Patents

Literature

76results about How to "Has a stirring effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

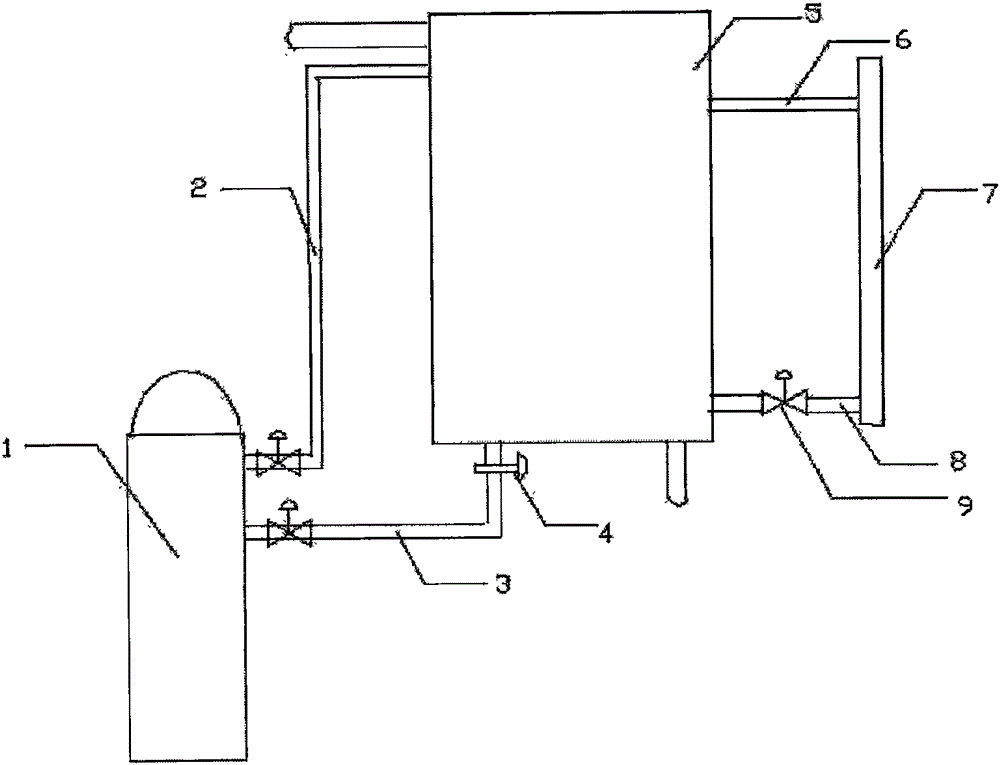

Device and method for autotrophy advanced nitrogen removal biological treatment of mature landfill leachate

ActiveCN105036335ACarbon savingLow running costTreatment with aerobic and anaerobic processesPeristaltic pumpAeration rate

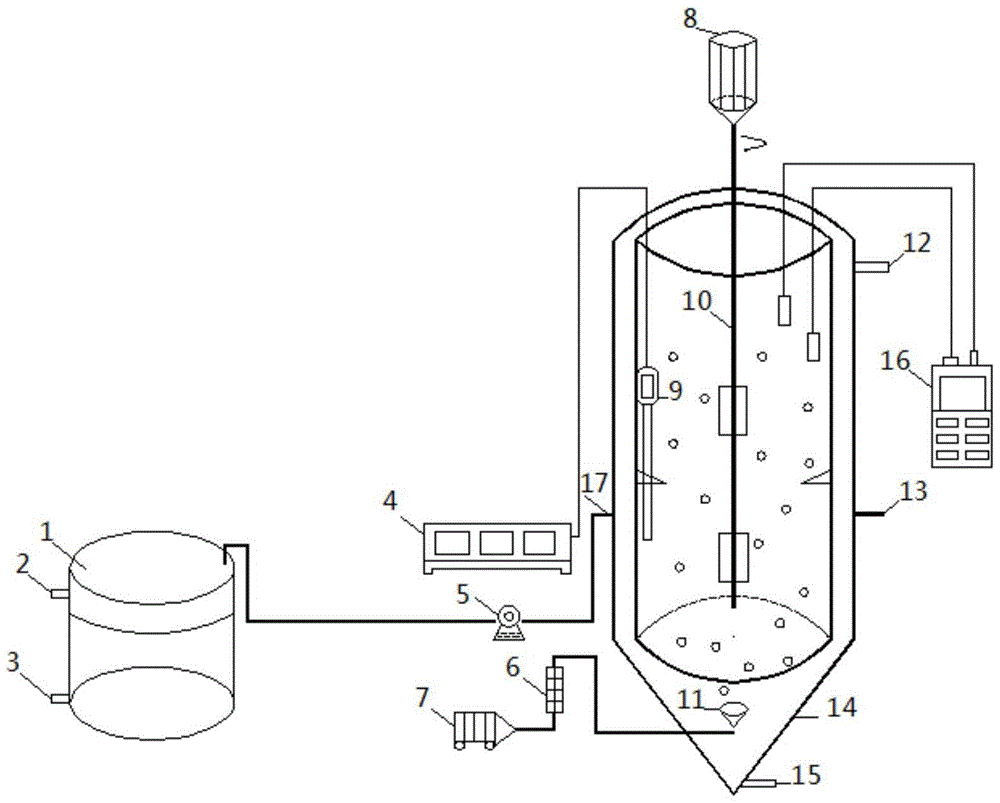

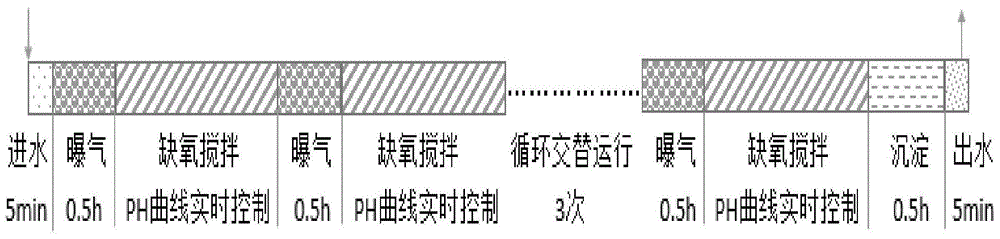

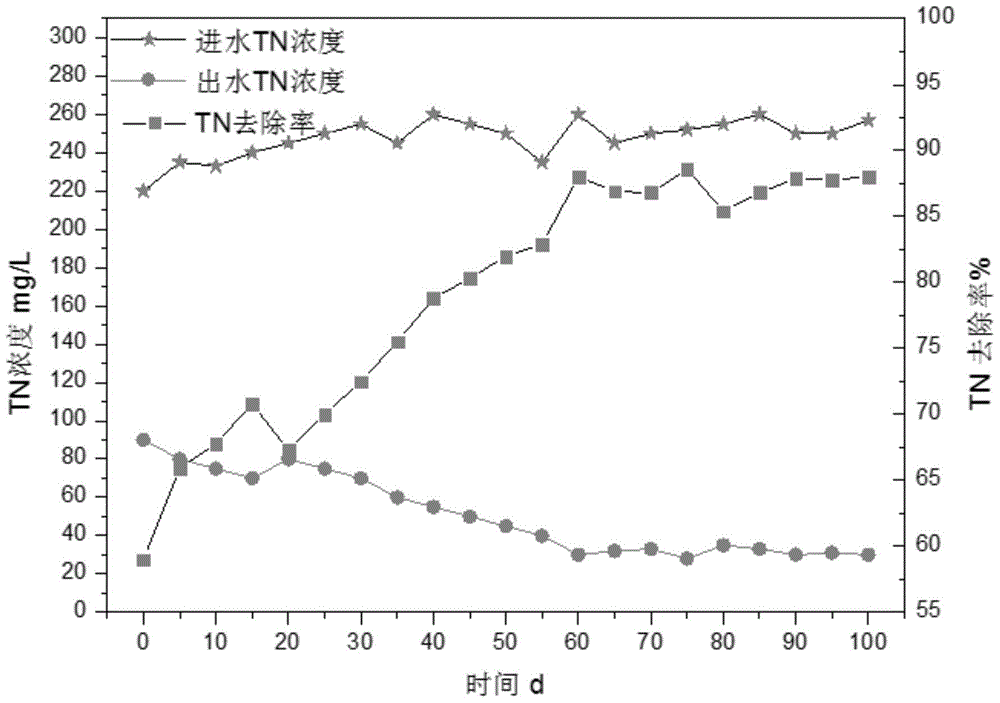

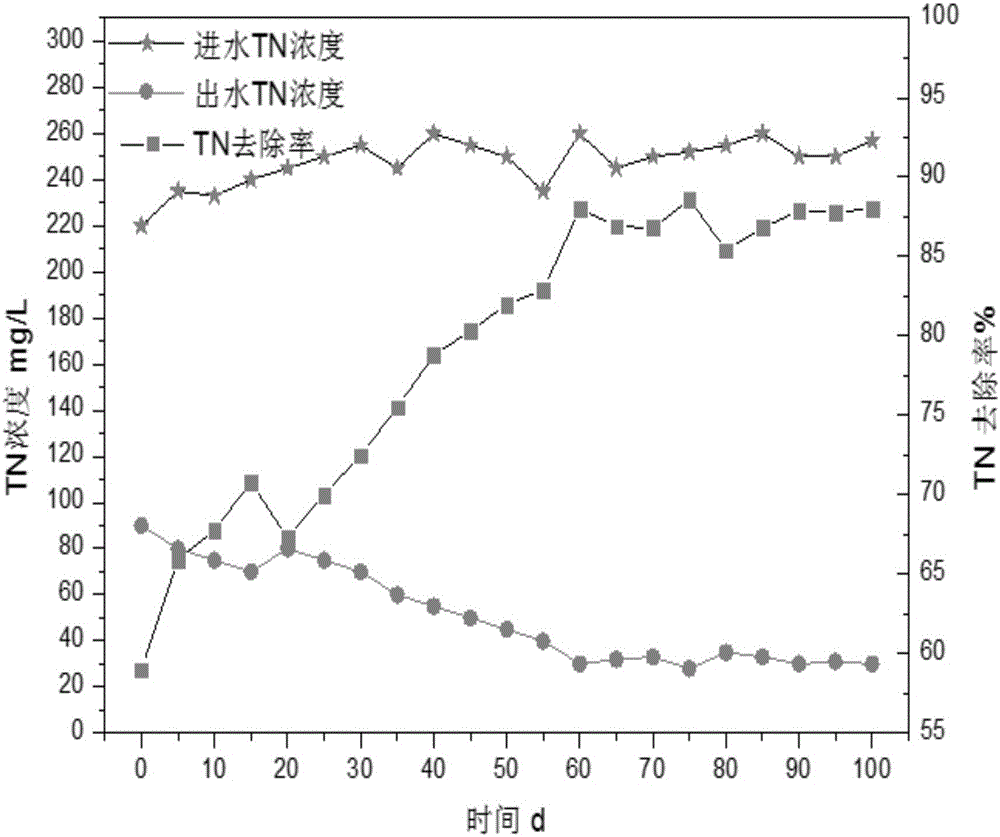

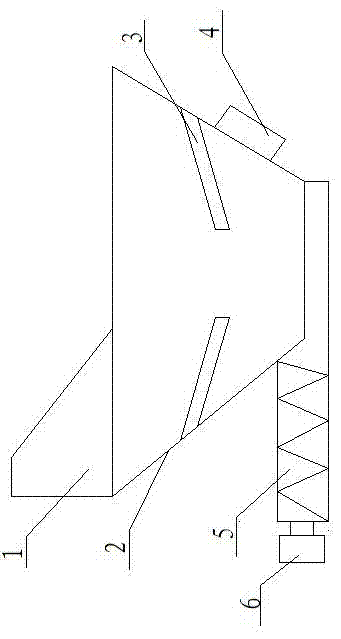

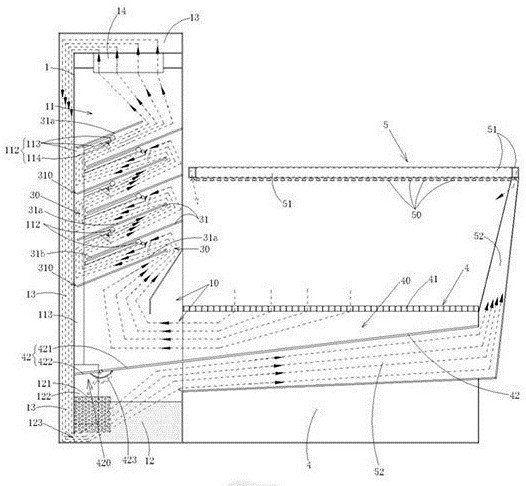

The invention belongs to the technical field of landfill leachate biological nitrogen removal and relates to a device and method for advanced nitrogen removal of mature landfill leachate. The device is provided with a raw water tank and an integrated autotrophy nitrogen removal SBR reactor. The integrated autotrophy nitrogen removal SBR reactor is internally provided with a heating device, a stirring device and an aeration device. The method comprises the following steps: the mature landfill lachate is driven into the integrated autotrophy nitrogen removal SBR reactor by a peristaltic pump to enable the dissolved oxygen of the reactor to be from 0.1 to 0.5 mg / L at the aeration stage through the control of the aeration rate so as to achieve short-range nitration-anaerobic ammoxidation; and nitrite nitrogen generated by the short-range nitration can be timely utilized by anaerobic ammonium oxidation bacteria through an operation method of circulating intermittent aeration of aeration / anaerobic stir to enable the nitrite nitrogen residue not to remain in the reactor. The mature landfill leachate advanced nitrogen removal device is applicable to the treatment of the mature landfill leachate, and the purpose of the mature landfill leachate advanced nitrogen removal is achieved without any addition of external carbon source conditions.

Owner:BEIJING UNIV OF TECH

Device and method for autotrophic advanced nitrogen removal biological treatment of mature landfill leachate

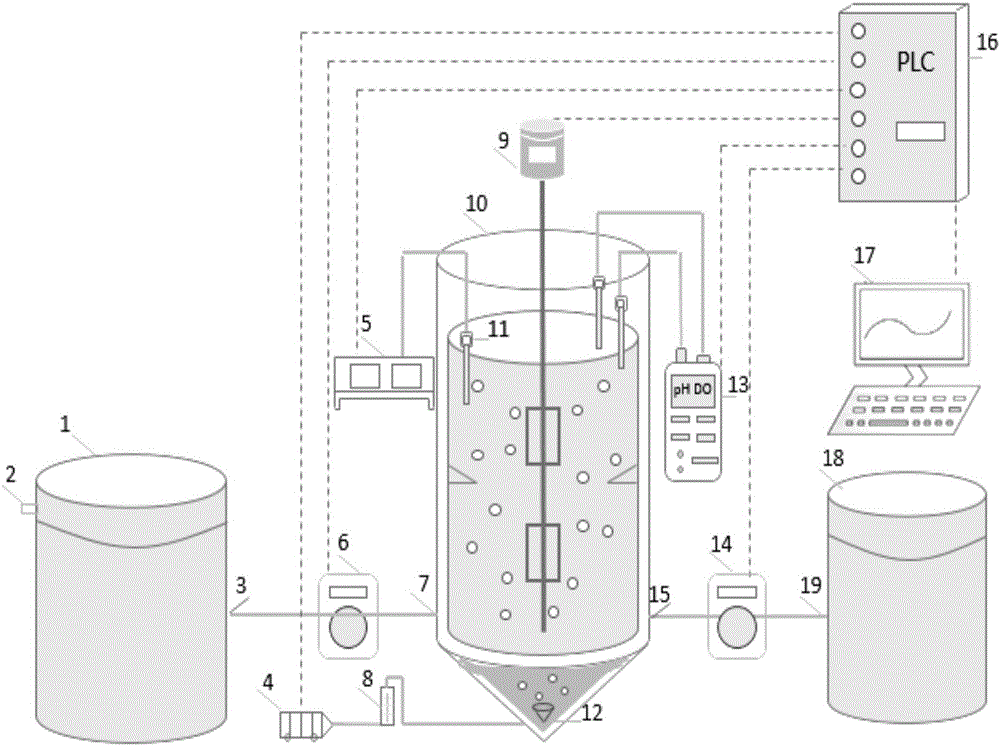

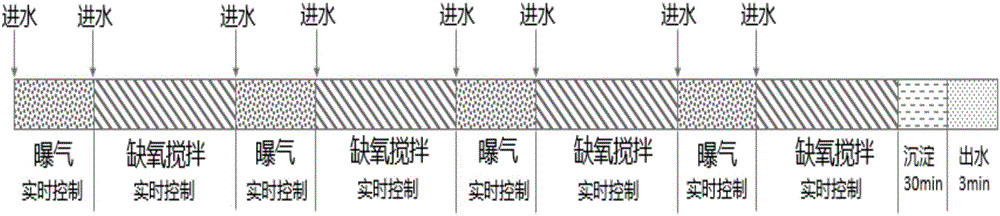

ActiveCN105776540ACarbon savingLow running costTreatment with aerobic and anaerobic processesControl systemAmmonia

The invention belongs to the technical field of biological nitrogen removal of landfill leachate, and relates to a device and method for autotrophic advanced nitrogen removal biological treatment of mature landfill leachate, in particular to a device and method for step-feed biological treatment of mature landfill leachate. The device is provided with a raw water tank, an outlet water tank, an integrated autotrophic nitrogen removal SBR reactor, a PCL control system and online detection equipment. Three types of bacteria, namely, ammonia oxidation bacteria, anaerobic ammonium oxidation bacteria and denitrification bacteria mainly exist in the integrated autotrophic nitrogen removal SBR reactor. A heating device, a stirring device and an aeration device are arranged in the integrated autotrophic nitrogen removal SBR reactor. A water inlet unit, an aeration unit, another water inlet unit and an anoxic stirring unit are included in one reaction period, and mature landfill leachate is rapidly pumped into the reactor through a water inlet pump at each aeration and anoxic stirring stage. Partial nitrification is carried out in each aeration stage, and anaerobic ammonia oxidation and denitrification are completed in each anoxic stirring stage. The process is simple, operation and management are convenient, and the purpose of advanced nitrogen removal of mature landfill leachate is achieved without adding any external carbon source.

Owner:BEIJING UNIV OF TECH

Welding method for low-carbon high-strength steel

ActiveCN103008846AImprove efficiencyHas a stirring effectArc welding apparatusLaser beam welding apparatusStress concentrationGas metal arc welding

The invention provides a welding method for low-carbon high-strength steel. The welding method for the low-carbon high-strength steel comprises the following steps of: 1) forming a welding groove on the low-carbon high-strength steel with a laser blanking method, and forming a welding line between the welding grooves of two pieces of low-carbon high-strength steel to be welded; and 2) welding the welding line by consumable electrode mixed gas metal arc welding, filling a welding wire in the welding process, and ensuring that the welding environment temperature is higher than 5DEG C. Specifically, the step 2) comprises the following steps of: 21) carrying out backing weld to the welding line by non-pulse consumable electrode mixed gas metal arc welding, forming a backing weld layer on the bottom of the welding line, and filling the welding wire in the welding process; and 22) carrying out cosmetic welding to the welding line by pulse consumable electrode mixed gas metal arc welding, forming a plurality of cosmetic layers above the backing weld layer, ensuring that two adjacent cosmetic layers are provided with overlay regions, and filling welding wire in the welding process. According to the welding method for the low-carbon high-strength steel, the stress concentration is lowered, and the welding quality of the low-carbon high-strength steel is improved.

