Process and system applied to super purification treatment of domestic garbage incineration flue gas

A technology of domestic waste incineration and treatment process, which is applied in the field of ultra-clean treatment process and system of domestic waste incineration flue gas, can solve problems such as difficult to achieve, and achieve the effects of improving emission indicators, excellent adsorption, and efficient adsorption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

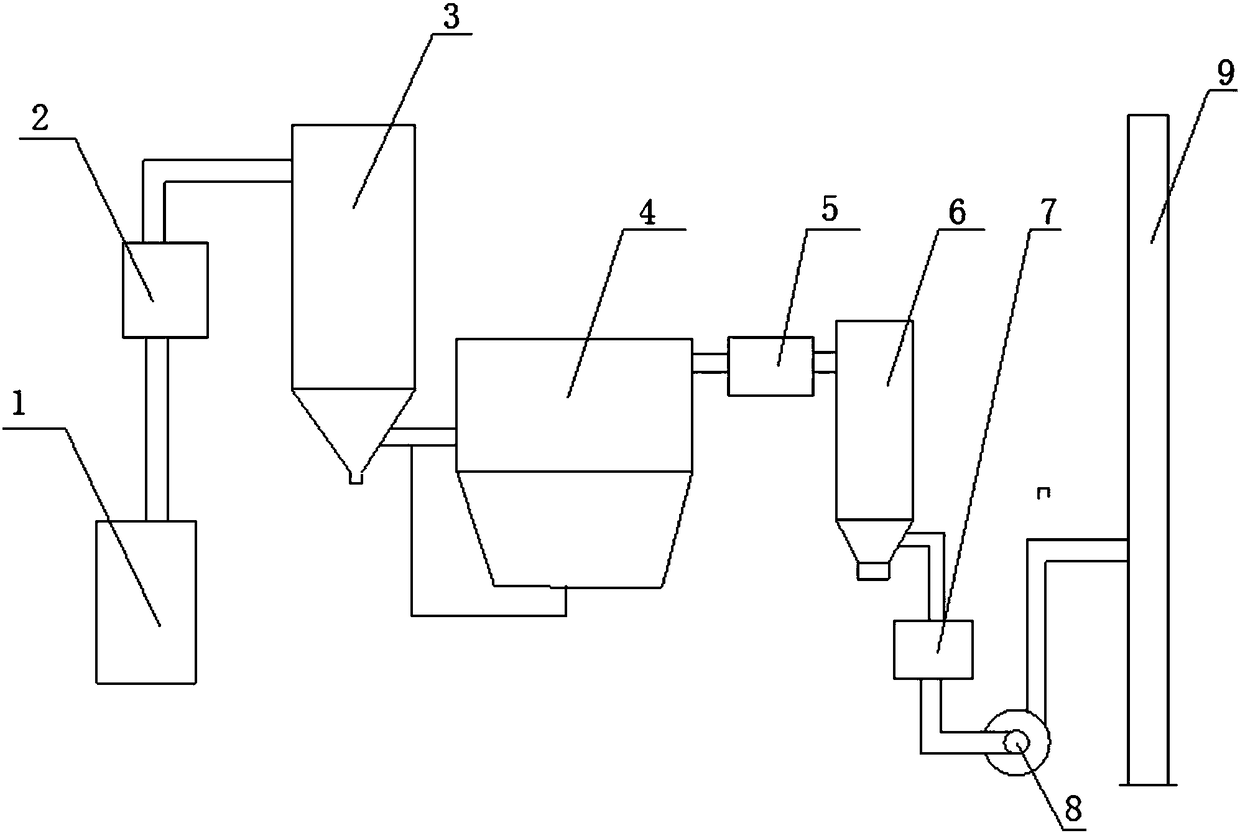

Image

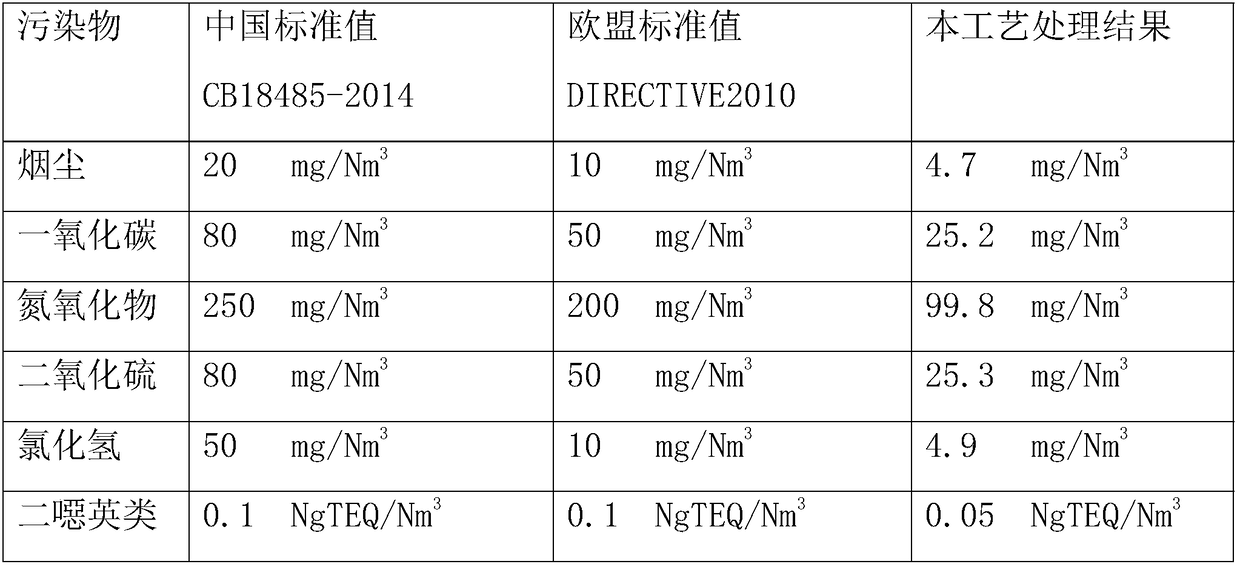

Examples

Embodiment 1

[0053] This embodiment provides a process for ultra-clean treatment of domestic waste incineration flue gas, including the following steps:

[0054] (1) Perform SNCR denitrification treatment on the flue gas in the waste heat boiler, wherein, in the SNCR treatment, ammonia water with a concentration of 40% is used as a reducing agent and sprayed into the high temperature area of the flue gas;

[0055] (2) Under the irradiation of ultraviolet light, the flue gas after the denitrification treatment is adsorbed by the composite adsorbent I;

[0056] (3) The flue gas after the adsorption treatment is sequentially subjected to semi-dry desulfurization treatment and bag dust removal treatment, wherein the semi-dry method is a rotary spray method;

[0057] (4) Add ozone to the flue gas after dedusting, the molar ratio of the amount of ozone added to the nitrogen oxides in the flue gas is 1:0.8, to obtain a mixed gas, and then use a 5% concentration of sodium hydroxide solution to t...

Embodiment 2

[0075] This embodiment provides a process for ultra-clean treatment of domestic waste incineration flue gas, including the following steps:

[0076] (1) Perform SNCR denitrification treatment on the flue gas in the waste heat boiler, wherein 40% concentration of urea is used as the reducing agent in the SNCR treatment and sprayed into the high temperature area of the flue gas;

[0077] (2) Under the irradiation of ultraviolet light, the flue gas after the denitrification treatment is adsorbed by the composite adsorbent I;

[0078] (3) The flue gas after the adsorption treatment is sequentially subjected to semi-dry desulfurization treatment and bag dust removal treatment, wherein the semi-dry method is a rotary spray method;

[0079] (4) Add ozone to the flue gas after dust removal, the molar ratio of the amount of ozone added to the nitrogen oxides in the flue gas is 1:0.5, to obtain a mixed gas, and then use 5% concentration of sodium hydroxide solution to treat the mixed ...

Embodiment 3

[0091] This embodiment provides a process for ultra-clean treatment of domestic waste incineration flue gas, including the following steps:

[0092] (1) Perform SNCR denitrification treatment on the flue gas in the waste heat boiler, wherein, in the SNCR treatment, ammonia water with a concentration of 40% is used as a reducing agent and sprayed into the high temperature area of the flue gas;

[0093] (2) Under the irradiation of ultraviolet light, the flue gas after the denitrification treatment is adsorbed by the composite adsorbent I;

[0094] (3) The flue gas after the adsorption treatment is sequentially subjected to semi-dry desulfurization treatment and bag dust removal treatment, wherein the semi-dry method is a rotary spray method;

[0095] (4) Add ozone to the flue gas after dedusting, the molar ratio of the amount of ozone added to the nitrogen oxides in the flue gas is 1:0.8, to obtain a mixed gas, and then use a 5% concentration of sodium hydroxide solution to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com