Patents

Literature

32results about How to "Improve emission targets" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hydroximic acid-type polymeric flocculant for removing heavy metal ions in sewage

InactiveCN101560004AImprove complexation effectGood flocculation effectWater/sewage treatment by flocculation/precipitationCarboxylic acidOxygen

The invention provides a hydroximic acid-type polymeric flocculant for removing heavy metal ions in sewage and the macromolecule thereof has three chains of different structures; the first chain is at least one out of an acrylamide or a derivative thereof, wherein the total weight percentage of the monomer is 10-90wt%; the second chain is at least two out of a carboxylic acid, sulfonic acid and hydroximic acid compound, wherein the total weight percentage of the monomer is 5-60wt%; the third chain is at least one out of a sulfur-contained, oxygen-contained or amido-contained lipid compound, wherein the total weight percentage of the monomer is 1-20wt%. The flocculant can effectively remove the heavy metal ions in sewage of electroplating, electronic and heavy metal industries, such as iron, copper, zinc, chrome, nickel, and the like, and the removal rate is more than 98%.

Owner:HUNAN NORMAL UNIVERSITY

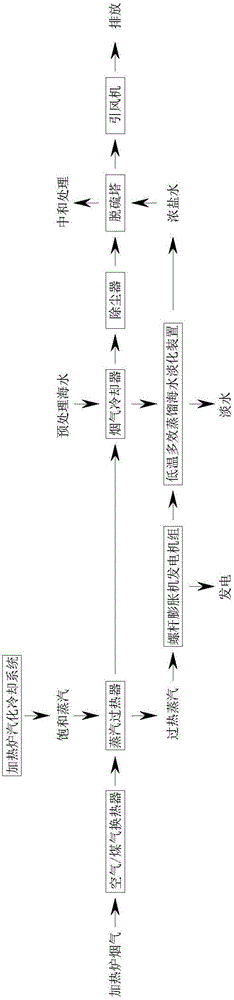

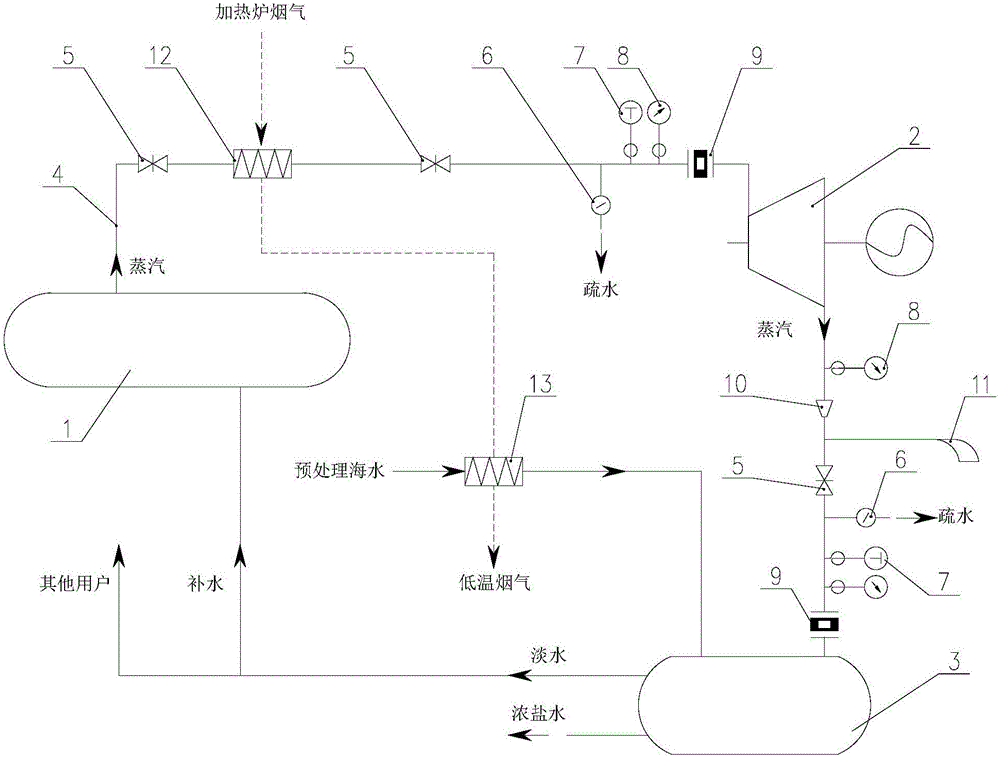

Heating furnace waste heat comprehensive utilization system and method

InactiveCN106052405ARealize cascade utilizationAddressing Adverse Effects of Power GenerationGeneral water supply conservationSeawater treatmentWater desalinationEngineering

The invention discloses a heating furnace waste heat comprehensive utilization system. The heating furnace waste heat comprehensive utilization system comprises a steam superheater, a power generator set and a sea water desalination device. The steam superheater is arranged in a heating furnace flue. Low pressure saturated steam generated by a heating furnace evaporated cooling system flows into the steam superheater and can be heated by heating furnace smoke to form superheated steam. The power generator set communicates with fluid of the steam superheater. The superheated steam generated in the steam superheater flows into the power generator set for power generation. The sea water desalination device communicated with fluid of the power generator set. The steam discharged by the power generator set flows into the sea water desalination device for sea water desalination. The invention further discloses a heating furnace waste heat comprehensive utilization method. Through the heating furnace waste heat comprehensive utilization system and method, gradient utilization of energy of the heating furnace steam is fully achieved, excessive pressure of the steam is used for power generation, and waste heat of the steam is further used for producing fresh water.

Owner:BERIS ENG & RES CORP

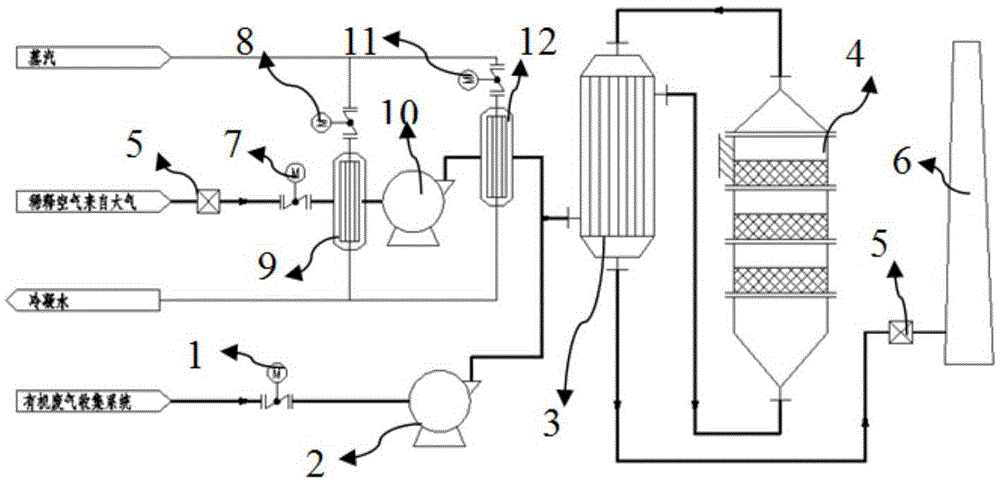

Energy saving method for catalytic oxidation treatment of large-flow VOCs gases

ActiveCN105605594AReduce energy consumptionSimple processIncinerator apparatusLower limitCombined use

The invention discloses an energy saving method for catalytic oxidation treatment of large-flow VOCs gases. The energy saving method comprises the following steps: heating air by adopting steam, mixing the large-flow VOCs gases with the heated hot air so as to obtain a mixed gas, and controlling the concentration of the VOCs gases in the mixed gas to be lower than the lowest limit of explosion; conveying the mixed gas into a catalytic reactor for catalytic oxidative reaction, carrying out waste heat recovery when exhaust gas after reaction enters an exhaust gas heat exchanger to be subjected to heat exchange with the mixed gas to enter the catalytic reactor, and discharging the up-to-standard gas after waste heat recovery through a high-altitude blow-down pipe. The energy saving method for catalytic oxidation treatment of large-flow VOCs can adapt to organic exhaust gas treatment working conditions including high target, high treatment capacity and complex composition, and is safe, low in energy consumption, simple in technological process and capable of cyclically utilizing a heating medium; besides, steam can be utilized to provide heat so as to reduce the requirement on power supply load especially when the local power supply load is relatively low; moreover, the energy saving method can also be used in combination with other exhaust gas recovery devices so as to improve the emission index.

Owner:CHINA PETROLEUM & CHEM CORP +1

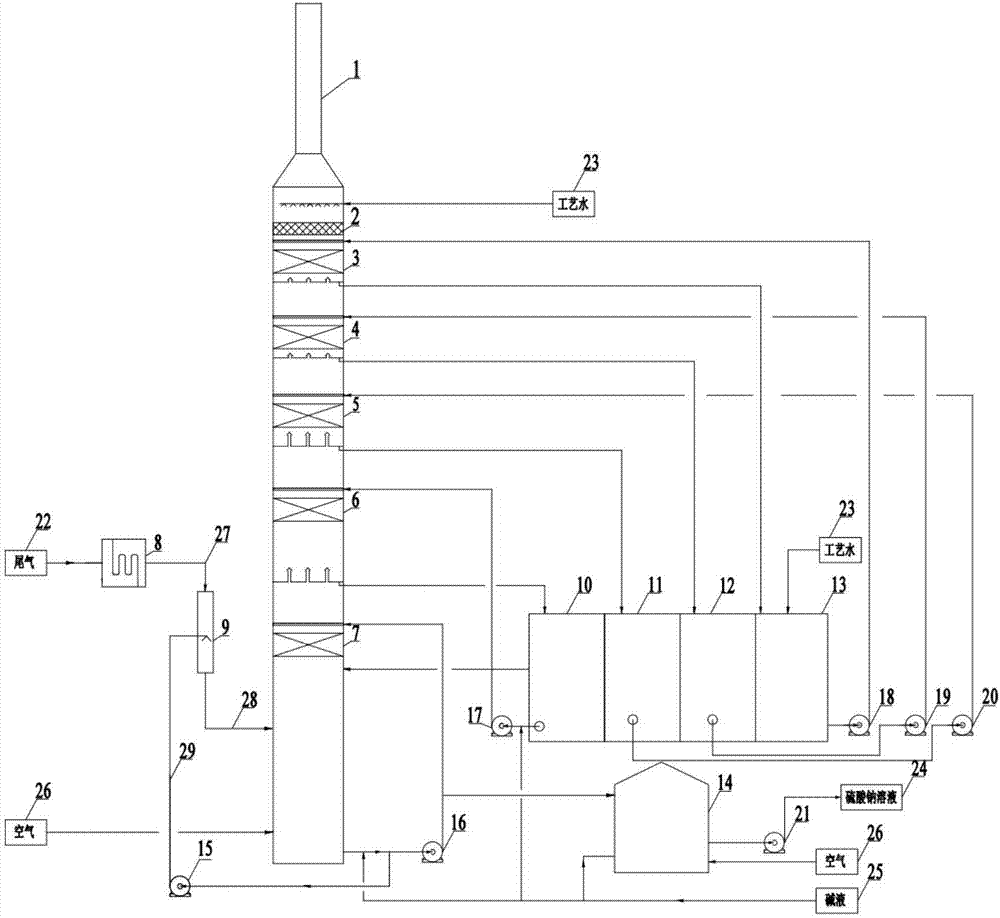

Method for desulfurizing exhaust gas

InactiveCN107115779AImprove solubilityEmission reductionDispersed particle separationDirect contact heat exchangersProcess engineeringSalt solution

The invention discloses a method for desulfurizing exhaust gas. The method comprises the following steps: firstly, carrying out heat exchange on the exhaust gas, and reducing the temperature to 190 to 250DEG C; secondly, enabling the exhaust gas subjected to heat exchange to enter a quench zone, enabling the exhaust gas to be in contact with absorption liquid, and then carrying out adiabatic saturation absorption on the exhaust gas so as to reduce the temperature of the exhaust gas to 60 to 80DEG C; thirdly, enabling the exhaust gas exhausted from the quench zone to enter a first absorption zone, enabling the exhaust gas to be in contact with sprayed absorption liquid in a filler and absorbing sulfur dioxide in the exhaust gas by the absorption liquid; fourthly, enabling the exhaust gas exhausted from the first absorption zone to enter a second absorption zone, enabling the exhaust gas to be in countercurrent contact with the sprayed absorption liquid in the filler, and removing all remaining sulfur dioxide from the exhaust gas; fifthly, carrying out multistage washing on the exhaust gas exhausted from the second absorption zone, and removing a salt solution entrained in the exhaust gas; sixthly, removing droplets in the exhaust gas exhausted from a multistage washing zone and then discharging. The method disclosed by the invention has the advantages that the operation is simple, operation expenses are reduced, the occupied area is greatly reduced, and emission indexes can be far lower than the environmental protection standard level; the method is in the leading level of technology.

