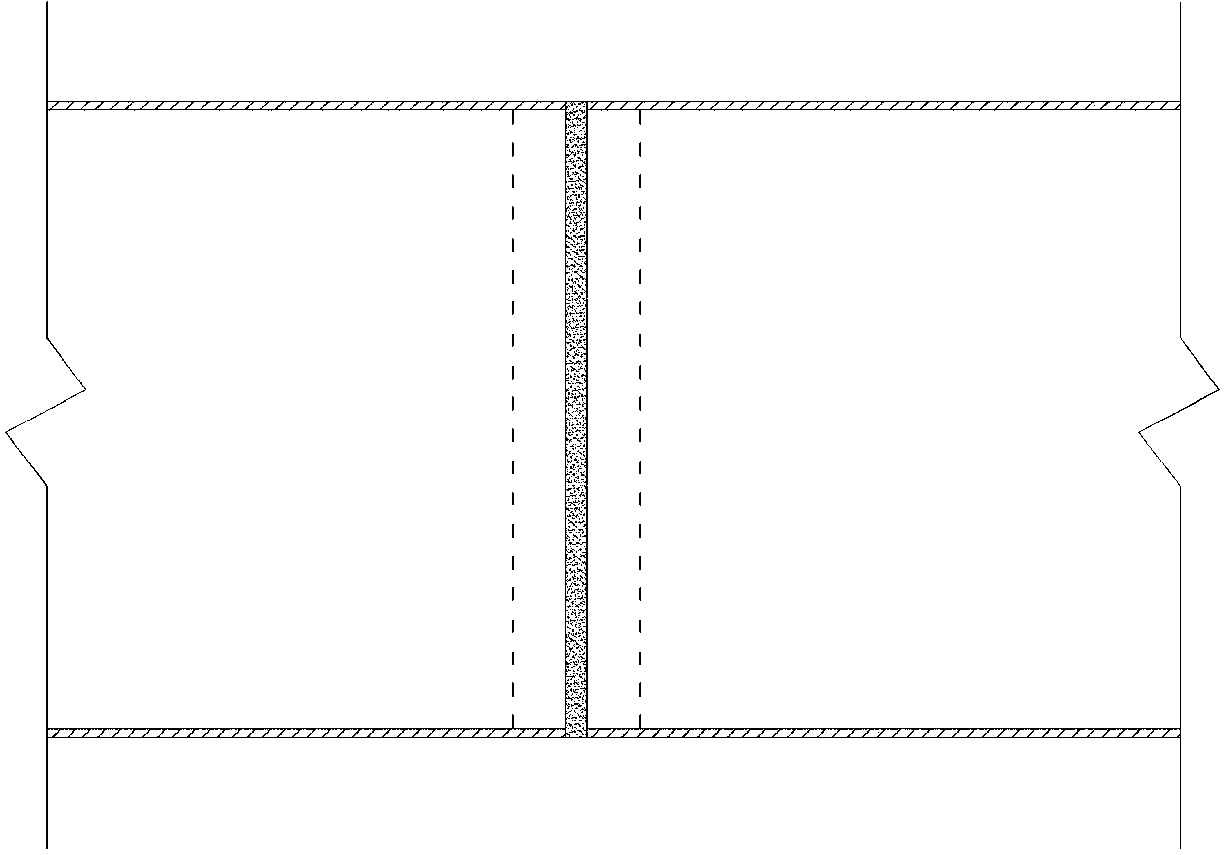

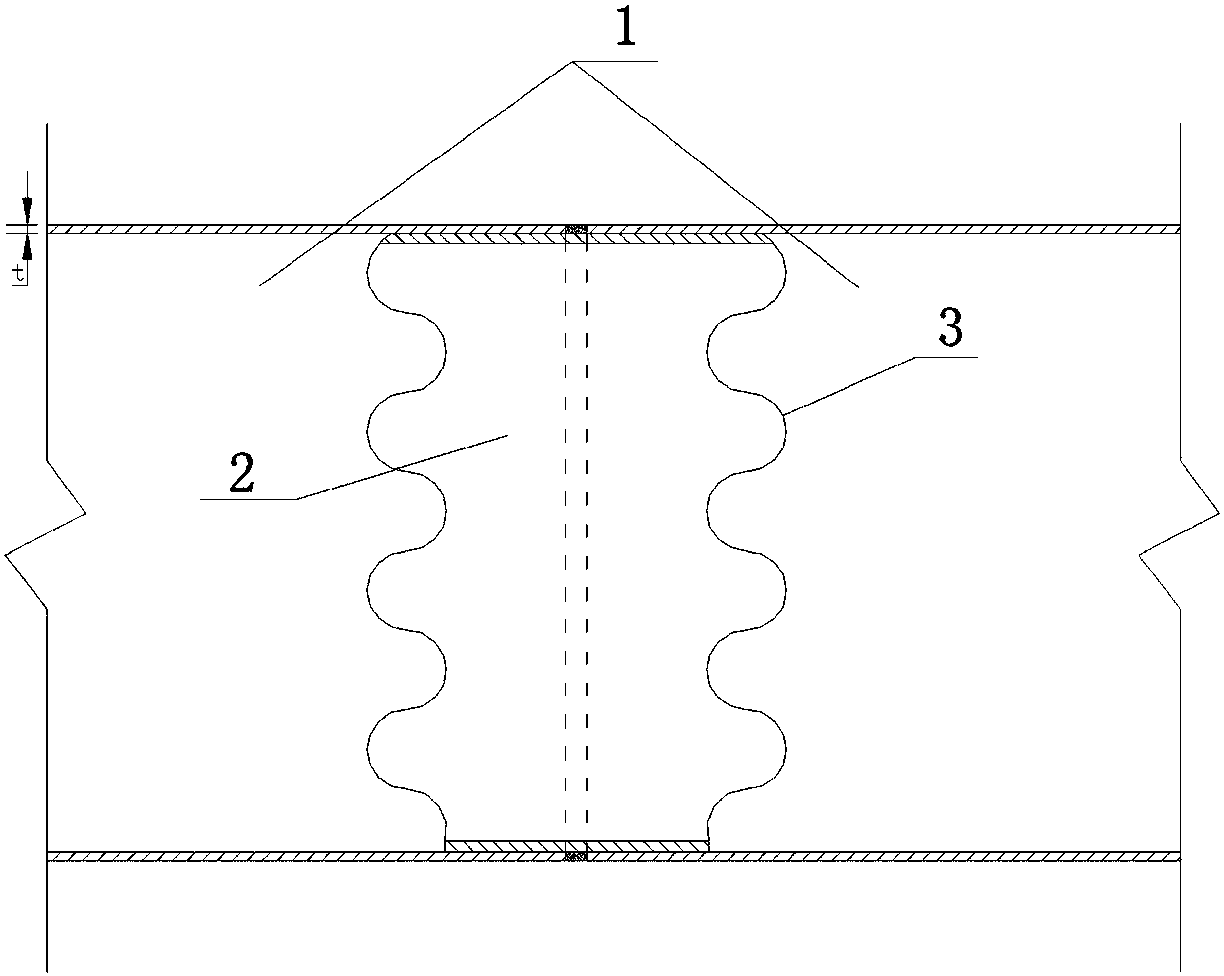

Image

Examples

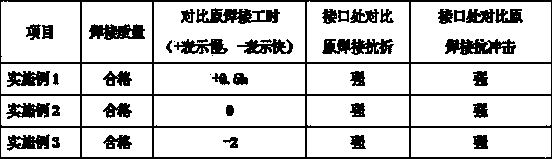

Embodiment 1

[0025] The diameter of the steel pipe column is 1000mm, the thickness of the pipe wall is 20mm, the diameter of the corrugated liner is 956mm, the thickness of the pipe wall is 22mm, the radius of the wave crest and wave bottom is 100mm, the width of the wave peak at both ends of the corrugated liner in the pipe is 800mm, and the width of the wave bottom at both ends is 600mm. The welding quality is qualified.

Embodiment 2

[0027] The diameter of the steel pipe column is 800mm, the pipe wall thickness is 16mm, the diameter of the corrugated liner is 764mm, the pipe wall thickness is 16mm, the wave crest and wave bottom radius are 75mm, the wave peak width at both ends of the wave liner inside the pipe is 700mm, and the wave bottom width at both ends is 550mm. The welding quality is qualified.

Embodiment 3

[0029] The diameter of the steel pipe column is 600mm, the pipe wall thickness is 12mm, the diameter of the corrugated liner is 572mm, the pipe wall thickness is 12mm, the wave crest and wave bottom radius are 50mm, the wave peak width at both ends of the corrugated liner in the pipe is 600mm, and the wave bottom width at both ends is 500mm. The welding quality is qualified.

[0030]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com