High-efficiency and energy-saving boiler burner for plasma water splitting and hydrogen production

A plasma, high-efficiency and energy-saving technology, applied in the direction of gas fuel burners, burners, combustion methods, etc., can solve the problems of large energy consumption and low efficiency, and achieve the effects of improving thermal efficiency, broad market prospects, and saving electric energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

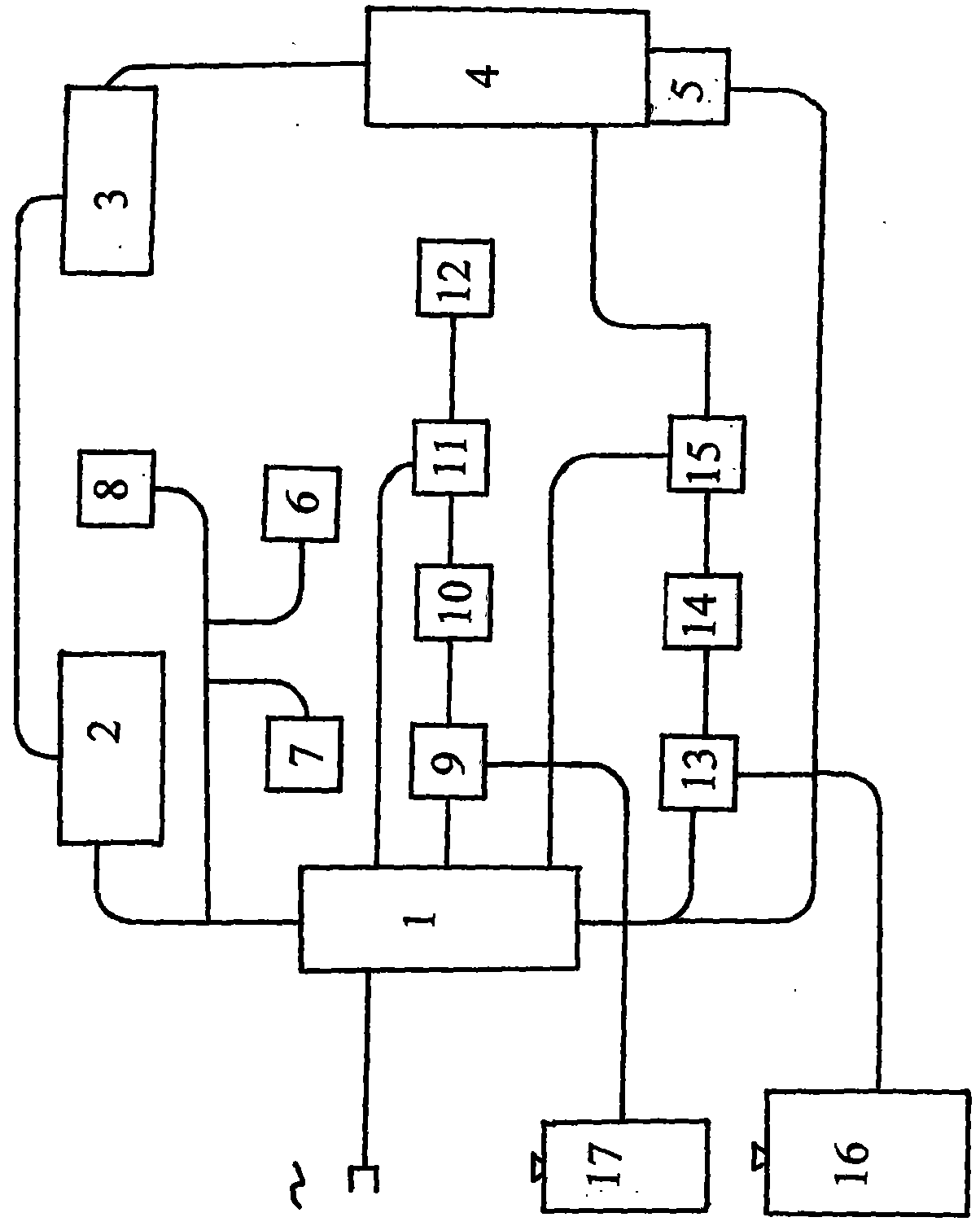

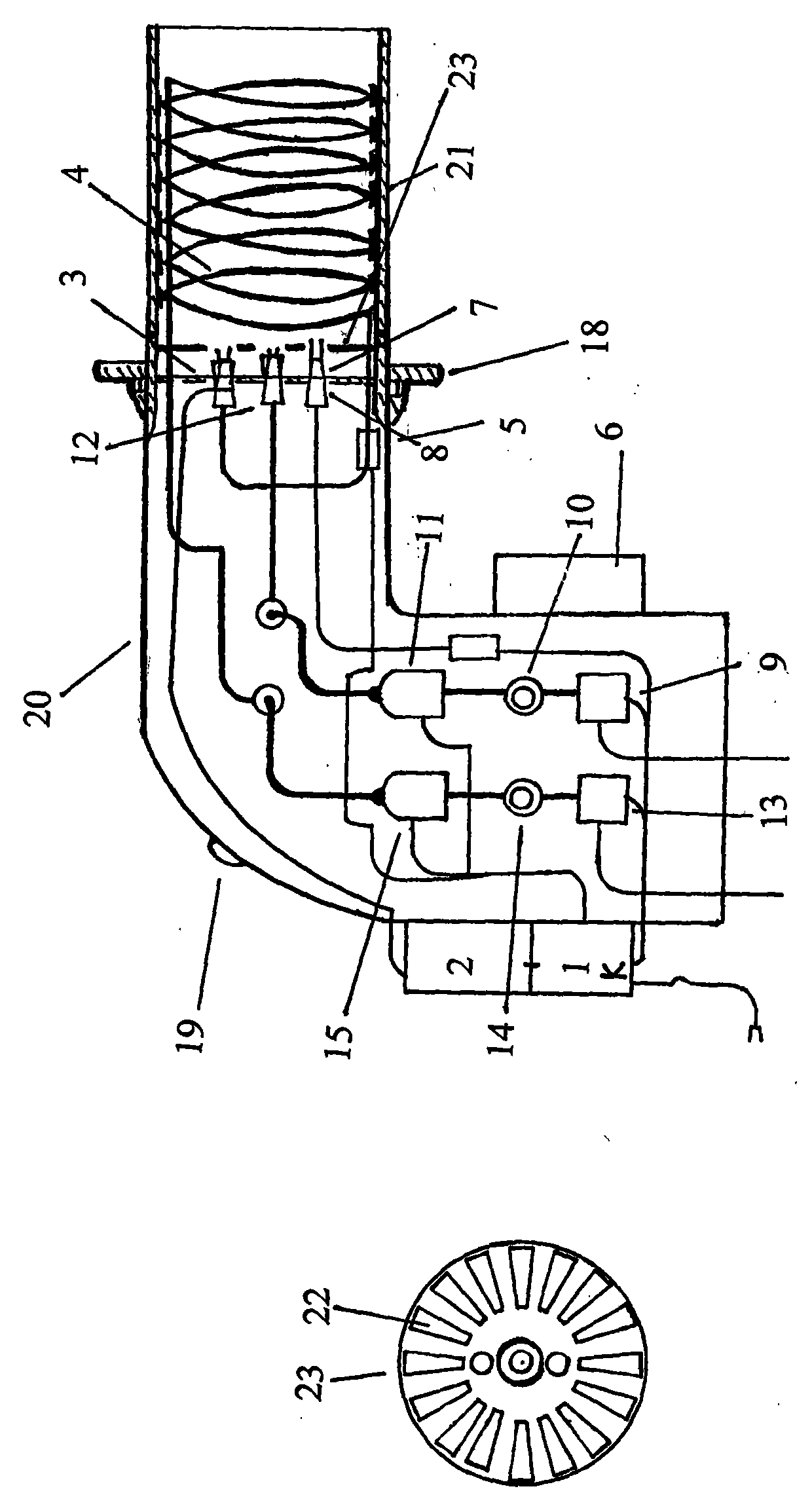

[0019] Examples of high-efficiency and energy-saving boiler burners for plasma water splitting and hydrogen production in the present invention figure 1 figure 2 Shown: intelligent controller (1), high-frequency high-voltage power supply (2), blower fan (6), electromagnetic valve (9) and (13), oil quantity regulating valve ( 10), oil pump (11), water volume regulating valve (14), water pump (15) and observation hole (19), electronic igniter (7), flame sensor (8) are installed in the boiler burner housing (20) , fuel injector (12), plasma arc catalytic injector (3), temperature sensor (5), burner housing (20) and flame-throwing burner (21) socket connection, in flame-throwing burner (21 ) is equipped with a water evaporator (4) and a wind sweeping disk (23), and a sweeping hole (22) is designed on the wind sweeping disk (23), and the burner housing (20) and the flame-throwing burner (21 ) The boiler burner mounting flange (18) is installed at the joint. One end of the water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com