Owner:SINOPEC NANJING ENG & CONSTR +1

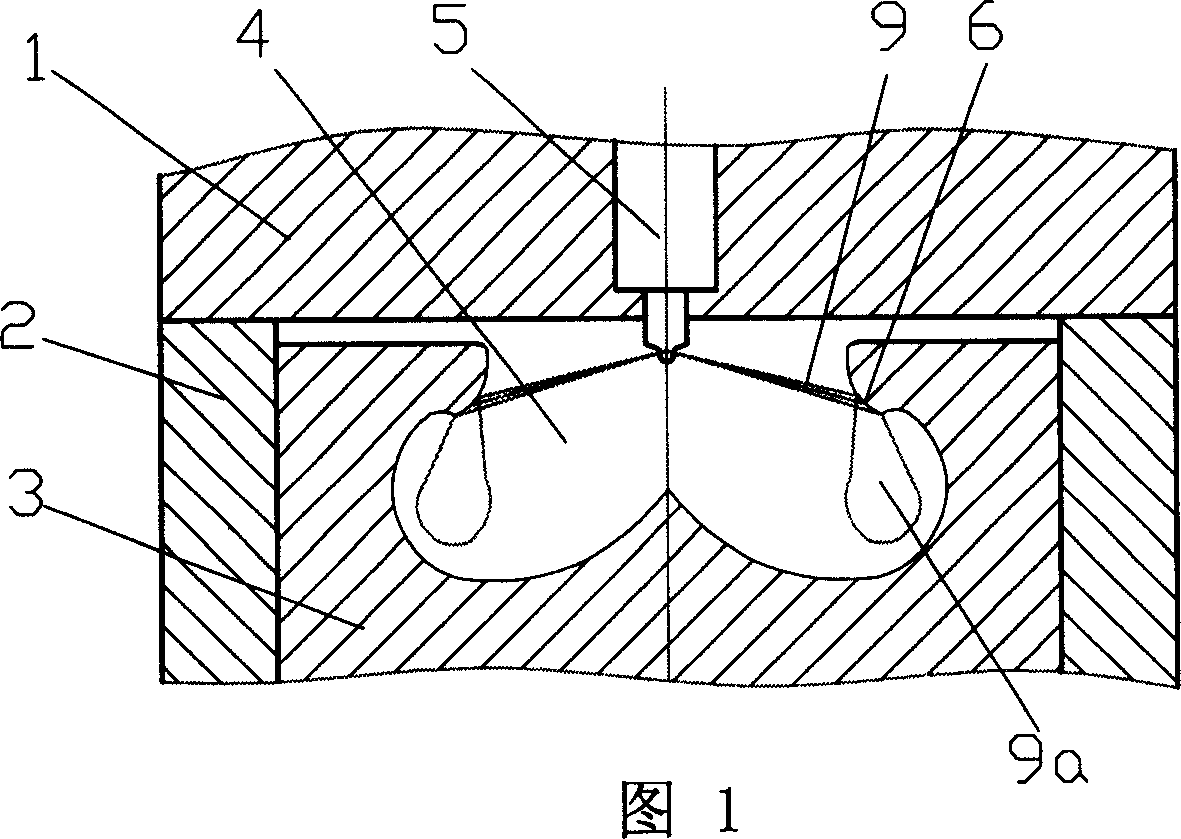

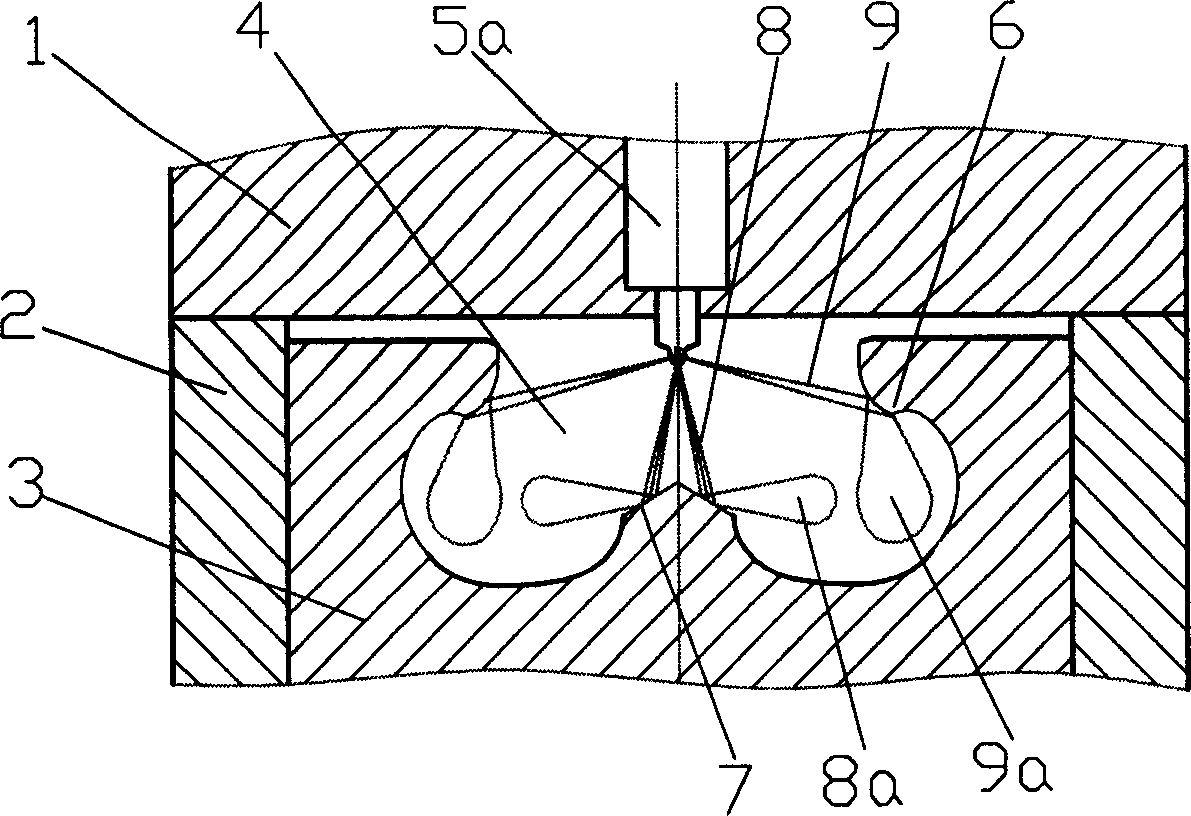

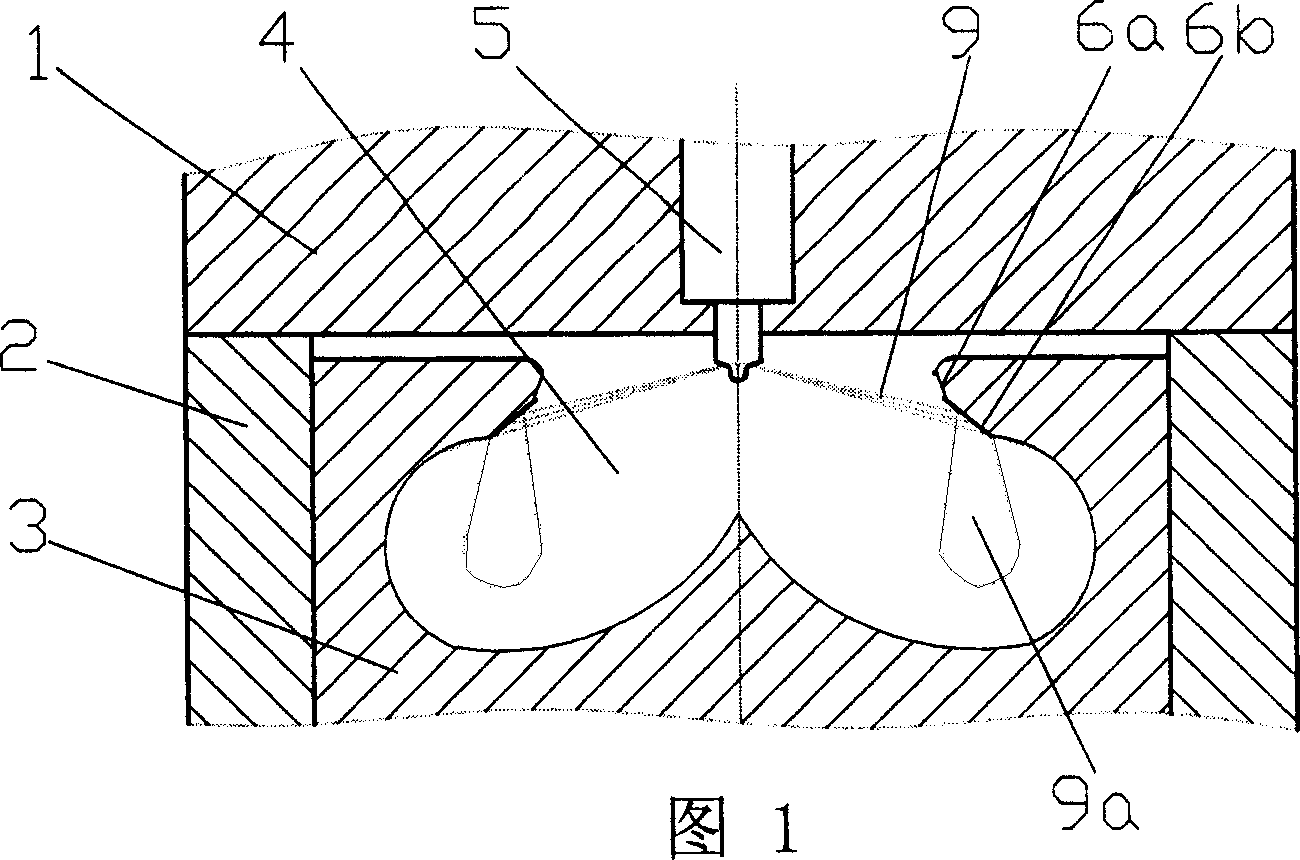

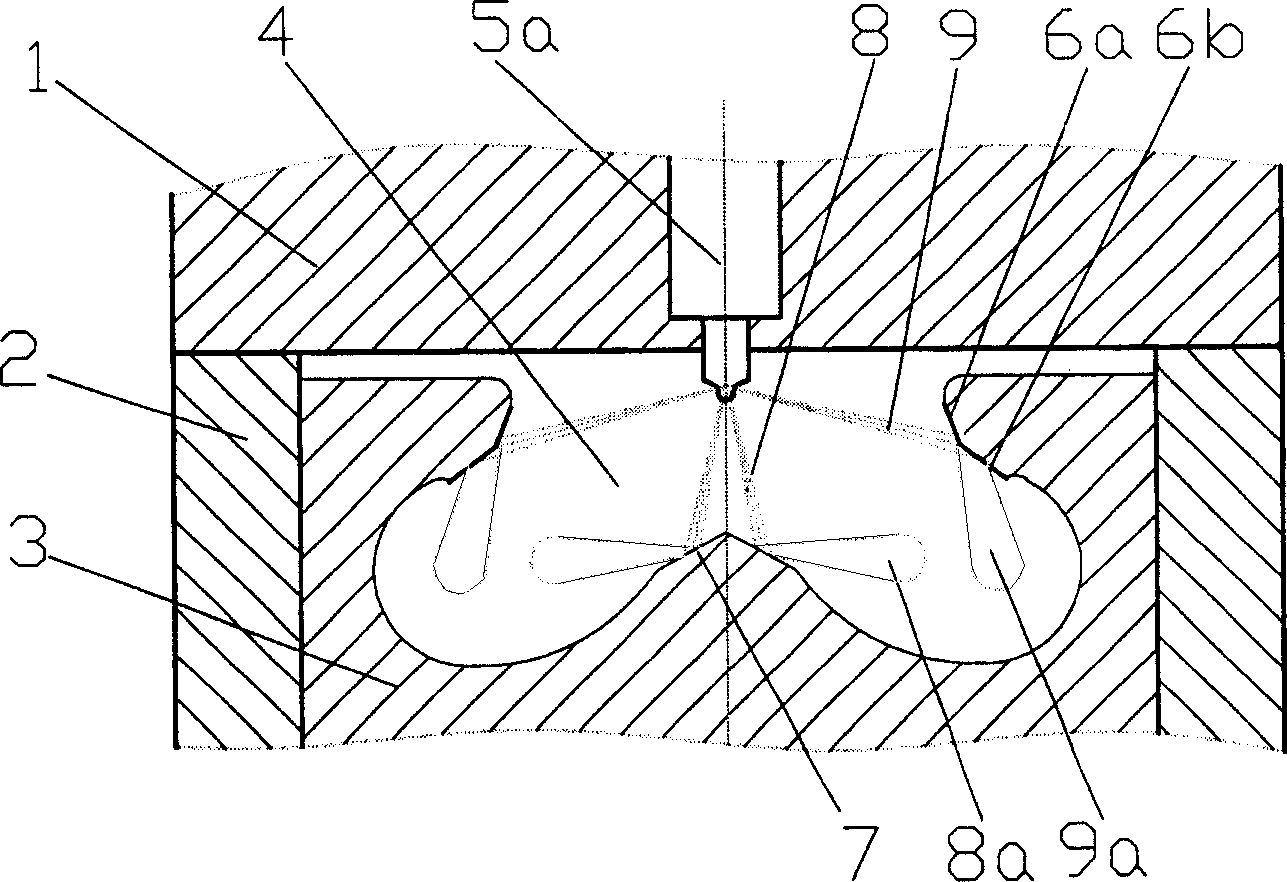

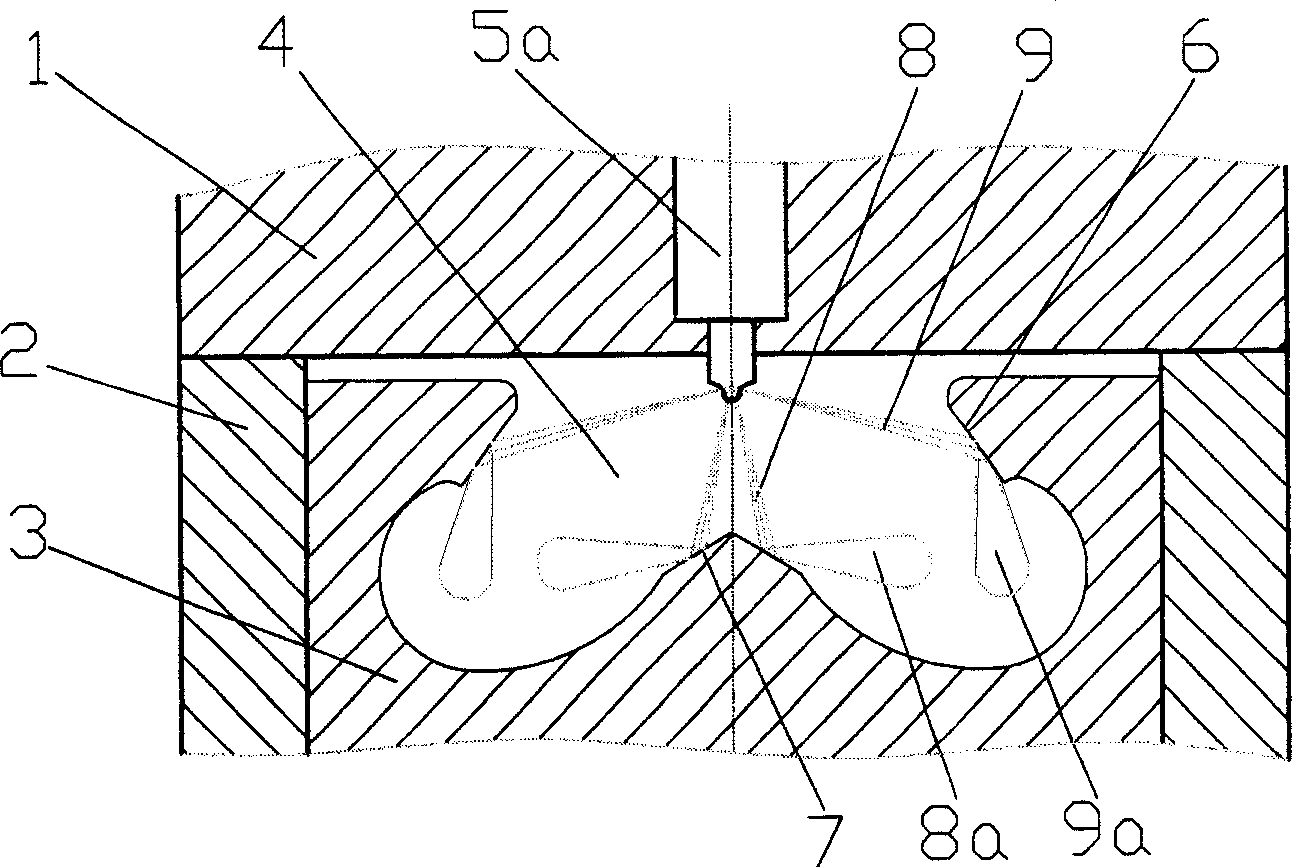

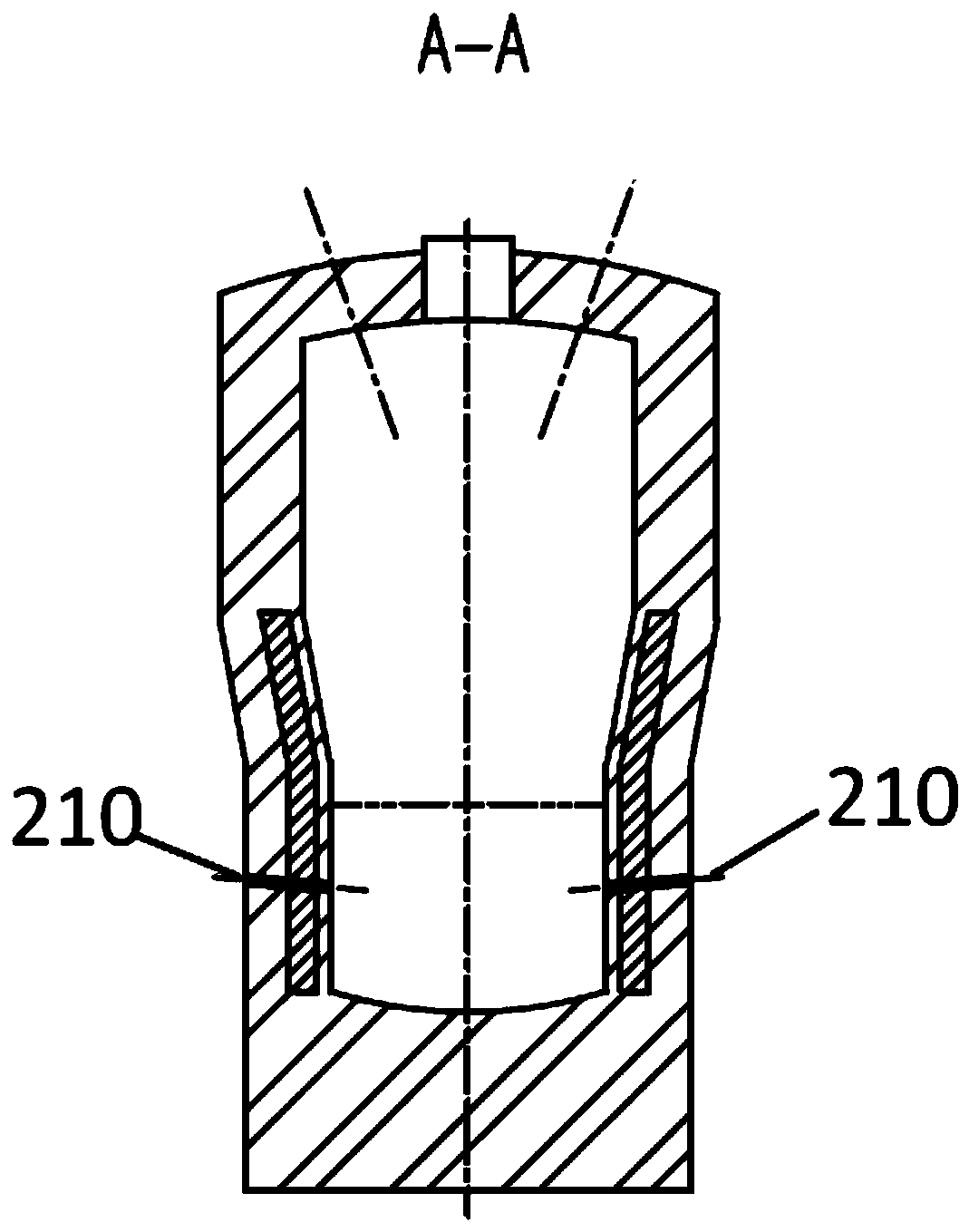

Spraying and diffusing combustion system of IC engine

InactiveCN1614209AFast spray dispersionThe spatial range of the distribution is largeInternal combustion piston enginesFuel injection apparatusCombustion chamberEngineering

A spray diffusion-type combustion system for IC engine features that a spray diffusing arc surface is arranged at the diameter-reduced position of combustion chamber for spraying the oil beam from the oil sprayer directly to the arc surface, so generating an oil beam diffused in wide range and quickly forming a relatively uniform gas mixture. Its advantages are quick and full combustion, low oil consumption, high power and less pollution.

Owner:DALIAN UNIV OF TECH

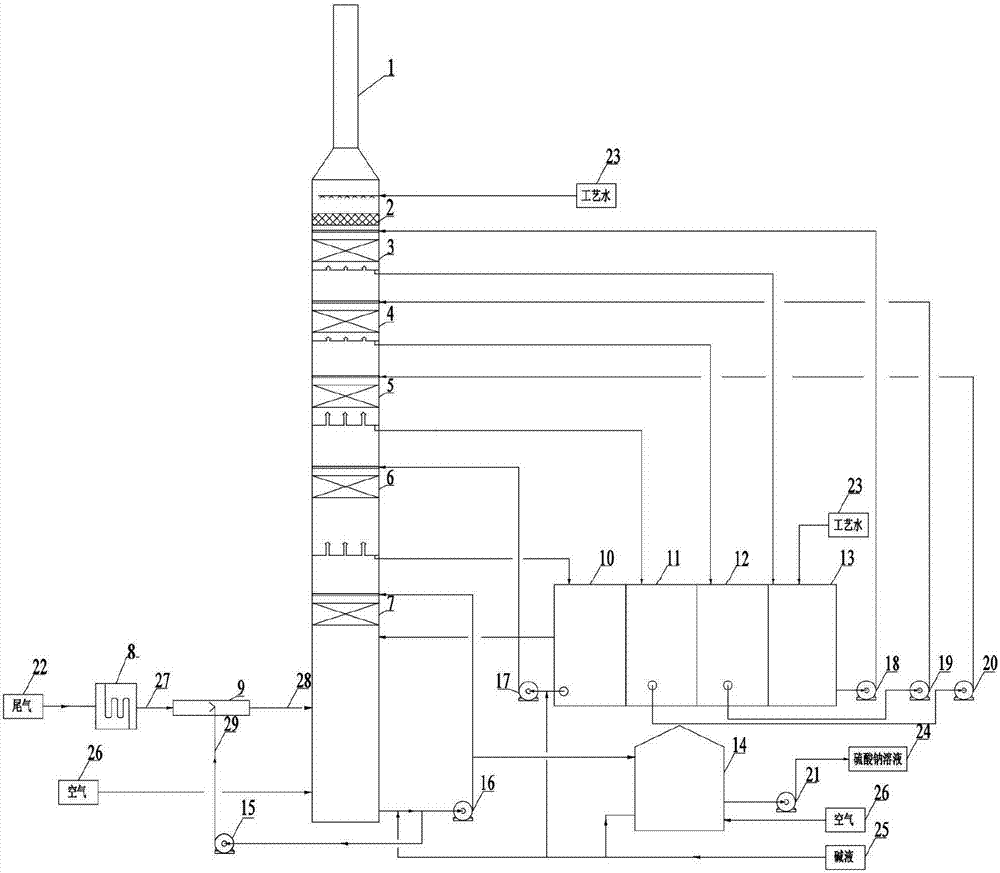

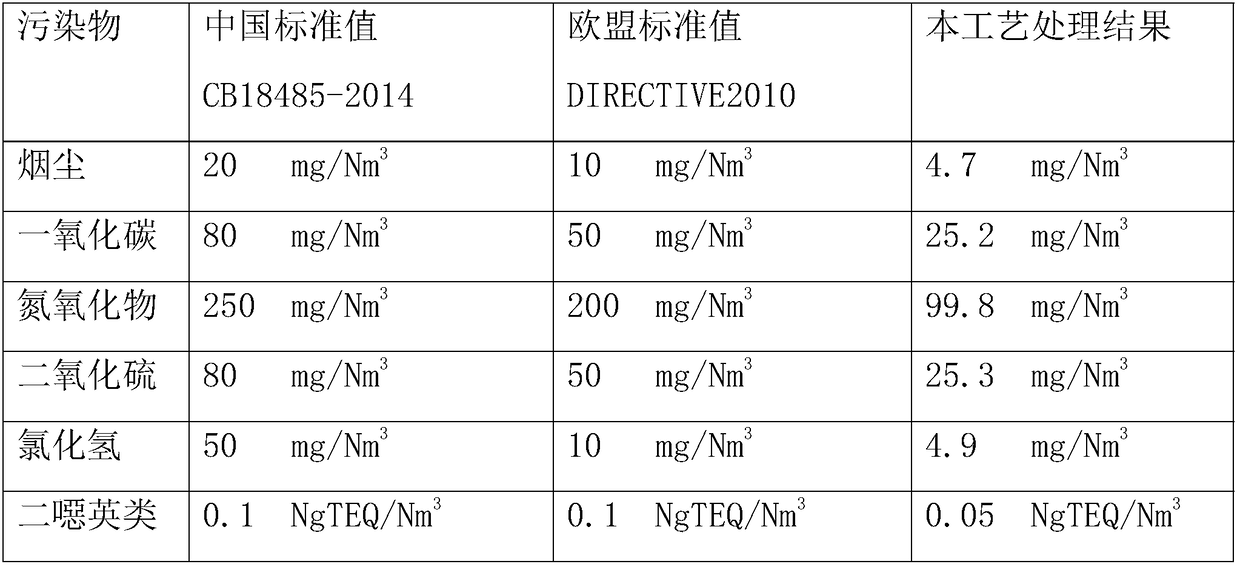

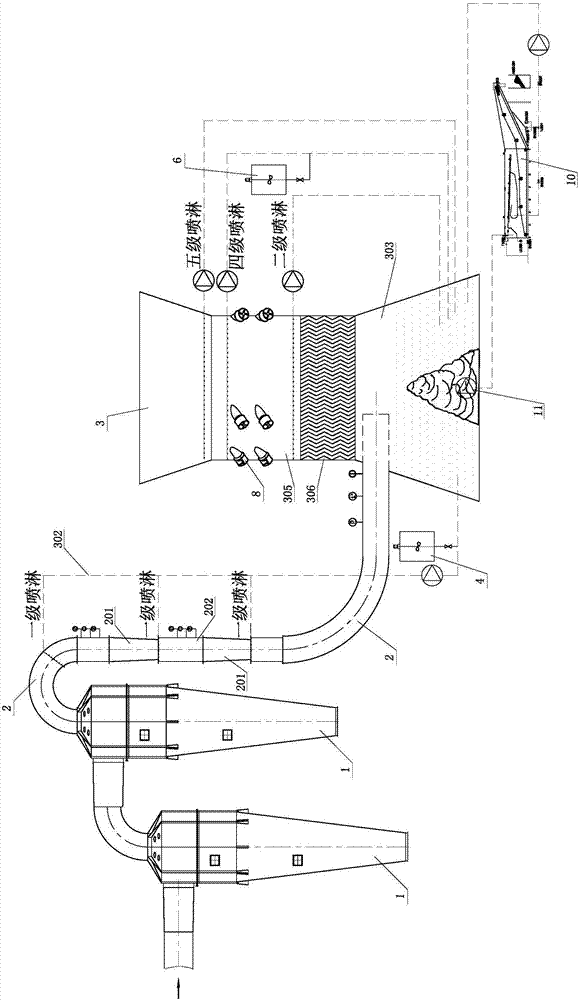

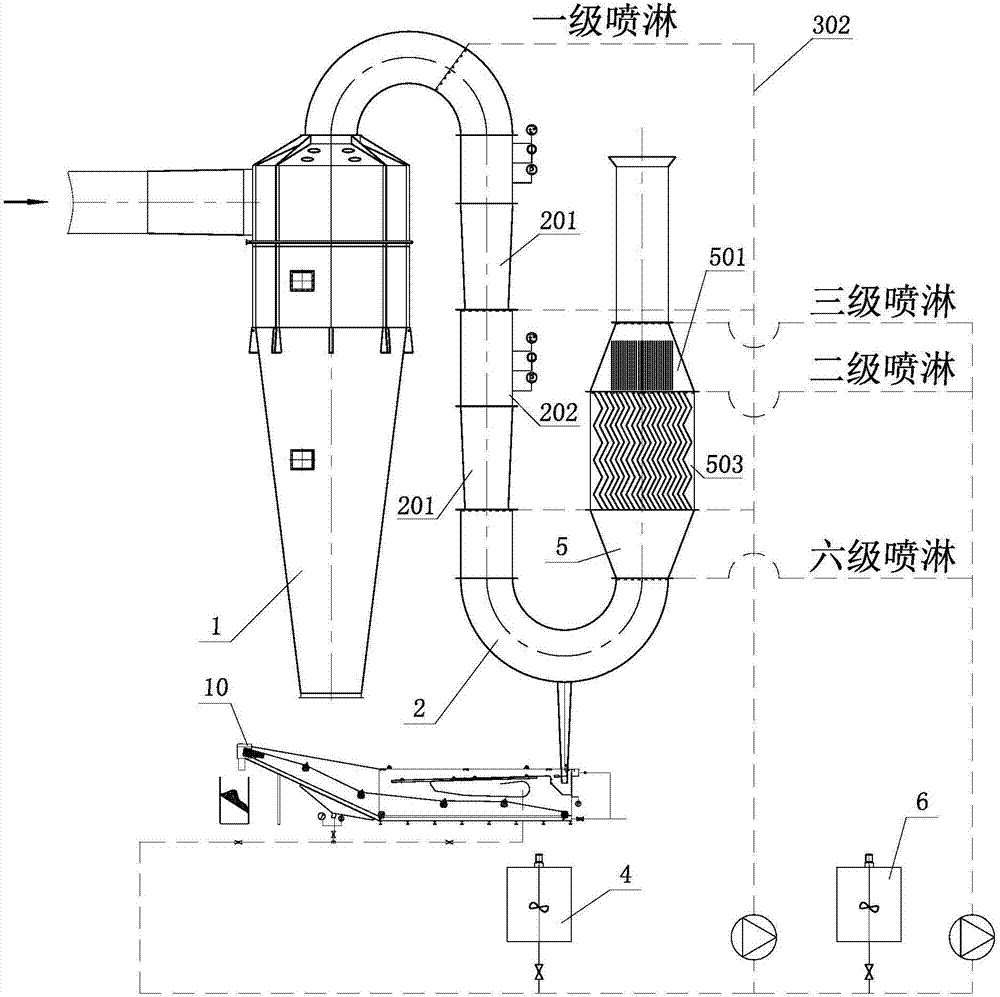

Process and system applied to super purification treatment of domestic garbage incineration flue gas

InactiveCN108434956AImprove emission targetsLow content of related substancesGas treatmentOther chemical processesFlue gasUltraviolet irradiation

The invention provides a process applied to super purification treatment of domestic garbage incineration flue gas. The process comprises the following steps: (1) carrying out SNCR denitration treatment on the flue gas in a waste heat boiler; (2) carrying out adsorption treatment on the flue gas subjected to denitration treatment by using a compound adsorbent I under ultraviolet irradiation; (3) successively carrying out semi-dry process desulphurization treatment and cloth bag dust removal treatment on the flue gas subjected to adsorption treatment; (4) adding ozone into the flue gas subjected to dust removal to obtain mixed gas, then eluting the mixed gas by using alkaline liquid; and (5) carrying out secondary adsorption on the flue gas obtained by eluting by using a compound adsorbentII. Through the process, the flue gas is successively subjected to SNCR denitration treatment, primary adsorption treatment, semi-dry process desulphurization treatment, cloth bag dust removal treatment, ozone oxidization treatment, eluting treatment via alkaline liquid and secondary adsorption treatment, so that the emission index of the treated flue gas is greatly improved and far exceeds the national environmental protection requirement.

