Gas replacement method and device for container

A gas replacement and container technology, which is used in the packaging of objects, liquid bottling, and packaging by pressurization/gasification under special gas conditions. Limits and other issues to achieve the effect of improving the gas replacement rate, preventing the re-inflow of air, and preventing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Hereinafter, the present invention will be described in further detail based on the embodiments shown in the drawings.

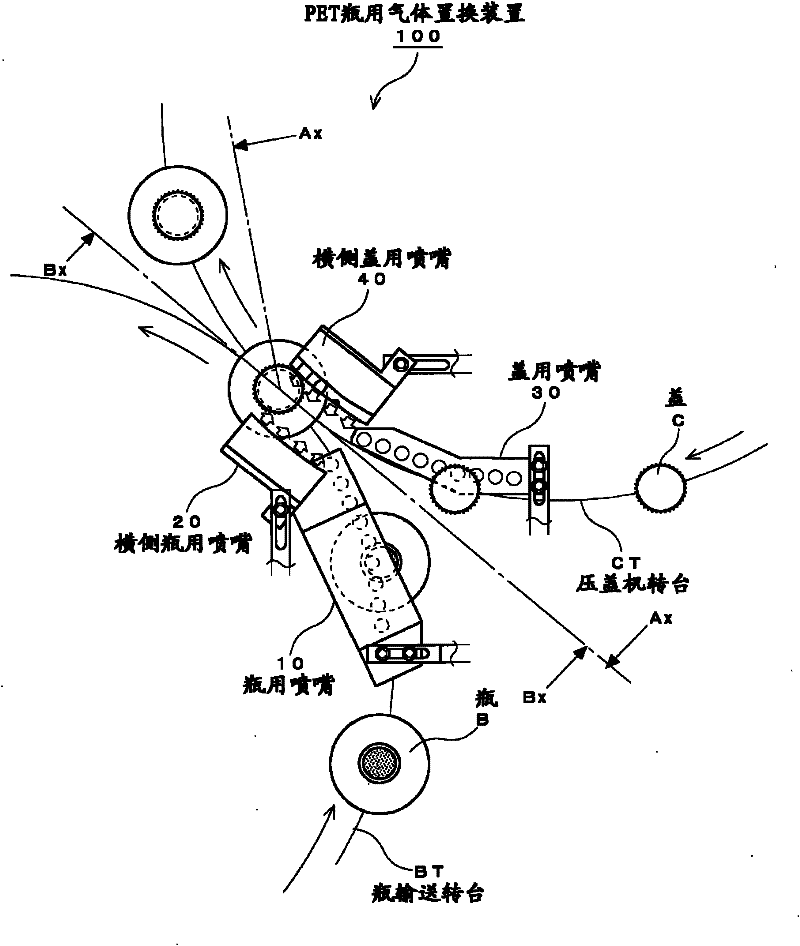

[0038] figure 1 It is an explanatory diagram showing the configuration of the gas replacement device 100 for PET bottles according to the present invention.

