Backing stage pressure reducers

A pressure reducer and pre-stage technology, which is applied in the direction of machines/engines, oil supply devices, internal combustion piston engines, etc., can solve the problem that the engine emission index is difficult to improve, and achieve the effect of improving the emission index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

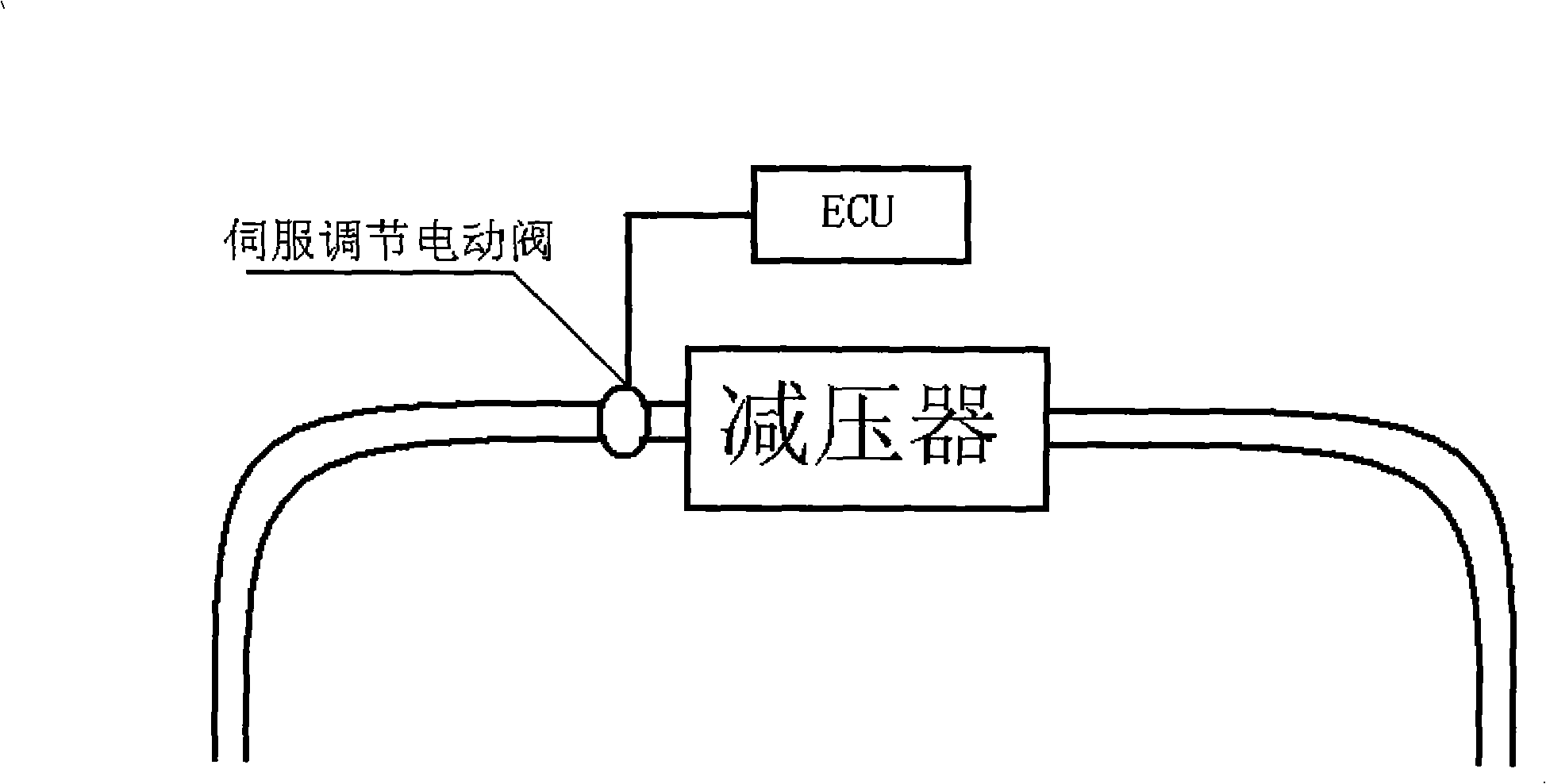

[0011] see figure 1 , the pre-stage pressure reducer, which includes at least two stages of decompression chambers and back pressure chambers, each stage of decompression chamber and back pressure chamber is separated by a diaphragm, and each stage of decompression chamber is provided with a valve seat. At least one side of the air inlet of the valve seat is provided with a servo-regulated electric valve, and the side of the air inlet of the valve seat between the decompression chamber and the back pressure chamber is provided with a servo-regulated electric valve, and the servo-regulated electric valve is controlled by the ECU (electrically controlled center) control.

[0012] The ECU (Electronic Control Center) collects air temperature inform...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com