Owner:青岛中车四方轨道车辆有限公司

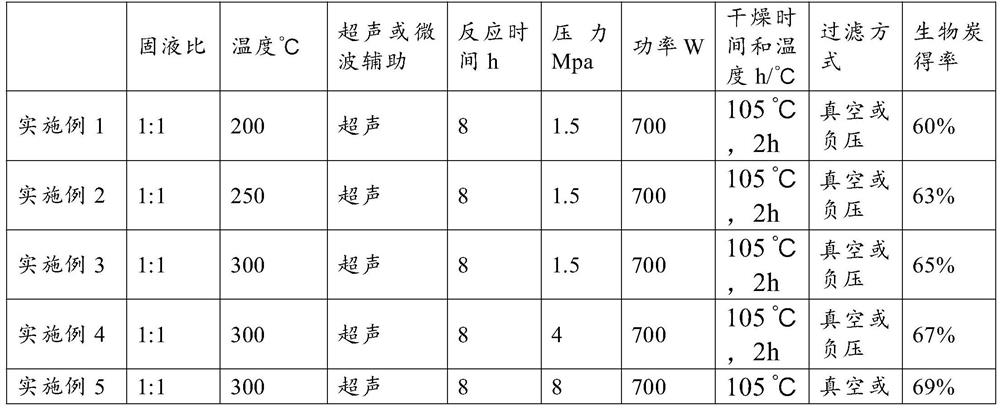

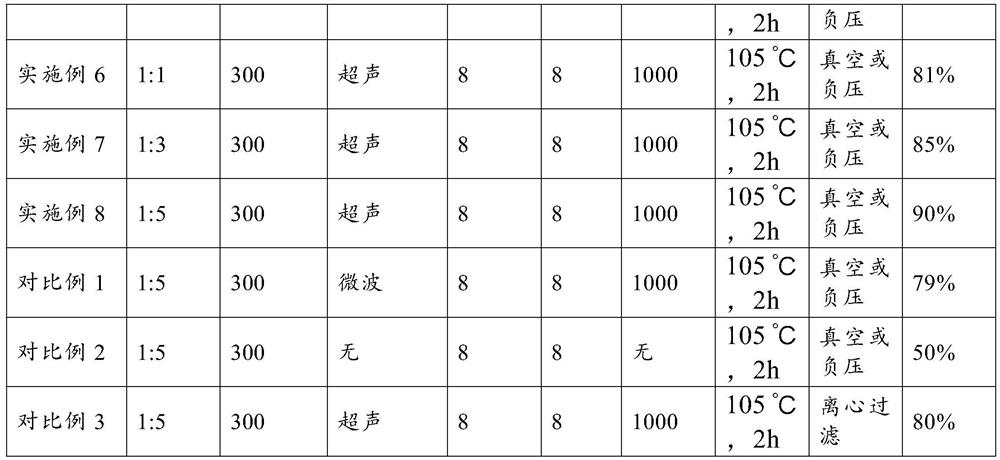

Method for preparing kitchen waste anaerobic biogas residue biochar through ultrasonic-assisted hydrothermal carbonization

ActiveCN111908753AHas a stirring effectIncrease moisture contentSludge treatment by pyrolysisWaste based fuelFiltrationProcess engineering

The invention discloses a method for preparing kitchen waste anaerobic biogas residue biochar by ultrasonic-assisted hydrothermal carbonization, which comprises the following steps: S1, mixing kitchenwaste anaerobic biogas residue with water, and carrying out hydrothermal carbonization reaction on the mixture under ultrasonic-assisted conditions to obtain a hydrothermal carbonization solution; and S2, carrying out cooling, filtering, drying, crushing and sorting operations the hydrothermal carbonization liquid to obtain biogas residue biochar. The method is simple and easy to implement and easy to popularize, wherein ultrasonic-assisted hydrothermal carbonization reaction is adopted, ultrasonic vibration has a certain stirring effect, the cavitation effect of ultrasonic can enable local high temperature and high pressure (5000 k or above) to be generated instantly, organic components difficult to carbonize in the organic components can also be carbonized, and the reaction is more complete. By means of vacuum filtration, so that the engineering level and the moisture content of a filtered product are greatly improved; by means of the crushing and sorting operations, the original materials with different shapes and non-uniformity can be further granulated, and the purity of the carbonized product is improved.

Owner:宁波首创厨余垃圾处理有限公司

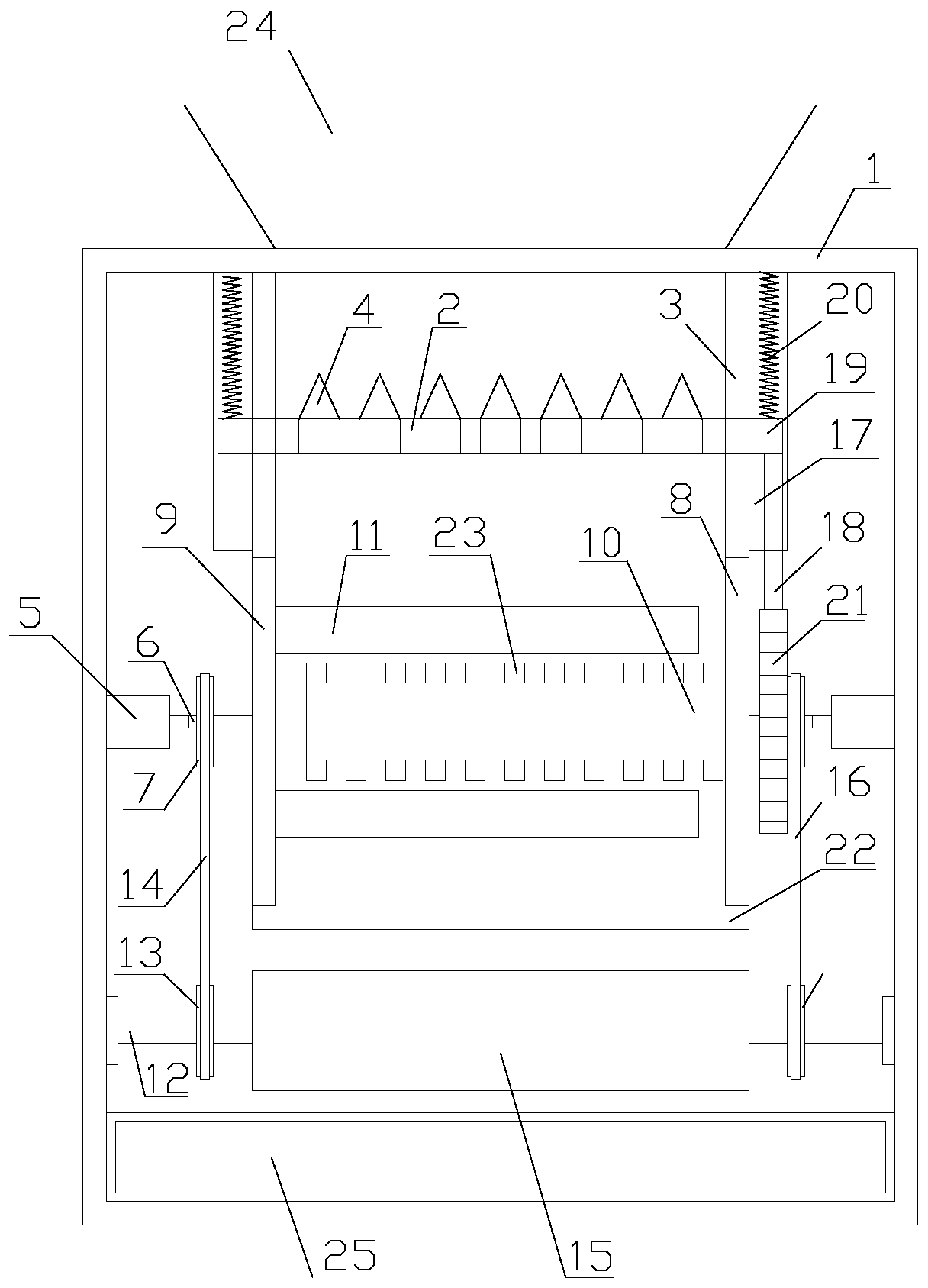

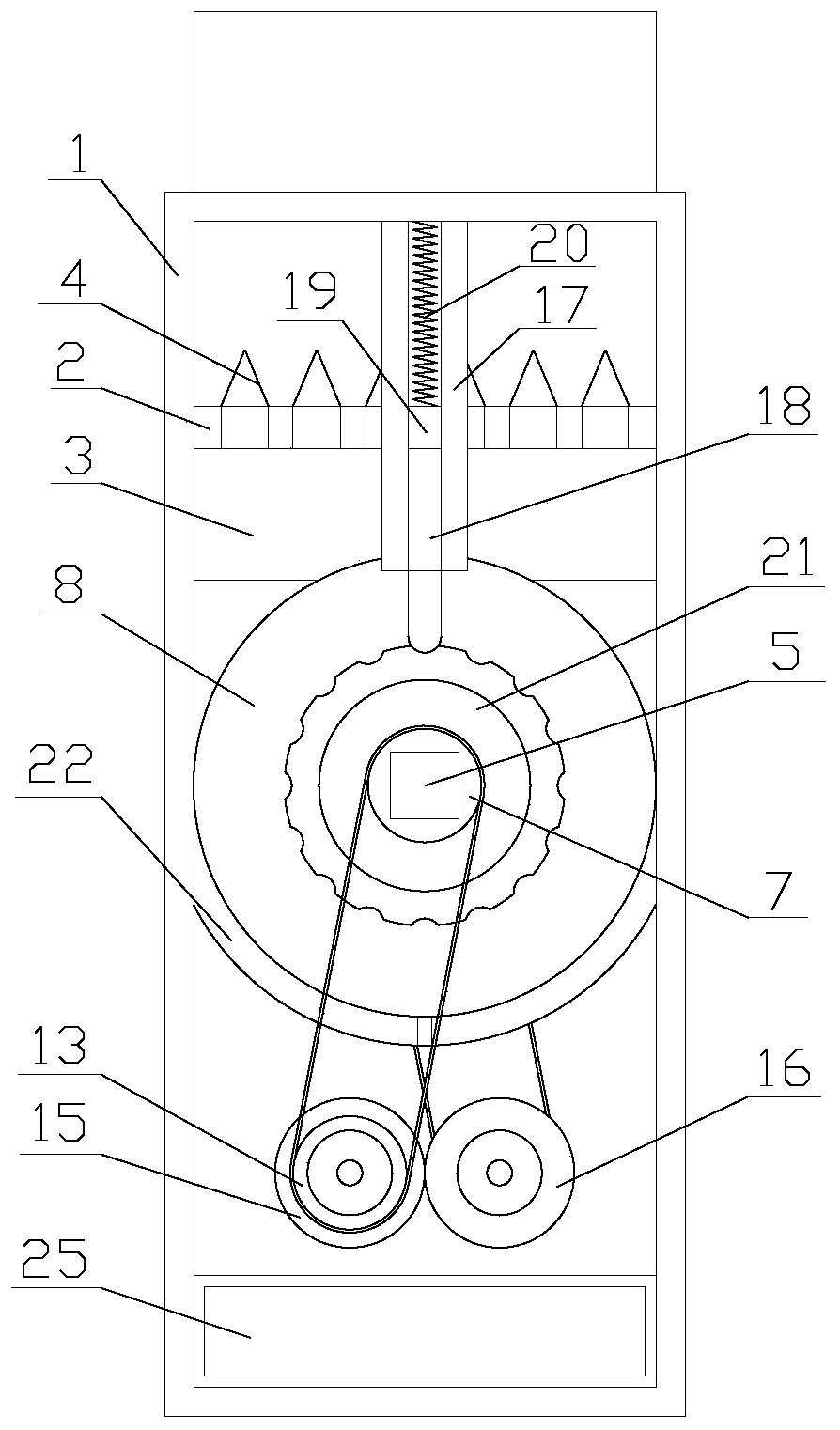

Glass crushing device

ActiveCN111468273AThe glass is crushed fully and evenlySave human effortGlass recyclingGrain treatmentsComposite materialEngineering

The invention relates to a glass crushing device. The glass crushing device comprises a box body, a driving mechanism, a first crushing mechanism, a second crushing mechanism and a third crushing mechanism; the first crushing mechanism, the second crushing mechanism and the third crushing mechanism are sequentially arranged in the box body from top to bottom; and the driving mechanism comprises two driving assemblies. According to the glass crushing device, glass is subjected to primary crushing through the first crushing mechanism, a bottom plate vibrates through a vibration mechanism, and collision between the glass and a crushing head is intensified, so that the glass is crushed more sufficiently; the glass is subjected to secondary grinding through the second crushing mechanism, secondary crushing is achieved, and meanwhile, a stirring roller has the stirring effect, so that the glass is crushed more sufficiently and uniformly; the glass is subjected to three-stage crushing throughthe third crushing mechanism, so that the glass is ground into powder; and large glass blocks are crushed into powder step by step through the three stages of crushing mechanisms, the glass is crushed more sufficiently and uniformly, manpower is saved, and the working efficiency is improved.

Owner:山东正信药用玻璃有限公司

Down filling device and filling method thereof

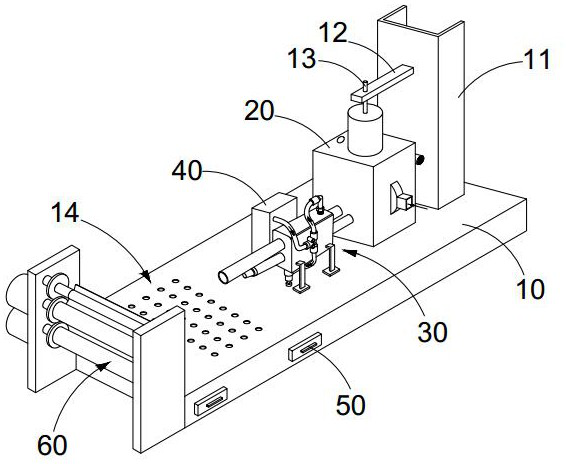

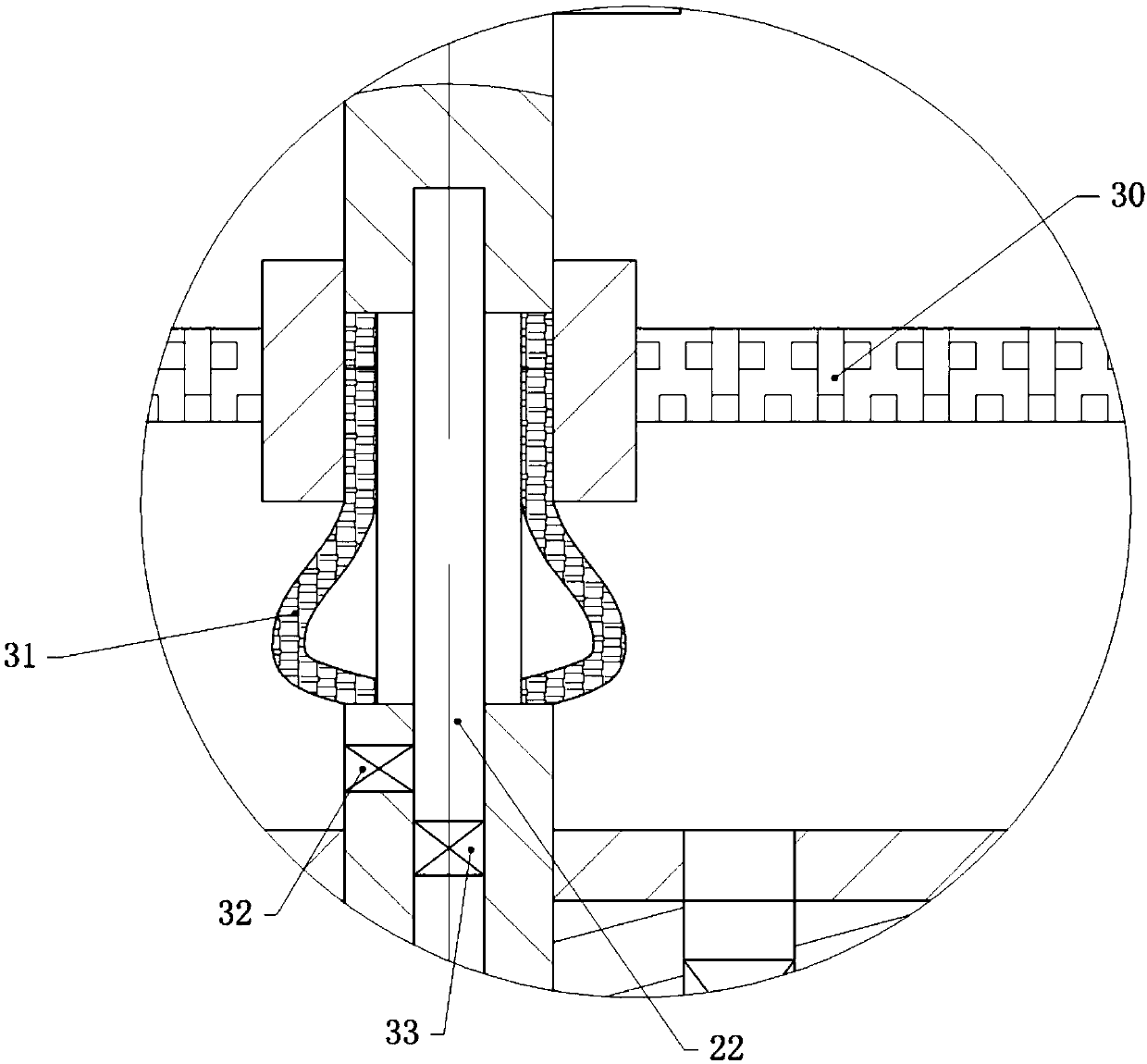

ActiveCN111609691AEasy to dryHas a stirring effectUpholstery manufactureDrying gas arrangementsAir pumpEngineering

The invention discloses a down filling device and a filling method thereof, and belongs to the field of down filling equipment. The down filling device comprises a rack and a down filling assembly, wherein a drying box is arranged on the rack; the down filling assembly is arranged on the rack and comprises a down filling base part; a fifth tube body and a fourth tube body are inserted into the down filling base part in a penetrating manner; the fifth tube body is connected with a first mounting tube in an assembled manner; the fourth tube body is connected with a second mounting tube in an assembled manner; an air pump is arranged on the rack; an air outlet end of the air pump is connected with one end of a second tube body; the other end of the second tube body is connected with a three-way tube; the other two ports of the three-way tube are connected with a first tube body and a third tube body respectively; the first tube body communicates with a first auxiliary air channel; and thethird tube body communicates with a second auxiliary air channel. The down filling device is good in down filling effect, down is not easy to remain in the down filling tube body, residual air in a down product in a down filling process is reduced, and the down in the down product is distributed uniformly.

Owner:临泉县诗雨娇服饰有限公司

Color printing printing ink supply device

ActiveCN109621776AVibrationPrevent subsidenceShaking/oscillating/vibrating mixersTransportation and packagingColor printingSpray nozzle

The invention relates to the technical field of printing, and particularly discloses a color printing printing ink supply device. The color printing printing ink supply device comprises a printing inkbox body and a stirring shaft. The stirring shaft penetrates through the printing ink box body, and stirring blades located in the printing ink box body are arranged on the stirring shaft. A cylinderbody is arranged below the printing ink box body, a piston only capable of sliding in the vertical direction is arranged in the cylinder body, and a cylindrical cam structure is formed by the stirring shaft and the piston. An air inflow one-way valve and an air exhaust one-way valve are arranged on the cylinder body, and an air exhaust port of the air exhaust one-way valve is communicated with the bottom of the printing ink box body. A mesh plate located below the stirring blades is arranged in the printing ink box body, the stirring shaft penetrates through the mesh plate, and the mesh platecan slide up and down relative to the stirring shaft. A printing ink passageway is formed in the stirring shaft, and the lower end of the printing ink passageway is communicated with a spray nozzle.A rubber bag communicated with the printing ink passageway is arranged below the stirring blades, the mesh plate moves up and down to extrude the rubber bag, a liquid drainage one-way valve is arranged in the printing ink passageway, a liquid inflow one-way valve is arranged on the side wall of the stirring shaft, and the concentration of printing ink can be uniform under the effects of stirring of the stirring blades and bubbles.

