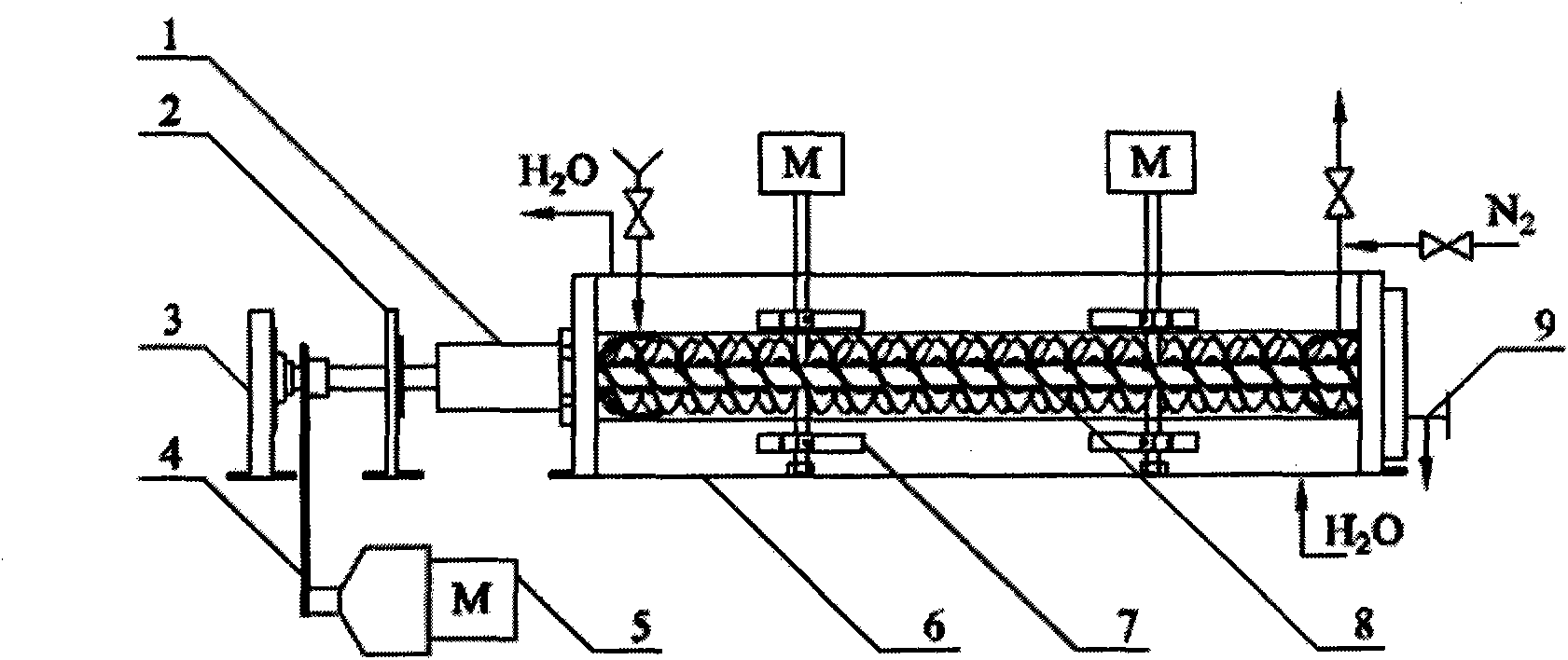

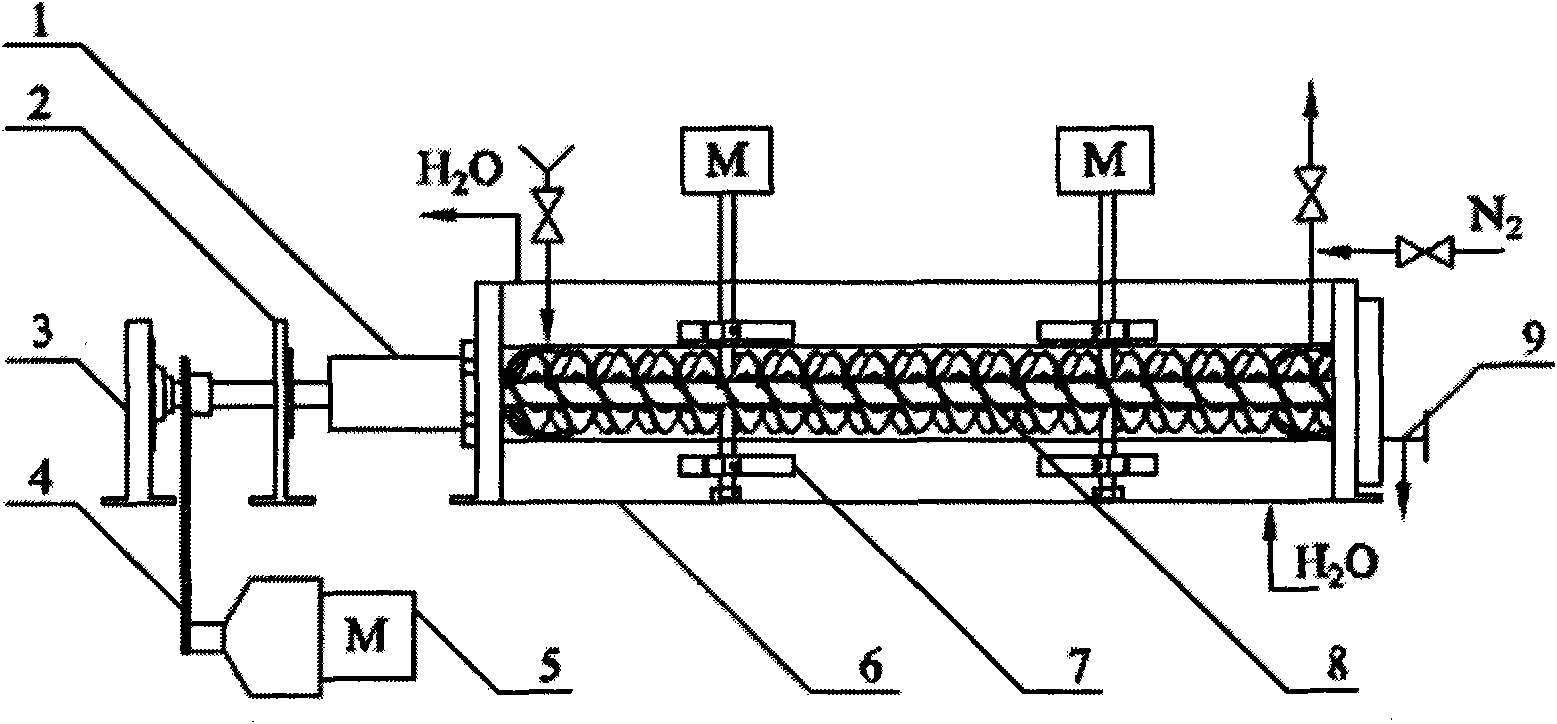

Double helical ribbon pipe type reactor for preparing high-performance polyacrylonitrile-based carbon fiber spinning solution

A technology of polyacrylonitrile-based carbon fiber and tubular reactor, which is applied in the fields of fiber chemical characteristics, climate sustainability, textiles and papermaking, etc. It can solve the problems of unsuitability for industrialization, and achieve the elimination of back-mixing, avoiding adhesion, and long-term reaction the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

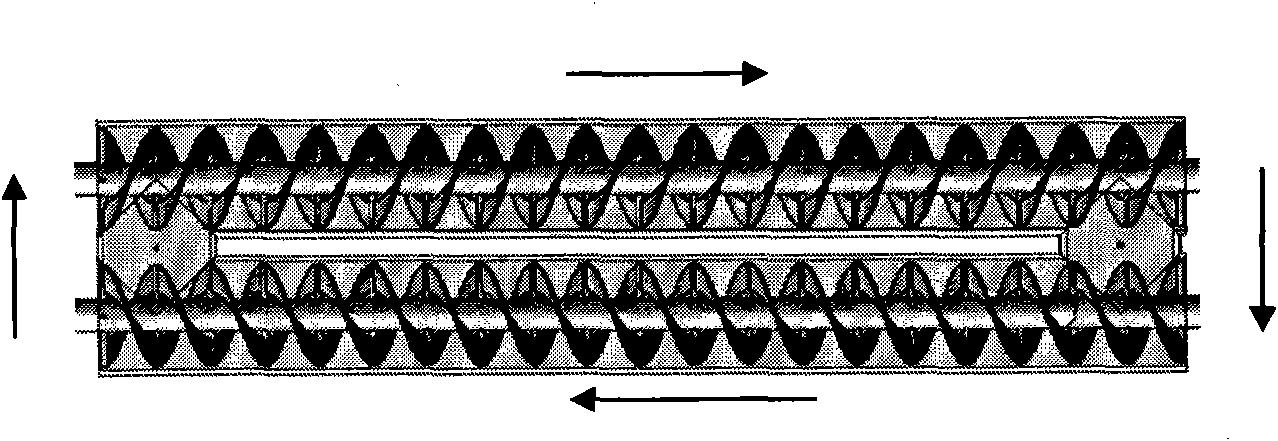

Method used

Image

Examples

Embodiment 1

[0035] Weigh 871.2g acrylonitrile, 8.8003g itaconic acid, 3117.4g dimethyl sulfoxide, 2.6400g azobisisobutyronitrile, 4000g in total. The temperature of the water bath in the reactor was set at 60° C., and the stirring speed was set at 30 rpm. The temperature measuring thermocouple showed that the difference between the temperature of the water bath and the reaction temperature was less than 3°C during the whole reaction process. After 25 hours, the reaction was stopped, and the measured monomer conversion rate was 90.01%, the viscosity average molecular weight was 197148g / mol, the weight average molecular weight was 230460g / mol, and the molecular weight distribution index was 2.1659.

Embodiment 2