Owner:重庆康达实业有限公司

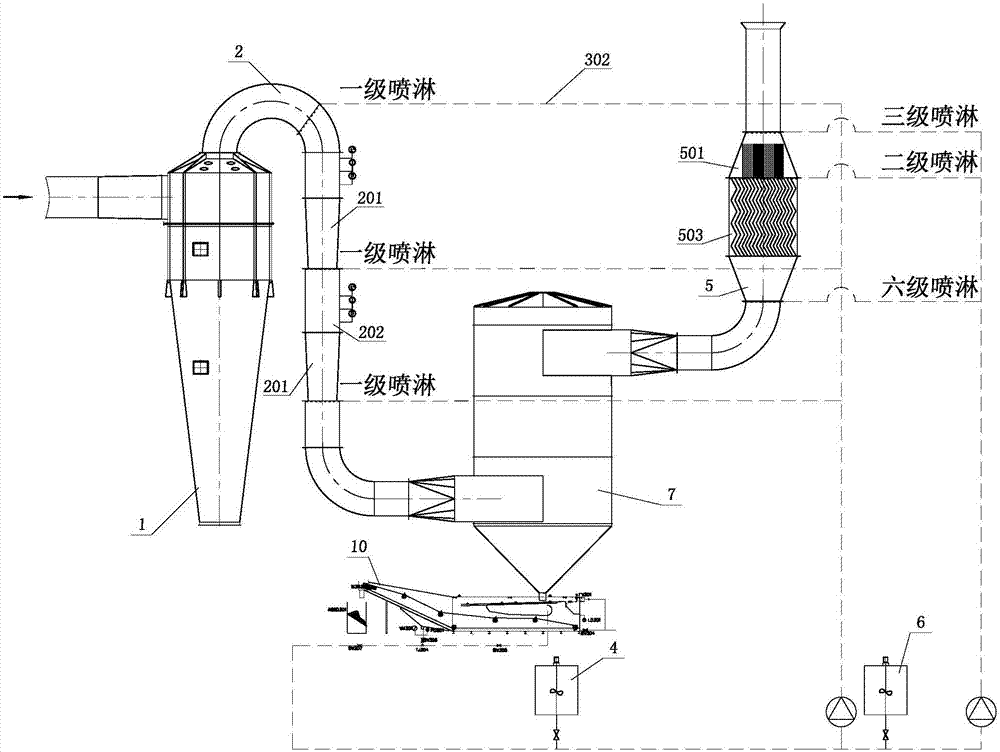

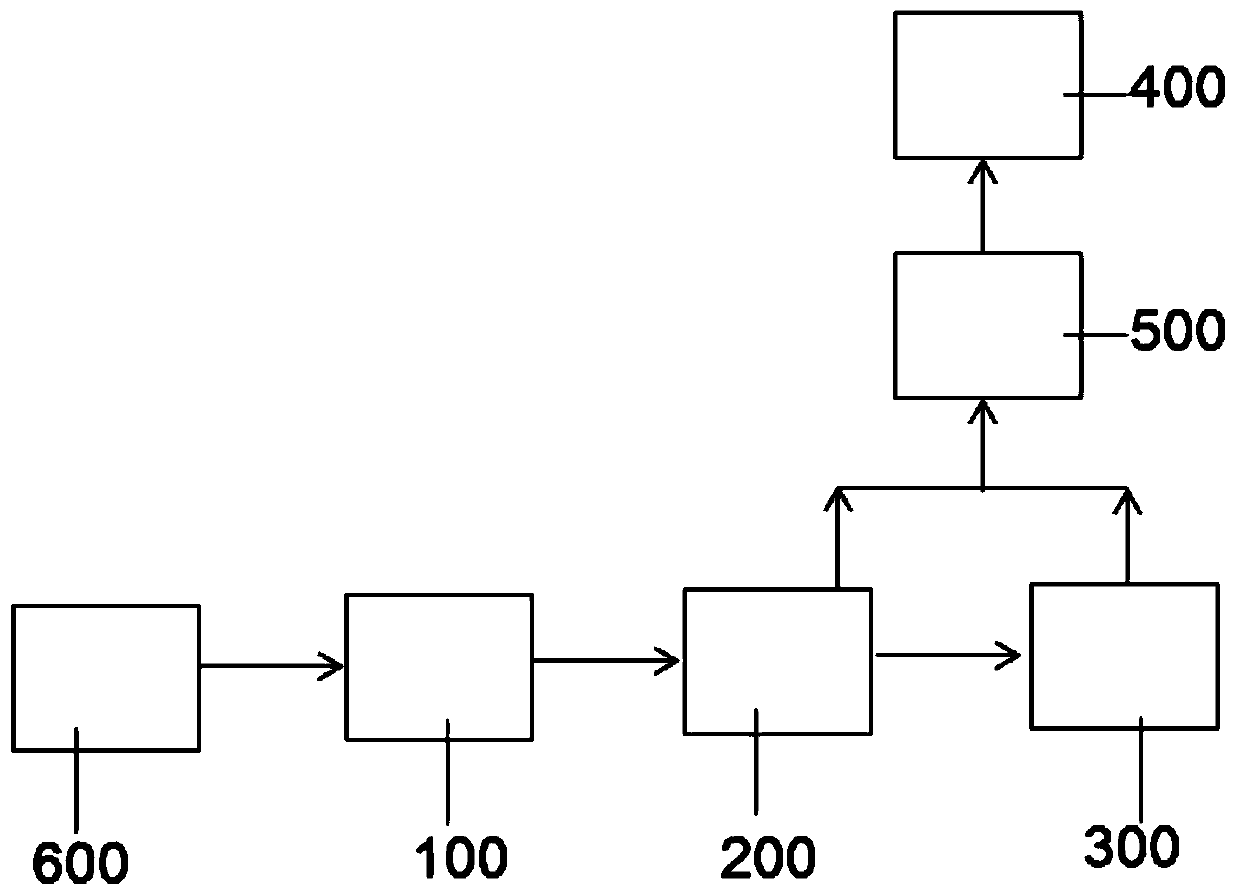

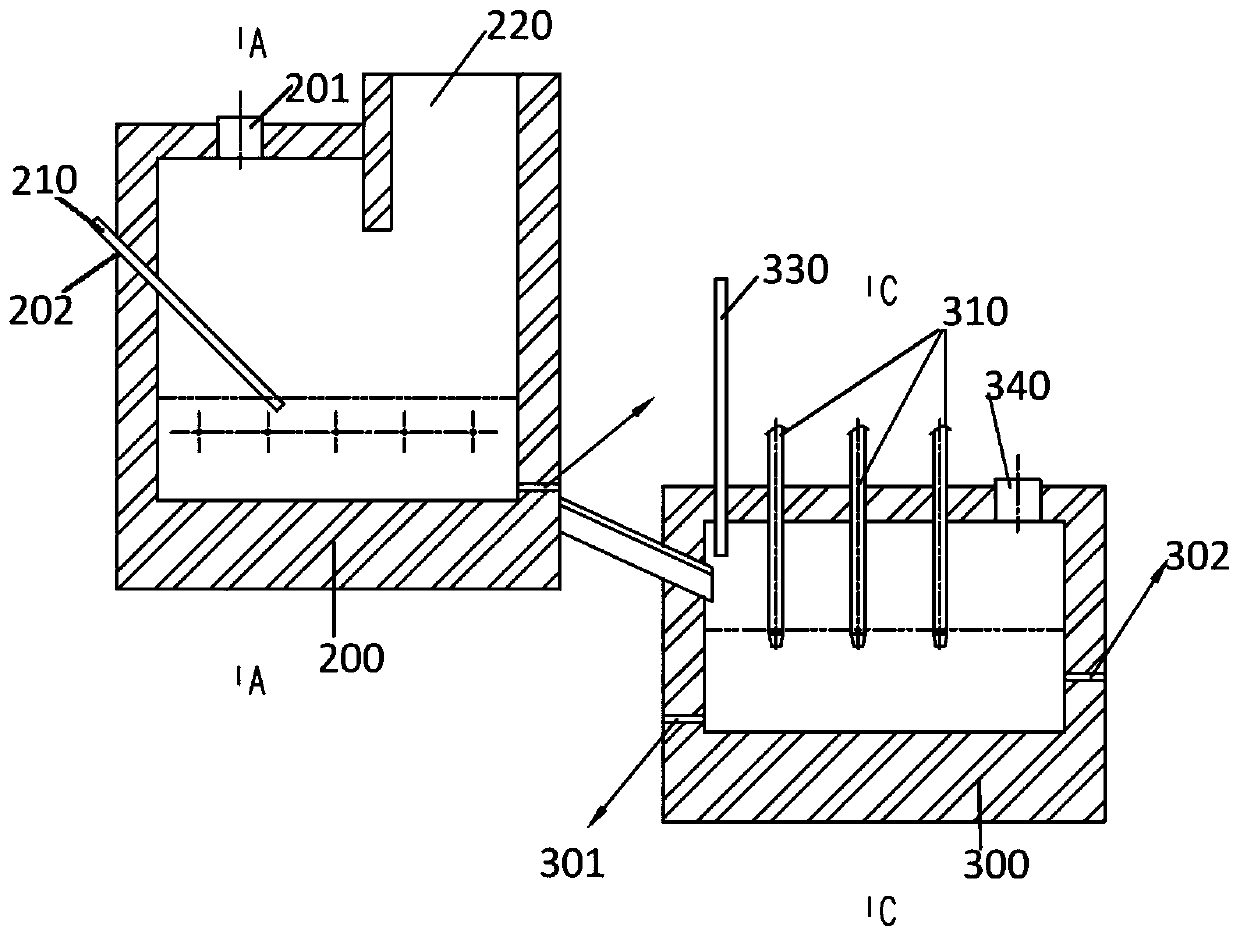

Improved process for biochemical treatment method of MDF dried tail gas and treatment system

PendingCN107413149AReduce processing burdenProbability of preventing cloggingCombination devicesLow speedSlag

The invention relates to an improved process for a biochemical treatment method of MDF dried tail gas and a treatment system. The improved process comprises the following steps: carrying out high-speed and high-pressure atomization spray cooling and aldehyde suction; and (2) carrying out low-speed smoke water film dust removal and aldehyde suction, wherein a moisture separation and slag condensing process is additionally set between the step (1) and the step (2) and comprises a gravity settling slag condensing process and a moisture rotary separation slag condensing process. By utilizing the moisture separation and slag condensing process, sludge and water in a preserved region can be timely exhausted and subjected to a water purification slag removal process, treated water can be circularly used in each procedure, a whole production system does not need to be halted during the slag discharging, manual cleaning is not required, and a separated clean water body can be discharged along with tail gas, so that the storage cost of the water body is lowered; and furthermore, a large amount of clean water body is taken away through the discharging of the tail gas, so that a 'white dragon' phenomenon is reduced, and the problem that a sewage treatment station needs to be built by increasing a huge investment so as to treat 'production wastewater' which is caused when 20-30 tons of condensate water is produced each hour is solved.

Owner:GLOBE ENVIRONMENTAL SHANGHAI

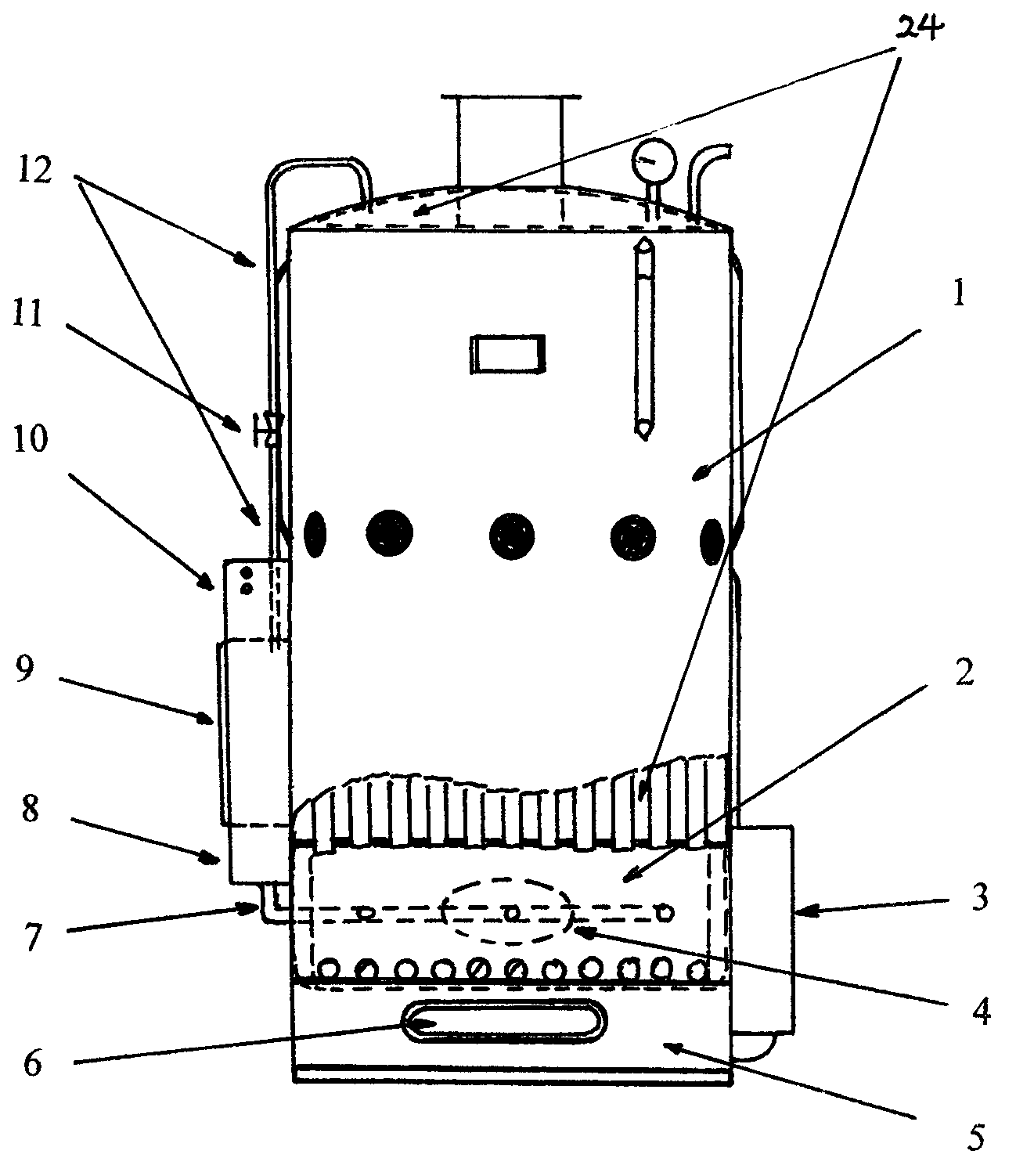

Efficient and energy-saving boiler for plasma water decomposition hydrogen production

InactiveCN103011075AImprove thermal efficiencyImprove emission targetsChemical industryHydrogen productionBoiler furnaceSlag

The invention discloses an efficient and energy-saving boiler for plasma water decomposition hydrogen production. The efficient and energy-saving boiler comprises a boiler body, a firebox, a boiler furnace, a blower, a slag chamber, a slag door, a feeding door, an injection pipe, a fire arrestor, a low-temperature plasma generator, a high-frequency high-voltage power supply, a steam switch and a steam pipeline, and is characterized in that a set of electrochemical water decomposition hydrogen production energy-saving equipment consisting of the fire arrestor, the low-temperature plasma generator, the high-frequency high-voltage power supply, the steam switch, the steam pipeline and the injection pipe is designed and mounted on a traditional boiler, so that the purposes of saving fuel by 30% and improving the emission reduction targets by 40% can be achieved. The efficient and energy-saving boiler is an ideal and upgraded high-tech product for enterprises in the industry of industrial and civil boilers, and has a very broad market prospect.

Owner:路运龙

Hydroxamic acid polymer flocculant capable of removing heavy metal ions in sewage

InactiveCN101560004BImprove complexation effectGood flocculation effectWater/sewage treatment by flocculation/precipitationHydroxamic acidCarboxylic acid