Owner:贵阳金汉诚广告器材有限公司

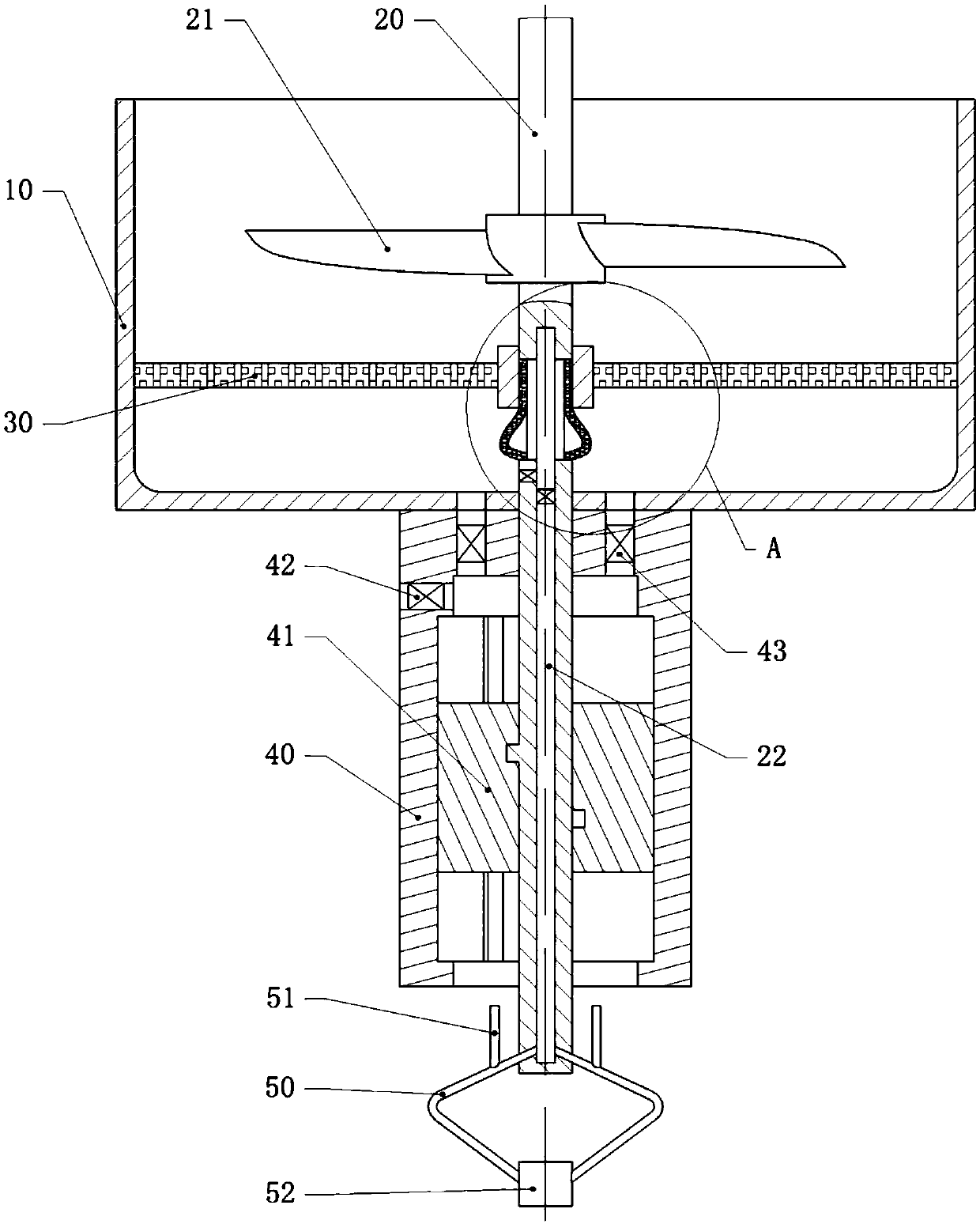

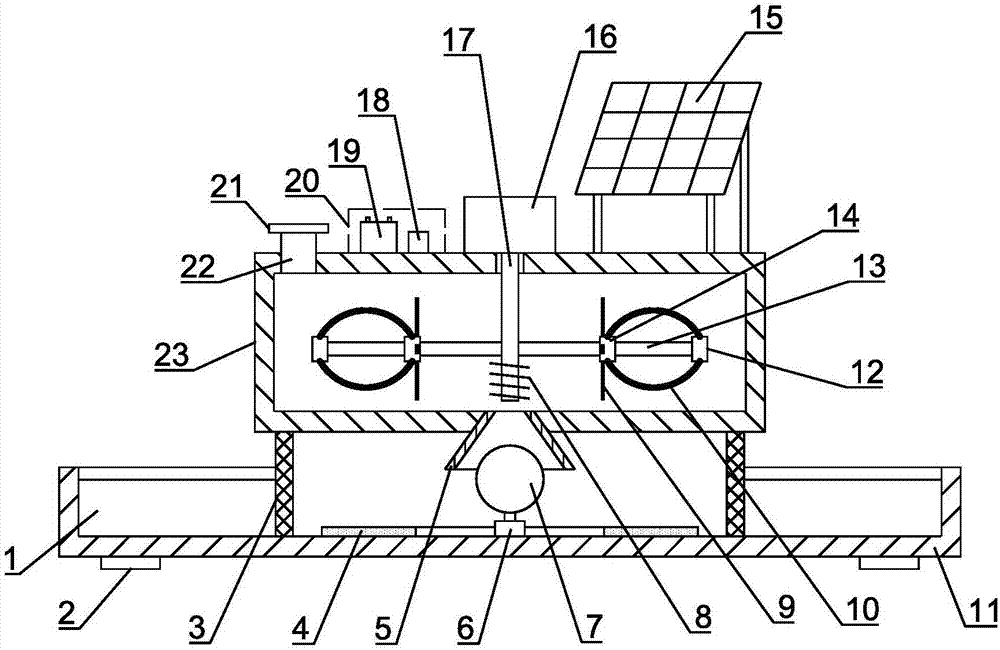

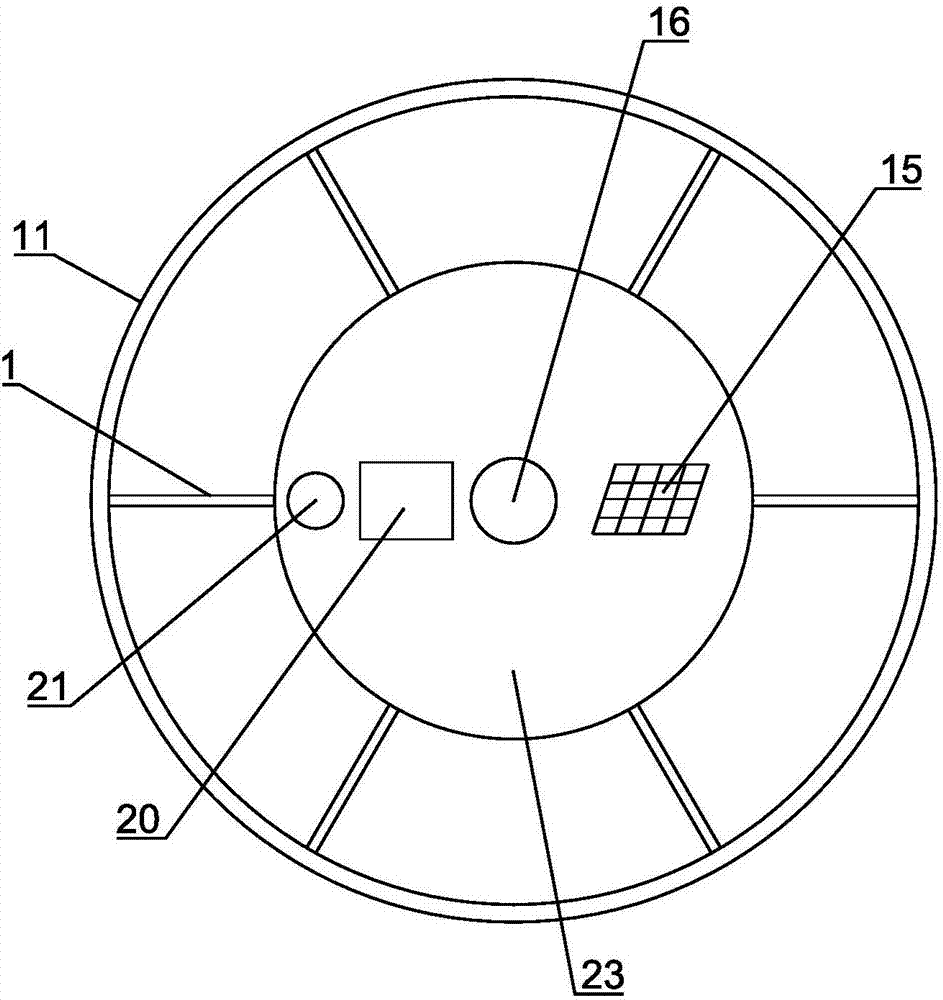

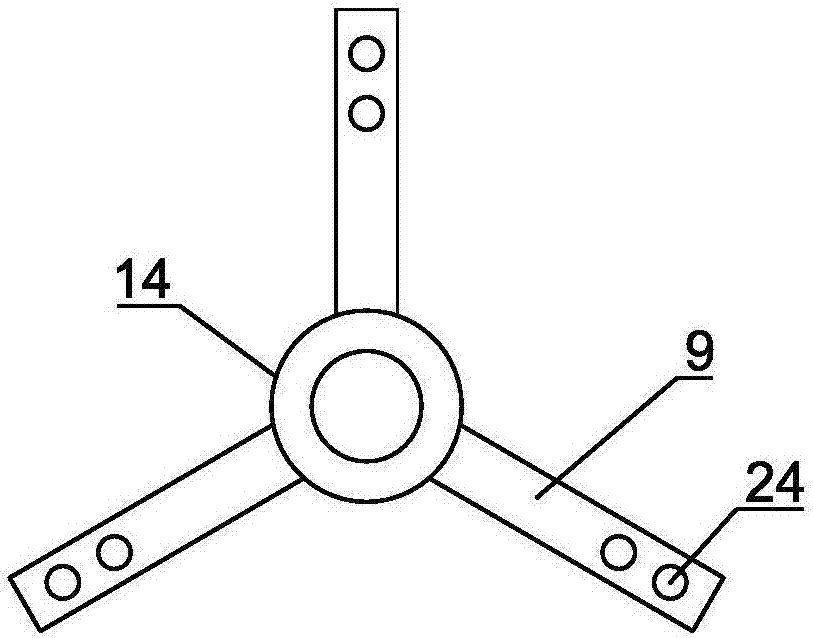

Self-controlled homogenizing energy-saving water drinking device for animal husbandry

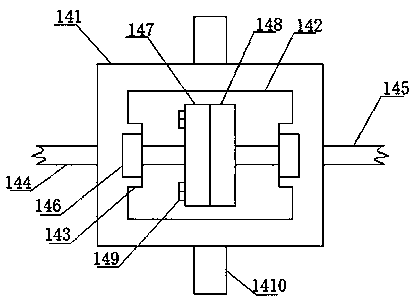

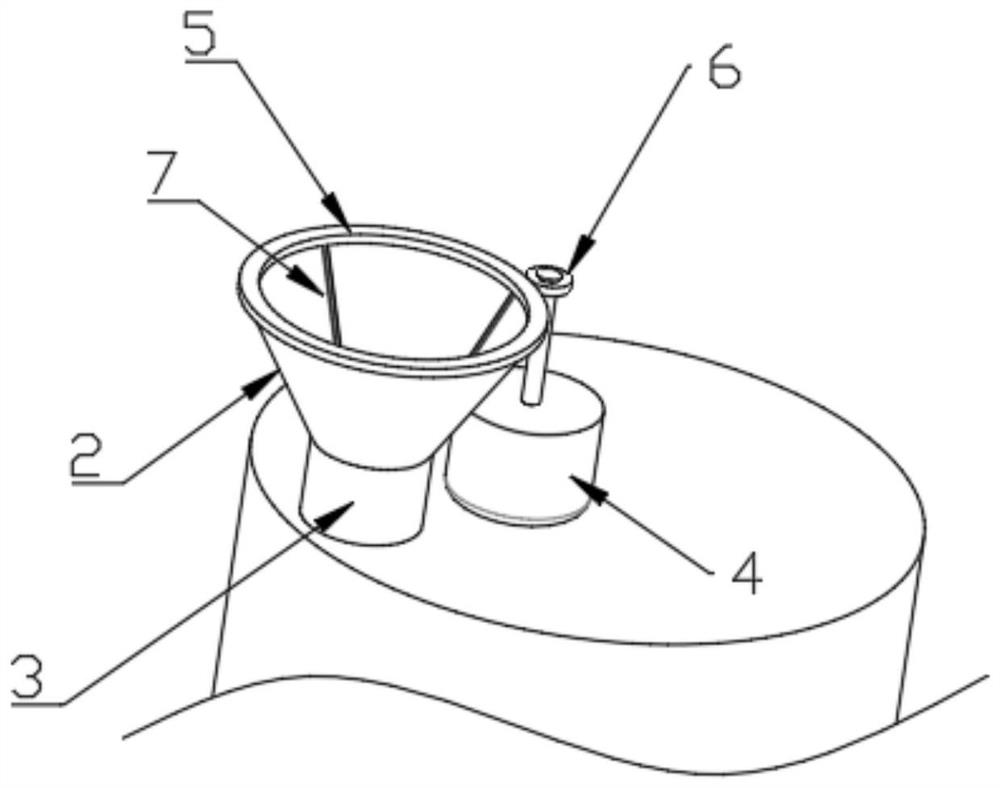

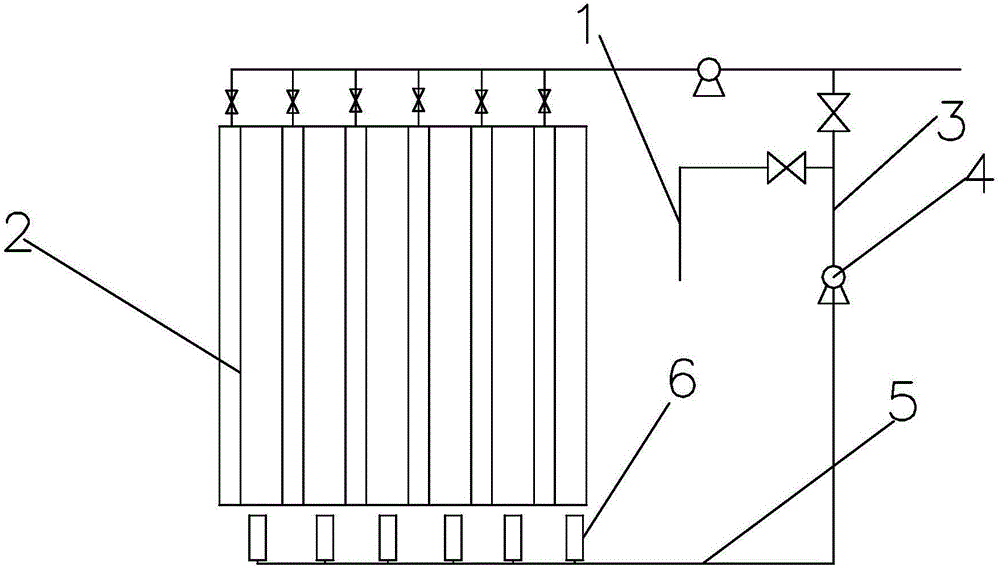

ActiveCN107494308AHas a stirring effectHas a heating effectAnimal watering devicesWater storage tankEngineering

The invention discloses a self-controlled homogenizing energy-saving water drinking device for the animal husbandry. The self-controlled homogenizing energy-saving water drinking device for the animal husbandry comprises a water drinking trough and a water storage tank, wherein the water storage tank and the water drinking trough are fixedly connected through a supporting net barrel; a conical cover is mounted in the middle of the bottom of the water storage tank; a self-control switch is mounted below the conical cover; a floating ball is mounted at the upper end of the self-control switch; an electric heating ring plate is mounted at the bottom of the inside of the water drinking trough; a plurality of sewage isolating plates are arranged on the outer side of the supporting net barrel; an output shaft of a driving motor on the top of the water storage tank is connected with a rotating shaft in the water storage tank; a plurality of stirring rods are mounted on the rotating shaft; a plurality of blades are mounted on the outer side of a sliding ring on each stirring rod; a plurality of elastic stirring fins are arranged between a sliding ring and a fixed ring in a straddling manner; and spiral blades are further mounted on the lower part of the rotating shaft. The self-controlled homogenizing energy-saving water drinking device for the animal husbandry is novel in structure, and is energy-saving and environmentally friendly; self-controlled homogenizing energy-saving water drinking of livestock can be realized; and therefore, the self-controlled homogenizing energy-saving water drinking device for the animal husbandry is popularized favorably.

Owner:ZHENGZHOU UNIV

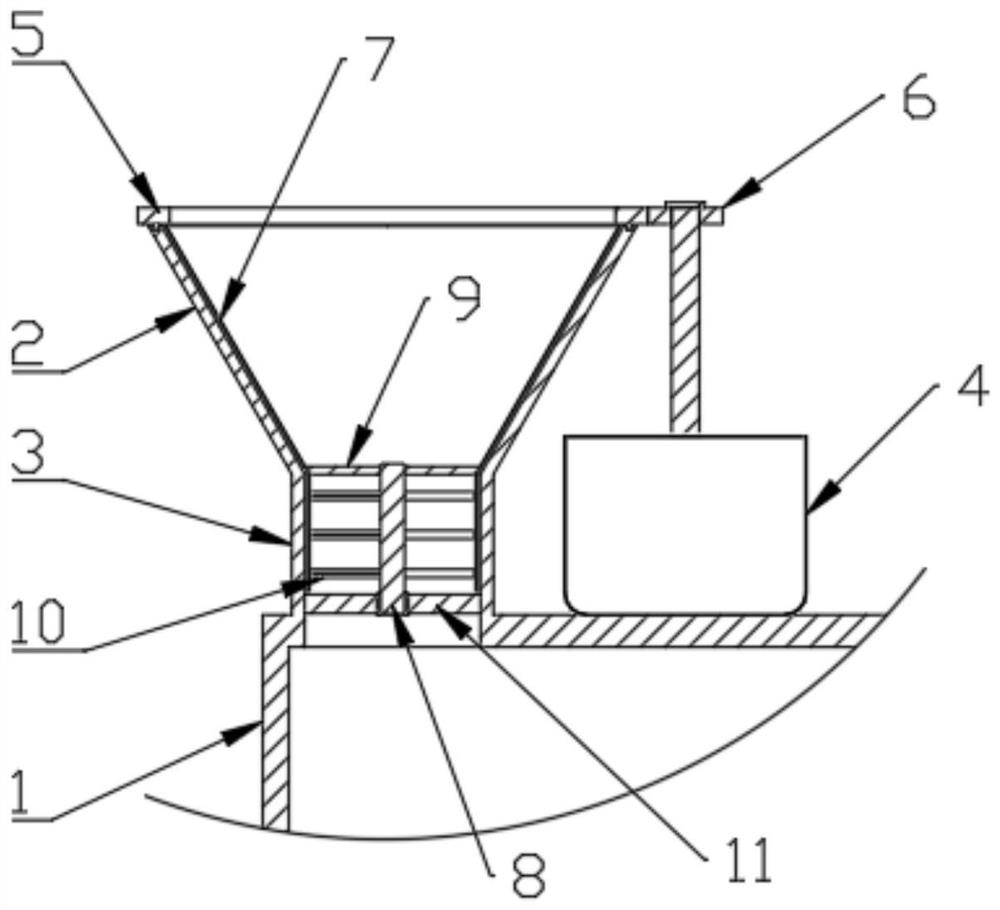

Hopper convenient to feed

InactiveCN103032882APrevent spillageAvoid cloggingLump/pulverulent fuel feeder/distributionEngineering

Owner:郭丰亮

Multifunctional vinasse smashing and drying device for baijiu production

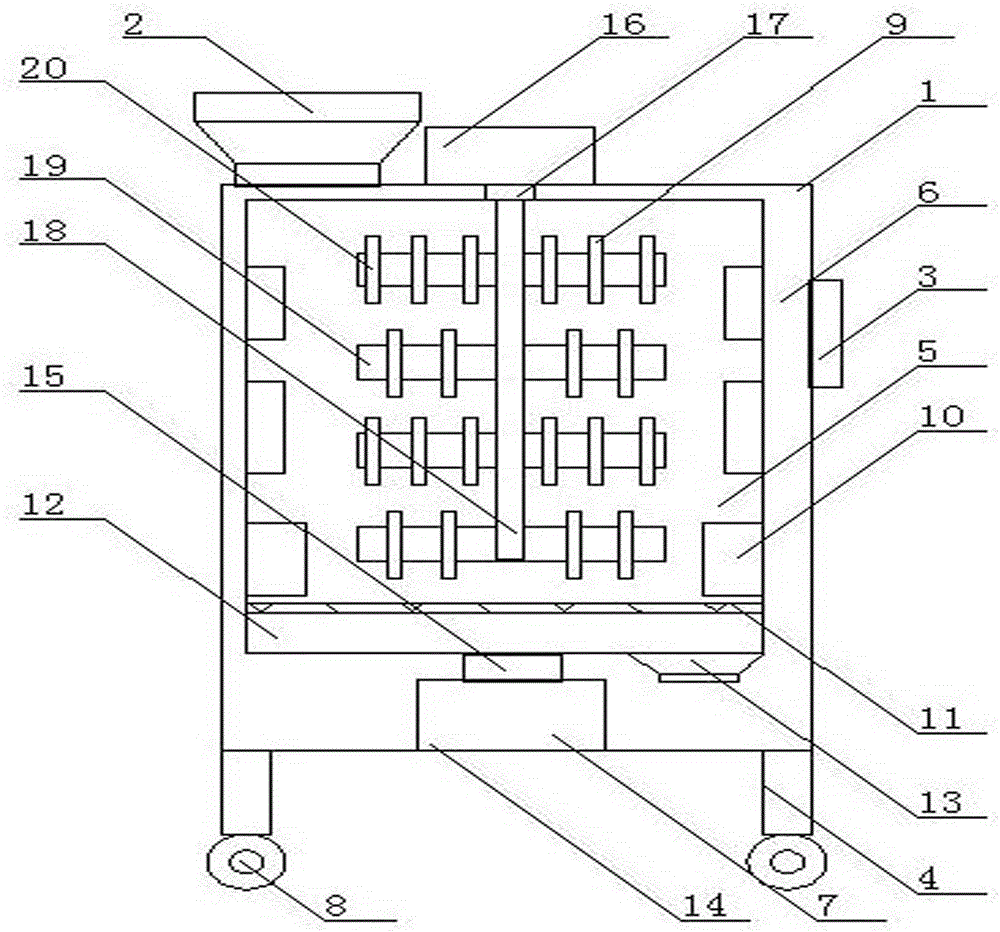

InactiveCN106017010AHas a stirring effectEfficient mixingDrying machines with non-progressive movementsGrain treatmentsMachineVinasse

The invention provides a multifunctional vinasse smashing and drying device for baijiu production. The multifunctional vinasse smashing and drying device for baijiu production comprises a machine body. A feed hopper is arranged on the left side of the top end of the machine body, a controller is arranged at the upper end of the right side of the machine body, supporting legs are arranged at the bottom end of the machine body, a treatment chamber is arranged at the upper end in the machine body, an interlayer is arranged between the machine body and the treatment chamber, a rotating device is arranged in the middle of the bottom end in the machine body, and the top end of the rotating device is connected with the bottom end of the treatment chamber. The multifunctional vinasse smashing and drying device for baijiu production has smashing and drying functions and rich functions, completes smashing, drying and stirring procedures at the same time, and is good in smashing and drying effect, easy to operate and convenient to use, and time and labor are saved.

