Flue gas ultra-clean treatment system

A treatment system and ultra-clean technology, applied in the separation of dispersed particles, chemical instruments and methods, and dispersed particle filtration, etc., can solve the problems of reducing the speed of flue gas, that is, filtering wind speed, large equipment volume, and high investment cost, so as to improve dust removal efficiency. and effect, improve the flue gas emission index, and reduce the cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

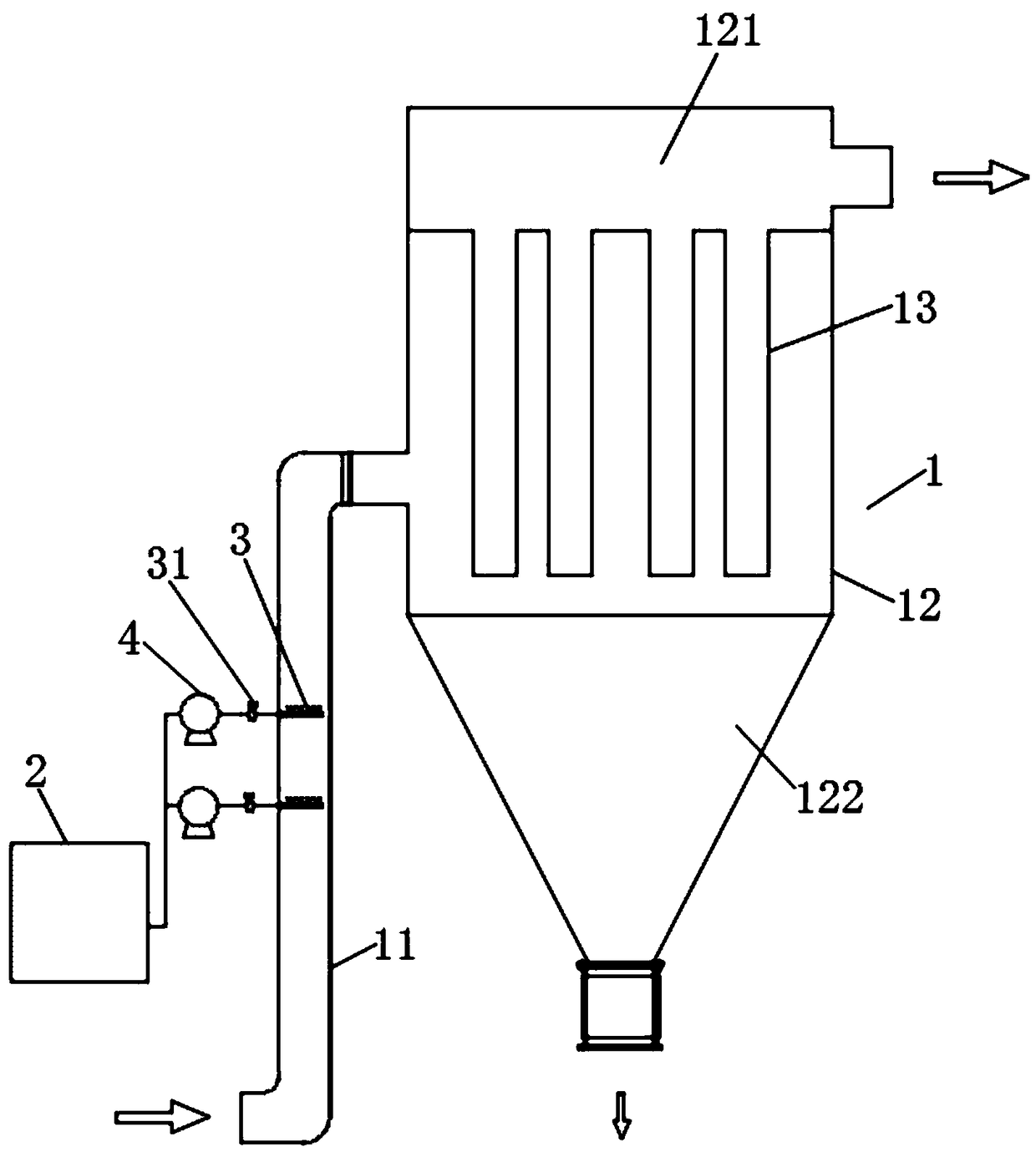

[0031] Example: such as figure 1 As shown, the flue gas ultra-clean treatment system of this embodiment includes a bag filter 1, an agglomerating agent solution liquid source 2 and an atomizing spray device 3;

[0032] The above-mentioned bag filter 1 has an inlet flue 11, and the above-mentioned atomizing spray device 3 is installed in the above-mentioned inlet flue 11;

[0033] The above-mentioned atomizing spray device 3 communicates with the above-mentioned agglomerating agent solution source 2 through a conveying device 4 .

[0034] During use, the dust enters the inlet flue 11, and at the same time, the conveying device 4 transports the agglomerating agent solution to the atomizing spray device 3, and atomizes and sprays the dust in the inlet flue 11, so that the agglomerating agent is fully mixed with the inlet flue. The smoke and dust in 11 are in contact, so that the small particles of smoke and dust are chemically agglomerated into large particles under the action o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com