Owner:HUNAN NORMAL UNIVERSITY

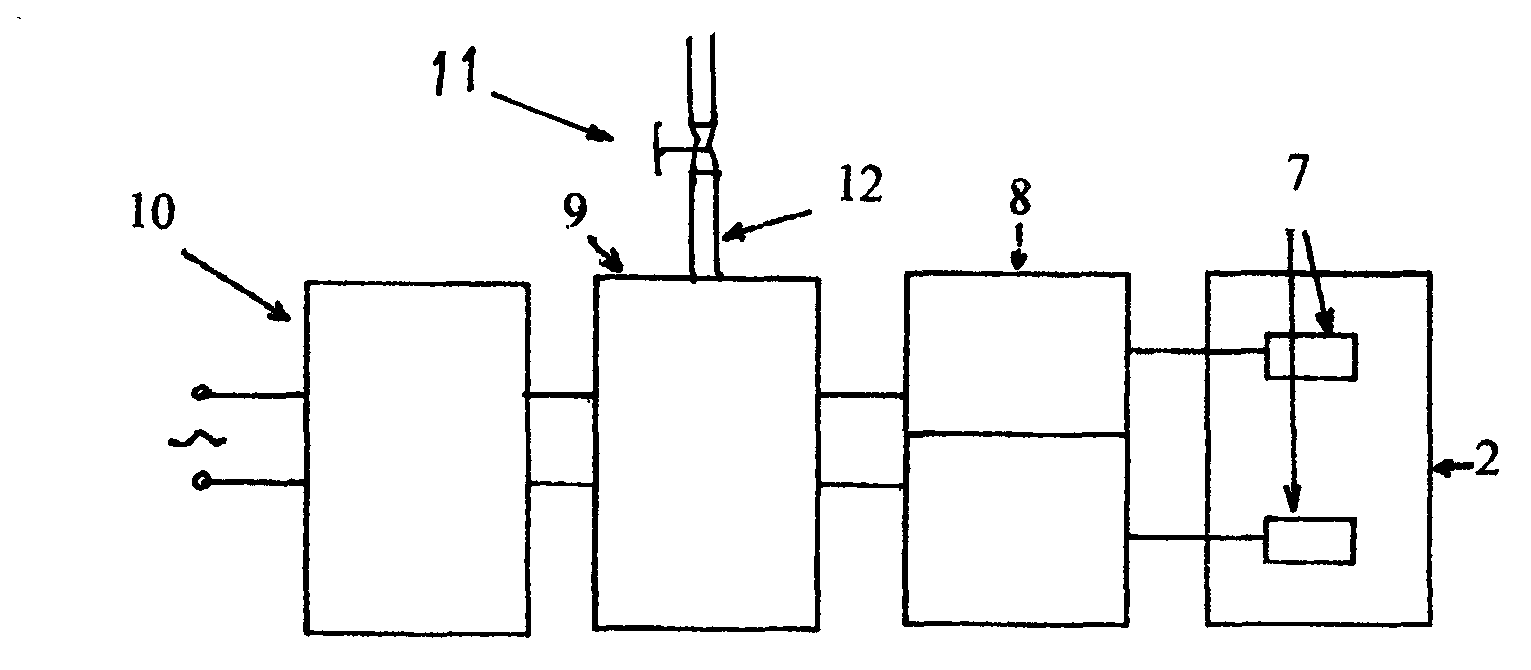

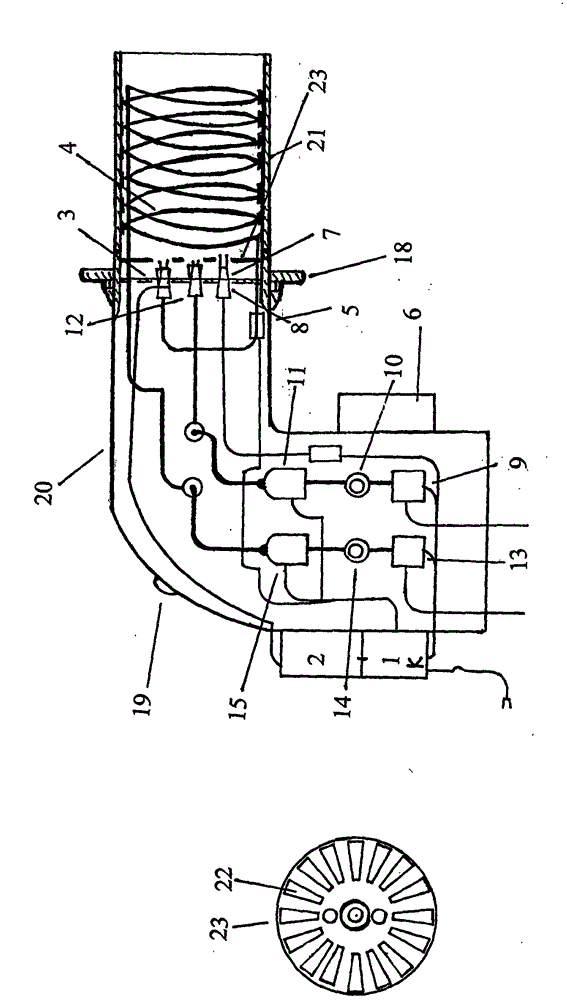

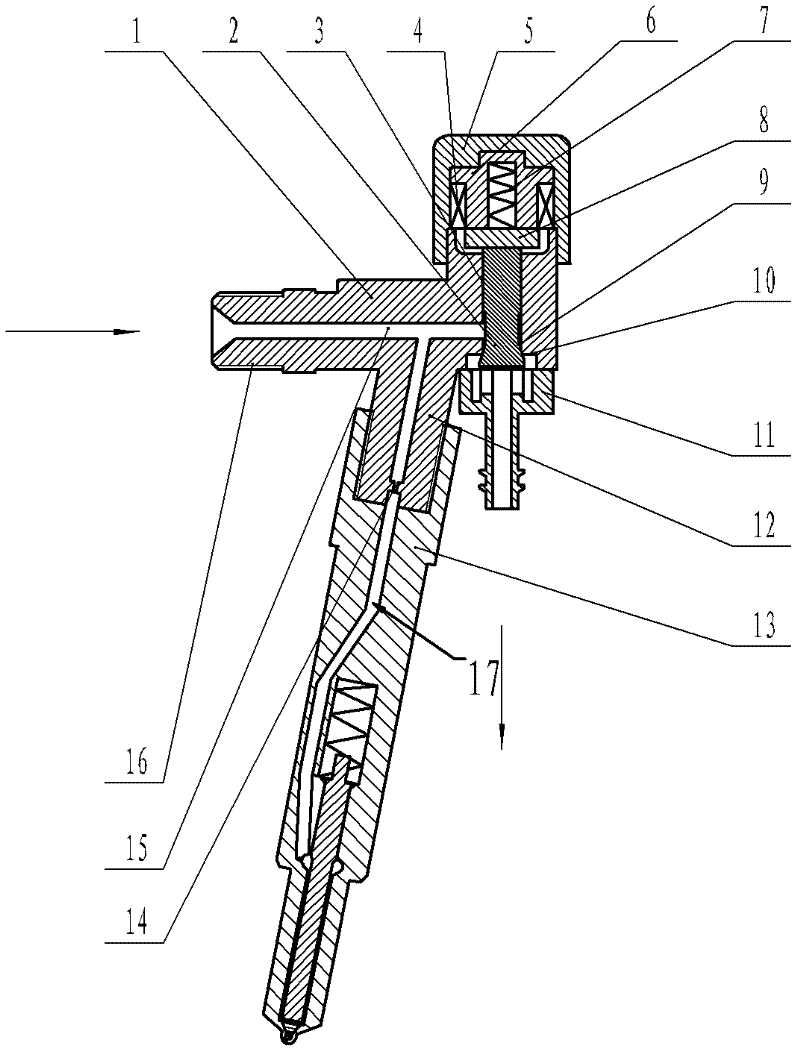

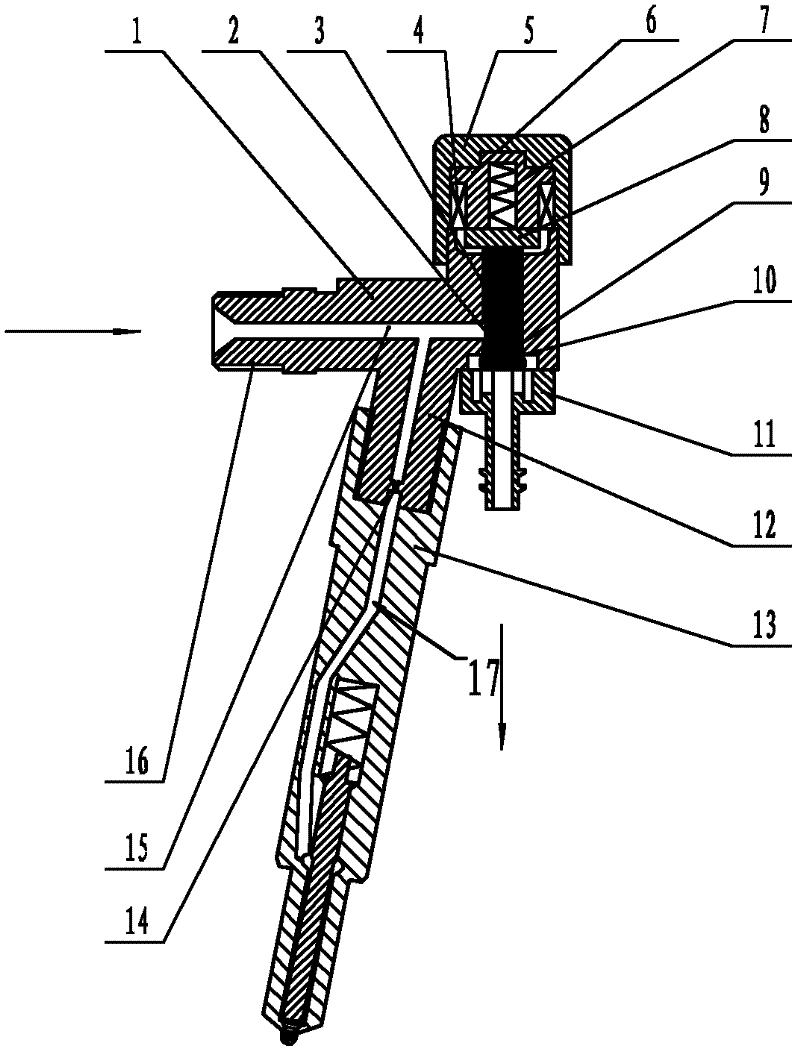

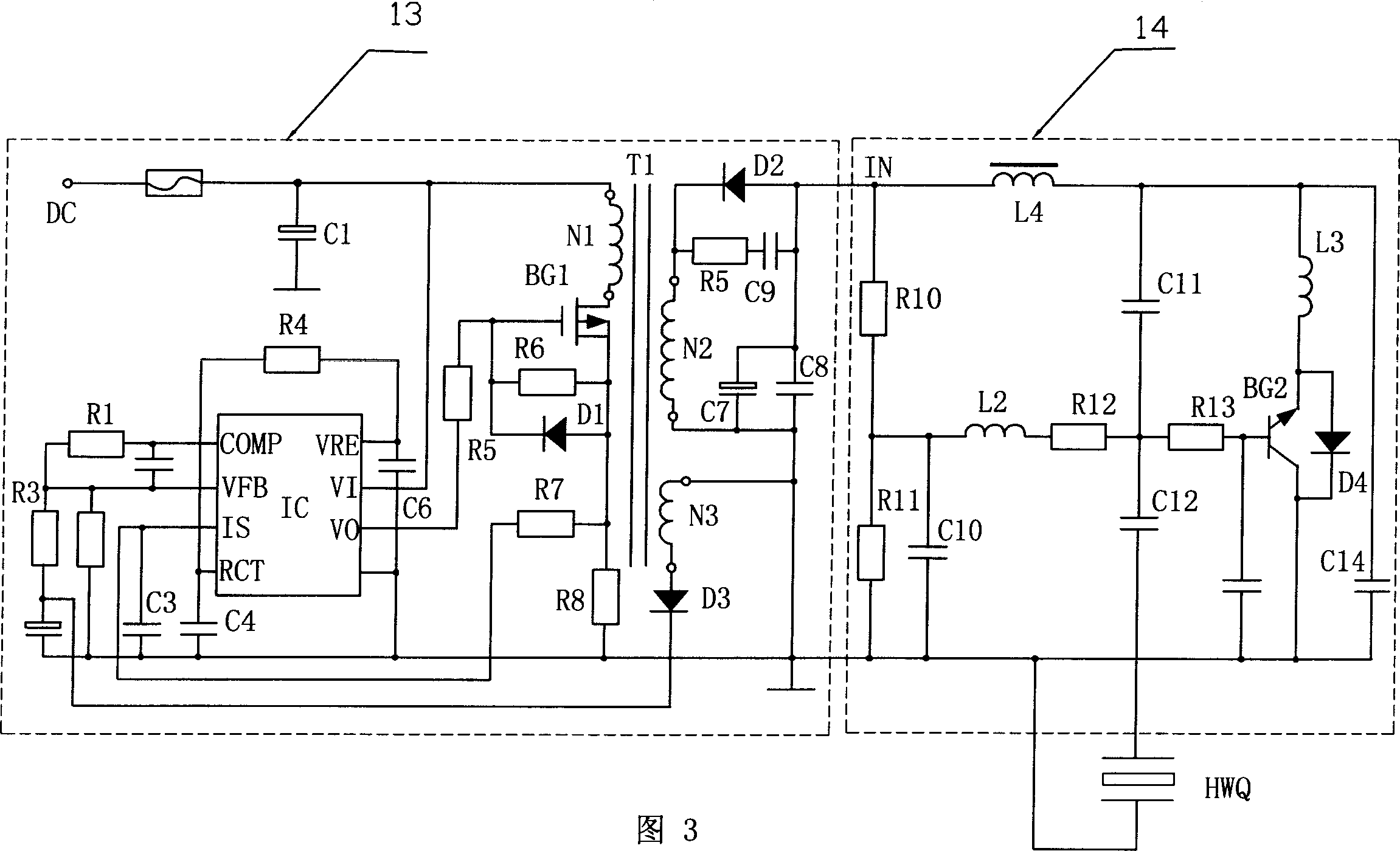

Efficient energy-saving boiler burner for plasma hydrolysis hydrogen generation

InactiveCN104654343AImprove emission targetsHigh thermal efficiencyLiquid fuel feeder/distributionChemical industrySprayerWater vapor

The invention discloses an efficient energy-saving boiler burner for plasma hydrolysis hydrogen generation. The efficient energy-saving boiler burner is composed of an intelligent controller, a high-frequency high-voltage power supply, a plasma electric arc catalysis ejector, a moisture evaporator, a water pump, a water amount regulating valve, a moisture evaporator, a temperature sensor, an oil pump, an oil quantity regulating valve, an electronic igniter, an oil sprayer, a fan, a magnetic valve, a flame spraying burner, a burner housing and an installing flange. Water is heated to produce water vapor, then the water vapor is rapidly decomposed in the plasma electric arc catalysis ejector to produce hydrogen and oxygen molecules and hydrogen and oxygen ions, the hydrogen and oxygen molecules and the hydrogen and oxygen ions and fuel or fuel gas are sprayed into a boiler hearth through the flame spraying burner to be burned, accordingly the purposes of increasing fuel or replacing a part of fuel to increase oxygen, remarkably saving the fuel and improving energy-saving emission-reducing indexes are achieved, and the efficient energy-saving boiler burner is an ideal upgraded new high-tech product in the industry.

Owner:路鹏

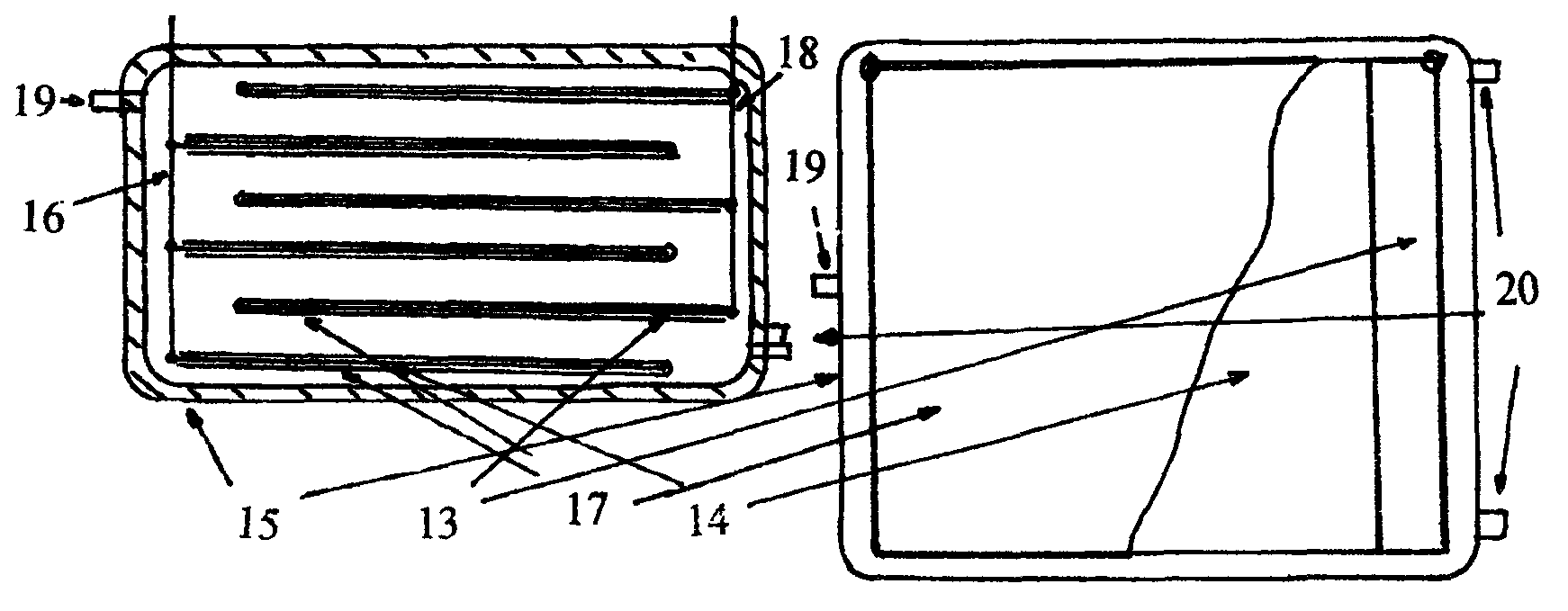

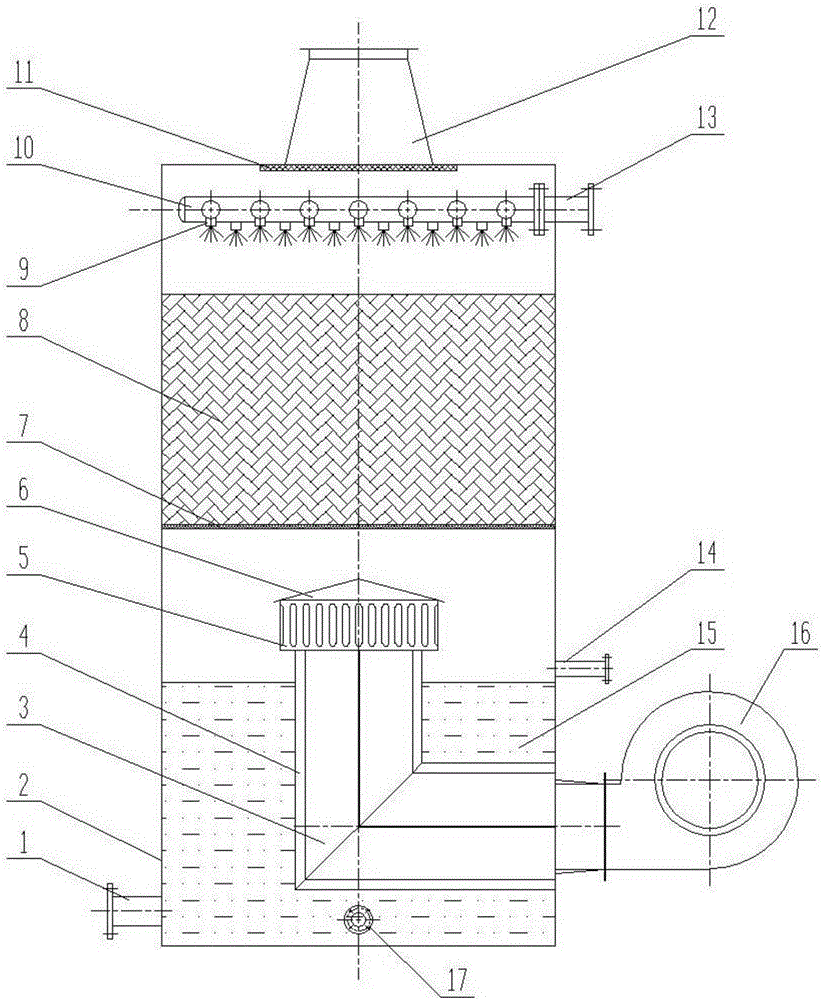

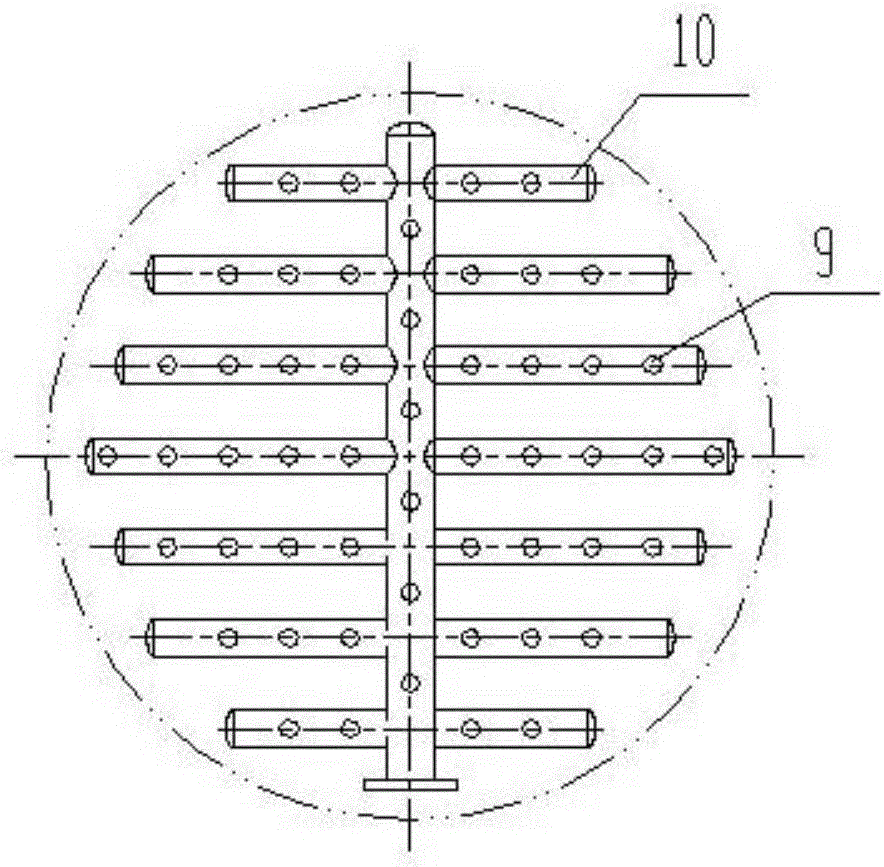

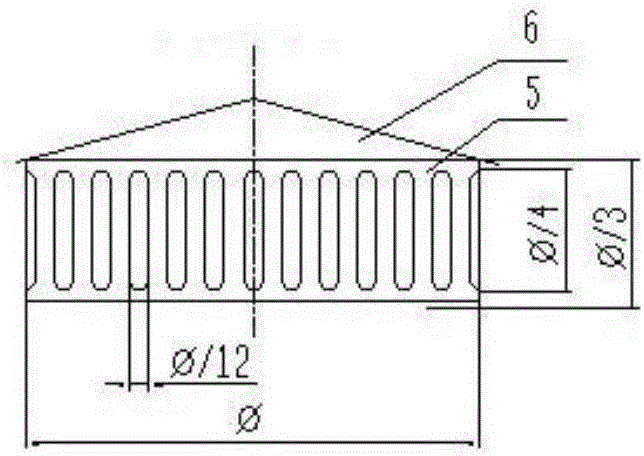

Direct-heating hot water boiler

InactiveCN106369816ALower emissions targetsImprove emission targetsWater heatersWater storageCombustor

The invention discloses a direct-heating hot water boiler which is composed of a boiler body, a fume pipe, a combustor, filler, a chimney and the like. The boiler body is of a vertical cylindrical structure and is divided into a filler chamber and a water storage chamber through a supporting partition plate. The fume pipe is located on the middle lower portion of the water storage chamber. Heat dissipation fin plates are installed on the outer wall of the pipe, and the heat exchange area can be increased. An exhaust pipe is assembled to the upper portion of the filler chamber, so that smoke is exhausted upwards evenly. A water blocking cap is used for preventing water from entering the fume pipe. An inlet water distributor is arranged in the filler chamber, so that water is sprayed downwards evenly. Through a temperature-resistant filtering cotton plate, residual water in the smoke can be filtered out and returned back to the water storage chamber. According to the direct-heating hot water boiler, the one cavity design is adopted, the structure is compact, and materials are saved and are about one quarter those of an ordinary boiler; the size is small, the space is saved, the manufacturing cost is low, through the structure, secondary heat exchange can be conducted, and the heat efficiency reaches 97% or over; and smoke exhaust indexes are higher than national standards, the smoke exhaust temperature is lower than 50 DEG C, and the heat efficiency is greatly improved.

Owner:大庆市豪迈德科技有限公司

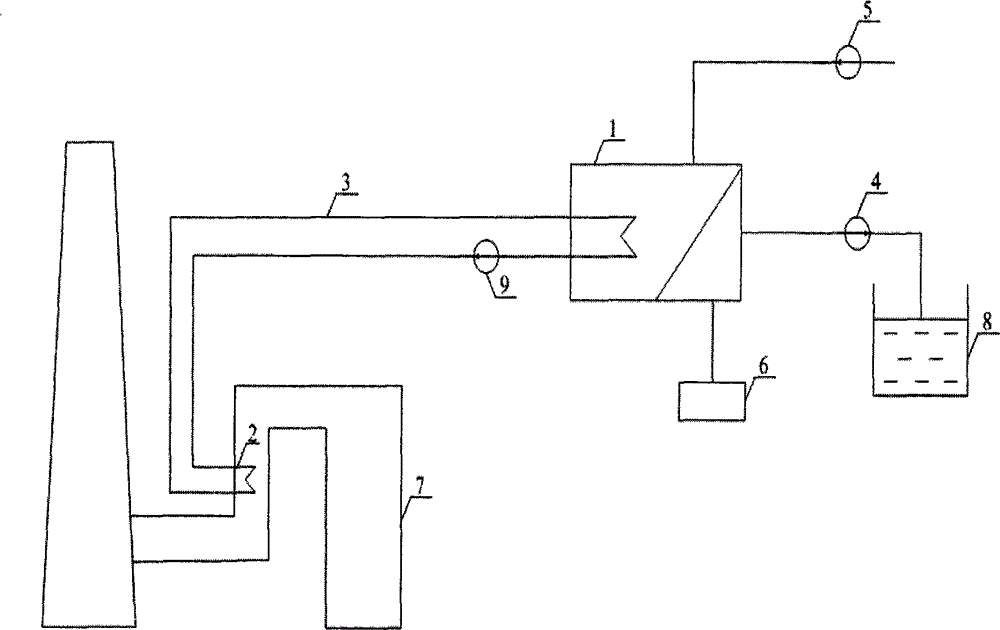

Desalination process system utilizing waste heat

InactiveCN105293611ALow running costImprove emission targetsGeneral water supply conservationWater/sewage treatmentProcess systemsOperational costs

The invention relates to a desalination process system utilizing waste heat. The system comprises a multi-effect evaporator, a heat exchanger, a pipeline, a desalination water pump, a water supply pump, a crystallization tank, a boiler, a desalination water tank and a circulating pump. Boiler flue gas waste heat or low-enthalpy-value steam pumped out from a low-pressure cylinder of a steam turbine is used as an energy source, and through the heat exchanger and the multi-effect evaporator, salt-containing water is changed into distilled water to realize a desalination purpose; the produced distilled water can be directly used as production water for a power plant or domestic water. According to the system, compared with the prior art, the electricity consumption, the occupied land size and the operation cost are greatly reduced, and secondary pollution caused by medicine utilization is avoided; the system is safe, simple, practical and reliable; by recycling flue gas exhaust heat discharged from the boiler or low-enthalpy-value steam pumped out from the steam turbine, the desalination process operation cost is greatly reduced, and a very high economic value is realized.