Owner:HARBIN SHANBAO LIQUOR IND

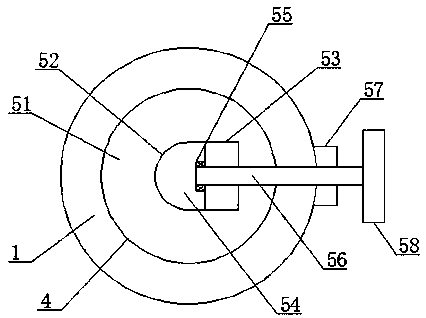

Processing method of Hainan white pine nuts

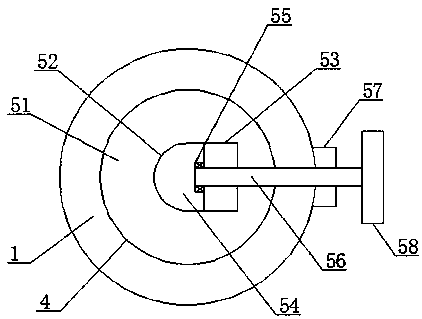

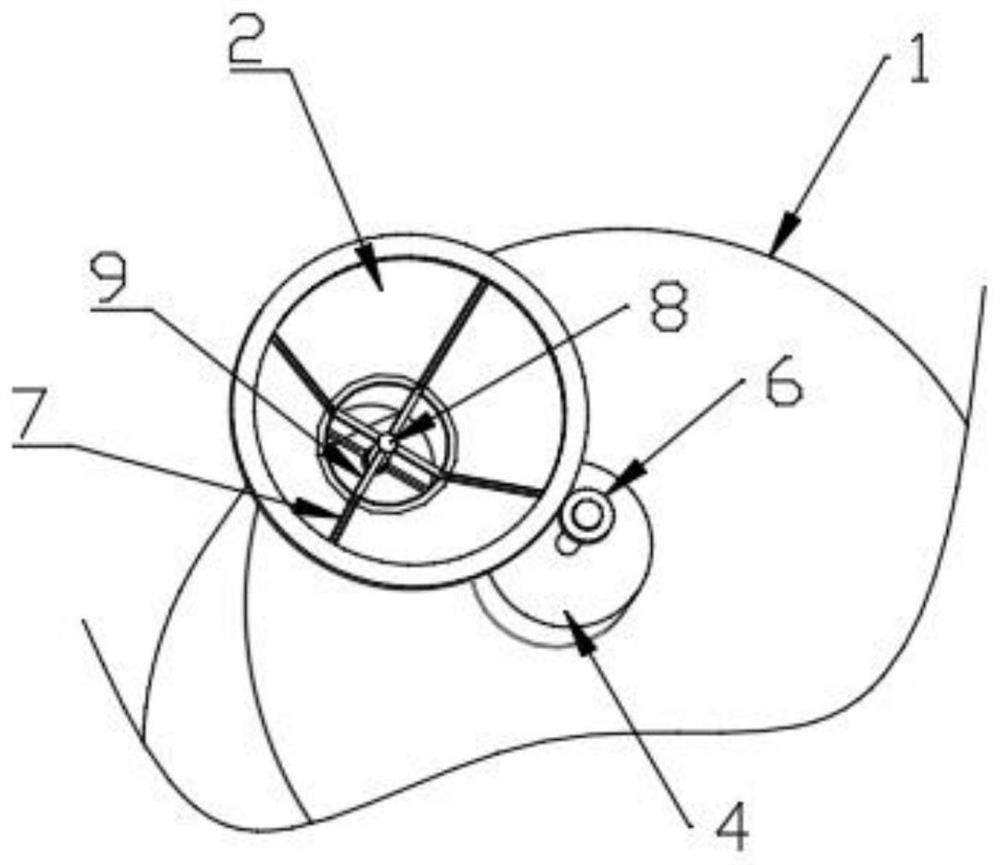

The invention discloses a processing method of Hainan white pine nuts. Hainan white pine nuts are processed through a Hainan white pine nut peel grinding device. The Hainan white pine nut peel grinding device comprises a base, an outer cylinder, an inner cylinder, a material crushing shaft and a planet wheel transmission mechanism, wherein the outer cylinder, the inner cylinder and the material crushing shaft are sequentially arranged from outside to inside; the outer cylinder is fixed on the base; the inner cylinder and the material crushing shaft are connected to the base in a rotating manner; a pressurizing cylinder which is placed at the upper end of the inner cylinder and communicates with the inner cylinder is connected to the base in a dismountable manner; a turbine is connected to the pressurizing cylinder in a rotating manner; the upper end of the material crushing shaft can be connected with the turbine; material crushing blades which are placed in the inner cylinder are fixed to the middle part of the material crushing shaft; flexible layers are arranged on the inner wall of the outer cylinder and the outer wall of the inner cylinder; an expansion cavity is formed between the flexible layer and the wall of the inner cylinder, another expansion cavity is formed between the flexible layer and the wall of the outer cylinder, and a peel grinding cavity is formed between the flexible layers; the swelling cavities communicate with the pressurizing cylinder; and the bottom of the peel grinding cavity communicates with the bottom of the inner cylinder. The rotation speed of the inner cylinder and the rotation speed of the material crushing shaft are changed, so that the volume of the peel grinding cavity can be changed, the friction between the Hainan white pine nuts can be increased, and the peel grinding efficiency can be improved.

Owner:贵州省务川县照石坊农林(集团)有限公司

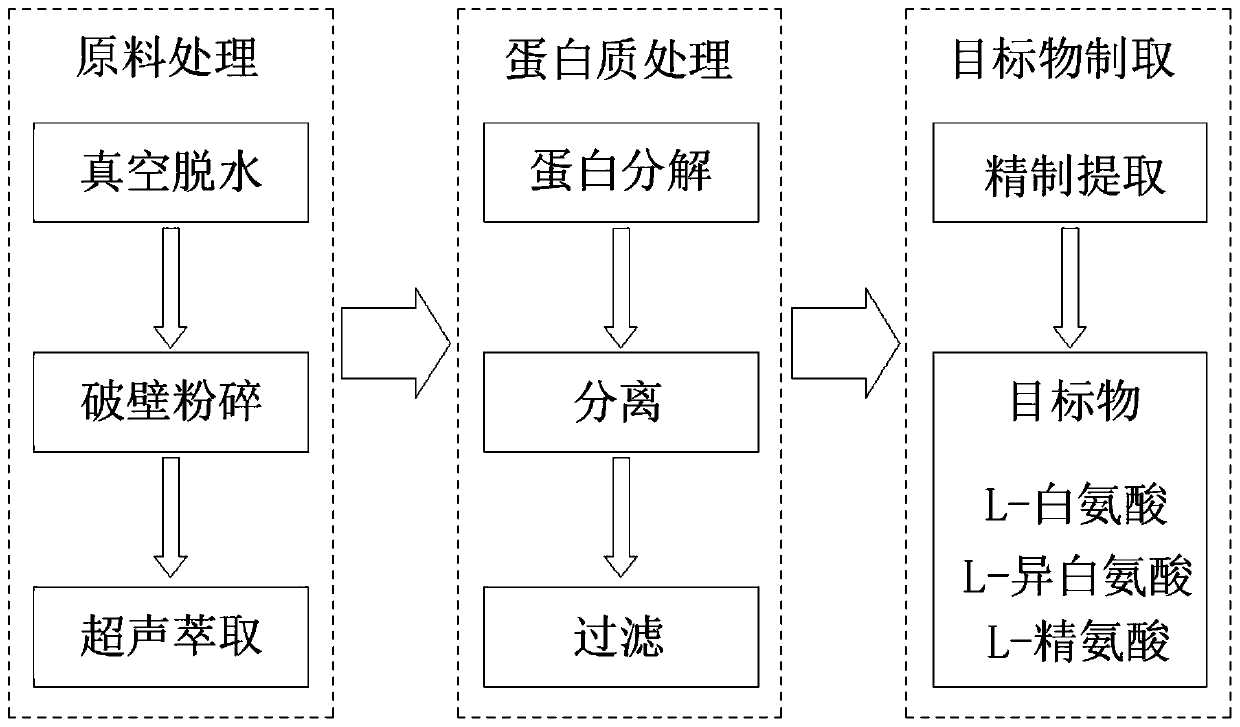

Preparation method for extracting amino acids from alfalfa

The invention discloses a preparation method for extracting amino acids from alfalfa, and belongs to the technical field of amino acid extraction. The preparation method for extracting the amino acidfrom the alfalfa comprises the steps of 1, vacuum dehydration, wherein the alfalfa stem and leaf parts without edible value are put into vacuum dehydration equipment for vacuum dehydration drying, anddry matter is obtained; 2, wall-breaking crushing, wherein the dry matter in step 1 is subjected to wall-braking crushing, and crushed matter is obtained; 3, ultrasonic extraction, wherein the crushed matter in step 2 is added into ultrasonic extraction equipment, and continuous extraction is conducted to obtain non-target product crude fiber and extraction liquid; 4, protein decomposition. Accordingly, various amino acids can be extracted from alfalfa stems and leaves without the edible value, the agricultural benefit is greatly improved, the preparation method is simple, industrialization is easy, and the technical gap of extracting various amino acids from the alfalfa stems and leaves in China is filled up.

Owner:蔡罗章

Circulating type stone polishing device

InactiveCN111775055AHas a stirring effectImprove the effect of dust suppressionGrinding/polishing safety devicesThermodynamicsDust control

The invention relates to a circulating type stone polishing device which comprises a dust removal cabinet, a workbench, a dust suppression mechanism and a dust removal mechanism. A dust removal chamber and a water tank disconnect from each other and communicate with each other through a chamber bottom of a dust suction chamber. The dust suppression mechanism comprises a dust suppression pipeline disposed on the upper side of the workbench. A plurality of air output through holes for outputting air in the direction towards the workbench are formed in the dust suppression pipeline. Dust air formed above the workbench passes through the dust suction chamber to be sucked into the dust removal chamber. The air subjected to dust removal treatment of the dust removal chamber sequentially passes through an exhaust pipeline, a water body in the water tank, a tank opening of the water tank and a communication channel to be conveyed into the dust suppression pipeline and to be blown from the airoutput through holes to the workbench. The air flow blown out by the dust suppression mechanism can blow the generated dust towards the dust suction chamber. Further, the adhesive force of the air flow and the dust is improved, the air flow cyclically flows, the escape rate of the dust is effectively reduced, and the dust removal rate is effectively improved; and the overall dust removal rate of the polishing device for the dust generated by polishing can reach 99.5% or above, and dust removal is remarkable.

Owner:惠安县辋川镇千绪广告设计部

Enzyme deactivation method for black tea

ActiveCN106819184AReduce intermediate processStable temperaturePre-extraction tea treatmentBlack teaPulp and paper industry

The invention discloses an enzyme deactivation method for black tea, and relates to a process for producing tea leaves. An enzyme deactivation device for the black tea is used for implementing the enzyme deactivation method and comprises a framework and a steam barrel. The steam barrel is fixed onto the framework, a piston is slidably connected into the steam barrel, a low-temperature water tank is arranged on the upper side of the piston, an enzyme deactivation barrel is arranged on the lower side of the piston, is positioned in the steam barrel and is fixed to the steam barrel, a high-temperature water tank is formed between the enzyme deactivation barrel and the steam barrel, a heating device is arranged in the high-temperature water tank, the low-temperature water tank is connected with the high-temperature water tank by a communicating pipe, and a stop valve is arranged on the communicating pipe; a gas guide pipe is fixed to the middle of the piston, the lower end of the gas guide pipe extends into the enzyme deactivation barrel, and the upper end of the gas guide pipe extends out of the low-temperature water tank; the lower end surface of the piston is in contact with the upper end surface of the enzyme deactivation barrel. The enzyme deactivation method has the advantages that enzyme deactivation can be carried out on tea leaves by the enzyme deactivation device, the internal temperatures of the enzyme deactivation barrel are stable, and enzyme deactivation procedures are easy to implement.

Owner:江西浮品会农业综合开发有限公司

Feed for raising cattle and sheep

InactiveCN108308418AHas a crushing effectHas a stirring effectFood processingAnimal feeding stuffAnimal feedHeifer calf

The invention relates to the technical field of processing of animal feed, and particularly discloses a feed for raising cattle and sheep. The feed is prepared from the following raw materials in parts by mass: 5-30 parts of dry hemp fimble leaf, 15-40 parts of dry straw, 10-30 parts of protein feed, 10-30 parts of energy feed, 1-6 parts of trace-element premix, 0.8-1.5 parts of calcium hydrogen phosphate and 0.5-1.2 parts of salt. When the feed is prepared, firstly the above raw materials are mixed to obtain a mixture, then the mixture is crushed and ground, and is sieved by a 40-mesh sieve to obtain mixed powder. The feed disclosed by the invention has the beneficial effects that when being crushed, the mixture can be further mixed simultaneously, so that the mixing time can be shortened, the processing steps can be reduced, and the processing cost can be reduced.

Owner:务川自治县洞家沟农业开发有限公司

Building construction device

InactiveCN107905537AHas a stirring effectIt has the function of conveying raw materialsBuilding material handlingInterior spaceArchitectural engineering

The invention discloses a building construction device. The building construction device comprises a primary inner hollow cylinder; a set of connecting plates are fixed to the bottom of the primary inner hollow cylinder through screws, ground foot supports are arranged at the middle ends of the bottoms of the set of connecting plates, and the ground foot supports and the connecting plates form a combined mechanism; a bevel opening accommodating cavity is formed in the middle end of the top of the primary inner hollow cylinder, and a cylindrical accommodating cavity is formed in the position, located at the bottom of the bevel opening accommodating cavity, of the interior of the primary inner hollow cylinder; a speed regulating and controlling mechanism for conveying materials is mounted atthe position, located in the cylindrical accommodating cavity, of the primary inner hollow cylinder; and a stirring accommodating cavity is formed in the position, located at the bottom of the cylindrical accommodating cavity, of the interior of the primary inner hollow cylinder. The building construction device has the effects of material stirring and material conveying; and the building construction device utilizes the rightward effect and the leftward effect of a motor to make the building construction device to choose the stirring and helical conveying effects according to the predetermine function, and practicability is high.

Owner:余坚

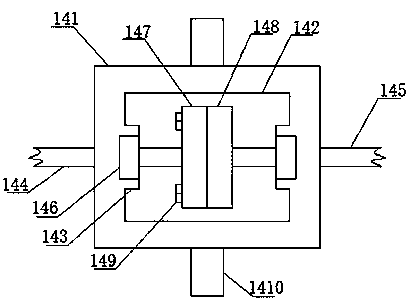

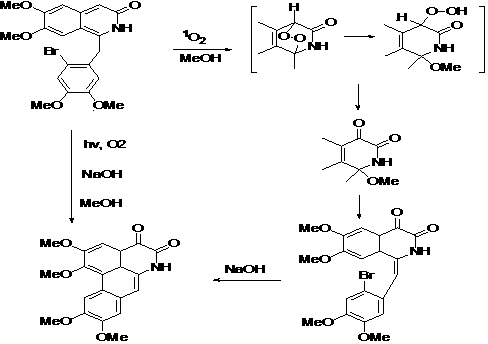

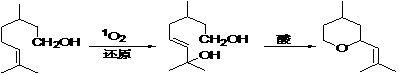

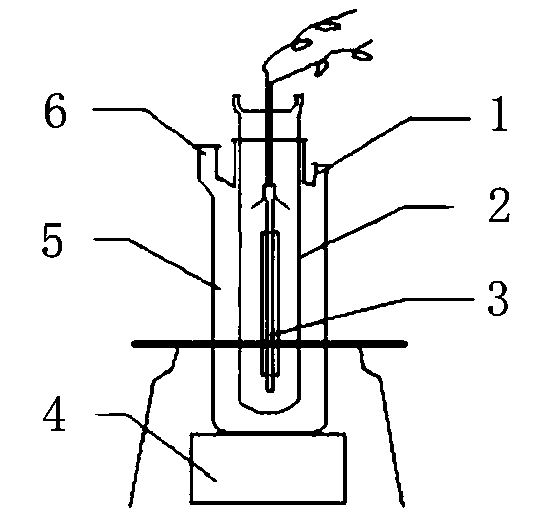

Photosensitized oxidation reaction equipment and application thereof

ActiveCN103785339AReduce complexitySimple structureEnergy based chemical/physical/physico-chemical processesPhotosensPerylene derivatives

The invention relates to photosensitized oxidation reaction equipment and application of the photosensitized oxidation reaction equipment. The photosensitized oxidation reaction equipment consists of a thermostatic bath and more than three photoreactors, wherein the photoreactors are fixed in the thermostatic bath and comprise a chromatographic column with a sand core; the middle of the chromatographic column is inlayed with a glass tube; a reaction system cavity is arranged between the chromatographic column and the glass tube; a light source is arranged in the middle of the glass tube; and an interface with a piston is arranged at the bottom of the chromatographic column. The equipment is used for photosensitized oxidization reaction, the photosensitizer is preferably tetraphenylporphyrin or a tetraphenylporphyrin derivative, the integrating degree between the absorption spectrogram of the tetraphenylporphyrin or the derivative thereof and the spectrogram of an LED light source is high, so that the light utilization ratio is high and the use amount of the photosensitizer is low. The photosensitized oxidation reaction equipment is simple in structure, low in manufacturing cost and safe and convenient to operate.

Owner:HUNAN KEYUAN BIO PRODS

Treatment method and equipment for sewage containing heavy metal ions

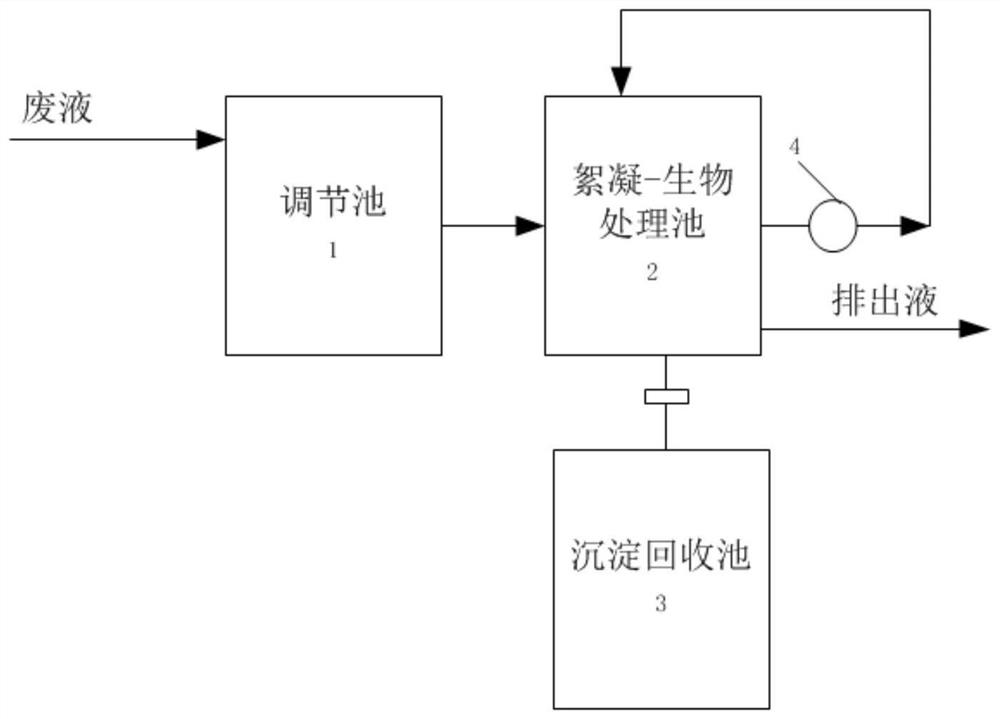

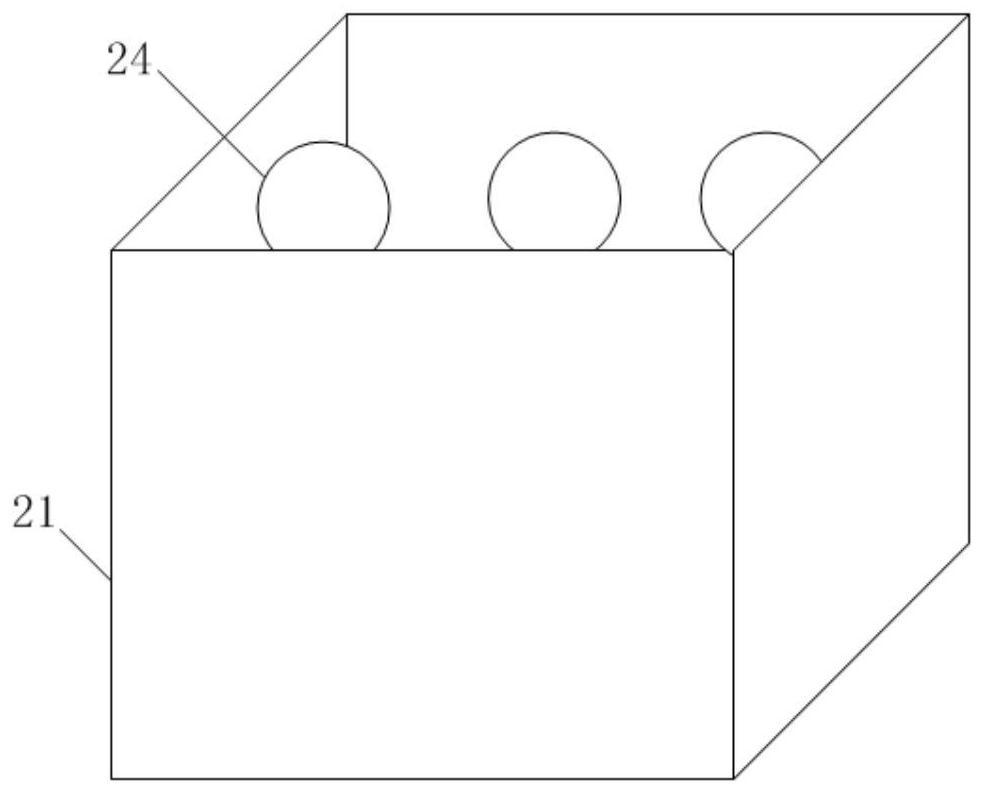

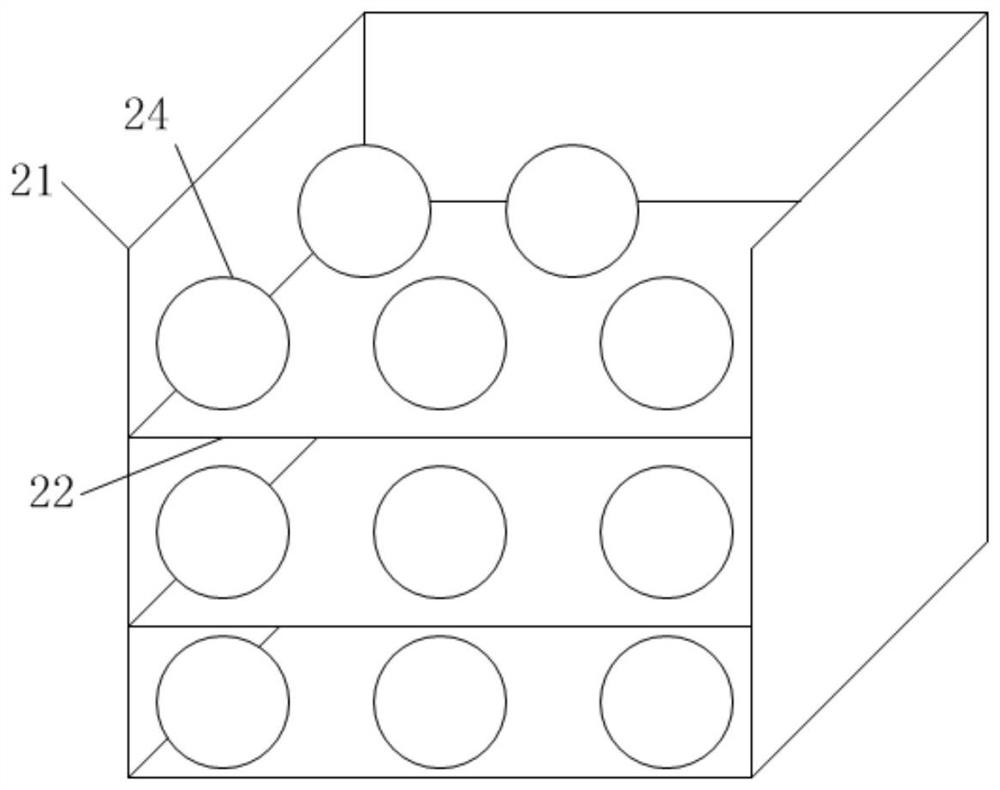

InactiveCN113185015ASimple processSave spaceWater contaminantsMultistage water/sewage treatmentMicroorganismFlocculation