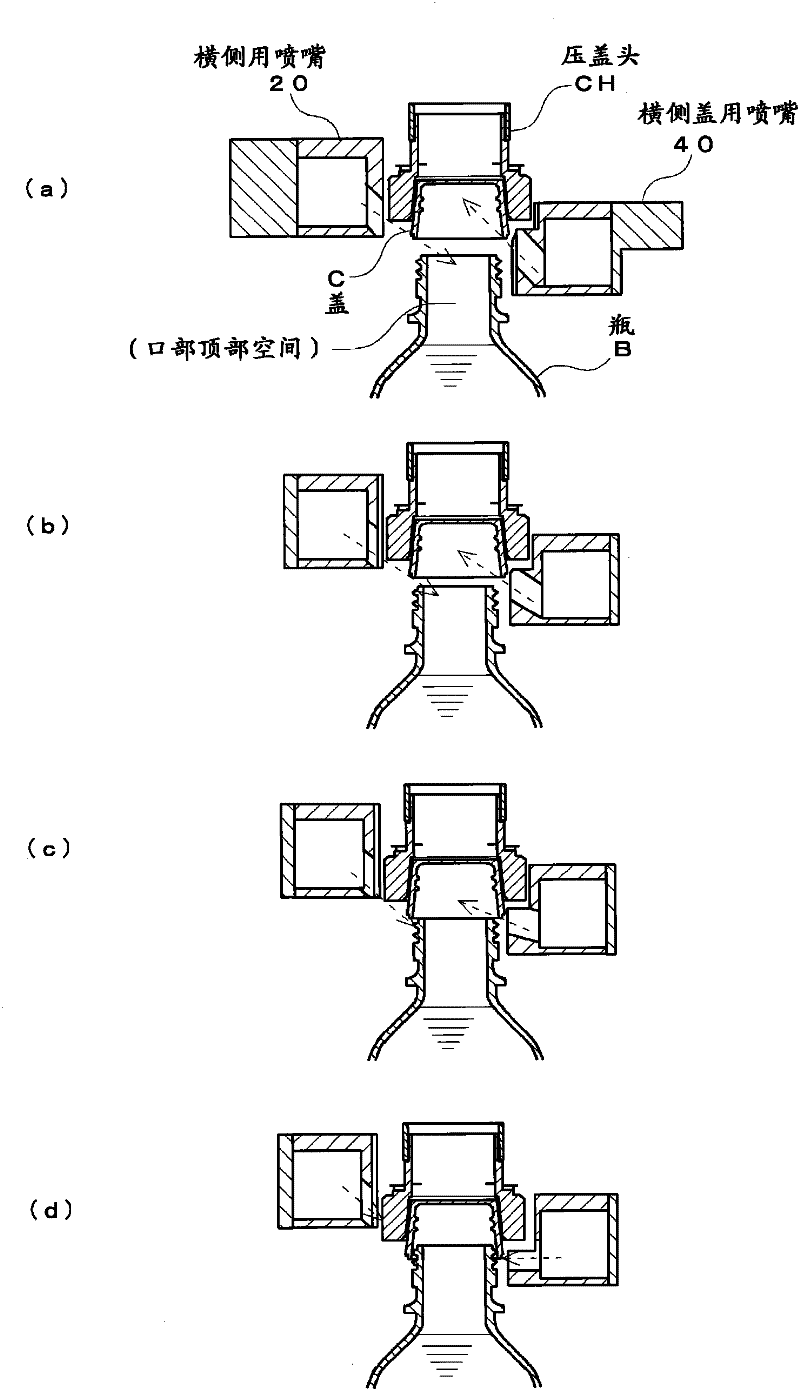

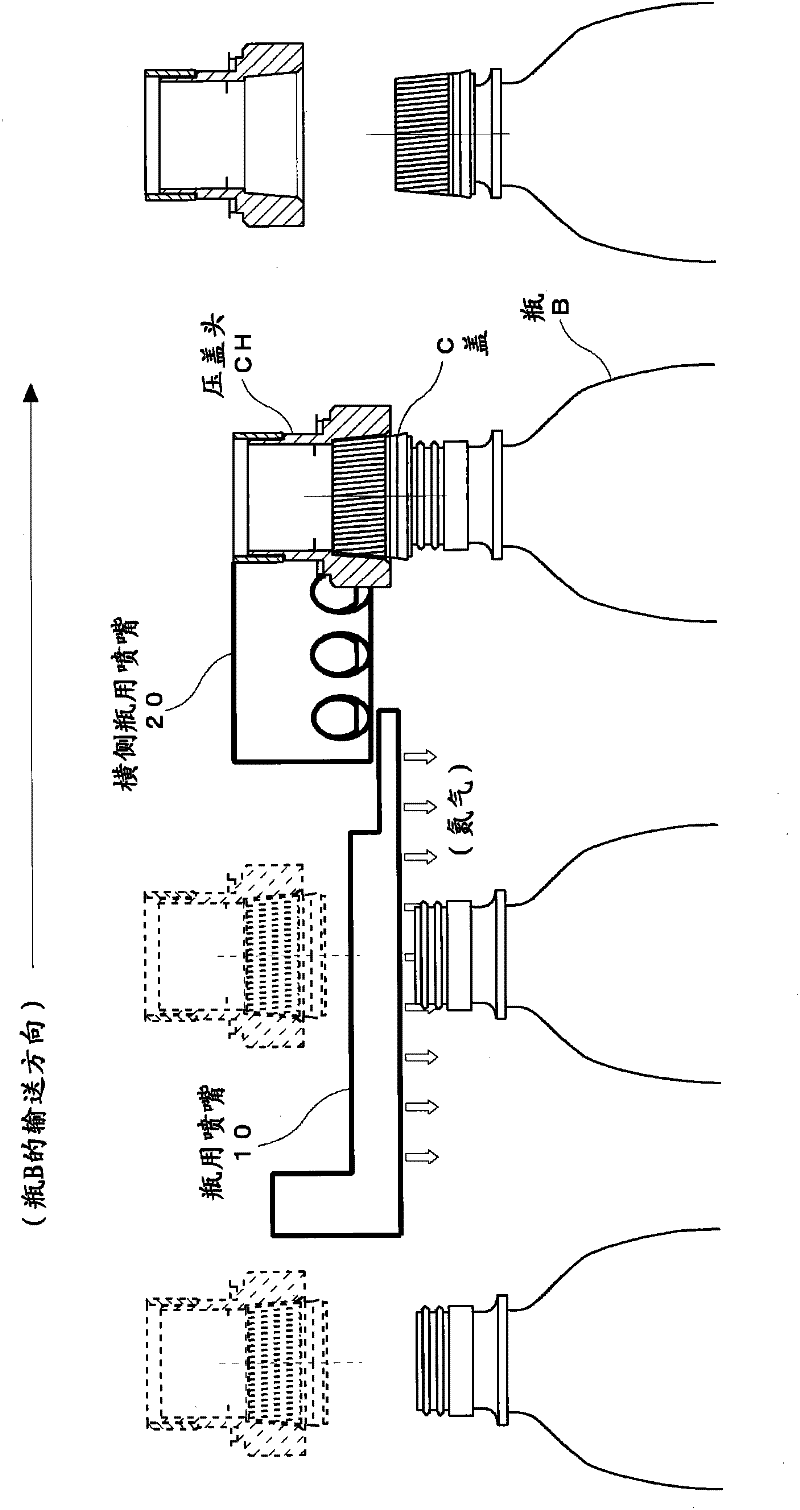

[0039] This PET bottle gas replacement device 100 is configured to include: a bottle nozzle 10 serving as a "first bottle nozzle" that flows nitrogen gas from above within a range that does not interfere with the capping head CH (not shown). The head space of the mouth of bottle B; the lateral bottle nozzle 20 as the "second bottle nozzle", after the gas replacement by the bottle nozzle 10 and immediately before the cap C and the mouth of the bottle B are fitted, the horizontal side The side bottle nozzle 20 allows nitrogen gas to flow into the head space of the mouth of bottle B from obliquely above; Inflow into the inside of the cap C; and the lateral side cap nozzle 40 as the "second cap no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com