Owner:刘炎军 +2

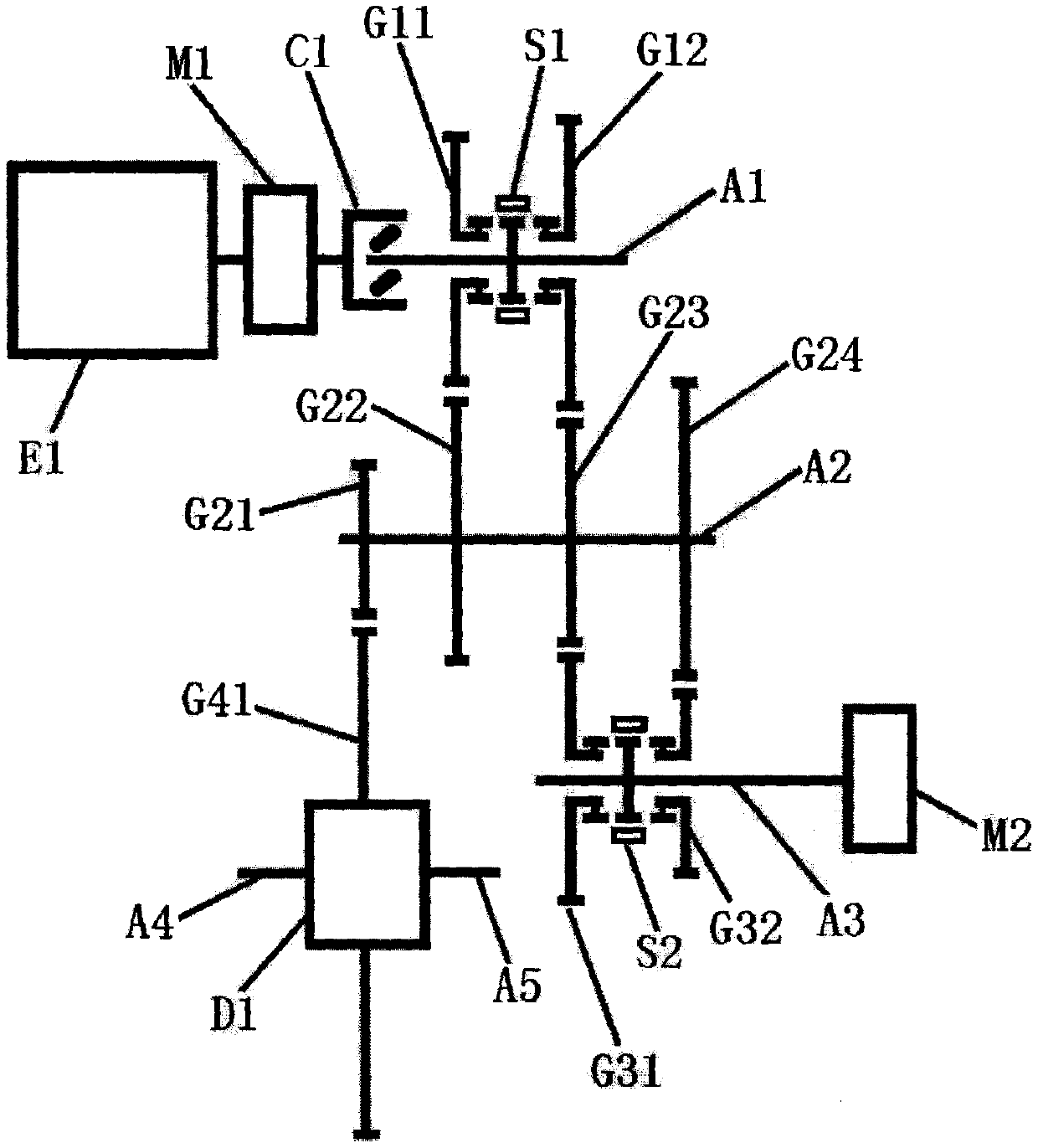

Hybrid electric vehicle system based on one-way clutch

InactiveCN111497593AGood energy saving effectImprove economyHybrid vehiclesGas pressure propulsion mountingAutomotive systemsGear drive

The invention provides a hybrid electric vehicle system based on a one-way clutch, belongs to the technical field of transportation machinery. The hybrid electric vehicle system is a shifting fork synchronizer gear shifting and speed changing mechanism based on the one-way clutch. The system is composed of an engine E1, a motor M1, a one-way clutch C1, a transmission shaft A1, a gear G11, a synchronizer S1, a gear G12, a transmission shaft A2, a gear G21, a gear G22, a gear G23, a gear G24, a motor M2, a transmission shaft A3, a gear G31, a synchronizer S2, a gear G32, a gear G41, a differential D1, a half shaft A4 and a half shaft A5. The one-way clutch C1 is used for achieving power decoupling of the gear shifting action of the transmission shaft A1. The vehicle system has nine working modes, can adapt to all working conditions required by vehicle running, can enable the engine to always work in the optimal fuel consumption rate interval, has independently designed climbing performance, low-speed acceleration performance and high-speed driving performance, supports unpowered interruption gear shifting and supports energy recovery.

Owner:江苏常州绿创新能源动力科技有限公司

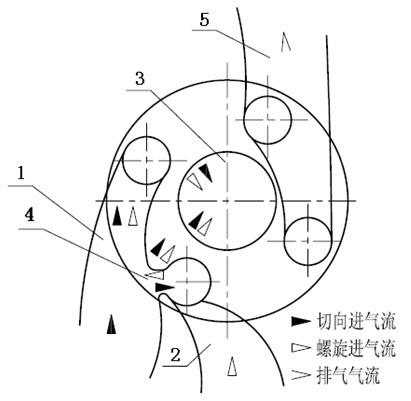

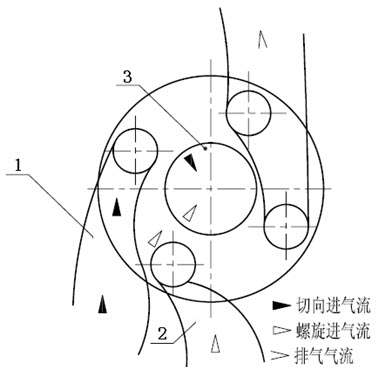

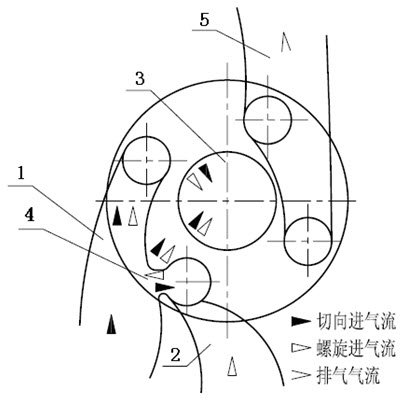

Communicated composite inlet channel system for four-valve diesel engine

InactiveCN101984244ALittle change in casting processImprove economyCombustion-air/fuel-air treatmentMachines/enginesInlet channelDieseling

The invention discloses a communicated composite inlet channel system for a four-valve diesel engine. A communicated gas inlet is arranged on the wall between a tangential inlet channel and a helical inlet channel and is used for communicating gases in the two inlet channels. Before two gases enter a cylinder, the gases are mixed, the tangential gas and the helical gas are interlaced and mixed mutually, and the gases are further mixed after the gases enter the cylinder; and because the gases are successively mixed twice, more partial turbulent flows are formed, thereby effectively improving the generating conditions of an oil and gas mixture and achieving good oil and gas mixing effect. Because the combustion is further sufficient, the economical efficiency and the dynamic property of the diesel engine are effectively improved, the generation of NOx and particulate matters is reduced, and the exhaust emission index is greatly improved. Compared with a separated inlet channel, the communicated composite inlet channel has very small casting process change and is suitable for batch production. The invention is also suitable for the inlet channel of a two-valve diesel engine.

Owner:DONGFENG CHAOYANG DIESEL ENGINE

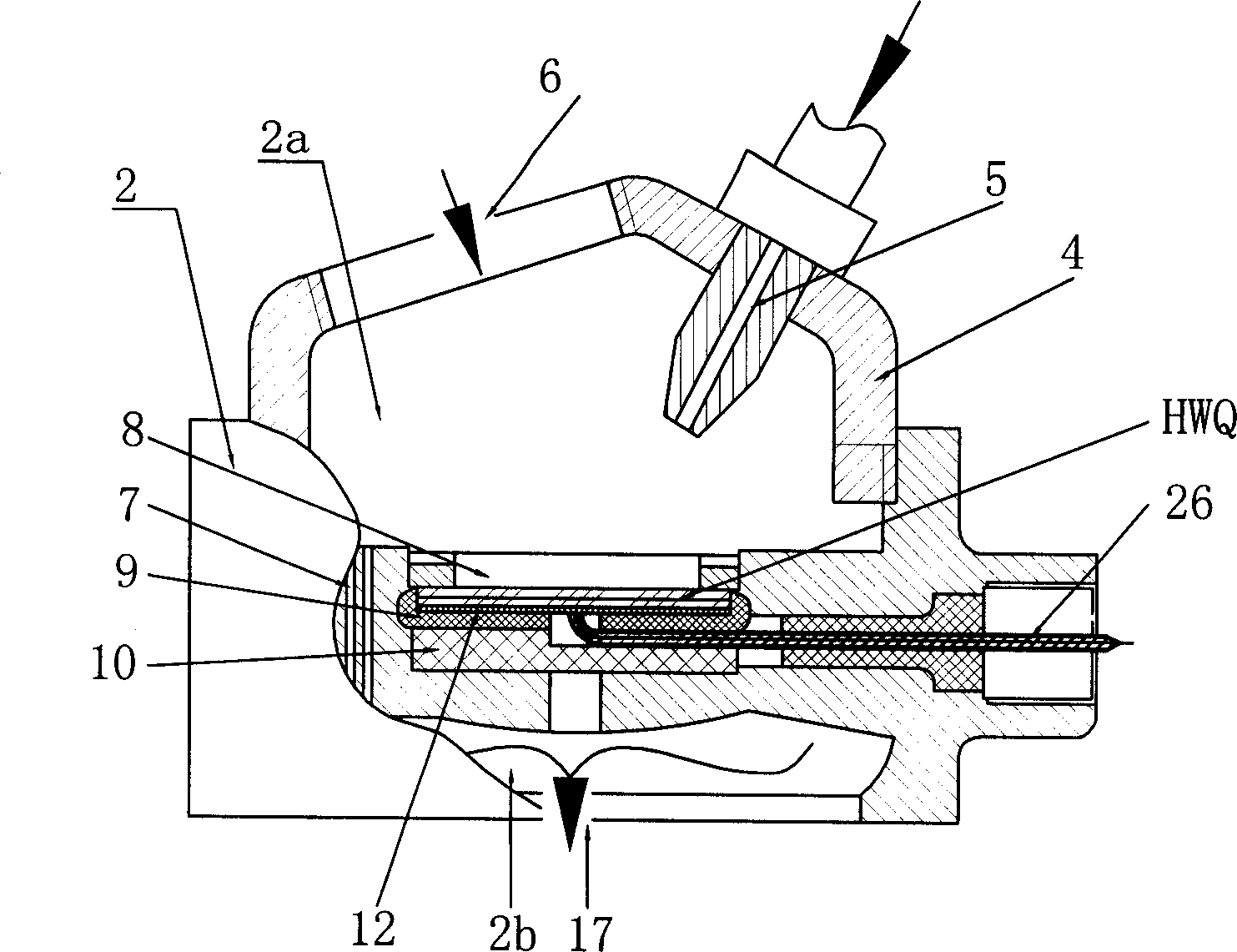

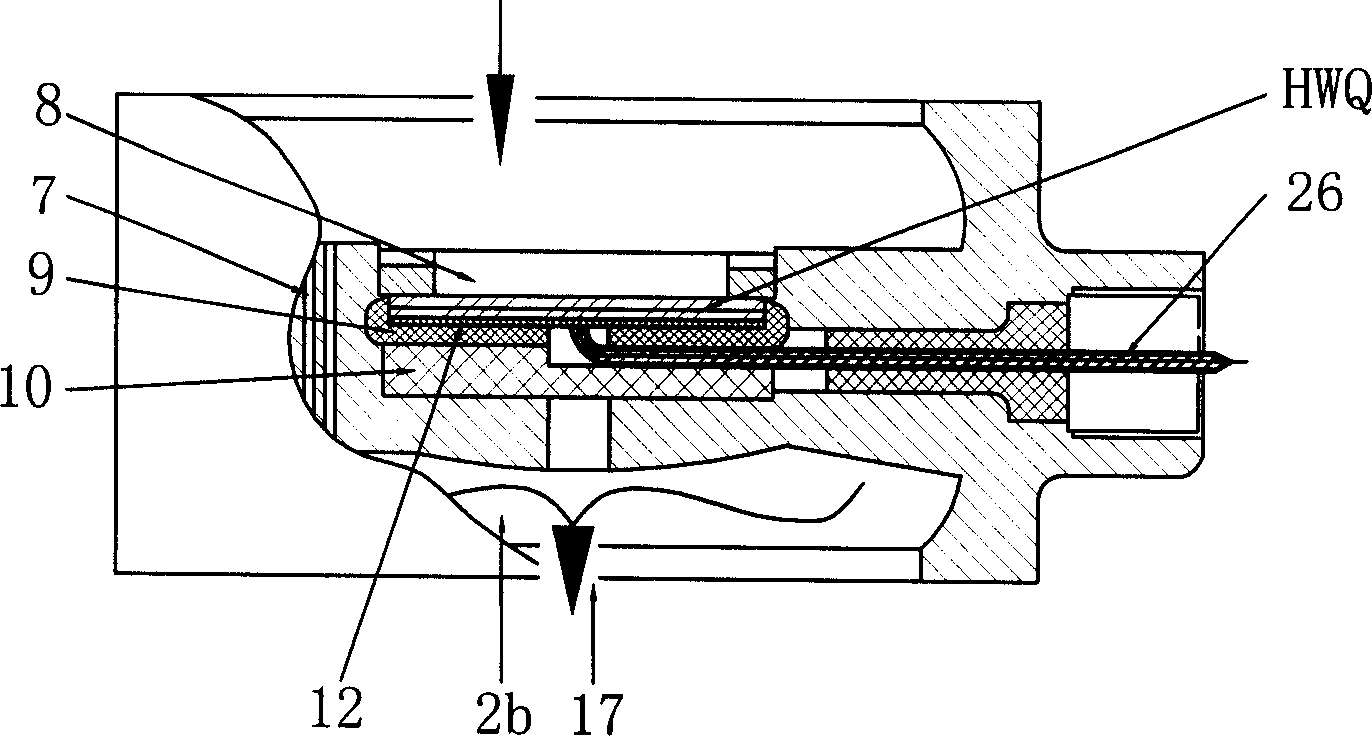

Electric control oil injector of diesel engine

InactiveCN102400823AQuick releaseImprove powerFuel injection apparatusMachines/enginesElectric controlHigh pressure

The invention discloses an electric control oil injector of a diesel engine, belonging to the technical field of control for the diesel engine and comprising a mechanical oil injector. The electric control oil injector is characterized in that an oil passage of an oil injector on the mechanical oil injector is connected with an electromagnetic valve; an electromagnetic valve body of the electromagnetic valve is provided with a high-pressure oil passage and an oil leakage channel which are controlled by a valve core; the high-pressure oil passage is externally connected with a high-pressure oil pipe joint; the oil leakage channel is externally connected with an oil leakage pipe joint; and the high-pressure passage is in a three-way type, one way leads to the high-pressure oil pipe joint, another way leads to the direction of the valve core, and the third way is connected to the oil passage of the oil injector by an orifice. The electric control oil injector solves the urgent problem that how to realize electric control oil injection on the basis of the existing mechanical oil injection mode so as to improve the dynamic property and the discharge index of the existing diesel engine, and has the advantages of high response capability, high bearing capability, high control accuracy, simple structure, good universality, reliable working, long service life, low cost and convenient installation and the like.

Owner:王晓燕

Ultrasonic electronic fuel carburetor

InactiveCN1828039AFully vaporizedSmall particlesInternal combustion piston enginesCombustion-air/fuel-air treatmentUltrasonic sensorAir filter

The invention discloses a vehicle ultrasonic electric fuel gasify device, which is formed by an ultrasonic power resource and a gasify room. Wherein, the gasify room comprises a frame whose inner chamber is separated by baffle plate into the upper gasify chamber and the lower outlet chamber; the upper part of gasify chamber has a oil inlet connecting the vehicle carburetor or has a oil injection hole connecting the fuel pump and the inlet connecting the air filter; the middle part of baffle plate is fixed with a ultrasonic energy exchanger; the baffle pate has air seams connecting the gasify chamber and the gas chamber; the lower part of outlet chamber has a mixed gas outlet connecting the mixed gas distribution pipeline; the down-lead of ultrasonic energy exchanger through the lead hole of frame is connected to the ultrasonic power resource. The invention can reduce the size of particle generating by gasifying the fuel, to make the fuel burn safer and improve the heat efficiency and discharge standard of fuel engine.

Owner:李伯清

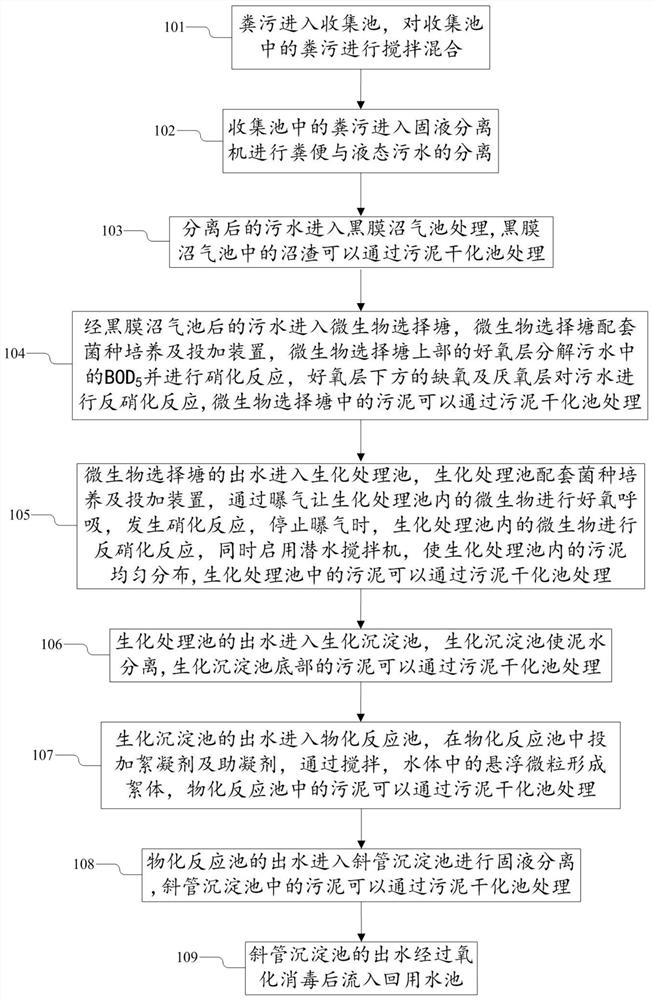

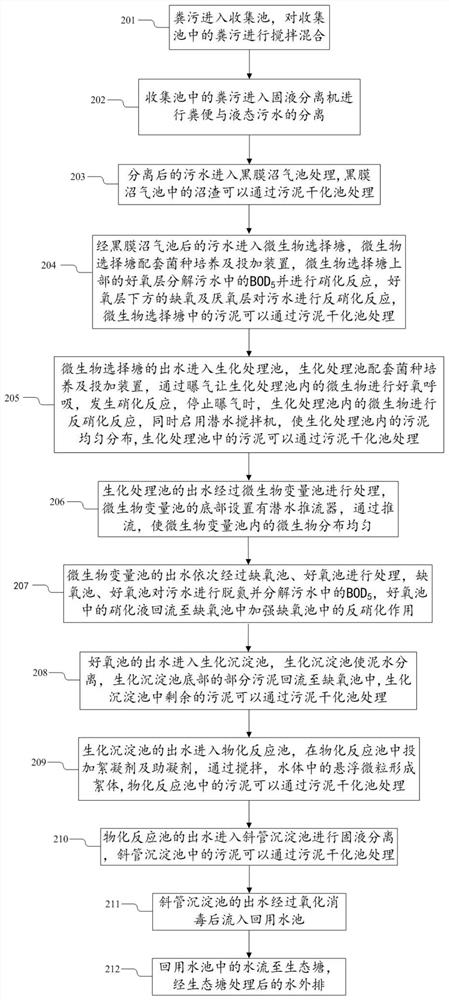

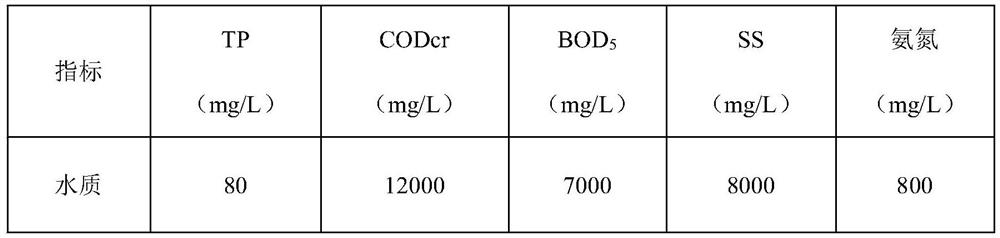

Livestock farm excrement treatment method

InactiveCN112279458AImprove emission targetsWith ecological restoration functionSludge treatmentTreatment using aerobic processesSuspended particlesBiology

The invention discloses a livestock farm excrement treatment method which comprises the following steps: conducting stirring and mixing in a collection tank, removing excrement and other suspended solids by a solid-liquid separator, feeding effluent of the solid-liquid separator into a black film biogas digester for anaerobic fermentation, feeding effluent of the black film biogas digester into amicroorganism selection pond for pretreatment, feeding effluent of the microorganism selection pond to a biochemical treatment pond for biochemical treatment, feeding effluent of the biochemical treatment pond to a biochemical sedimentation pond for mud-water separation, and feeding effluent of the biochemical sedimentation pond to a physicochemical reaction pond to enable suspended particles to form flocs, then conducting solid-liquid separation in an inclined tube sedimentation pond, conducting overoxidation disinfection on water obtained after solid-liquid separation, enabling the disinfected water to flow into a reuse water pond, and conduct direct discharge or further deep treatment on the water in the reuse water pond according to requirements. According to the present invention, thetreatment method has characteristics of reasonable design, effective treatment on degradation-resistant organic matter, high ammonia nitrogen and manure with severely-imbalanced C / N ratio can be achieved, the removal rate of organic matter and ammonia nitrogen can reach 90% or above, and environmental pollution can be effectively treated.