The invention belongs to the technical field of sewage treatment, and particularly relates to a treatment method and equipment for sewage containing heavy metal ions. The method comprises the following steps: sewage is introduced into an adjusting tank, the sewage of which the pH is adjusted by the adjusting tank enters a flocculation-biological treatment tank, a flocculating agent loaded on the flocculation-biological treatment tank performs flocculation treatment on heavy metal ions, and the flocculated heavy metal ions enter a channel cavity and are adsorbed and degraded by microorganisms; and the flocculation-biological treatment pond comprises a pond body, a plurality of transverse grid plates are arranged in the pond body, the pond body is divided into a plurality of storage areas, a collecting body is placed on the transverse grid plate in each storage area, and the collecting bodies are used for loading the flocculating agent and the microorganisms. Flocculation treatment and biodegradation treatment are combined in one device, equipment space is saved, flocculation treatment and biodegradation treatment are carried out at the same time, and the sewage treatment process is simplified.

Owner:XIANYANG NORMAL UNIV

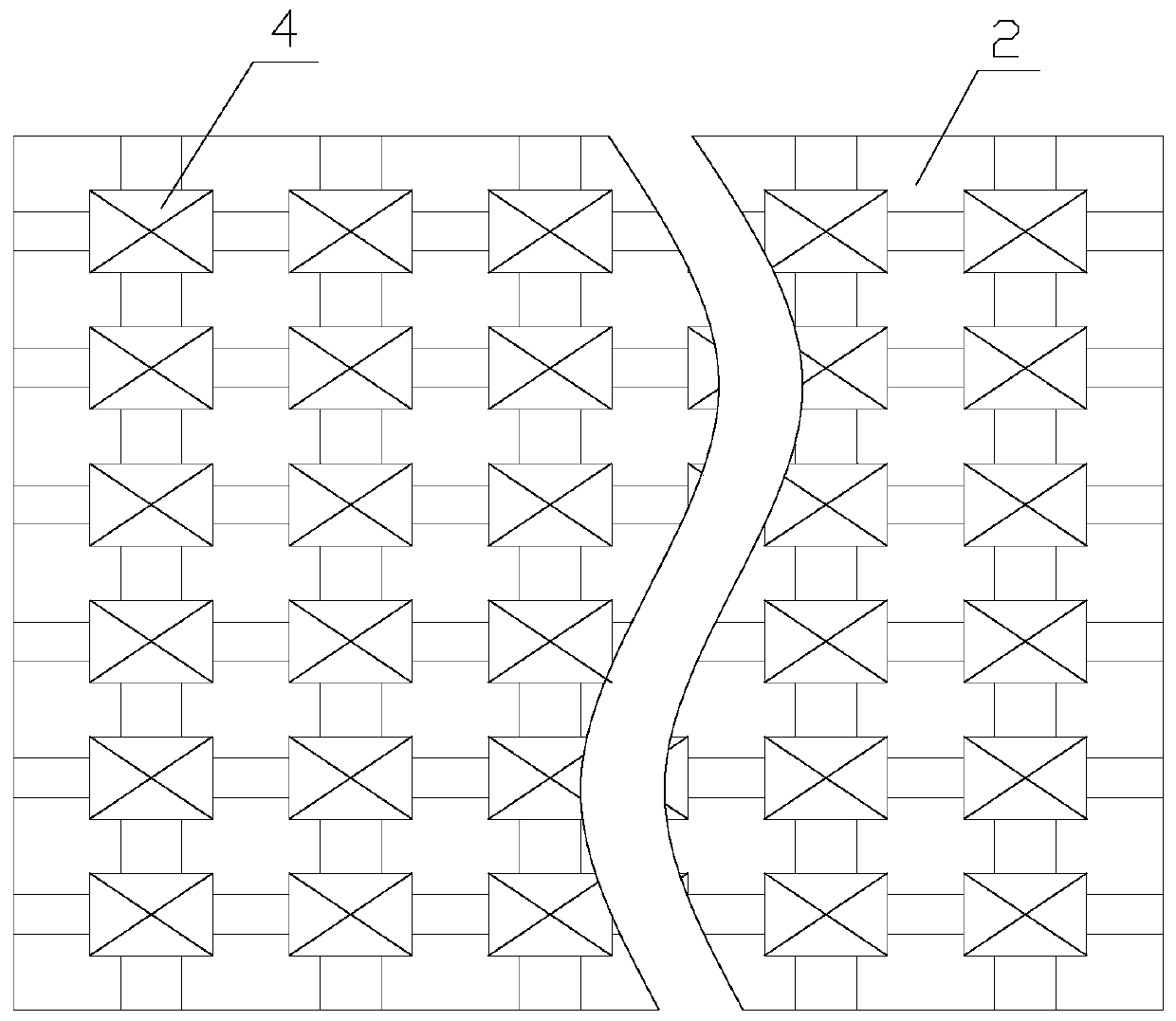

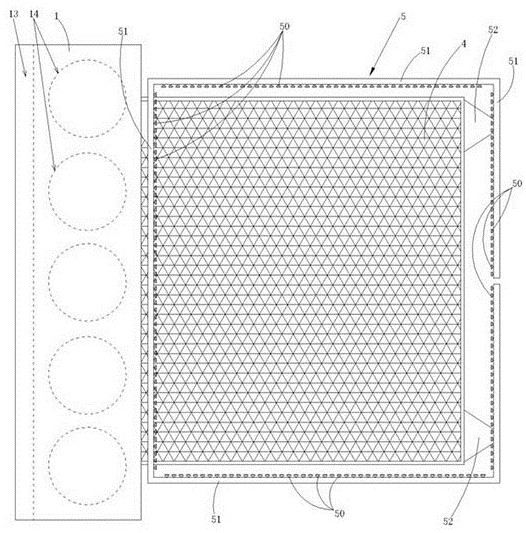

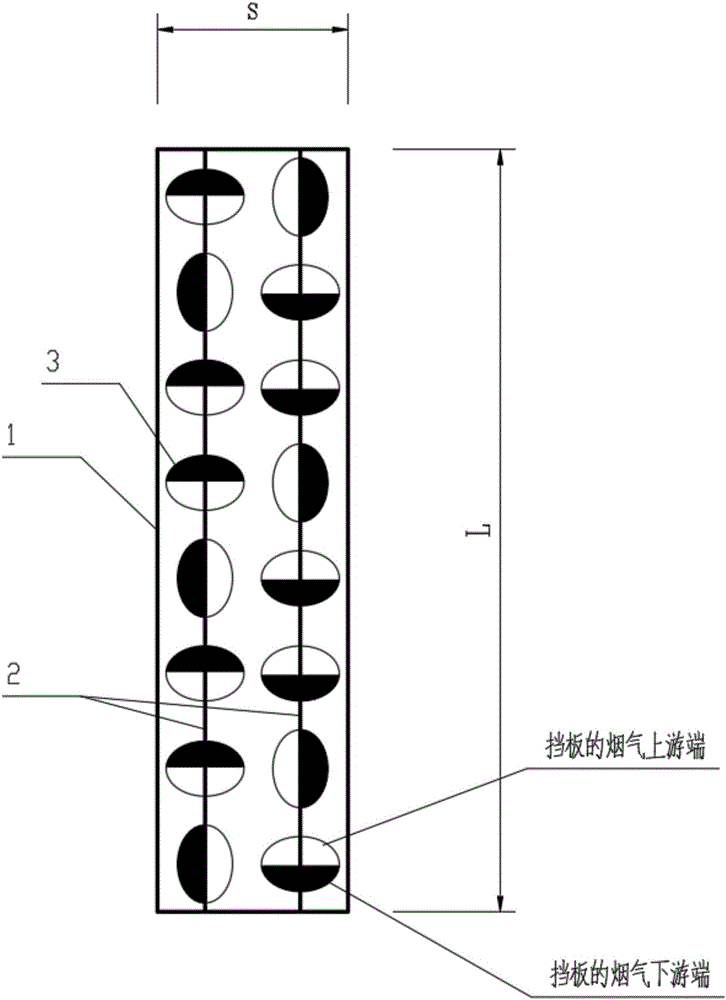

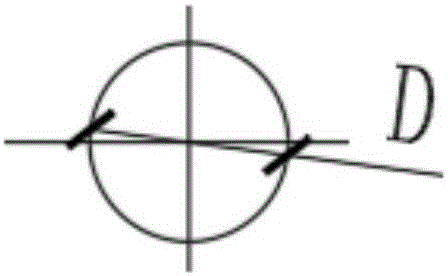

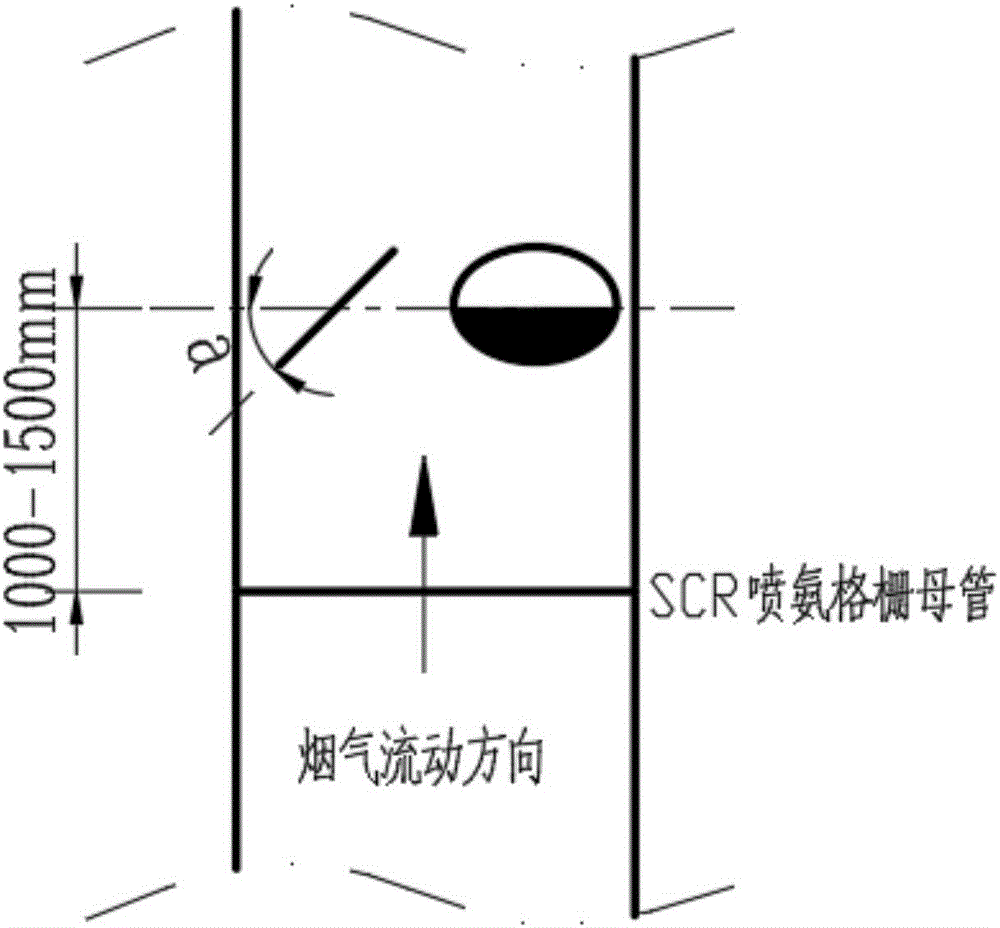

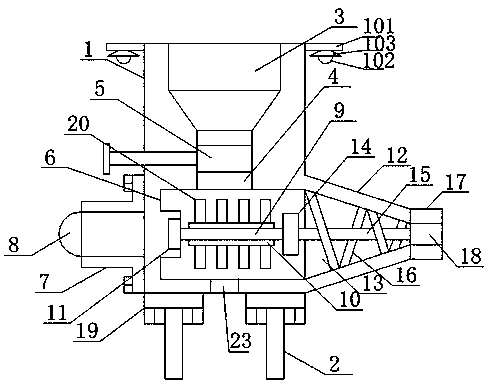

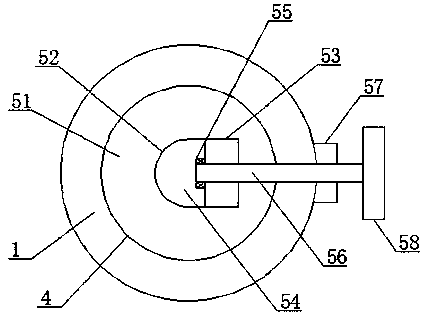

High-efficiency flow mixer for front flue of SCR denitration device

InactiveCN105964161AImprove uniformityEfficient mixed flowFlow mixersTransportation and packagingField uniformityStructural engineering

The invention relates to a high-efficiency flow mixer for a front flue of an SCR denitration device. The high-efficiency flow mixer comprises a plurality of circular steel pieces and connecting rods, wherein the circular steel pieces are welded and fixed inside a flue wall through the connecting rods; the diameter D of each circular steel piece is 1 / 10 to 1 / 9 of the length L of a long side of a cross section of the flue; the thickness of each circular steel piece is 6-10mm; the number n of the circular steel pieces is related to the long-width ratio L / S of the cross section of the flue; when the long-width ratio L / S is within 1-1.5 and is within 4.5, the number of the circular steel pieces is 16; when the long-width ratio L / S is within 1.5-2.3 and 3.5-4.5, the number of the circular steel pieces is 12; when the long-width ratio L / S is within 2.3-3, the number of the circular steel pieces is 8; when the long-width ratio L / S is within 3-3.5, the number of the circular steel pieces is 10. The high-efficiency flow mixer has the beneficial effects that flow can be mixed efficiently, the flow field uniformity can be improved, and the denitration efficiency can be improved; the high-efficiency flow mixer is convenient to mount and light in weight.

Owner:ZHEJIANG TIANDI ENVIRONMENTAL PROTECTION TECH CO LTD

Improved cutting fluid recycling device in machining field

ActiveCN108202268AHas a stirring effectWith material conveying functionMaintainance and safety accessoriesEngineeringGlobal structure

The invention discloses an improved cutting fluid recycling device in the machining field. The improved cutting fluid recycling device comprises a main hollow column shell, a connecting plate is fixedto the bottom of the main hollow column shell through a stud, and supporting legs which form a global structure with the connecting plate are arranged in the middle of the bottom of the connecting plate; and a tapered smooth cavity is formed in the middle of the top of the main hollow column shell, an annular smooth cavity is formed in the portion, located at the bottom of the tapered smooth cavity, of the interior of the main hollow column shell, a fluid inlet speed changing structure is installed on the portion, located in the annular smooth cavity, of the main hollow column shell, and a stirring smooth cavity is formed in the portion, located at the bottom of the annular smooth cavity, of the interior of the main hollow column shell. The improved cutting fluid recycling device not onlyhas a material stirring effect, but also has a material conveying effect; in addition, the device selects the stirring effect and the screw feeding effect according to preset functions through the rightward action and the leftward action of a force transmission device, and the practicability is high.

Owner:河北联硕机械制造有限公司

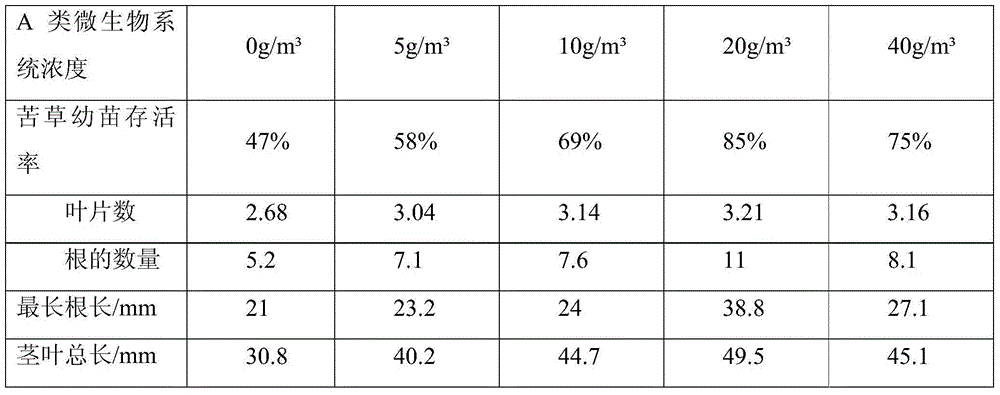

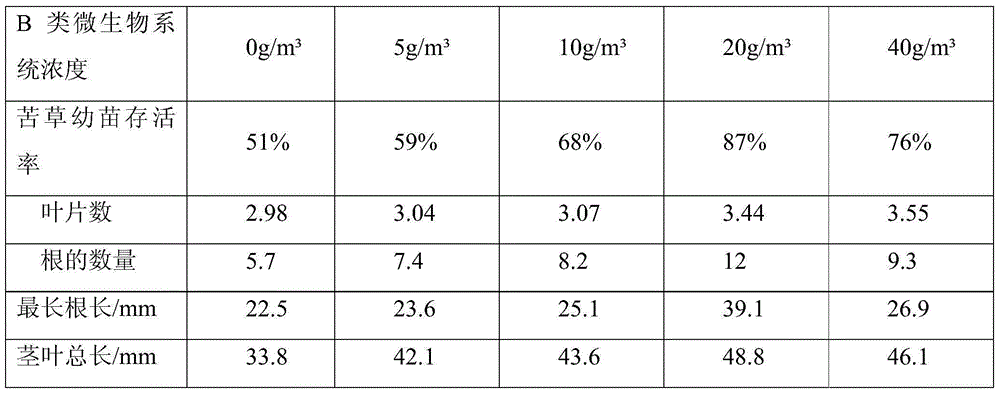

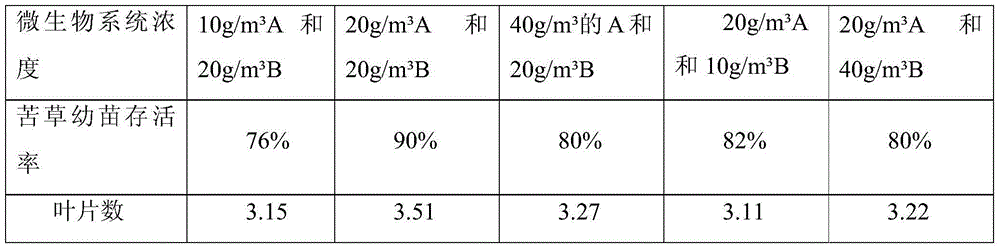

Method of adding microorganisms for promoting growth of common andrographis herbs

InactiveCN105981637AEnhanced nitrification/denitrification capacityGrow wellTreatment with aerobic and anaerobic processesCultivating equipmentsEutrophic waterCost (economic)

The invention relates to the field of environmental engineering, in particular to a method for promoting the growth of bitter grass seedlings and its application. The method comprises the following steps: adding a water body containing microorganisms into an incubator, placing bitter grass seedlings in the water body containing microorganisms for cultivation, supplemented by intermittent aeration. The method of the invention is simple, increases the survival rate of the bitter weed seedlings by more than 10-30%, has low economic cost, is suitable for actual production and application, and has great significance for the rapid growth and reproduction of the bitter weed in eutrophic water bodies.

