Composite foundation construction method

A construction method and composite foundation technology, which is applied in the direction of foundation structure engineering, building, sheet pile wall, etc., can solve the problems of increased engineering cost and increased engineering quantity, and achieve the effects of simple process, reduced engineering cost, and simple production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

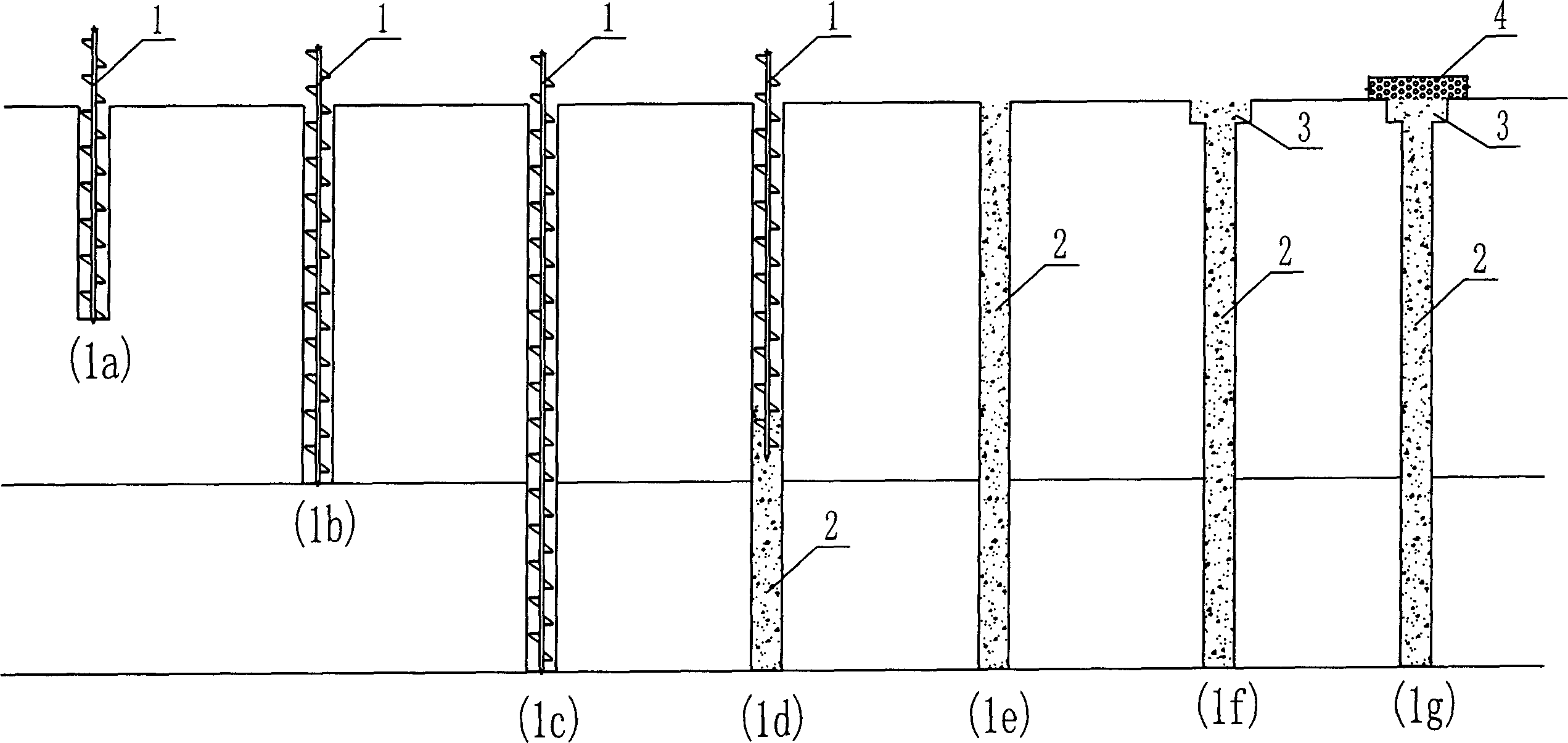

[0029] As the construction method of the concrete pile of an embodiment of the present invention, it comprises the following steps, at first, as figure 1 As shown in a, the drilling rig is in place, and the hole is drilled auger at the pile position; then, as shown in figure 1 As shown in b, auger drilling to the conventional pile end bearing layer; then, as figure 1 As shown in c, continue to drill to a certain depth; after that, if figure 1 As shown in d, while pumping the hydraulic mixed filler into the borehole, the drill pipe is lifted; then, as figure 1 As shown in e, the drill pipe is pulled out of the surface, and the pressure filling is completed; then, as shown in figure 1 As shown in f, excavate the soil body around the top of the pile to form a pile top diameter expansion part connected with the pile body, and pour the pile top diameter expansion part; finally, as figure 1 As shown in g, a mattress layer is laid on top of the pile.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com