Owner:广州市龙运博环保技术有限公司

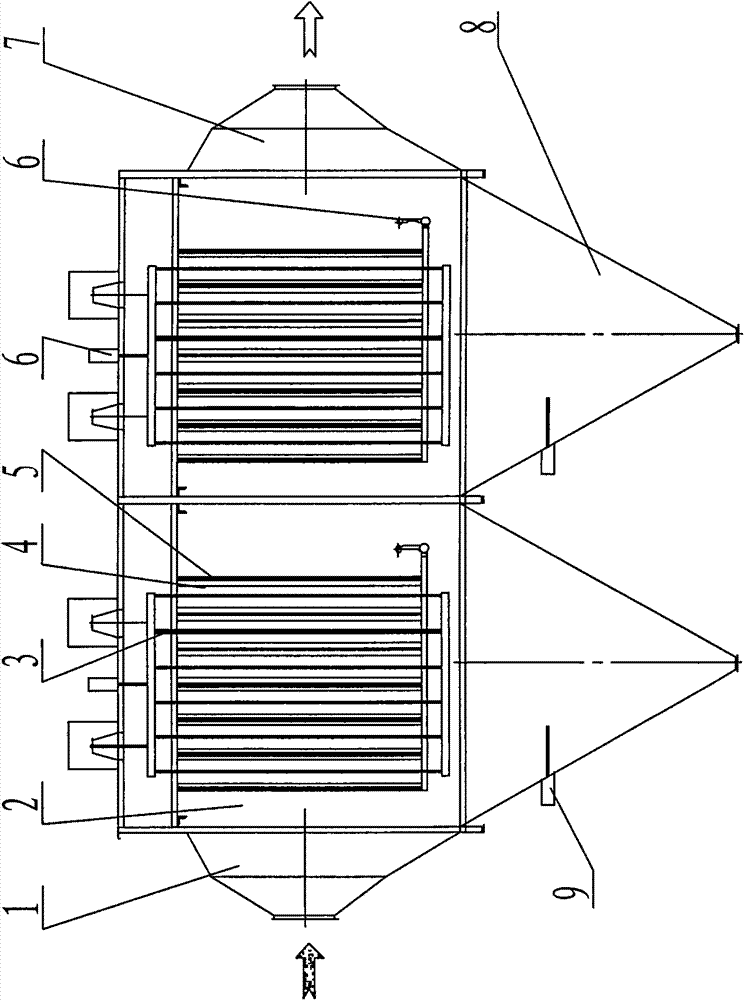

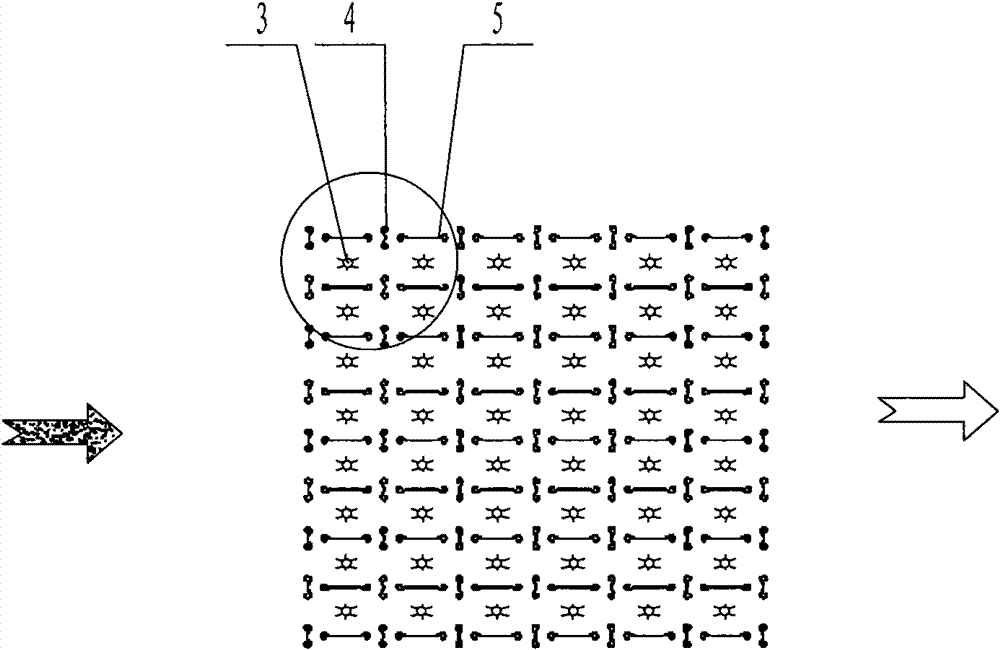

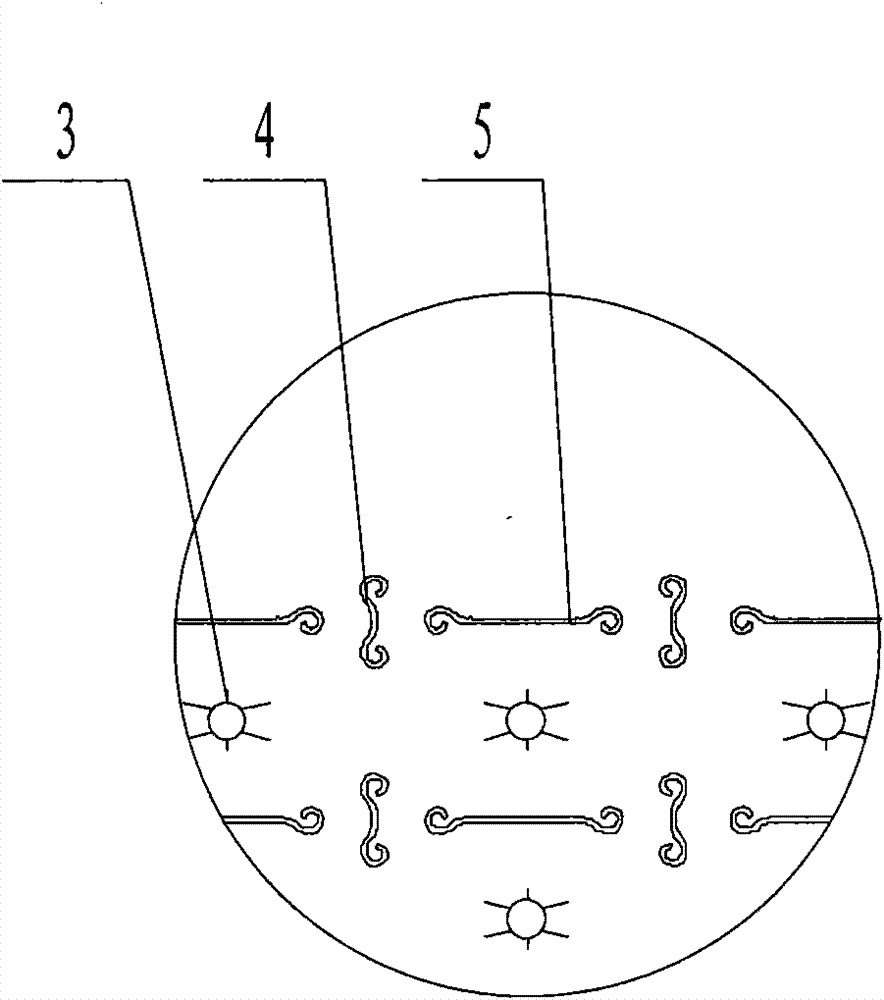

Longitudinal and horizontal plate line combined type electrostatic field dust-removing equipment

The invention relates to longitudinal and horizontal plate line combined type electrostatic field dust-removing equipment comprising a shell, an inlet smoke box, an outlet smoke box, an ash bucket, discharge electrodes, dust collection electrodes and a shaking device, wherein the ash bucket is arranged below the shell; the discharge electrodes and the dust collection electrodes are arranged in the shell at intervals; the dust collection electrodes are distributed in a longitudinally and horizontally combining manner so as to form a rectangular array structure; the discharge electrodes are distributed in a radial shape and arranged in the center of each rectangular array unit of the dust collection electrodes; each dust collection electrode comprises two parts; the intermediate shapes of longitudinally arranged dust collection electrode sections are straight, and both sides naturally transit to form an arc-shaped wind preventing structure; the intermediate shapes of horizontally arranged dust collection electrode sections are straight, and both sides naturally transit to form the arc-shaped wind preventing structure, therefore the dust collection electrodes with the section shapes can enhance the critical sparking voltage, strengthen the electrostatic fields and prevent the collected dust particles from secondarily flying through the arc-shaped wind preventing structures.

Owner:JIANGSU YUDA POWER STATION AUX EQUIP & VALVE MFR

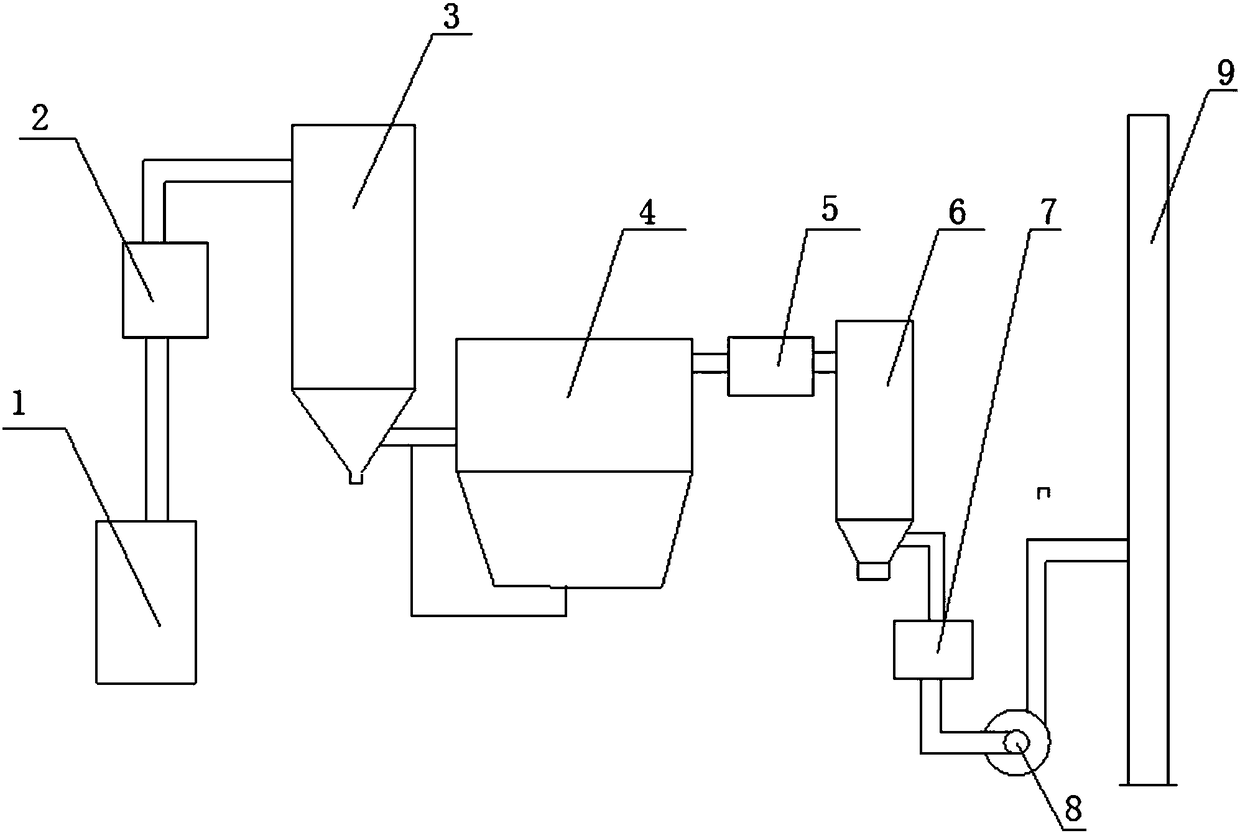

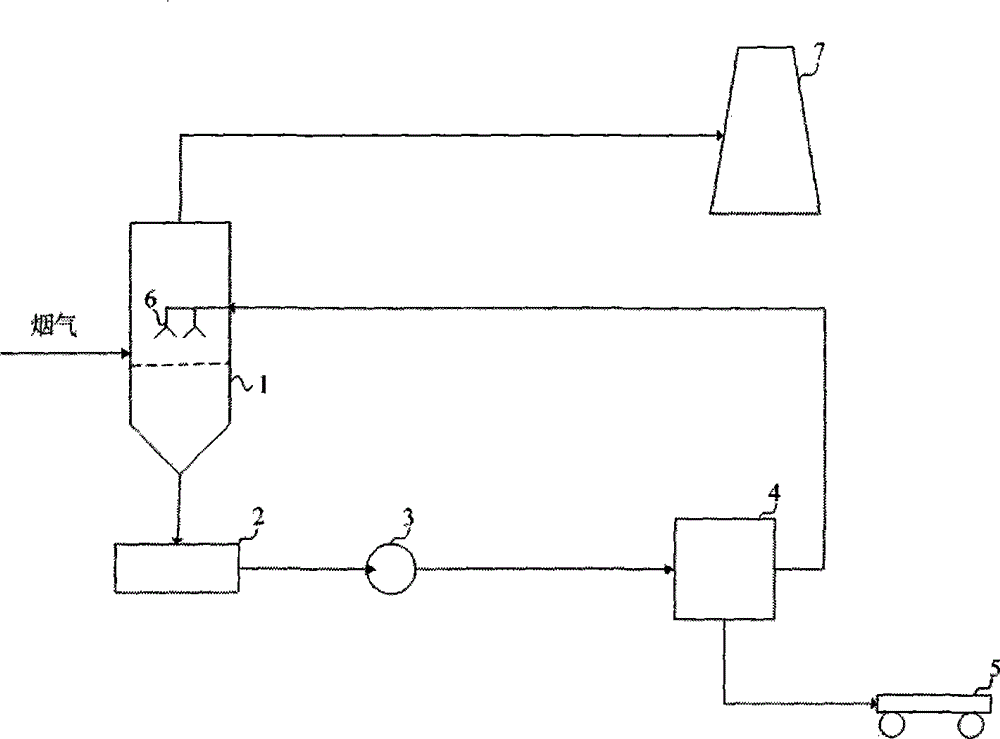

Process system for improving dust removal, desulfurization and demercuration efficiency of boiler flue gas

InactiveCN105013268ALow running costHigh economic valueSludge treatment by de-watering/drying/thickeningUsing liquid separation agentFlocculationProcess systems

The invention relates to a process system for improving dust removal, desulfurization and demercuration efficiency of boiler flue gas. The process system comprises an efficient wet dust collector or a desulfurization tower, a flocculation basin, a sewage pump, an efficient sewage treatment and concentration device, a dewatering machine, a sprayer and a chimney. The efficient sewage treatment and concentration device is utilized to achieve water recycling, and no secondary pollution is produced. The process system for improving dust removal, desulfurization and demercuration efficiency of the boiler flue gas is safe, simple, practical and reliable, so that the original power utilization and operation costs and byproducts are greatly reduced, emission index is reduced, the energy-saving and environmental-protection purposes are achieved, and the process system has very high economic value and has great promotional value.

Owner:刘炎军 +2

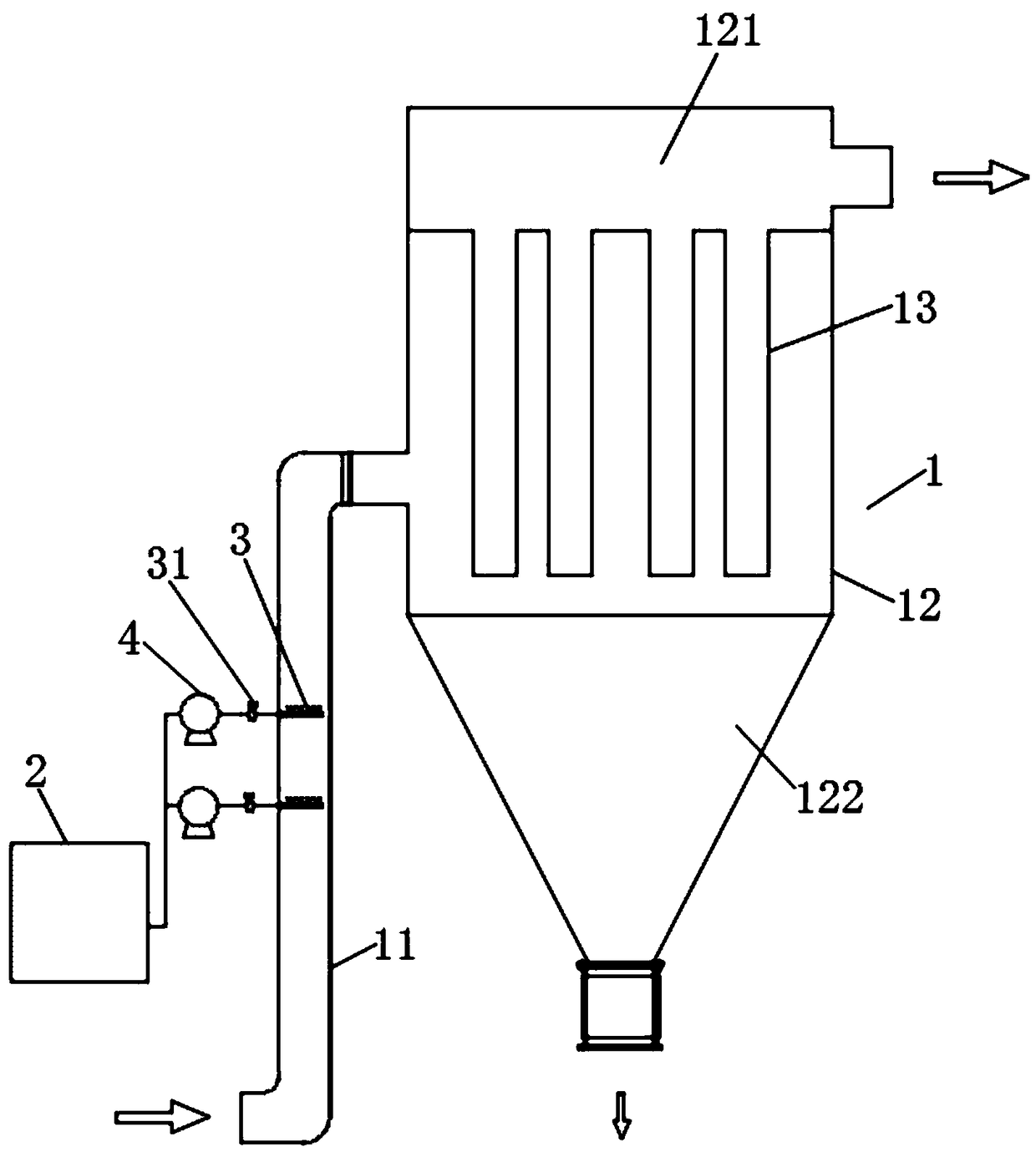

Flue gas ultra-clean treatment system

InactiveCN109499247AImprove emission targetsSimple structural designCombination devicesDispersed particle filtrationBaghouseEngineering

The invention relates to a flue gas dedusting technology, in particular to a flue gas ultra-clean treatment system. The flue gas ultra-clean treatment system comprises a bag type dust collector, an agglomerating agent solution source and an atomizing and sprinkling device, wherein the bag type dust collector is provided with an inlet flue; the atomizing and sprinkling device is mounted in the inlet flue; the atomizing and sprinkling device is in communication with the agglomerating agent solution source through a conveying pipe; and a conveying device is arranged on the conveying pipe. The system has the advantages of being simple and reasonable in structural design, significantly improving the dust removal efficiency and effect, improving the flue gas emission index, and reducing the usecost.

Owner:武汉天空蓝环保科技有限公司

Diffusing and spraying combustion system of IC engine

InactiveCN1288331CIncrease involvementImprove economyInternal combustion piston enginesFuel injection apparatusCombustion systemCombustion chamber

A diffusion spray type combustion system for IC engine features that a spray diffusing conic surface is arranged at the diameter-reduced position of combustion chamber for spraying the beam from the oil sprayer directly to it, so generating an oil beam diffused in wire range and quickly forming a relatively uniform gas mixture. Its advantages are quick and full combustion, low oil consumption, high power and less pollution.

Owner:DALIAN UNIV OF TECH

Smelting system for iron-based multi-metal mineral materials

The invention provides a smelting system for iron-based multi-metal mineral materials. The iron-based multi-metal mineral materials comprise iron element, titanium element and vanadium element. The smelting system comprises a mixing device, a smelting-pool smelting device and an electrothermal reduction device, wherein the mixing device is provided with a proportioning inlet and a mixing outlet; the smelting-pool smelting device is provided with a first charge port, a second charge port and a melt outlet, the first charge port is formed in the top of the smelting-pool smelting device, the second charge port is formed in the sidewall of the smelting-pool smelting device, and the mixing outlet is formed in a manner of communicating with the first charge port and / or the second charge port; and the electrothermal reduction device is provided with a deslagging port, a metal discharge port and a melt inlet, and the melt inlet communicates with the melt outlet. The smelting system combining the mixing device, the efficient smelting-pool smelting device and the electrothermal reduction device is capable of effectively increasing the recovery rate for the vanadium element, and lowering theoperation labor intensity, and further has the advantage of reducing the comprehensive energy consumption, increasing the environmental emission indexes, and the like.

Owner:CHINA ENFI ENGINEERING CORPORATION

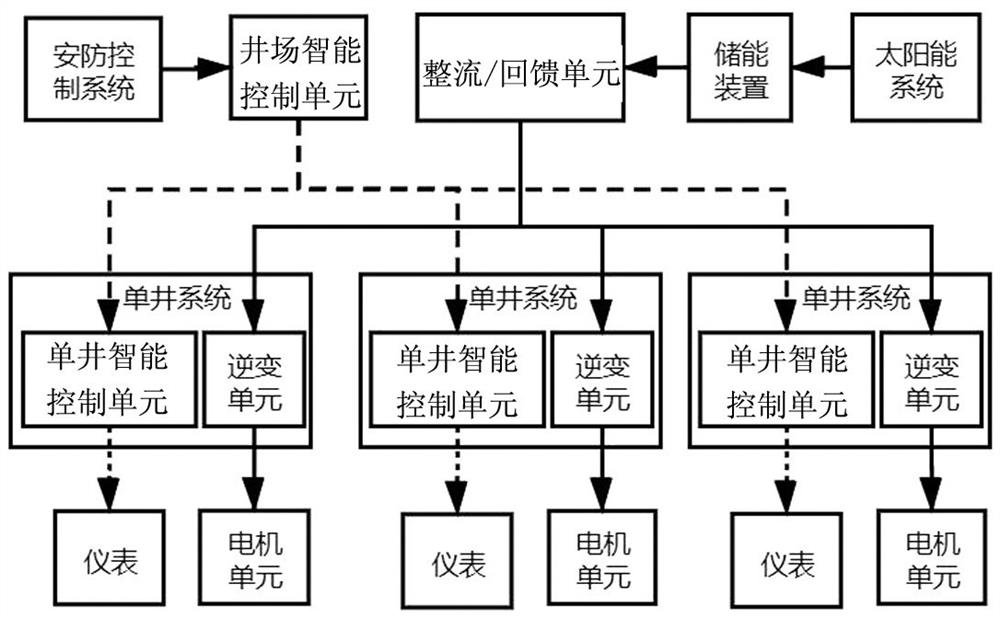

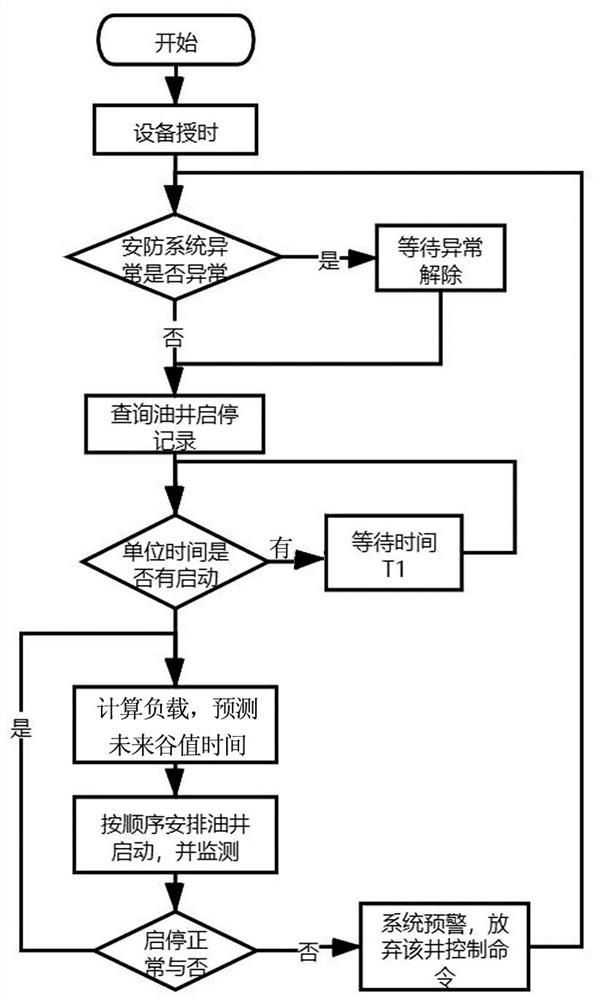

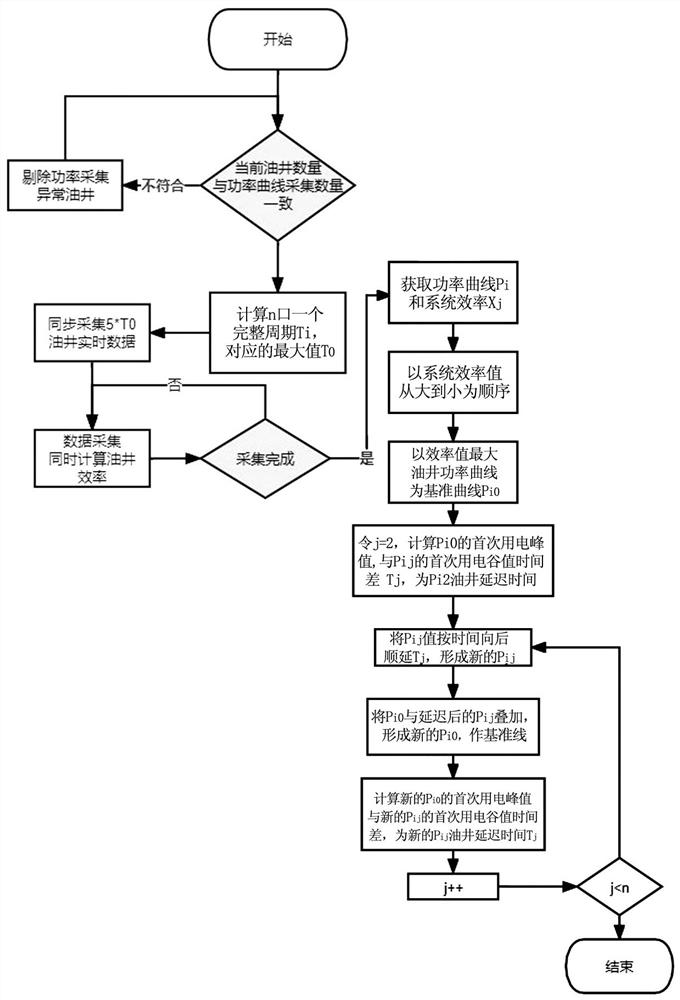

Green and low-carbon intelligent group control method and system for oil extraction system

ActiveCN114776268AImprove emission targetsAchieve co-optimizationBatteries circuit arrangementsAC motor controlIndustrial engineeringSecurity controls

According to the green low-carbon intelligent group control method and system for the oil extraction system, an existing oil well control system is improved and effectively fused with a solar system, a buffer device is provided for a common direct current bus technology, meanwhile, solar energy serves as supplementary energy, and the utilization rate of electric energy and the emission index of well site carbon are effectively increased. Intelligent optimization of the whole well site is achieved based on well site intelligent control, the purpose of collaborative optimization of energy and production targets is achieved, possibility is provided for energy-saving and efficient production of crude oil, meanwhile, a security control system is combined, system safety is effectively improved, and potential safety hazards of the well site are reduced.