Owner:SHANGHAI OCEAN UNIV

Reagent bottle with potent shaking well function

InactiveCN109876715AHas a stirring effectShake well quicklyShaking/oscillating/vibrating mixersTransportation and packagingEngineeringGravitation

The invention relates to a reagent bottle with a potent shaking well function. During using, due to the action of gravity, magnetic beads aggregate at the center of the bottom of a bottle body, and the reagent bottle can perform circulation forward and reverse self-rotation along with the rotation of an instrument; when rotation starts, the reagent bottle can rotate immediately, at the time, magnetic bead liquid above bottom fillets can roll over upwardly under the upward action of oblique slopes on the two sides of the bottom fillets, the magnetic beads are driven by water flow and elevates upwardly, but upward action of the bottom fillets is limited, and the magnetic beads cannot roll over quickly to the uppermost layer of the reagent bottle; at the time, two fillets of the side wall areprovided with same oblique slopes, the magnetic bead liquid is subjected to the action of the fillets of the side wall and then aggregates inwardly, due to the fact that the two fillets are symmetrically distributed, and two parts of the magnetic bead liquid aggregate inwardly and impact on each other, so that the magnetic bead liquid further has a stirring action on the rolled-over magnetic beads during rotation; and the two fillets cooperate with each other to realize rapid shaking well of the magnetic beads.

Owner:SUZHOU HYBIOME BIOMEDICAL ENG CO LTD

Tea drying device

InactiveCN108770956AIncrease profitSimple control structurePre-extraction tea treatmentElectrostatic separationDrive motorAir heater

Relating to the technical field of tea production, the invention specifically discloses a tea drying device. The device comprises a discharge pipe, a drying barrel, a driving motor and a hot air mechanism. The discharge pipe consists of an entrance section, a throat and a diffusion section. A drying cavity is disposed between the drying barrel and the discharge pipe, and suction holes are disposedon the side wall of the throat. The hot air mechanism includes an air heater, a two-position three-way reversing valve installed at the top of the discharge pipe and cams disposed on the inner wall of the drying barrel, the two-position three-way reversing valve is equipped with an air inlet communicated with the air heater, a first exhaust port communicated with the entrance section of the discharge pipe and a second exhaust port communicated with the drying barrel, the two-position three-way reversing valve is internally provided with a valve core abutting against the cams, and during the reciprocating motion of the valve core relative to the cams, the first exhaust port and the second exhaust port are in reciprocating communication with the air inlet. The drying barrel is connected toa power supply negative pole, and the throat is connected to a power supply positive pole. The device provided by the invention can screen tea according to the tea drying degree so as to obtain the superior grain tea.

Owner:贵州省黔馨生态茶业有限公司

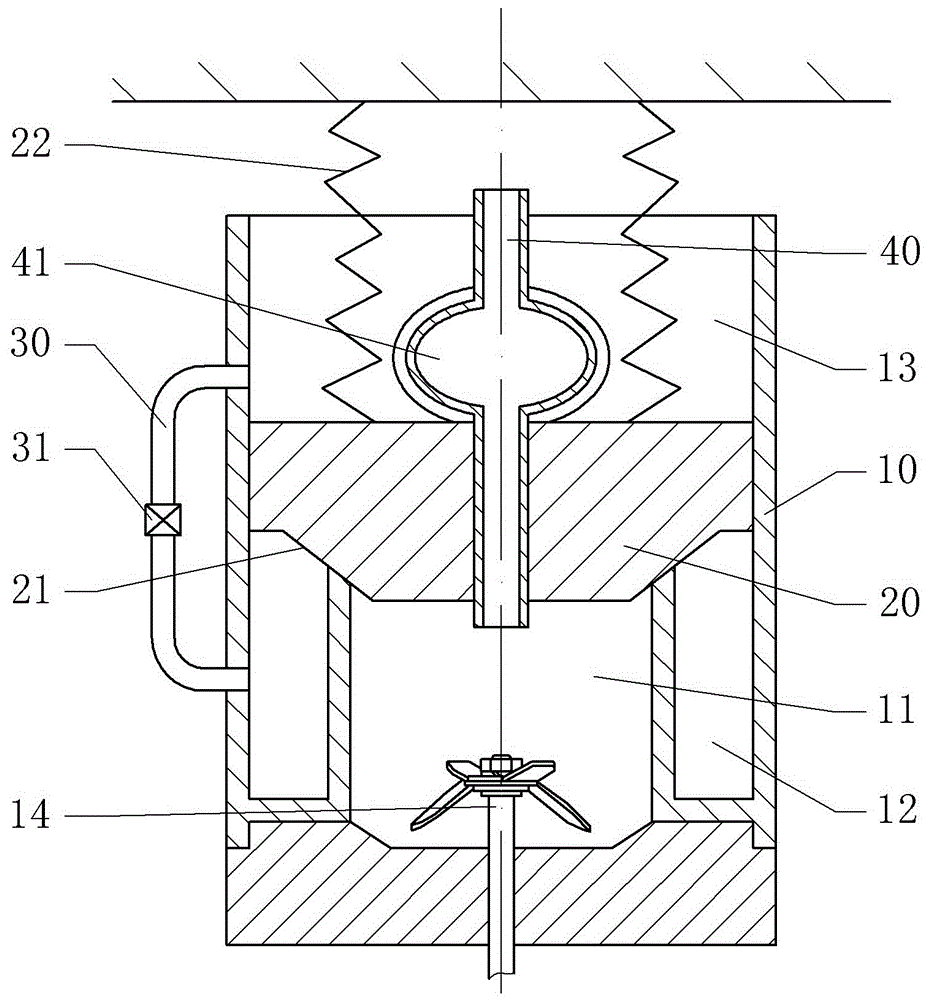

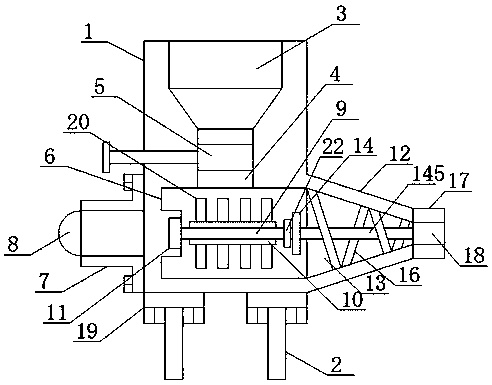

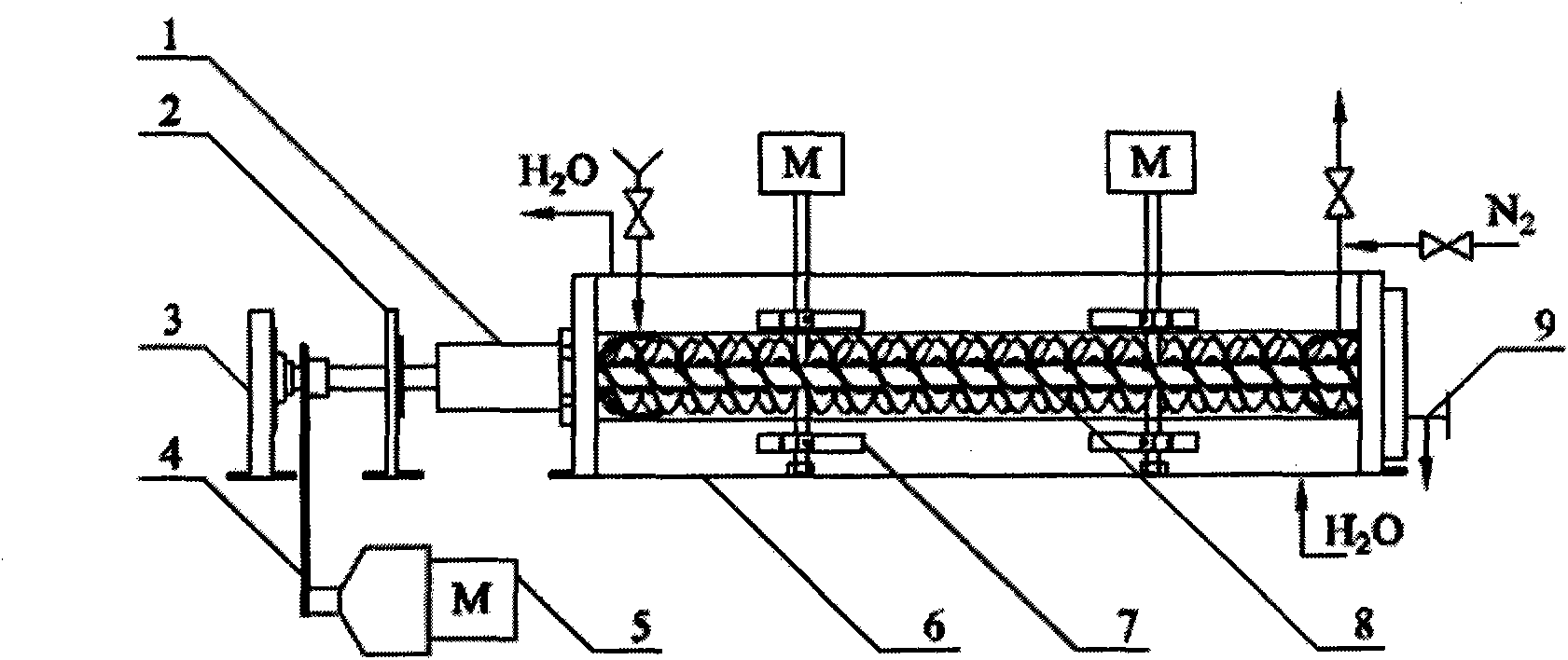

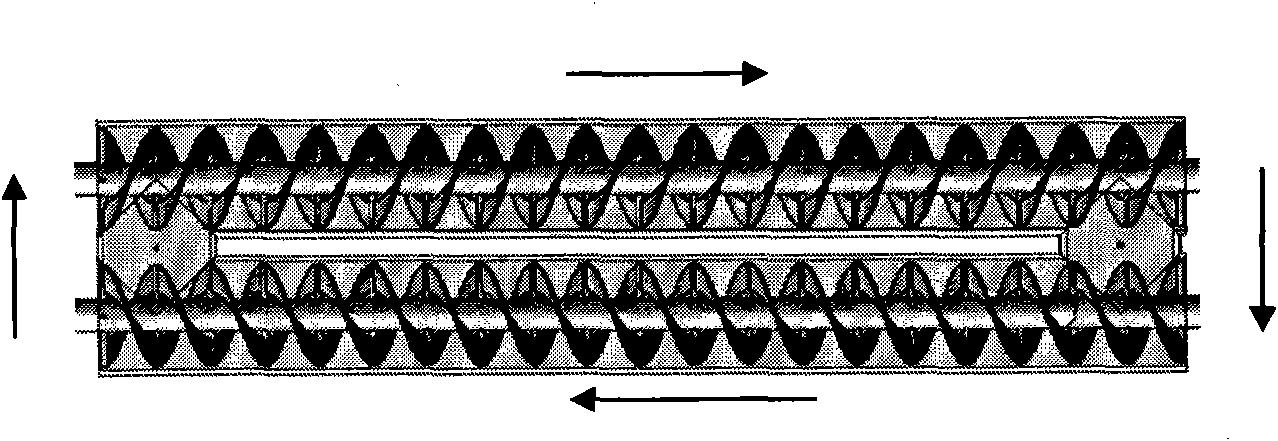

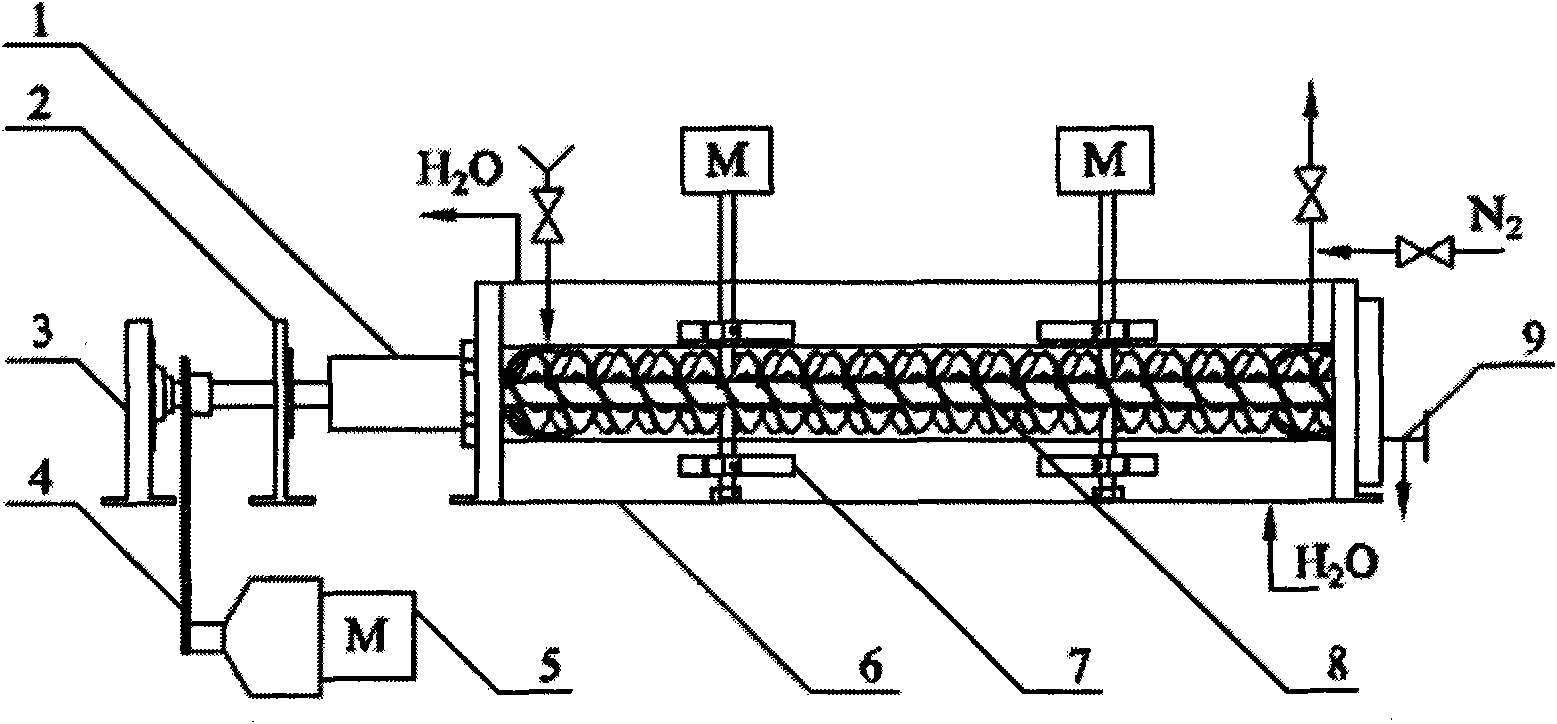

Double helical ribbon pipe type reactor for preparing high-performance polyacrylonitrile-based carbon fiber spinning solution

InactiveCN101857660AMeet the requirements of long reaction timesHas a stirring effectChemical industryTextile/flexible product manufactureWater bathsEngineering

The invention relates to a double helical ribbon pipe type reactor, which is particularly suitable for preparing high-performance polyacrylonitrile-based carbon fiber spinning solution. The reactor consists of a mechanical shaft seal, a bearing seat, a transmission chain, a variable-frequency speed reducing motor, a constant-temperature water bath cell, a water bath stirrer and a double helical ribbon stirrer, wherein the double helical ribbon stirrer consists of a stainless steel pipe and a helical ribbon paddle which is arranged in the pipe and has almost the same length as the pipe.

Owner:EAST CHINA UNIV OF SCI & TECH

Novel building construction device

InactiveCN107901224APracticalHas a stirring effectDischarging apparatusCement mixing apparatusMixing chamberRaw material

The invention discloses a new type of building construction device, comprising a primary inner hollow cylinder, the bottom of the primary inner hollow cylinder is fixed with a set of connecting plates by screws, and the middle end of the bottom of the connecting plate is provided with a combined type The foundation of the mechanism, the middle end of the top of the primary inner hollow cylinder is provided with a slanted cavity, and the inside of the primary internal hollow cylinder is provided with a cylindrical cavity at the bottom of the slanted cavity. The main inner hollow cylinder is equipped with a feeding speed control mechanism inside the cylindrical cavity, and the inside of the primary inner hollow cylinder is provided with a mixing cavity at the bottom of the cylindrical cavity. The invention not only has the function of stirring raw materials, but also has the function of conveying raw materials, and the device utilizes the right and left functions of the motor to make the device select the function of stirring and screw feeding according to the predetermined function, and has strong practicability.

Owner:余坚

Convenient-to-feed mixing equipment for captopril intermediate production

InactiveCN113083127AAvoid stickingHas a stirring effectTransportation and packagingHollow article cleaningCaptoprilEngineering

The present invention discloses convenient-to-feed mixing equipment for captopril intermediate production, which comprises an outer shell, a feeding port, an anti-blocking assembly and a driving assembly, wherein the outer shell is used for providing a space for stirring and mixing raw materials; the feeding port is formed in the upper end of the outer shell, is of a cylindrical structure, and is used for providing a channel for raw materials to enter the outer shell; the anti-blocking assembly comprises a plurality of scraping strips, the scraping strips are arranged on the inner wall of the feeding opening in a sliding mode and extend to a lower end opening from an upper end opening of the feeding port, and the scraping strips can rotate around the axis of the feeding port; and the driving assembly is used for driving the scraping strips to rotate around the axis of the feeding port. In the rotating process of the scraping strips, raw materials attached to the inner wall of the feeding port are continuously scraped away, then the raw materials can be prevented from being attached and gathered on the inner wall of the feeding port, meanwhile, the rotating scraping strips have a certain stirring effect on the raw materials, and a certain anti-blocking effect is achieved.

Owner:JINXI SPRING PHARMA

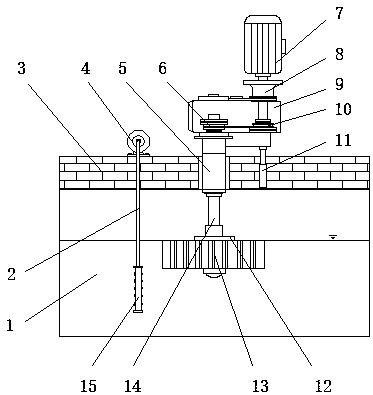

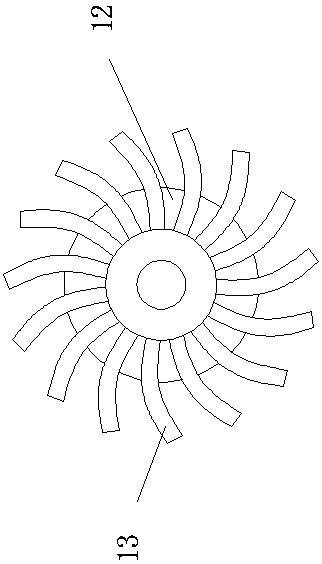

Aerating equipment for controlling water pollution

InactiveCN107758854APrevent corrosionIncrease contact areaTreatment using aerobic processesBiological treatment apparatusImpellerSludge

The invention discloses aerating equipment for controlling water pollution. The aerating equipment for controlling water pollution comprises a sewage pond, a wall body, a mounting rack, a speed controlling chassis and impellers, wherein an aerating pump is arranged on the top of the wall body, one side of the aerating pump is connected to a hose, an aerating pipe is mounted at the bottom end of the hose, the mounting rack is arranged on one side of the aerating pump, the mounting rack is mounted in the wall body, a rotary shaft is arranged in the mounting rack, a first belt wheel is mounted onthe top end of the rotary shaft, and the first belt wheel is mounted in the speed control chassis. The aerating equipment disclosed by the invention has the beneficial effects that by designing the aerating pipe and the impellers, fine bubbles are formed in water and float upward to pass through a water layer; the water surface is severely stirred by means of the impellers and new liquid interfaces are in contact with atmosphere continuously, so that the contact area with water is large; and the aerating equipment plays a stirring role to prevent wastewater from being corroded, so that the active sludge of the treated sewage is maintained in a suspended state, and therefore, the treatment efficiency is improved.

