Nitrogen-feeding mixing device

A stirring device and nitrogen-passing technology, applied in the directions of transportation and packaging, dissolving, mixer, etc., can solve the problems of complicated operation and high cost of electricity, and achieve the effect of uniform stirring and production cost saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

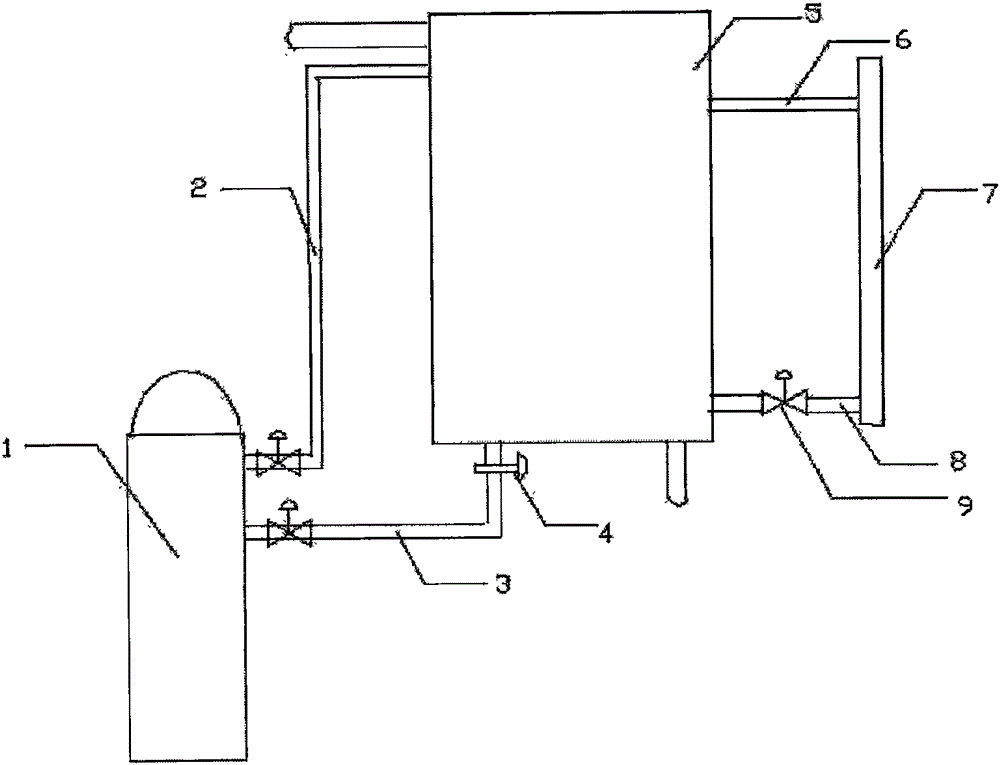

[0010] Reference attached figure 1 , A nitrogen agitating device, comprising: a nitrogen tank 1 and a storage tank 5. Two inlet pipes 2 and 3 are arranged on the upper part of the nitrogen tank 1, and the inlet pipe I 2 and the inlet pipe II 3 are respectively connected to the storage tank At the bottom and upper part of 5, the connection between the inlet pipe II 3 and the bottom of the storage tank 5 is provided with a check valve 4 to prevent the liquid in the storage tank from flowing back into the inlet pipe II 3. Two connections are provided on the other side of the storage tank 5. There is a connecting pipe I 6 and a connecting pipe II 8 with a liquid level gauge 7, and the air inlet pipe I 2 and the air inlet pipe II 3 are both provided with a control valve 9. The upper connecting pipe I 6 has no control valve, and the lower connecting pipe II 8 is equipped with a control valve 9.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com