Owner:陕西埃菲克能源科技有限公司

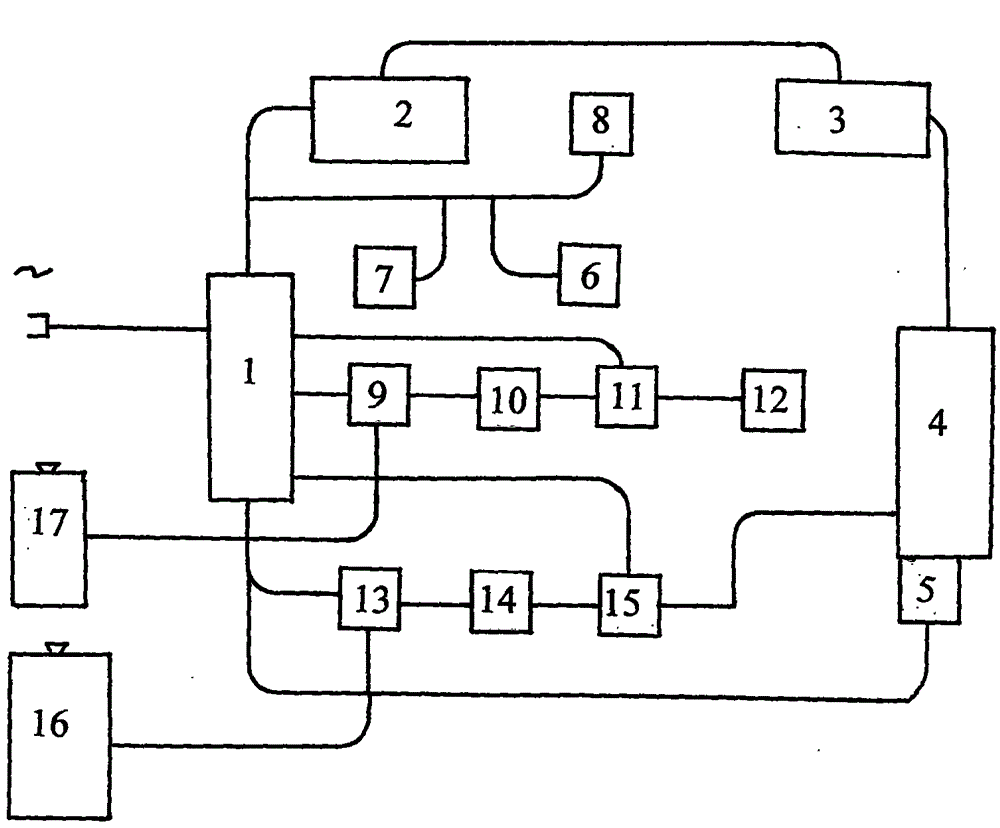

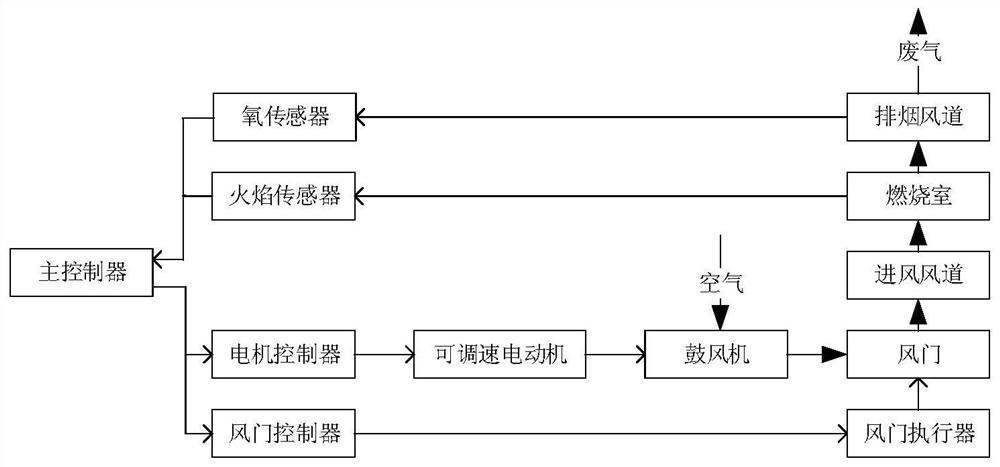

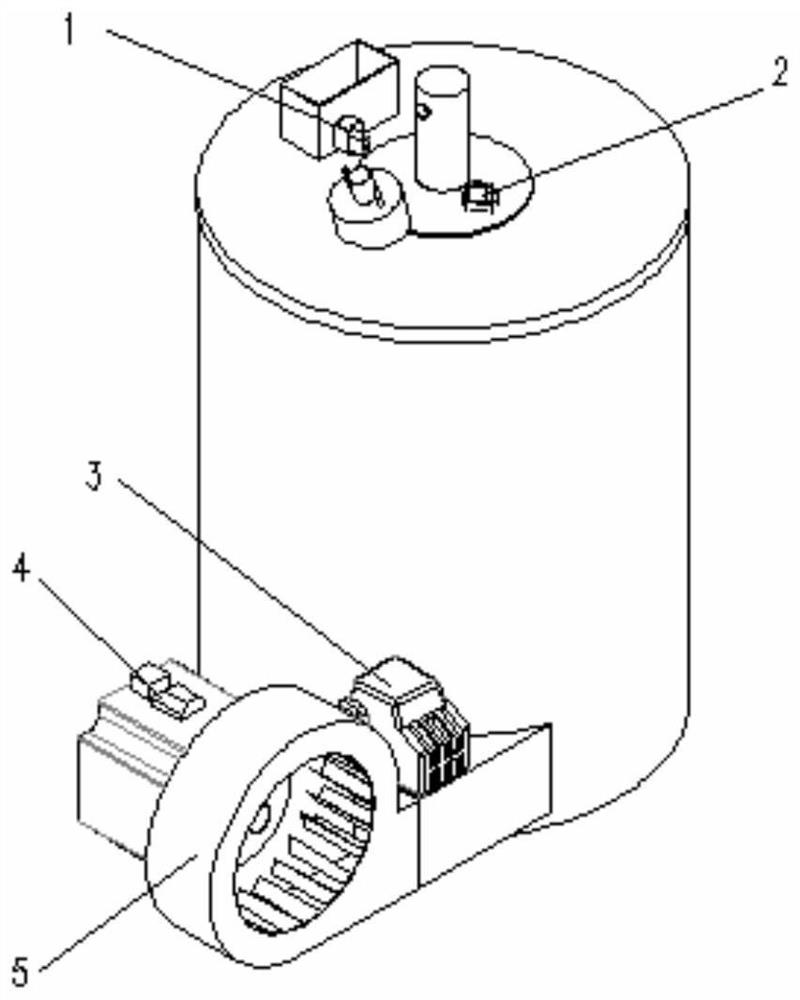

Air quantity control system used for power adjustable coil pipe type fuel heater

PendingCN111678168AImprove emission targetsAir supply regulationBlast-producing apparatusCombustion chamberAir volume

The invention relates to the technical field of fuel heaters, in particular to an air quantity control system used for a power adjustable coil pipe type fuel heater. The system comprises a master controller, an oxygen sensor, a flame sensor, a motor controller, a damper controller, a speed adjusting motor, an air blower, a damper executor and a damper. The oxygen sensor is arranged on a smoke exhaust air flue, the flame sensor is mounted in a combustion chamber, the oxygen sensor is used for collecting the content of oxygen of waste gas, the flame sensor is used for collecting combustion states, a signal is fed back to the master controller, the master controller controls the motor controller and the damper controller, the motor controller drives the speed reducing motor to adjust the rotating speed of the air blower to change the air quantity and the air pressure of air entering in the air flue, the damper controller controls the damper executor to rotate a damper to the determined angle, the air flue air quantity is changed, the system is energy-saving and environment-friendly, system running is stable and reliable, and emission indexes can be improved.

Owner:TIANJIN JIEQIANG POWER EQUIP

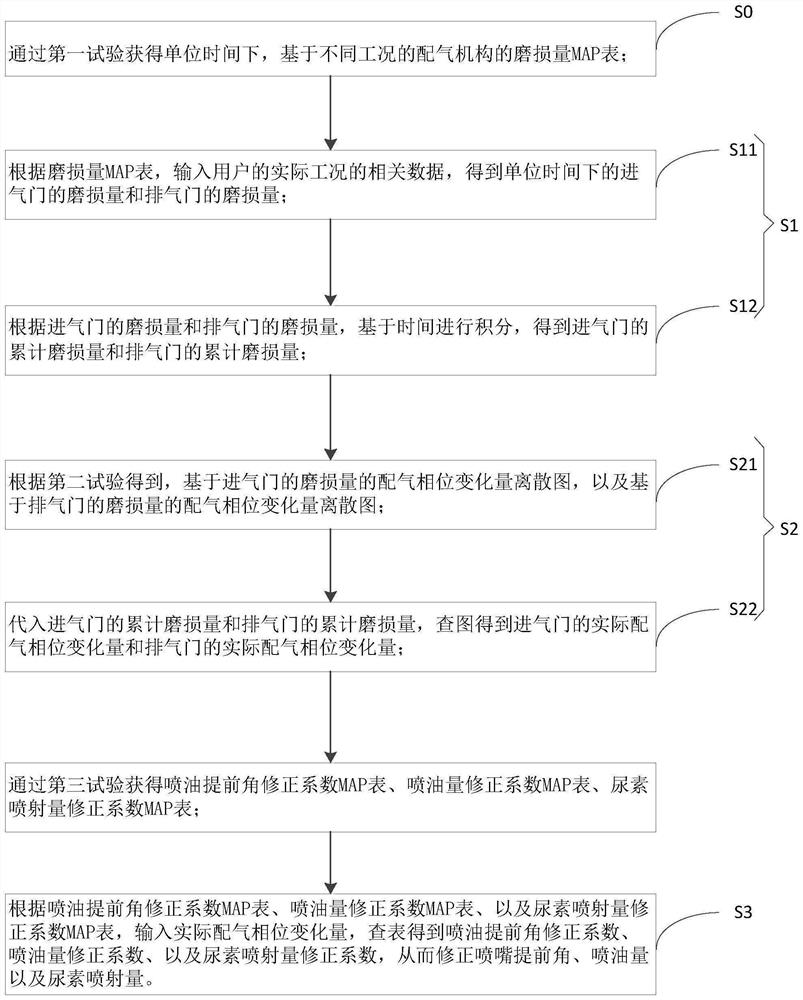

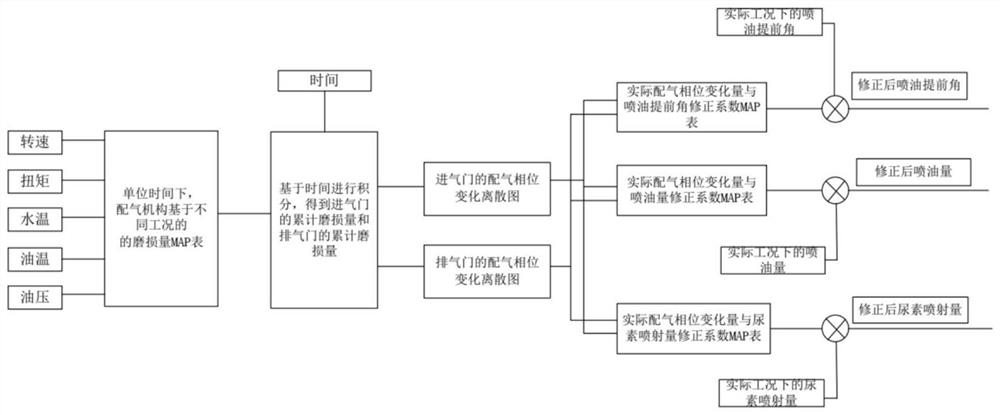

Engine parameter correction method and engine

ActiveCN114370346AImprove performanceImprovements in emission indicatorsElectrical controlExhaust apparatusEngineeringMechanics

The invention belongs to the technical field of engines, and discloses an engine parameter correction method and an engine, and the engine parameter correction method comprises the following steps: S1, according to an abrasion loss MAP table of a valve mechanism, calculating to obtain an accumulated abrasion loss of the valve mechanism under an actual working condition; s2, according to the accumulative abrasion loss, the actual valve timing phase change amount is calculated; and S3, according to the fuel injection advance angle correction coefficient MAP table, the fuel injection quantity correction coefficient MAP table and the urea injection quantity correction coefficient MAP table, the actual gas distribution phase change amount is input, the fuel injection advance angle correction coefficient, the fuel injection quantity correction coefficient and the urea injection quantity correction coefficient are obtained through table look-up, and the nozzle advance angle, the fuel injection quantity and the urea injection quantity are corrected. According to the engine parameter correction method, the actual valve timing change quantity of the valve timing mechanism is obtained by calculating the accumulated abrasion loss of the valve timing mechanism of the engine, then the parameters such as the fuel injection advance angle, the fuel injection quantity and the urea injection quantity of the engine are optimized, and the performance and emission indexes of the engine are optimized.

Owner:WEICHAI POWER CO LTD

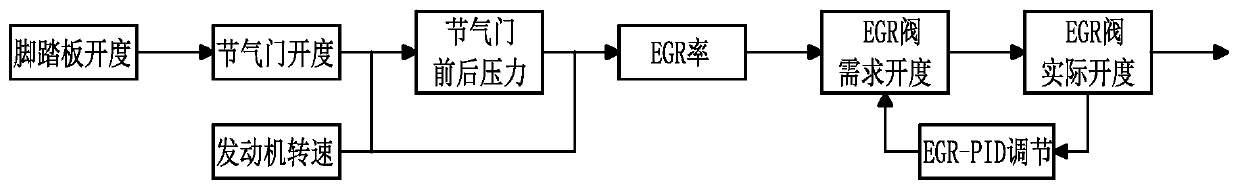

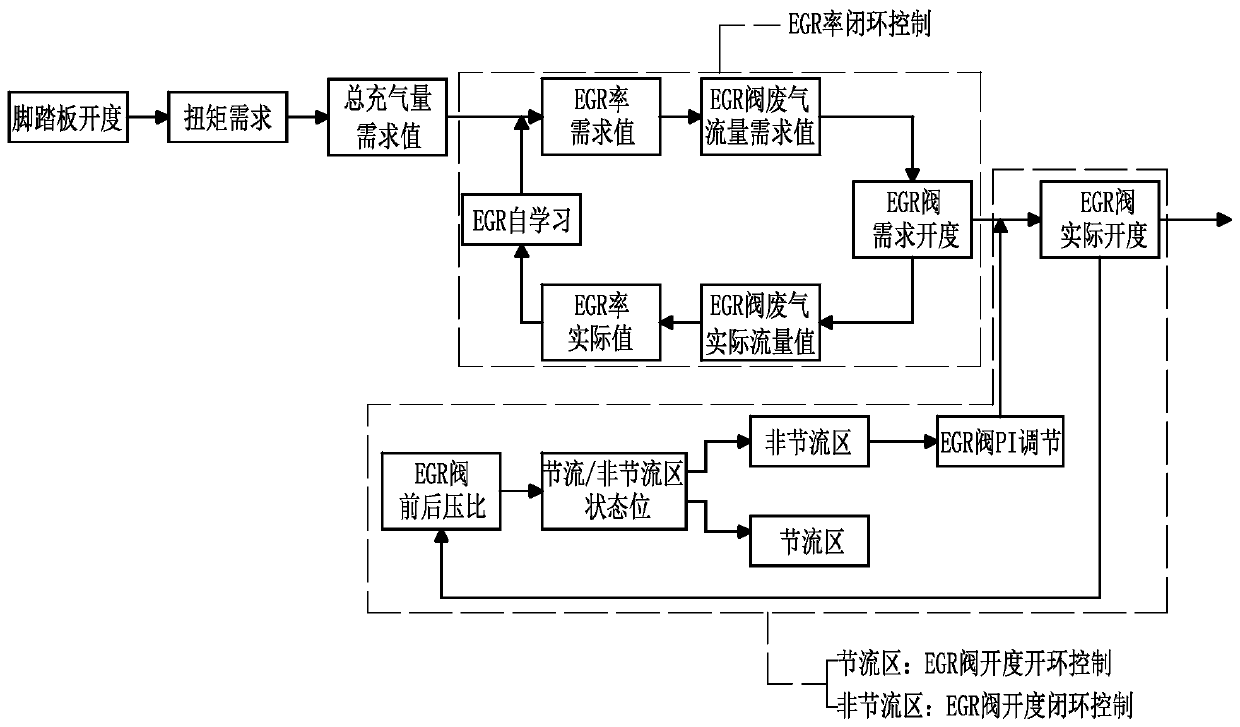

Butterfly valve egr control method for natural gas engine

ActiveCN106968812BEasy to controlBurn fullyElectrical controlMachines/enginesClosed loopButterfly valve

The invention discloses a butterfly valve type EGR control method for a natural gas engine. The method uses the demand opening degree of an EGR valve as a feedback signal to conduct inner layer small closed-loop control, and EGR rate demand value is used as the feedback signal to conduct outer layer large closed-loop control, so that the exhaust gas flow penetrating through the EGR valve is precisely controlled. In actual calibration or operation, control of the exhaust gas flow, especially the transient control, can be relatively accurate through the accurate closed-loop of the EGR rate and control and response of EGR valve opening closed-loop, so that more sufficient burning and high-level emission targets are ensured.