Owner:黄玉琰

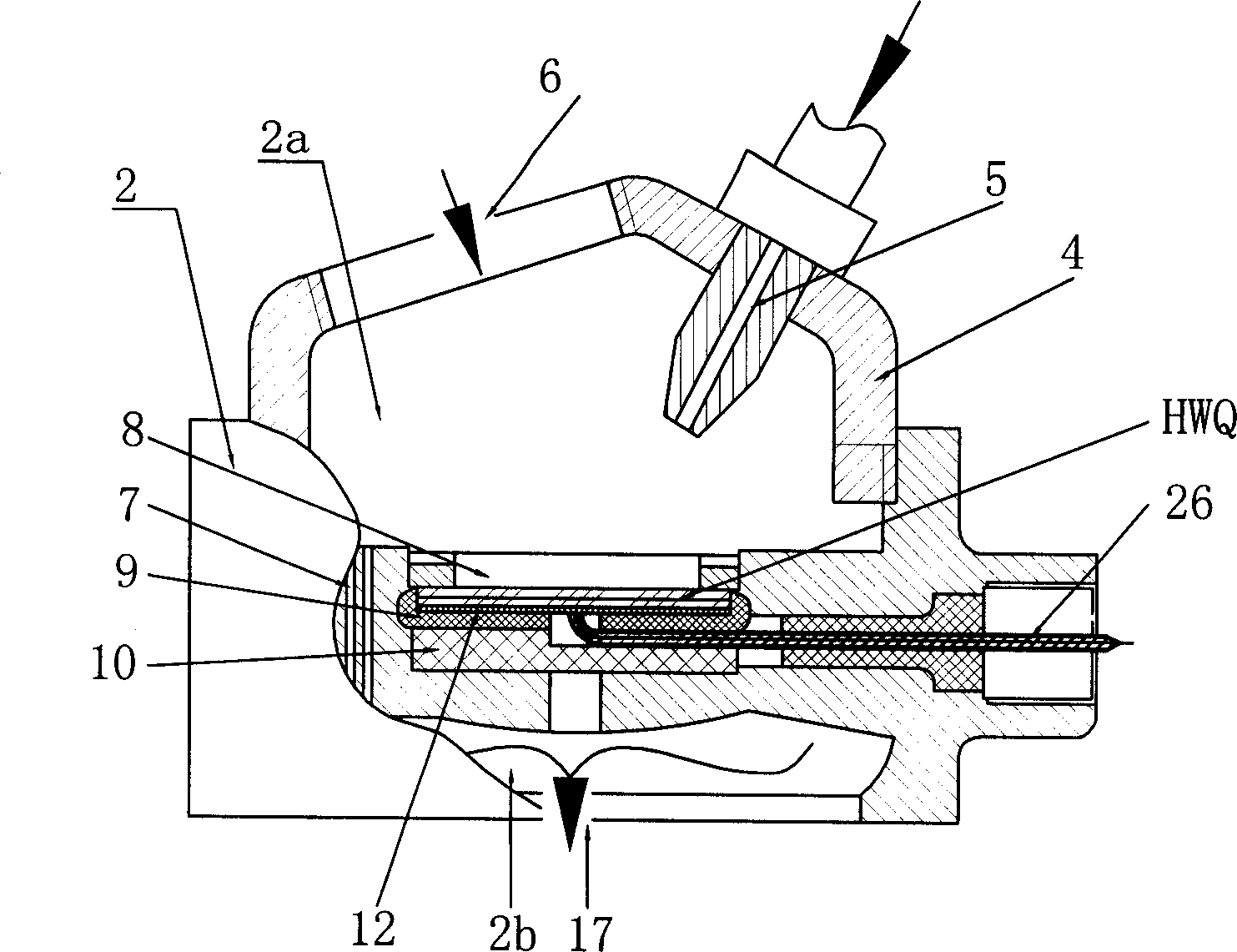

Ultrasonic electronic fuel carburetor

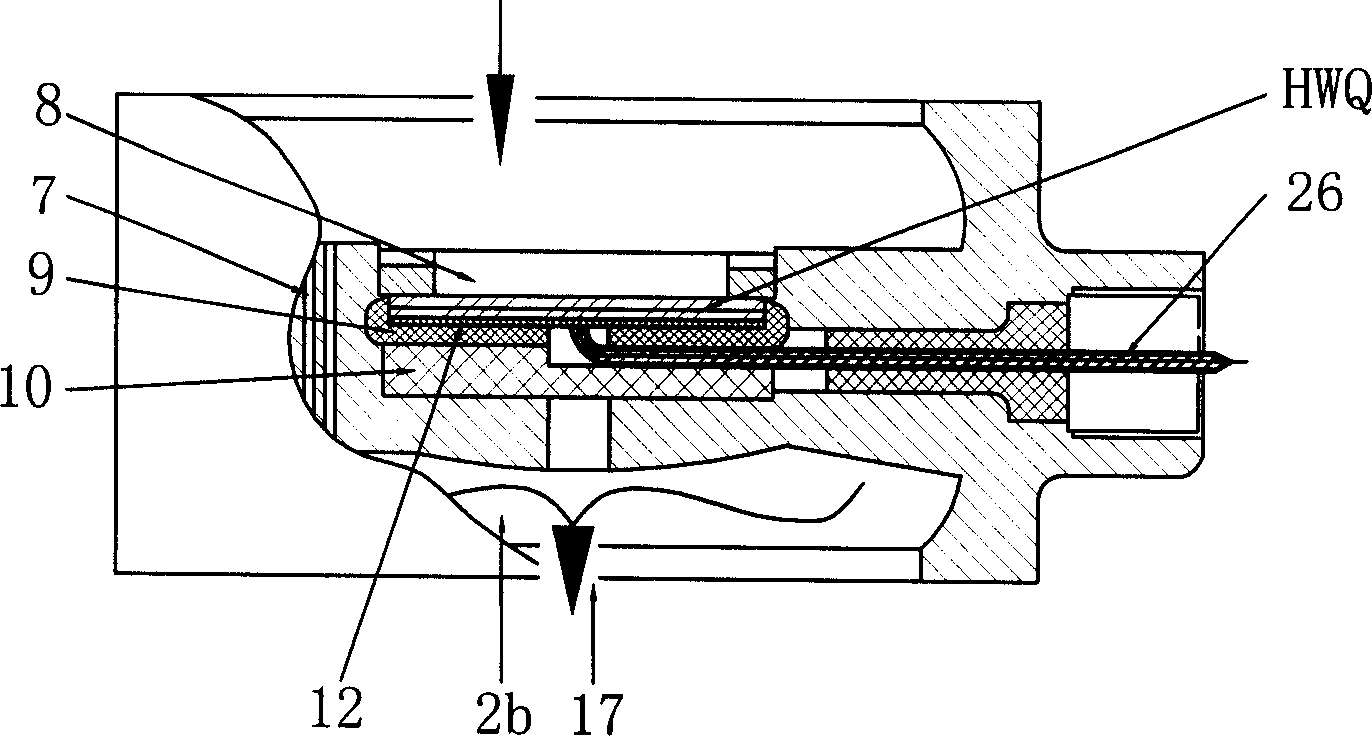

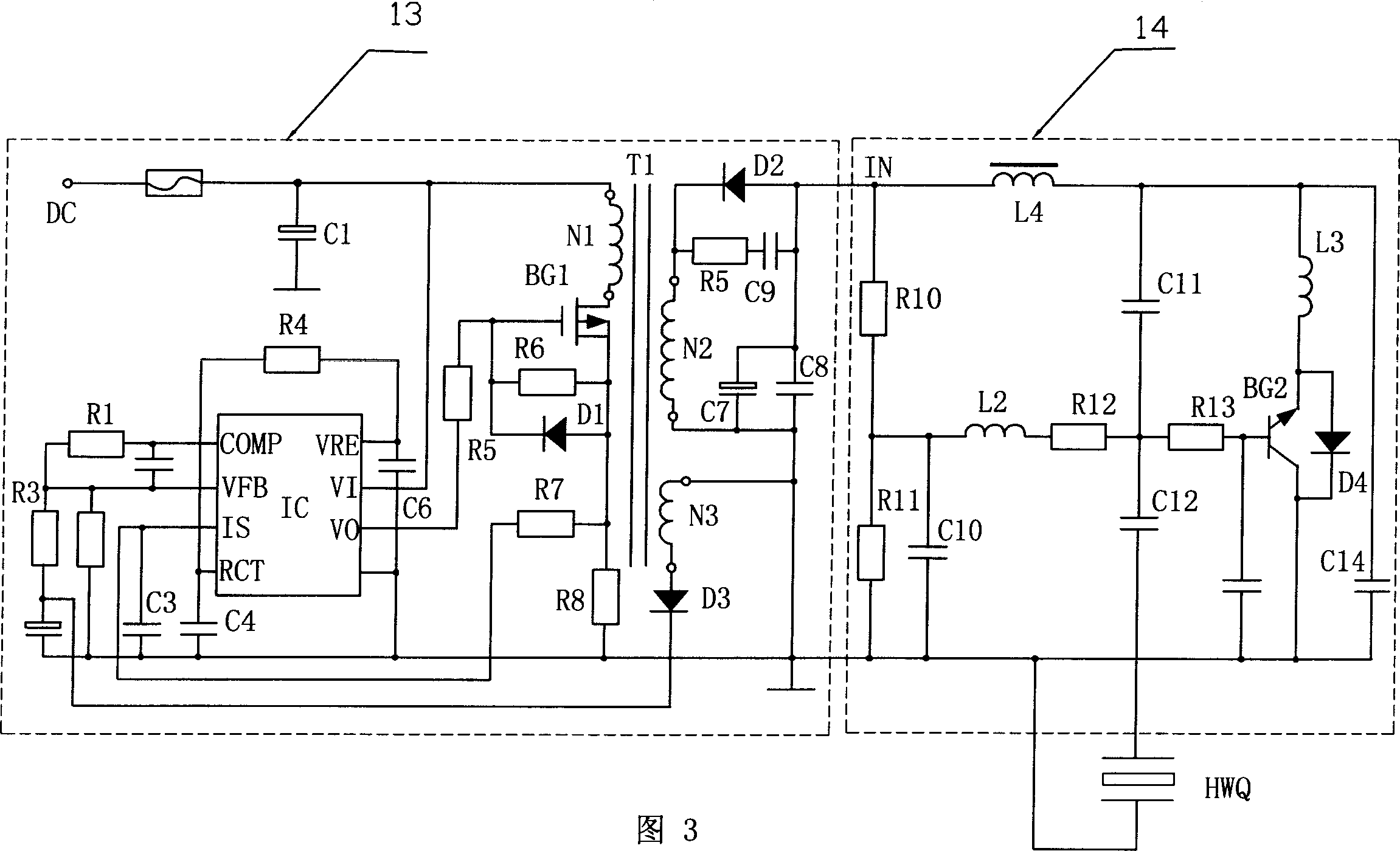

InactiveCN1828039AFully vaporizedSmall particlesInternal combustion piston enginesCombustion-air/fuel-air treatmentUltrasonic sensorAir filter

The invention discloses a vehicle ultrasonic electric fuel gasify device, which is formed by an ultrasonic power resource and a gasify room. Wherein, the gasify room comprises a frame whose inner chamber is separated by baffle plate into the upper gasify chamber and the lower outlet chamber; the upper part of gasify chamber has a oil inlet connecting the vehicle carburetor or has a oil injection hole connecting the fuel pump and the inlet connecting the air filter; the middle part of baffle plate is fixed with a ultrasonic energy exchanger; the baffle pate has air seams connecting the gasify chamber and the gas chamber; the lower part of outlet chamber has a mixed gas outlet connecting the mixed gas distribution pipeline; the down-lead of ultrasonic energy exchanger through the lead hole of frame is connected to the ultrasonic power resource. The invention can reduce the size of particle generating by gasifying the fuel, to make the fuel burn safer and improve the heat efficiency and discharge standard of fuel engine.

