Ultrasonic electronic fuel carburetor

A technology of ultrasonic electronics and vaporization devices, which is applied in the direction of charging systems, combustion engines, internal combustion piston engines, etc., can solve the problems of large and uneven oil mist particles, and achieve the effects of complete combustion, sufficient vaporization, and sufficient oil and gas mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

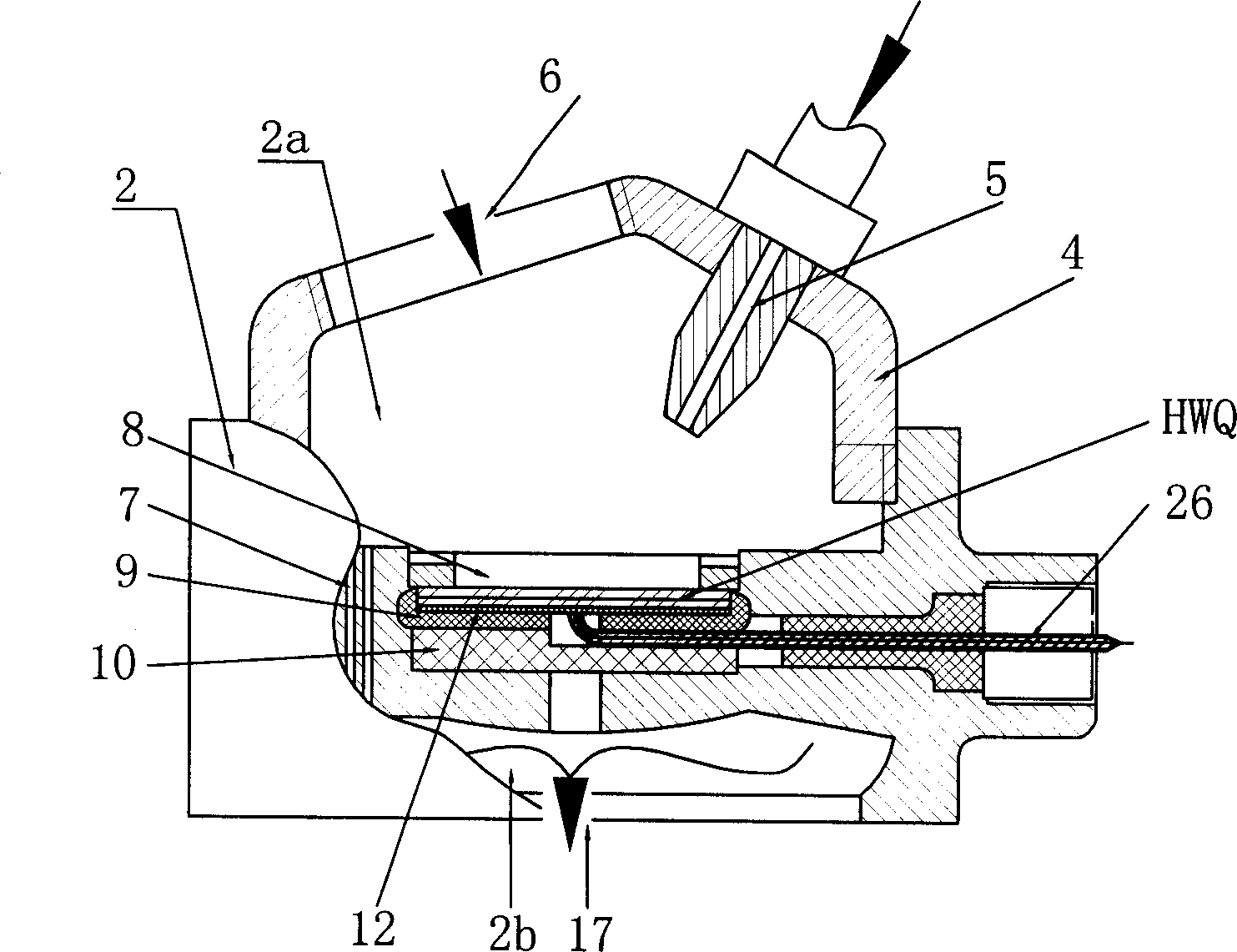

[0029] figure 1 It is shown that a specific embodiment of the present invention is: an automotive ultrasonic electronic fuel vaporization device, which is composed of an ultrasonic power source and a vaporization chamber 2, wherein the specific composition of the vaporization chamber 2 is: the inner cavity of the housing 4 The upper part of the vaporization chamber 2a and the lower part of the gas outlet chamber 2b are