[0037] Weigh 990.0g acrylonitrile, 10.0000g itaconic acid, 2999.0g dimethyl sulfoxide, 1.0000g azobisisobutyronitrile, 4000g in total. The temperature of the water bath in the reactor was set at 60° C., and the stirring speed was set at 60 rpm. The temperature measuring thermocouple showed that the difference between the temperature of the water bath and the reaction temperature was less than 3°C during the whole reaction process. After 25 hours, the reaction was stopped, and the measured monomer conversion rate was 71.38%, the viscosity-average molecular weight was 271708 g / mol, the weight-average molecular weight was 311342 g / mol, and the molecular weight distribution index was 1.8799.

Embodiment 3

[0039] Weigh 871.2g of acrylonitrile, 8.8006g of itaconic acid, 3117.4g of dimethyl sulfoxide, and 2.6403g of azobisisobutyronitrile, totaling 4000g. The temperature of the water bath in the reactor was set at 55° C., and the stirring speed was set at 30 rpm. The temperature measuring thermocouple showed that the difference between the temperature of the water bath and the reaction temperature was less than 3°C during the whole reaction process. After 28 hours, the reaction was stopped, and the measured monomer conversion rate was 86.47%, the viscosity-average molecular weight was 232390 g / mol, the weight-average molecular weight was 267540 g / mol, and the molecular weight distribution index was 2.0212.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com