Implementation method of a marine dual-fuel oil-gas multi-point gas injection control system

An implementation method and control system technology, applied in the direction of fuel injection control, fuel injection device, electrical control, etc., can solve the problems of reduced engine life, weakened regulation effect, inconsistent cylinder pressure, etc., to improve emission indicators, improve stability, Guaranteed consistent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

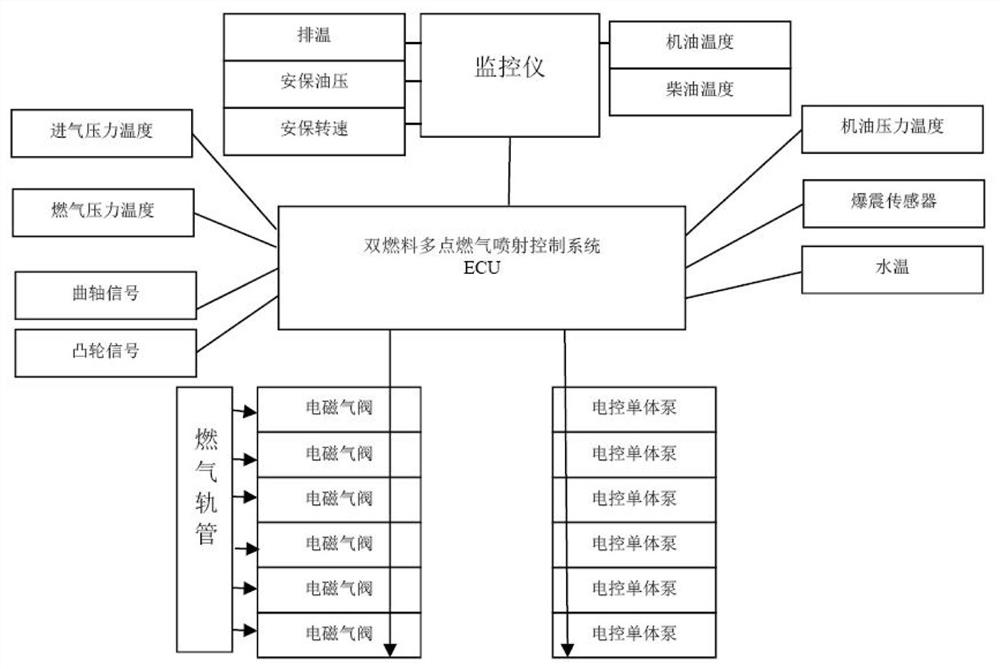

[0050] Example 1, such as figure 1 As shown, a marine dual-fuel oil-gas multi-point gas injection control system includes an ECU, and the ECU is connected with monitors, several solenoid valves, several electronically controlled unit pumps, oil pressure and temperature sensors, knock sensors, water temperature sensors, air intake Pressure and temperature sensor, gas pressure and temperature sensor, crankshaft sensor and cam sensor, the monitor is connected with exhaust temperature, safety oil pressure, safety speed, engine oil temperature and diesel temperature, and the solenoid valve is connected with gas rail pipe.

[0051] The engine carrier is a marine engine, equipped with an electronically controlled unit pump. On the basis of the existing engine, gas injection rails, gas injection valves, gas injection pipes, gas supply pipelines and corresponding gas switches are added. The gas pressure is calculated according to the engine power and the flow rate of the gas injection ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com