Owner:李伯清

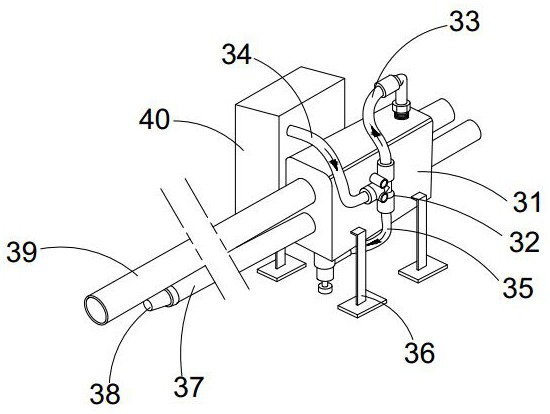

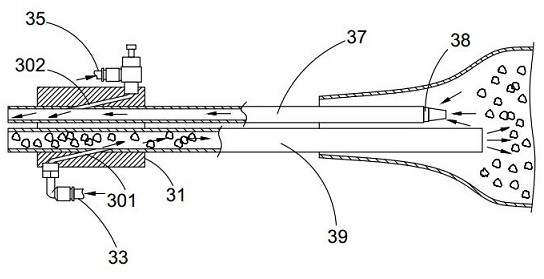

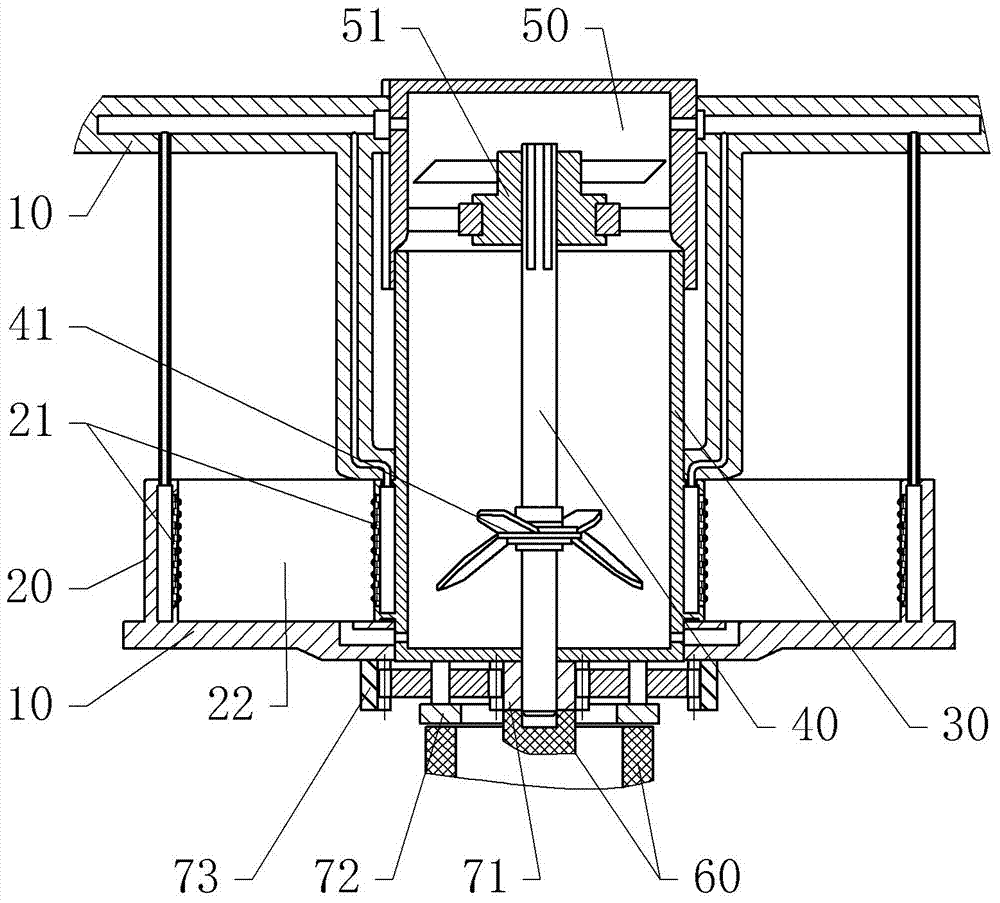

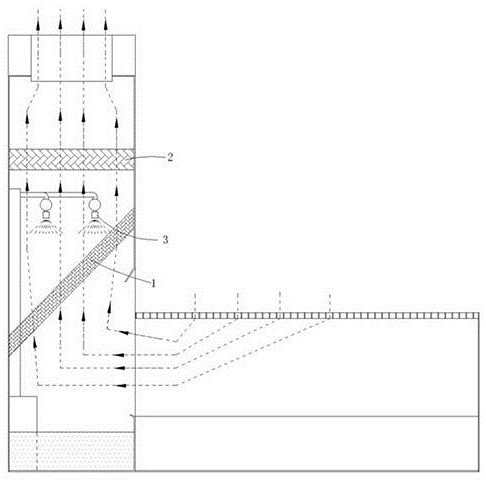

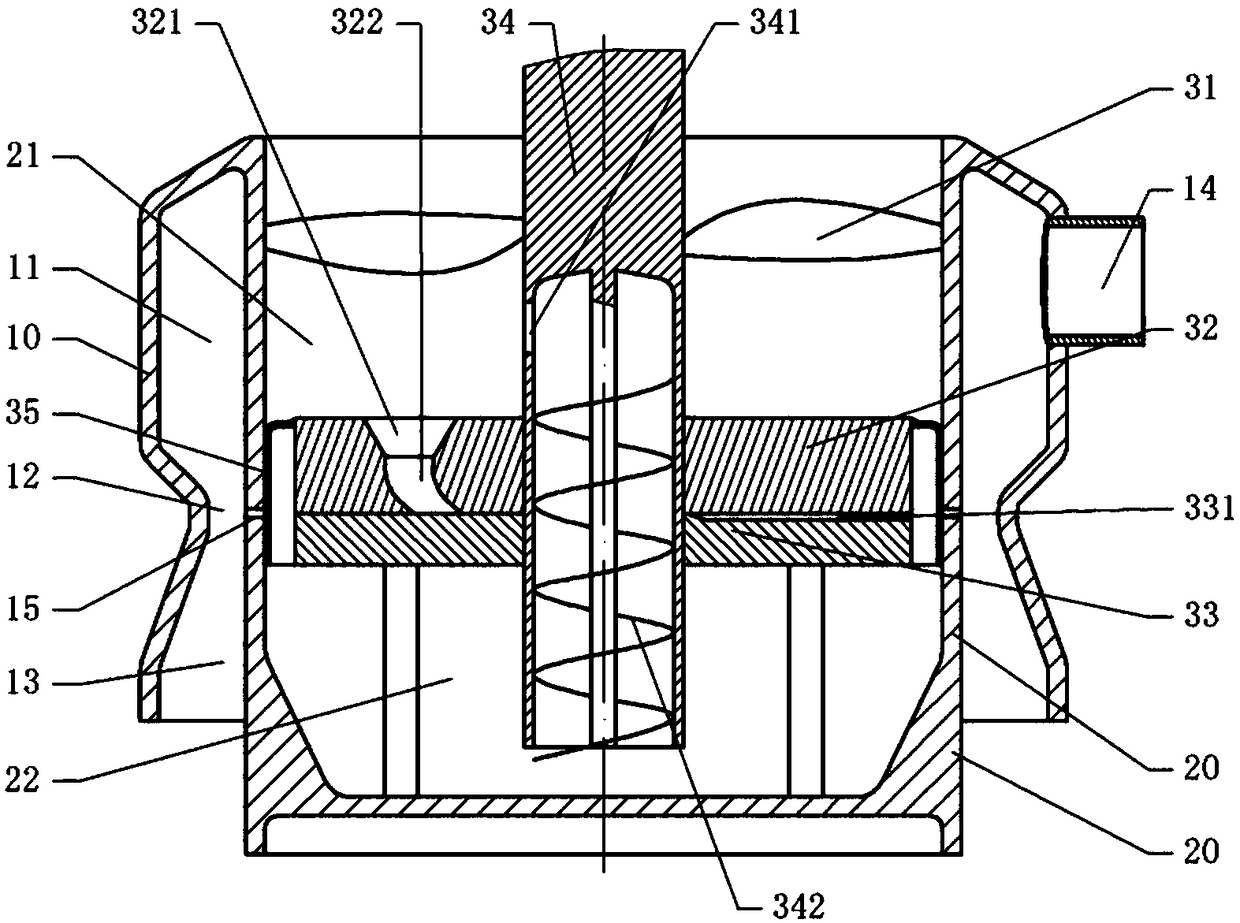

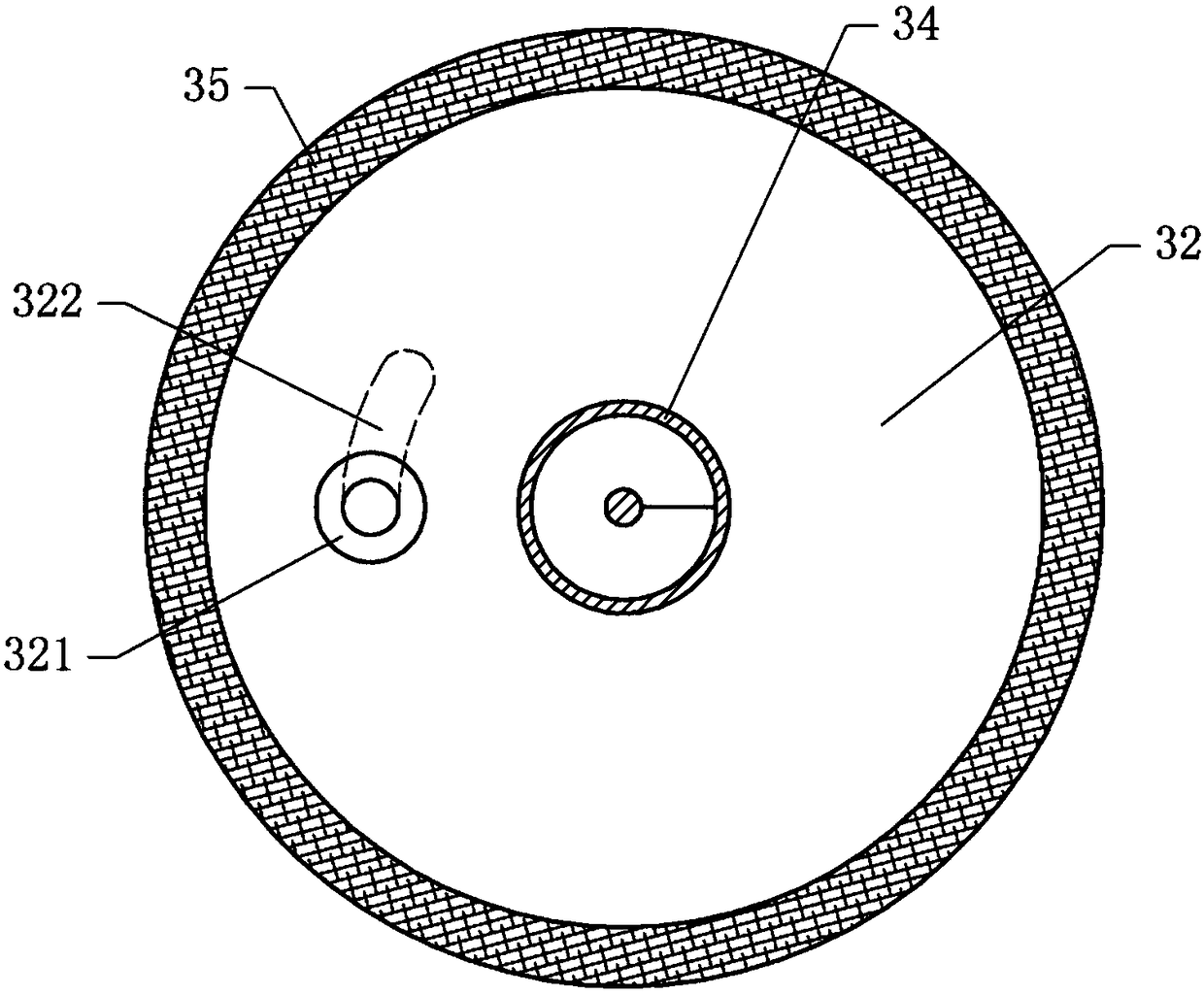

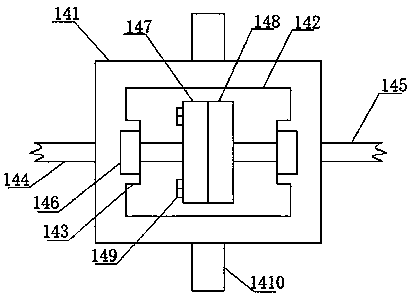

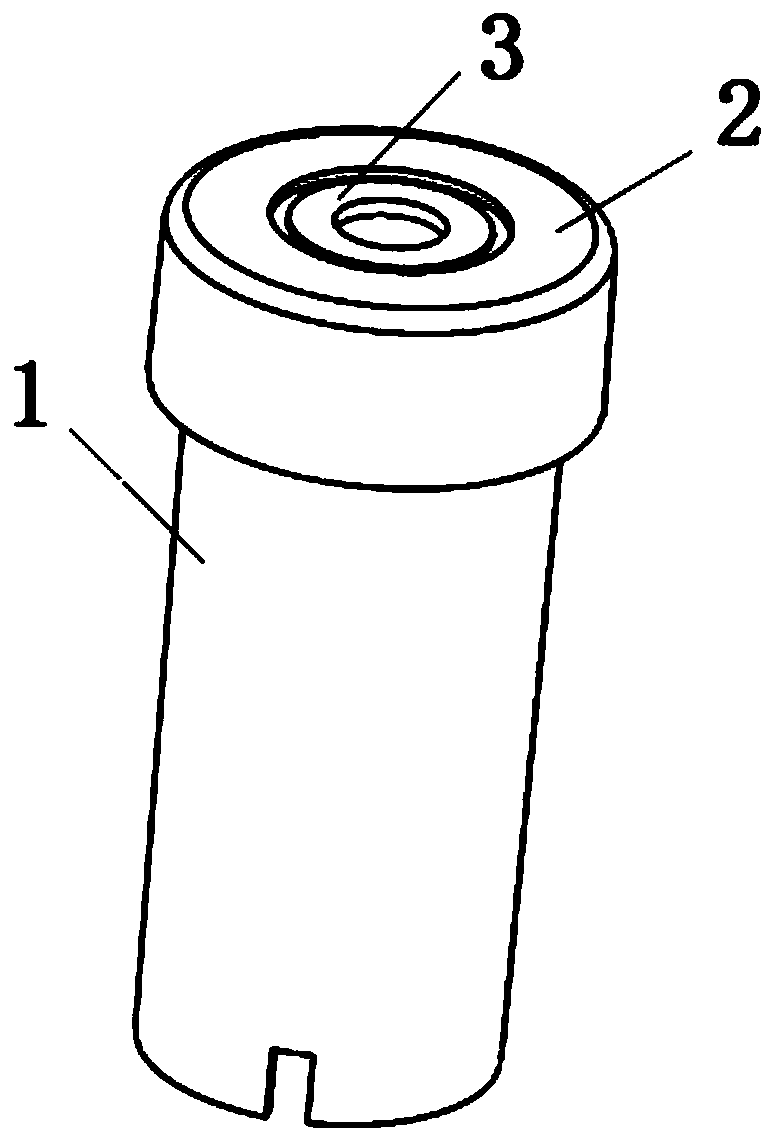

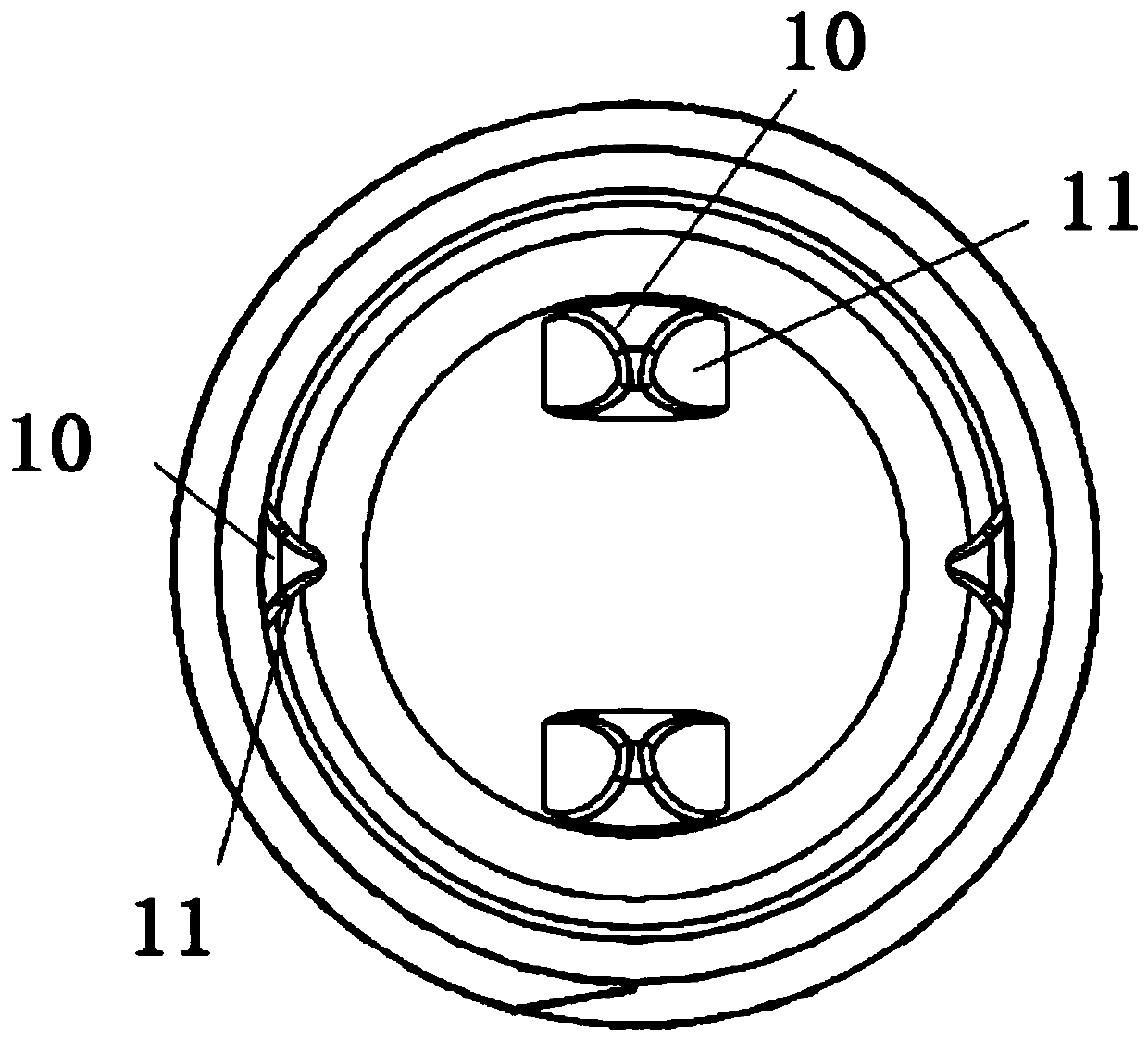

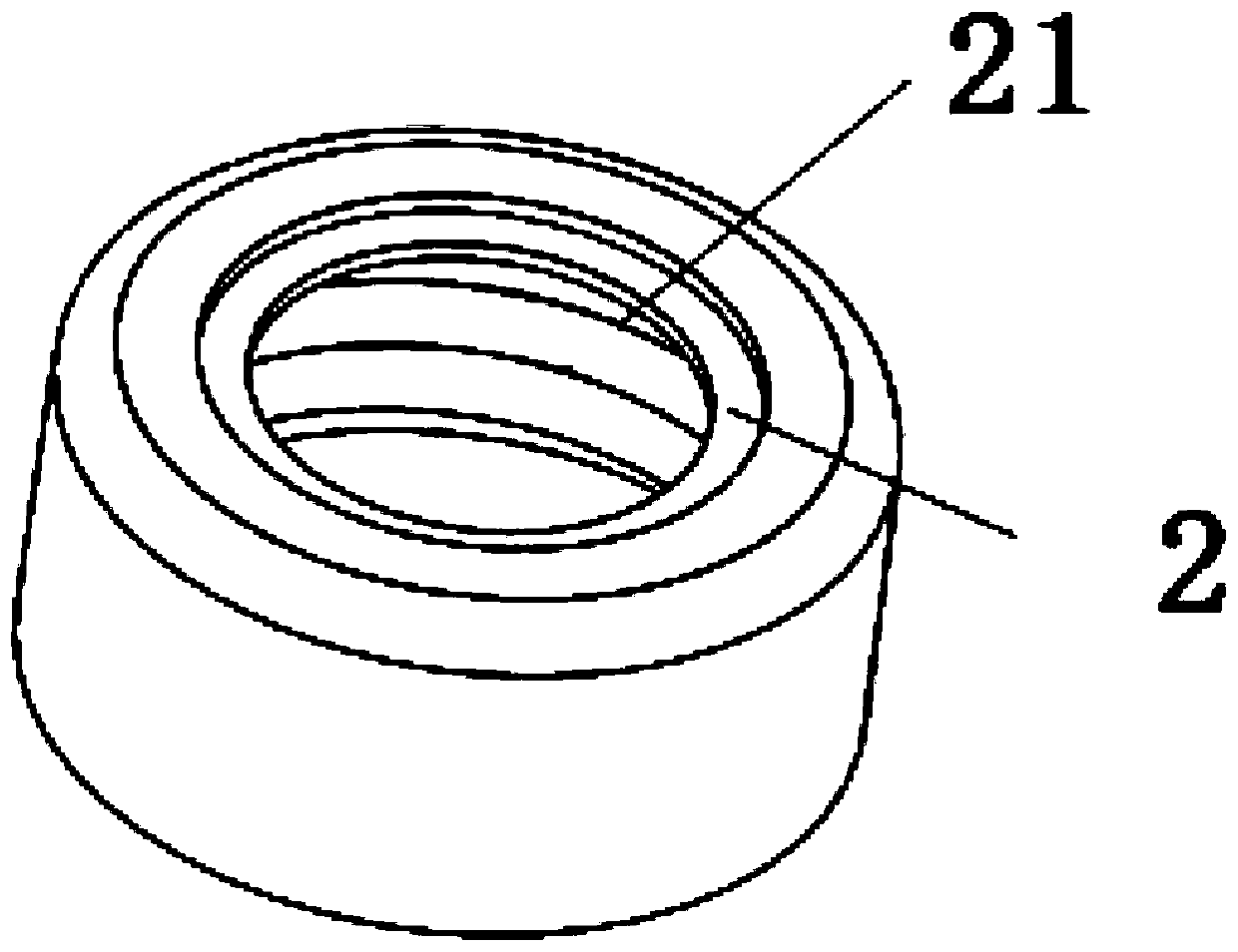

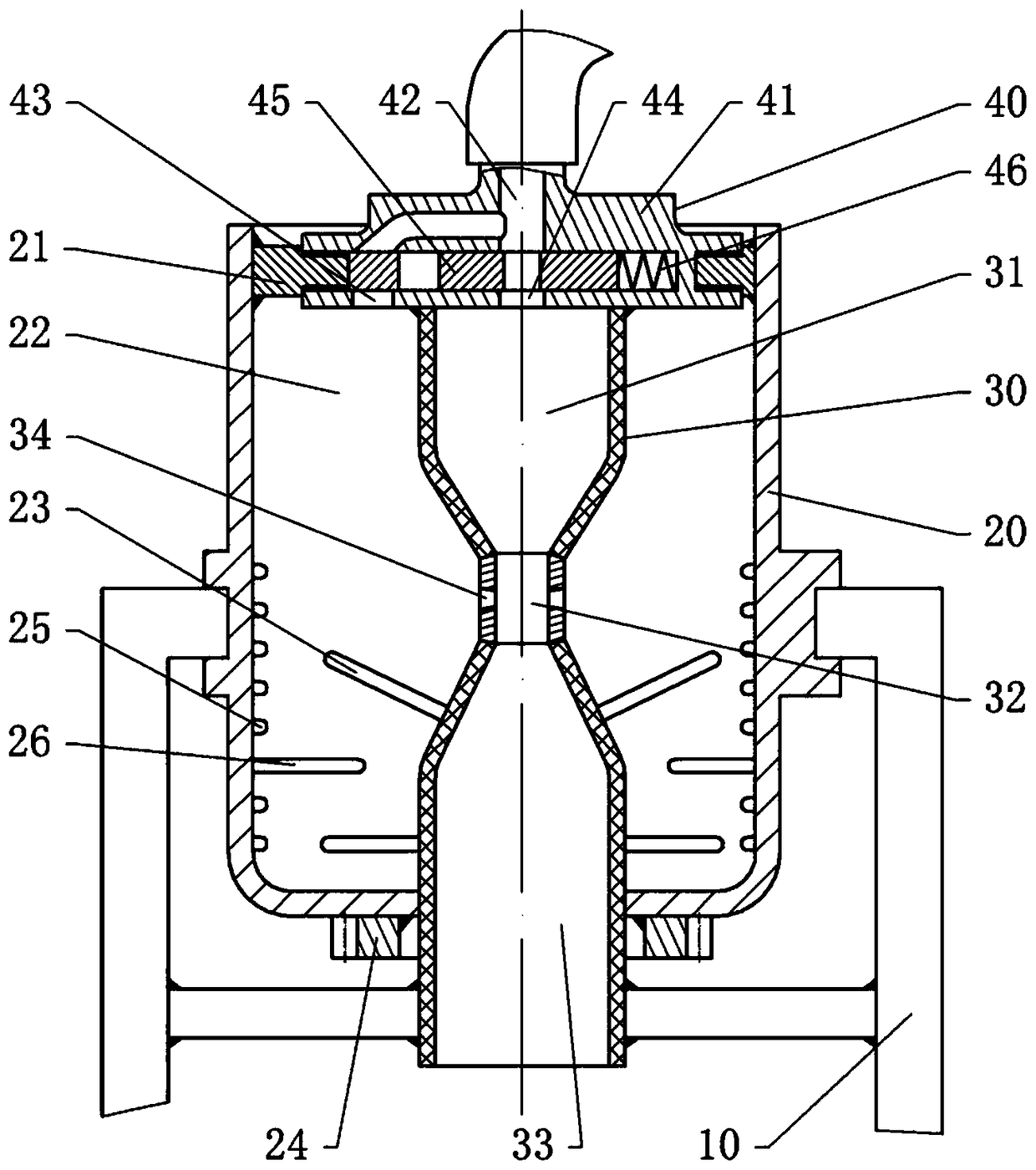

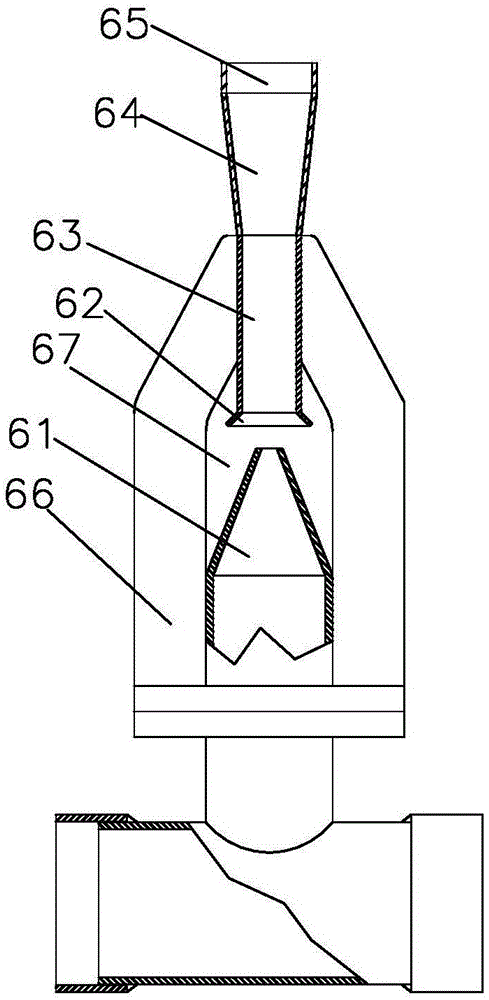

Anaerobic master boot record (MBR) module

ActiveCN105776537AAvoid cloggingGood flushabilitySpecific water treatment objectivesTreatment with anaerobic digestion processesComing outSewage

The invention belongs to the field of sewage treatment, and discloses an anaerobic master boot record (MBR) module.The anaerobic MBR module comprises an MBR membrane module and a flushing mechanism which are arranged inside an anaerobic tank, and the flushing mechanism is located at the bottom of the MBR membrane module.A water outlet is formed in the MBR membrane module and connected with a reflux branch pipe which is communicated with a water inlet of the flushing mechanism through a circulating pump.The anaerobic MBR module has the advantages that water separated out by the MBR membrane module is pumped into the flushing mechanism, the flushing mechanism performs back flushing on an MBR membrane, blocking of the MBR membrane module is effectively avoided, the water comes out continuously without interruption, a jet device has a stirring effect and stirs and mixes sewage water evenly, the flushing area of a jetting nozzle is large, and the flushing effect is better than that of a flushing mechanism in the prior art.

Owner:JIANGSU GUOSONG ENVIRONMENT SCI & TECH DEV CO LTD +1

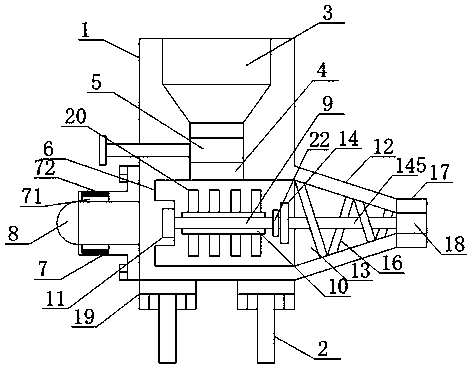

Nitrogen-feeding mixing device

InactiveCN106606976AStir wellReduce manufacturing costTransportation and packagingMixersNitrogen gasCheck valve

The invention discloses a nitrogen-feeding mixing device. Compared with the traditional mixing device, the nitrogen-feeding mixing device has outstanding features of operation simpleness and low cost. The technical scheme comprises that two nitrogen feeding pipes are connected to the upper part of a nitrogen tank, the bottom and the top of a storage tank are respectively connected to the nitrogen feeding pipes, the joint of the nitrogen inlet pipe II and the storage tank is provided with a check valve for preventing the liquid in the storage tank from flowing back into the nitrogen pipe II, at one side of the storage tank, an upper connection pipe and a lower connection pipe are connected to a liquidometer, the nitrogen pipes are provided with control valves, according to demands, the nitrogen feeding situation is controlled, the lower connection pipe is provided with a control valve, and the upper connection pipe has no a control valve. The nitrogen-feeding mixing device improves the accuracy of the operation.

Owner:DONGYING YINQIAO CHEM CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com