Owner:WEICHAI XIGANG NEW ENERGY POWER

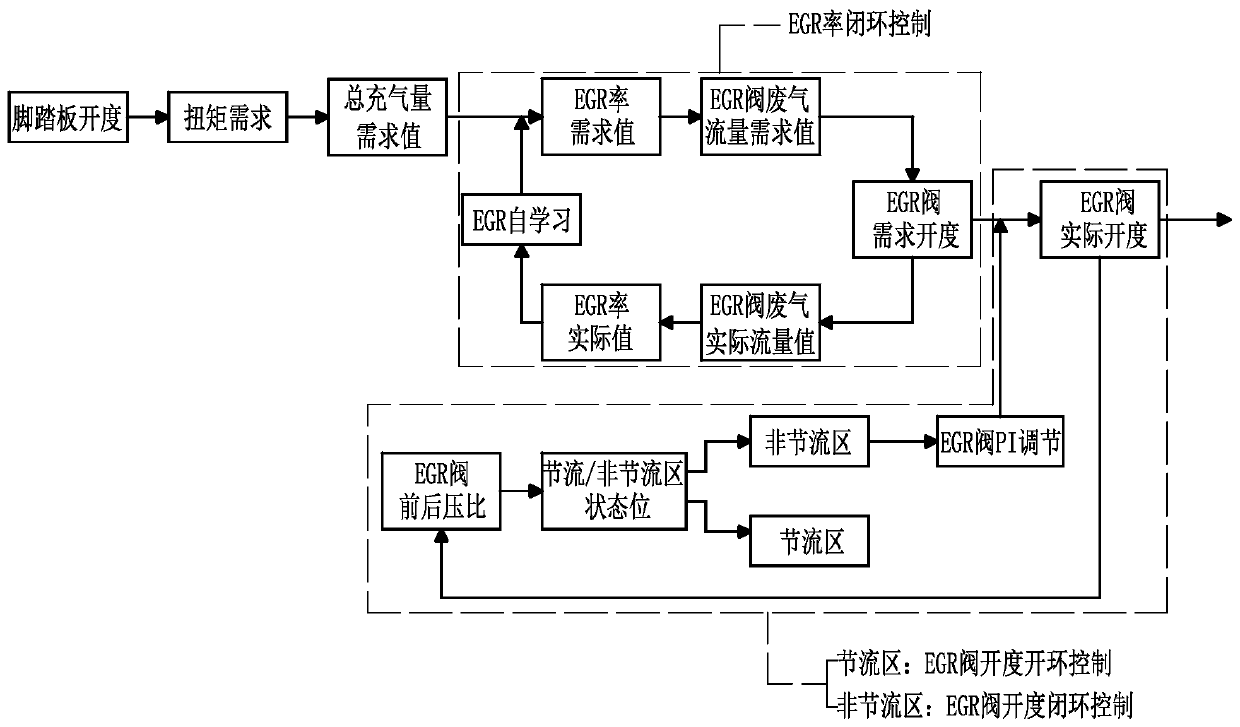

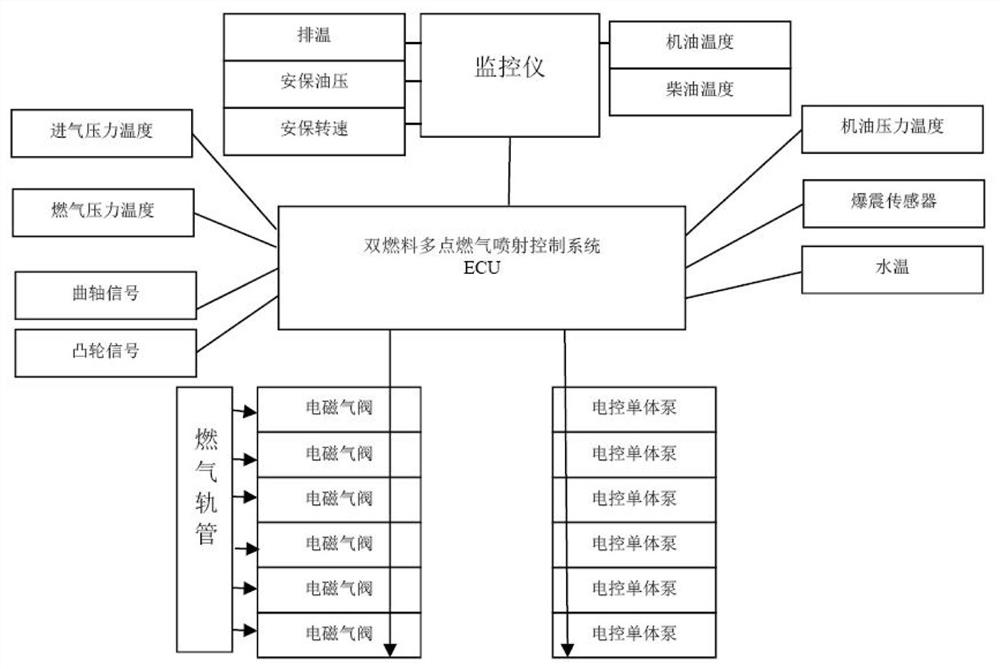

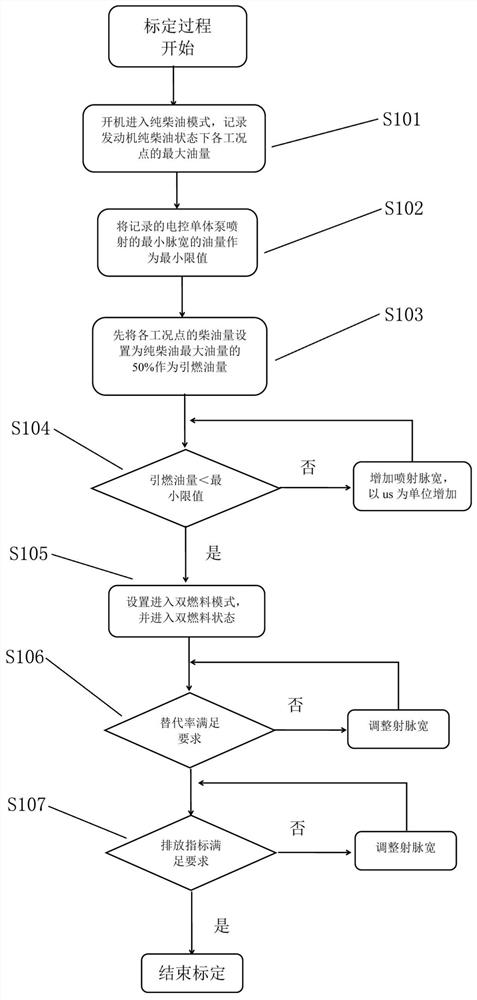

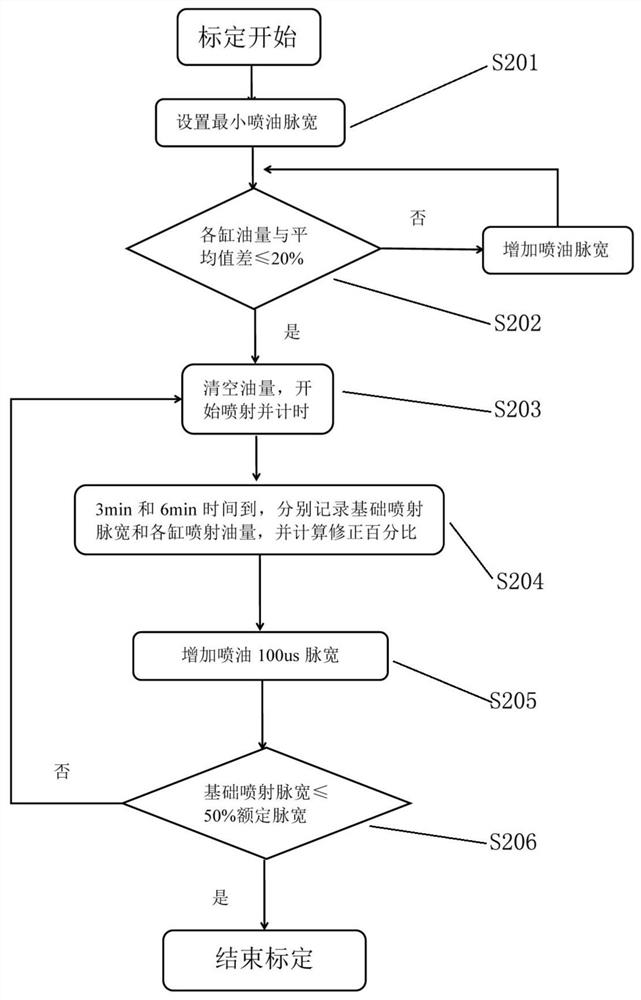

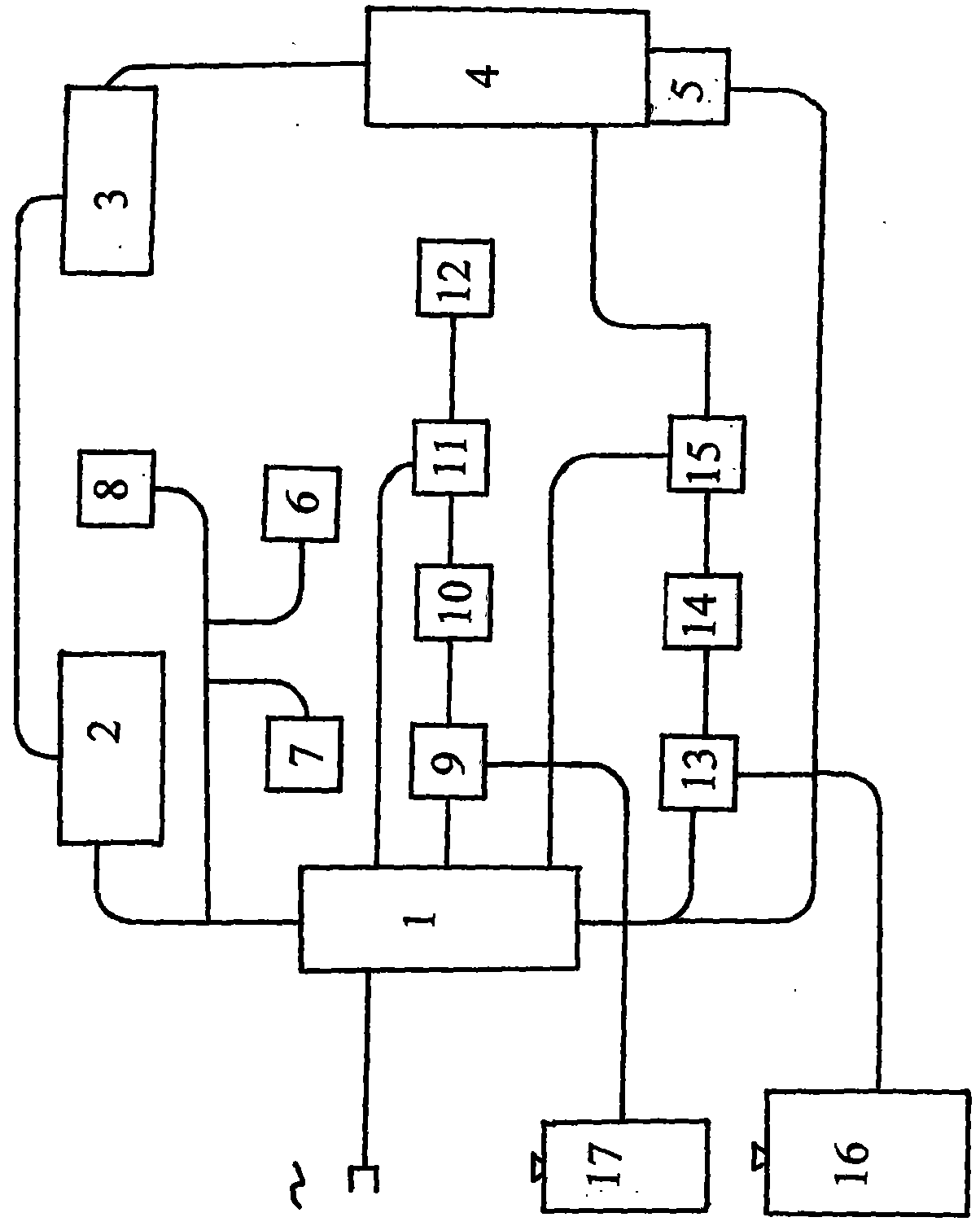

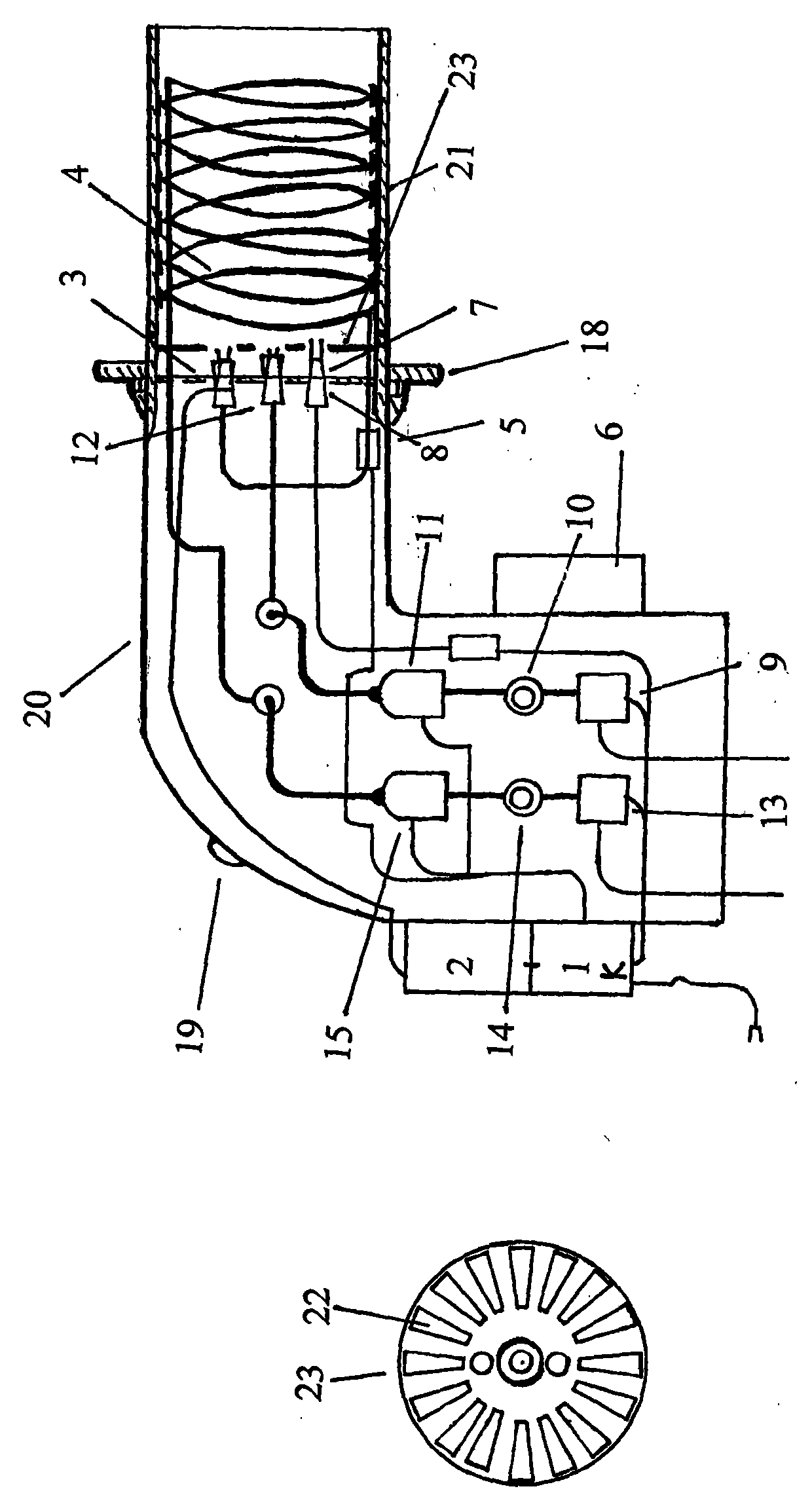

Implementation method of a marine dual-fuel oil-gas multi-point gas injection control system

ActiveCN113606050BIncrease replacement rateImprove stabilityElectrical controlEngine testingControl systemFuel oil

Owner:WEIFANG LICHUANG ELECTRONICS TECH

High-efficiency and energy-saving boiler burner for plasma water splitting and hydrogen production

InactiveCN104654343BImprove emission targetsHigh thermal efficiencyLiquid fuel feeder/distributionChemical industryWater vaporSprayer

The invention discloses an efficient energy-saving boiler burner for plasma hydrolysis hydrogen generation. The efficient energy-saving boiler burner is composed of an intelligent controller, a high-frequency high-voltage power supply, a plasma electric arc catalysis ejector, a moisture evaporator, a water pump, a water amount regulating valve, a moisture evaporator, a temperature sensor, an oil pump, an oil quantity regulating valve, an electronic igniter, an oil sprayer, a fan, a magnetic valve, a flame spraying burner, a burner housing and an installing flange. Water is heated to produce water vapor, then the water vapor is rapidly decomposed in the plasma electric arc catalysis ejector to produce hydrogen and oxygen molecules and hydrogen and oxygen ions, the hydrogen and oxygen molecules and the hydrogen and oxygen ions and fuel or fuel gas are sprayed into a boiler hearth through the flame spraying burner to be burned, accordingly the purposes of increasing fuel or replacing a part of fuel to increase oxygen, remarkably saving the fuel and improving energy-saving emission-reducing indexes are achieved, and the efficient energy-saving boiler burner is an ideal upgraded new high-tech product in the industry.

Owner:路鹏

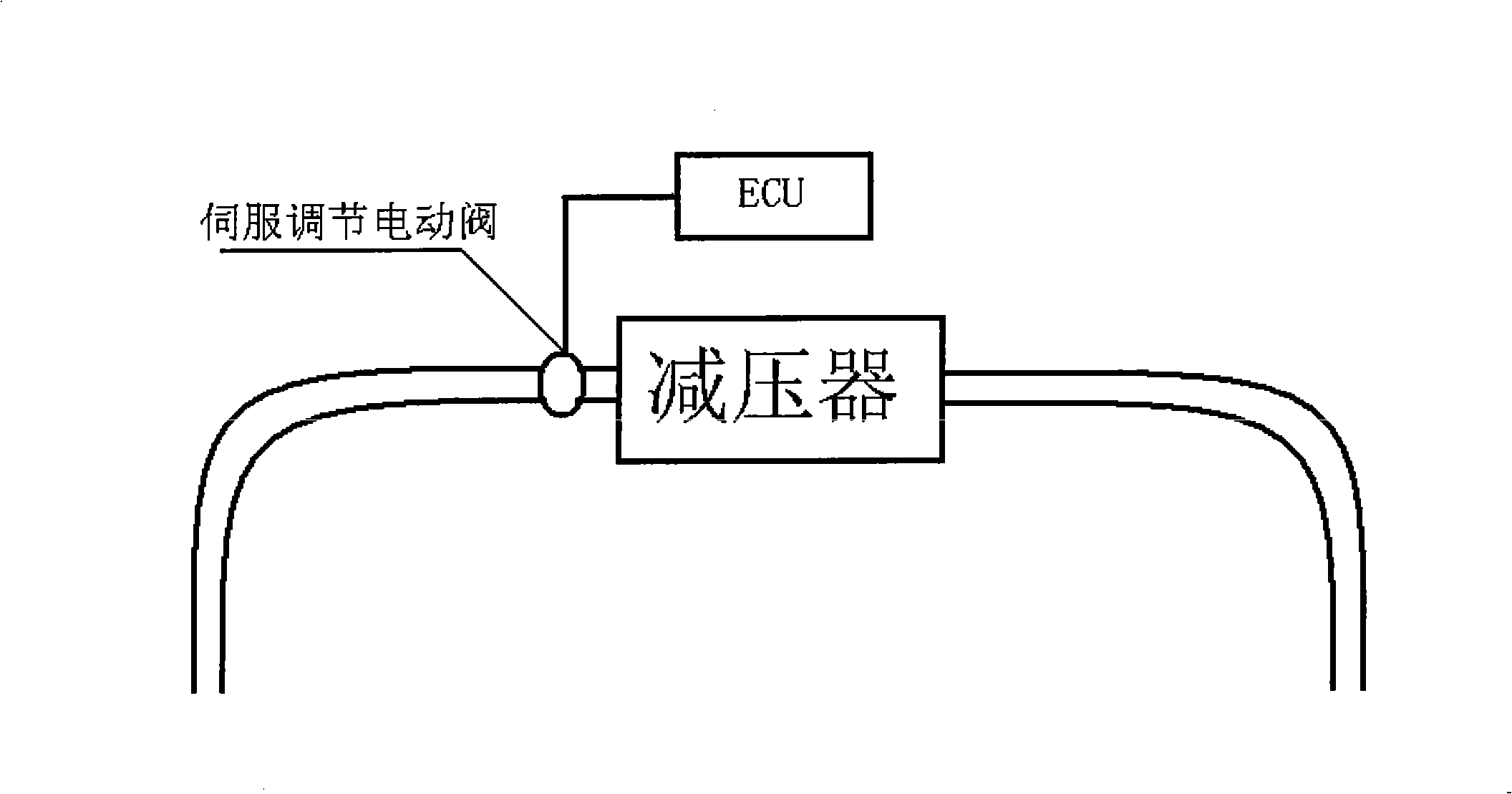

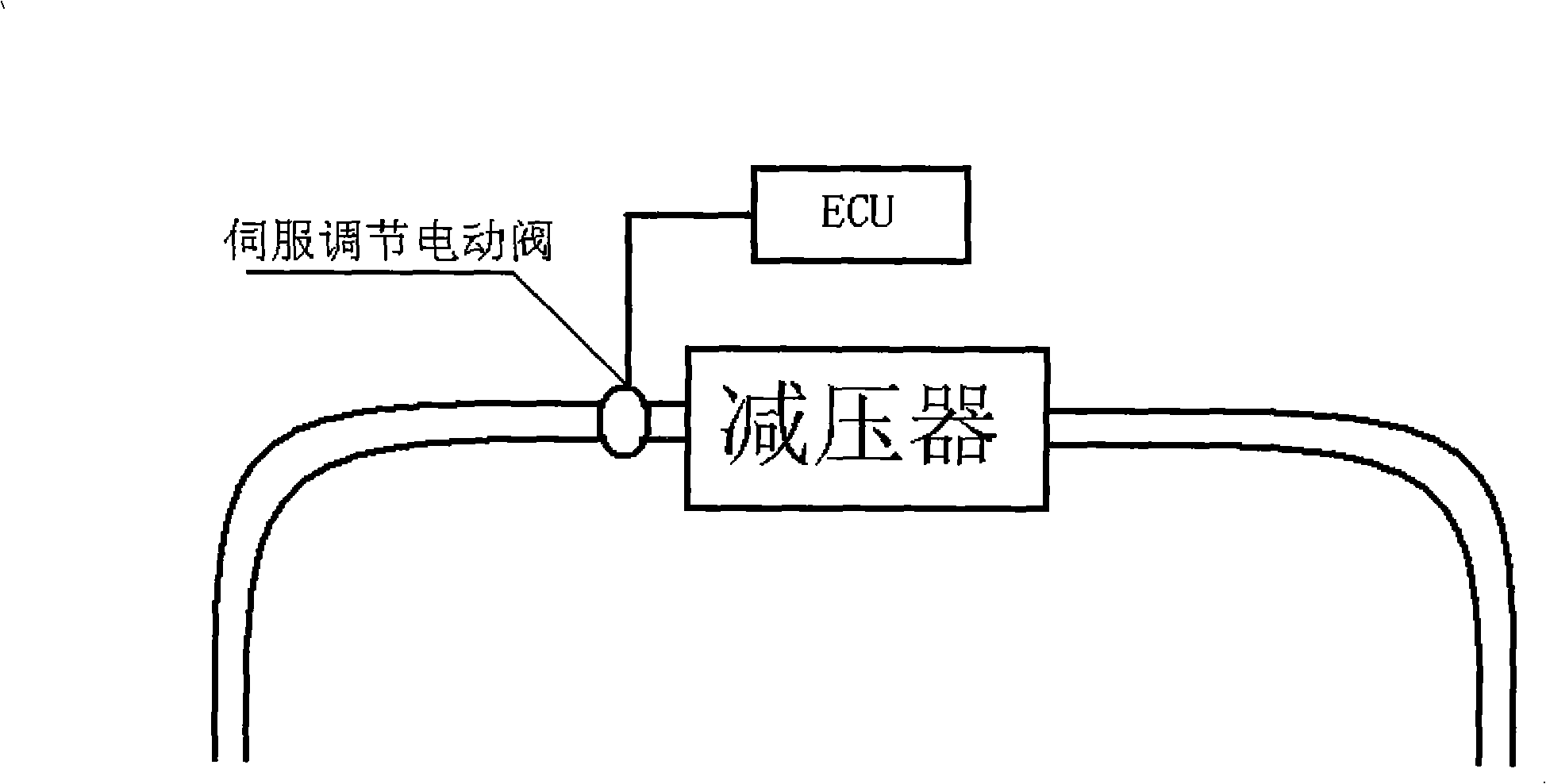

Gas system of backing stage pressure reducers

InactiveCN101275505AImprove emission targetsInternal combustion piston enginesFuel supply apparatusEngineeringReducer

The invention relates to a gas system of a pre-stage reducer, comprising at least two stages of reduction chambers and back pressure chambers, each stage of reduction chamber and back pressure chamber are separated by a diaphragm, valve seats are arranged between the stages of reduction chambers. The invention is characterized in that the gas inlet side of at least one valve seat is provided with a servo regulating electric valve. The gas inlet side of the valve seat between the reduction chamber and the back pressure chamber is provided with a servo regulating electric valve controlled by an ECU (electric control center).

Owner:SHANGHAI ZHONGYOU ENTERPRISE GRP CO LTD +1

Backing stage pressure reducers

InactiveCN101275512AImprove emission targetsInternal combustion piston enginesFuel supply apparatusEngineeringBack pressure

The invention relates to a pre-stage reducer, comprising at least two stages of reduction chambers and back pressure chambers, each stage of reduction chamber and back pressure chamber are separated by a diaphragm, valve seats are arranged between the stages of reduction chambers. The invention is characterized in that the gas inlet side of at least one valve seat is provided with a servo regulating electric valve. The gas inlet side of the valve seat between the reduction chamber and the back pressure chamber is provided with a servo regulating electric valve controlled by an ECU (electric control center); the flow of the output gas of the reducer is adjusted appropriately according to the working condition of the gas engine of an automobile, thus to improve the emission index of the engine, reaching to the Europe 2# standard.

Owner:SHANGHAI ZHONGYOU ENTERPRISE GRP CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com