separated by a partition; the upper part of the vaporization chamber 2a is provided with an oil and gas inlet connected to the car carburetor, or the upper part of the vaporization chamber is provided with a fuel injection connected to the car fuel pump Port 5 and the air inlet 6 connected to the automobile air filter; the ultrasonic transducer HWQ is fixed in the middle of the partition, and the air gap 7 connecting the vaporization cavity 2a and the outlet cavity 2b is provided on the partition; the lower part of the outlet cavity 2b A mixed gas outlet 17 connec...

Embodiment 2

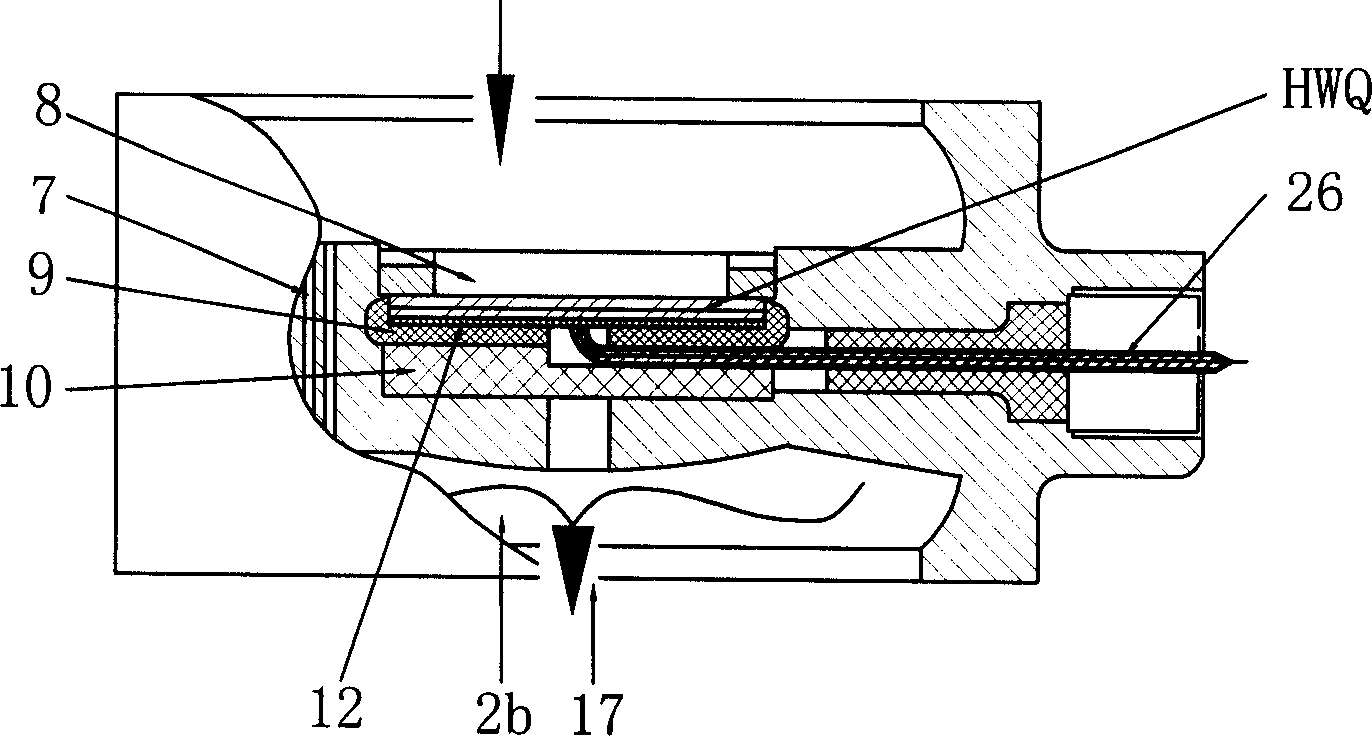

[0037] figure 2 It is shown that this embodiment is basically the same as the first embodiment, except that the upper part of the vaporization chamber does not have the fuel injection port 5 and the air intake port 6, but an oil and gas inlet connected to the car carburetor.

