Anaerobic master boot record (MBR) module

A block and anaerobic pool technology, applied in anaerobic digestion treatment, special treatment targets, water/sludge/sewage treatment, etc., can solve problems such as MBR membrane clogging, achieve excellent flushing effect, uniform mixing, and avoid clogging Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

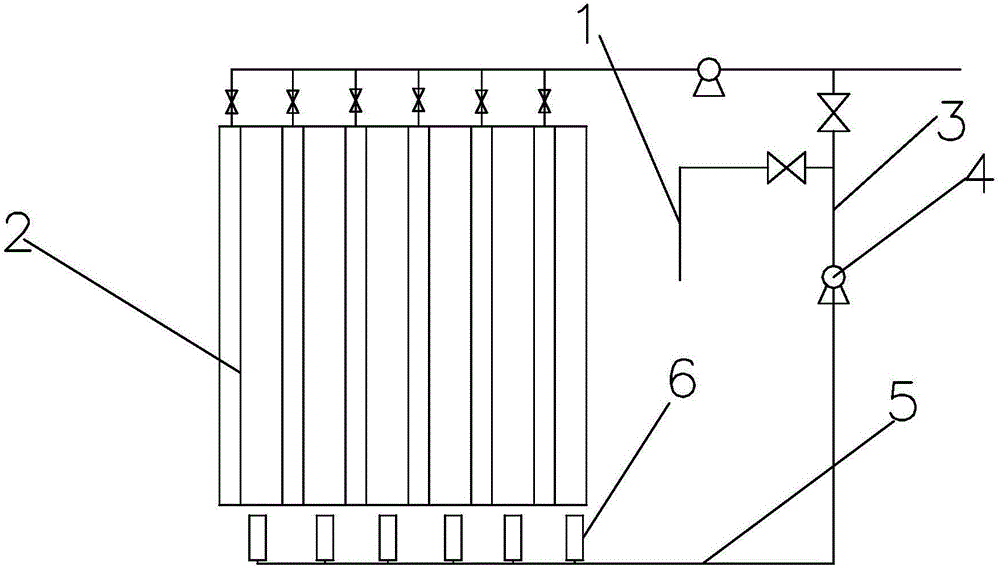

[0020] Such as figure 1 As shown, a kind of anaerobic MBR module, comprises MBR membrane module 2 and flushing mechanism, described MBR membrane module 2 and flushing mechanism are all arranged in the anaerobic tank, and described flushing mechanism is positioned at described MBR membrane module 2 Bottom; the MBR membrane module 2 is provided with a water outlet, and the water outlet of the MBR membrane module 2 is connected with a return branch pipe 3, and the return branch pipe 3 communicates with the water inlet of the flushing mechanism through a circulation pump 4, and the A bypass pipe 1 communicating with the anaerobic tank is provided on the return branch pipe 3, and a valve is arranged on the return branch pipe 3 and the bypass pipe 1, and the valve is located at the front part of the water inlet of the circulation pump 4, and One end of the bypass pipeline 1 is located at the upper part of the anaerobic tank.

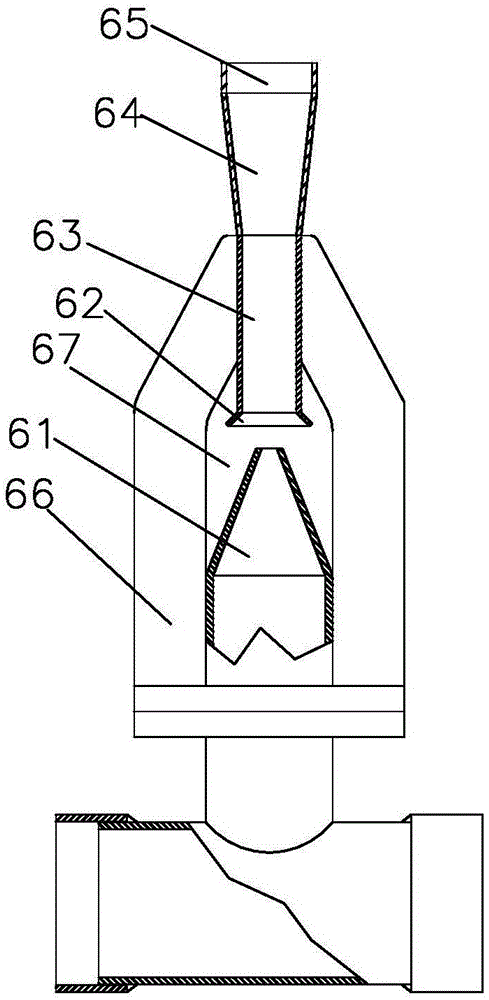

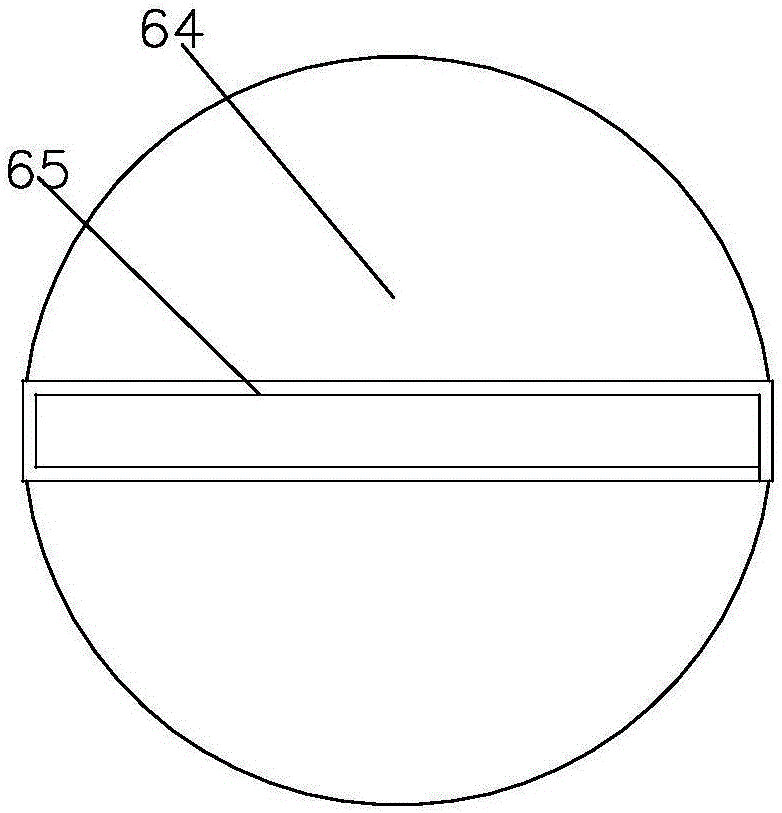

[0021] Specifically, such as figure 2 with 3 As show...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com