[0038] The device of the present invention can be installed on a single combustion chamber of an engine to realize single-chamber vaporization, and multiple combustion chambers can be installed at the same time to realize multi-chamber vaporization to ensure complete vaporization.

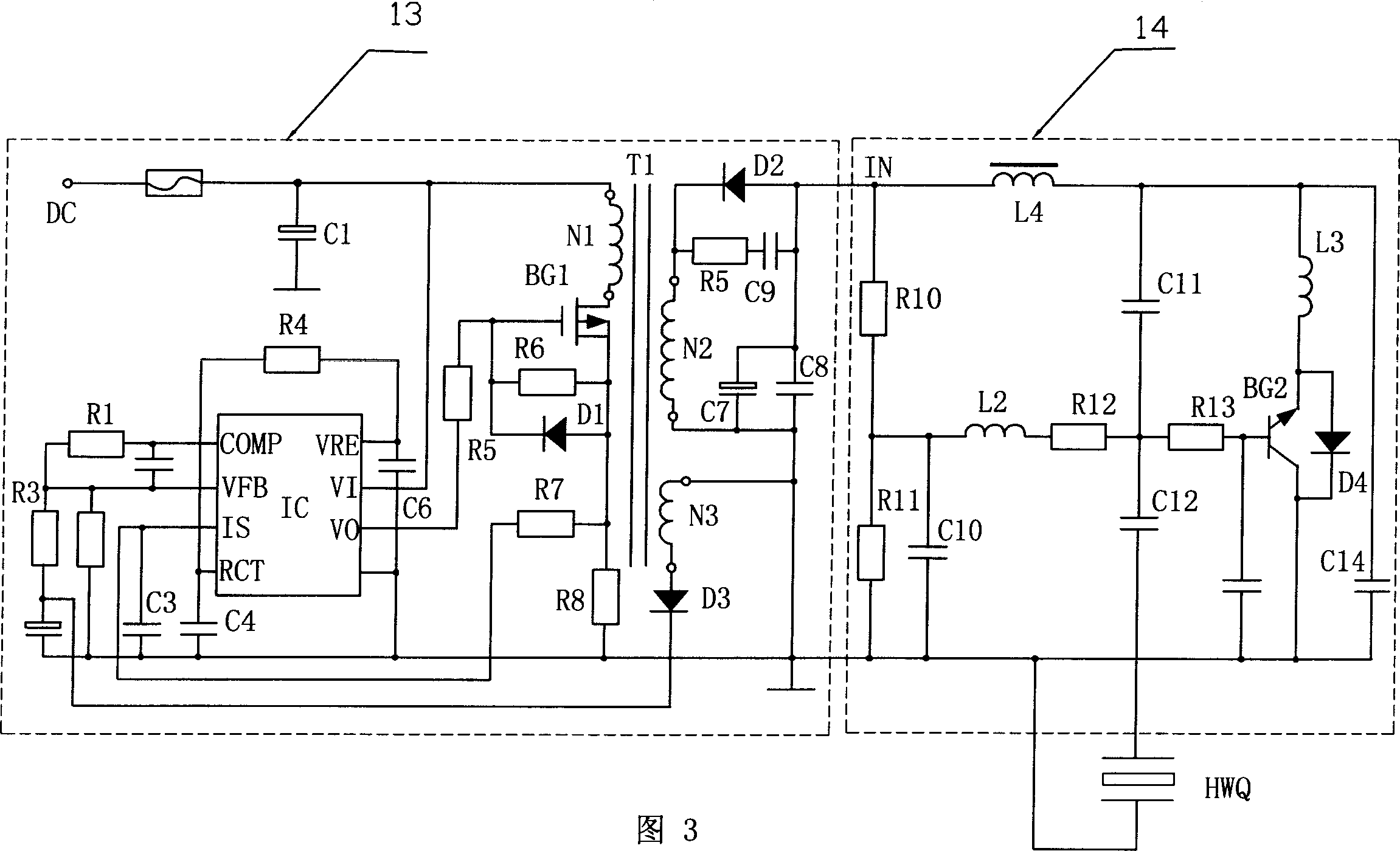

[0039] When the present invention is actually implemented, the switching regulated power supply can be replaced with other circuits that can transform the 12V direct current of the automobile engine into a matching ultrasonic power source input voltage. The ultrasonic power source can also use other circuits that can generate ultrasonic frequencies and whose power is adapted to the ultrasonic transducer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com