Efficient and energy-saving boiler for plasma water decomposition hydrogen production

A high-efficiency, energy-saving, plasma technology, applied in hydrogen production, sustainable manufacturing/processing, chemical industry, etc., can solve problems such as high energy consumption and low efficiency, achieve improved thermal efficiency and emission targets, broad market prospects, and economical The effect of electricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

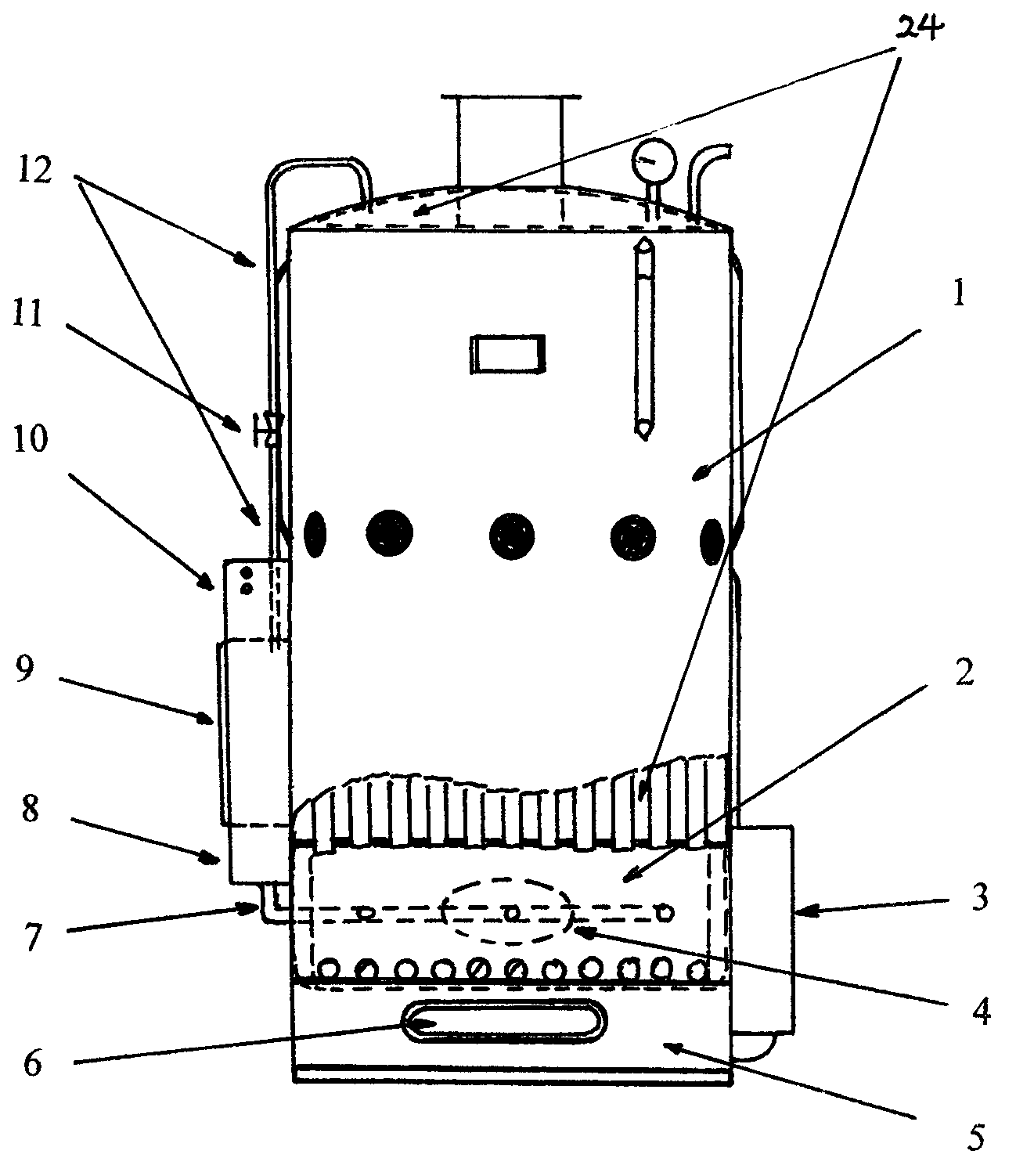

[0019] figure 1 In the shown embodiment, fan (3), slag chamber (5), slag door (6), charging door (4), flame arrester (8), low temperature plasma Generator (9), high-frequency high-voltage power supply (10), steam switch (11), steam pipeline (12), design and install injection pipe (7) in boiler furnace (2). The high-frequency high-voltage power supply (10) is connected with the low-temperature plasma generator (9), and the low-temperature plasma generator (9) is connected with the flame arrester (8) and the steam pipeline (12), and the steam pipeline (12) is connected with the steam switch ( 11), the steam switch (11) is connected with the steam pipe (12), and the steam pipe (12) is connected with the top of the furnace (24), and the flame arrester (8) is connected with the injection pipe (7), and the injection pipe (7) The other end is installed in the boiler furnace (2).

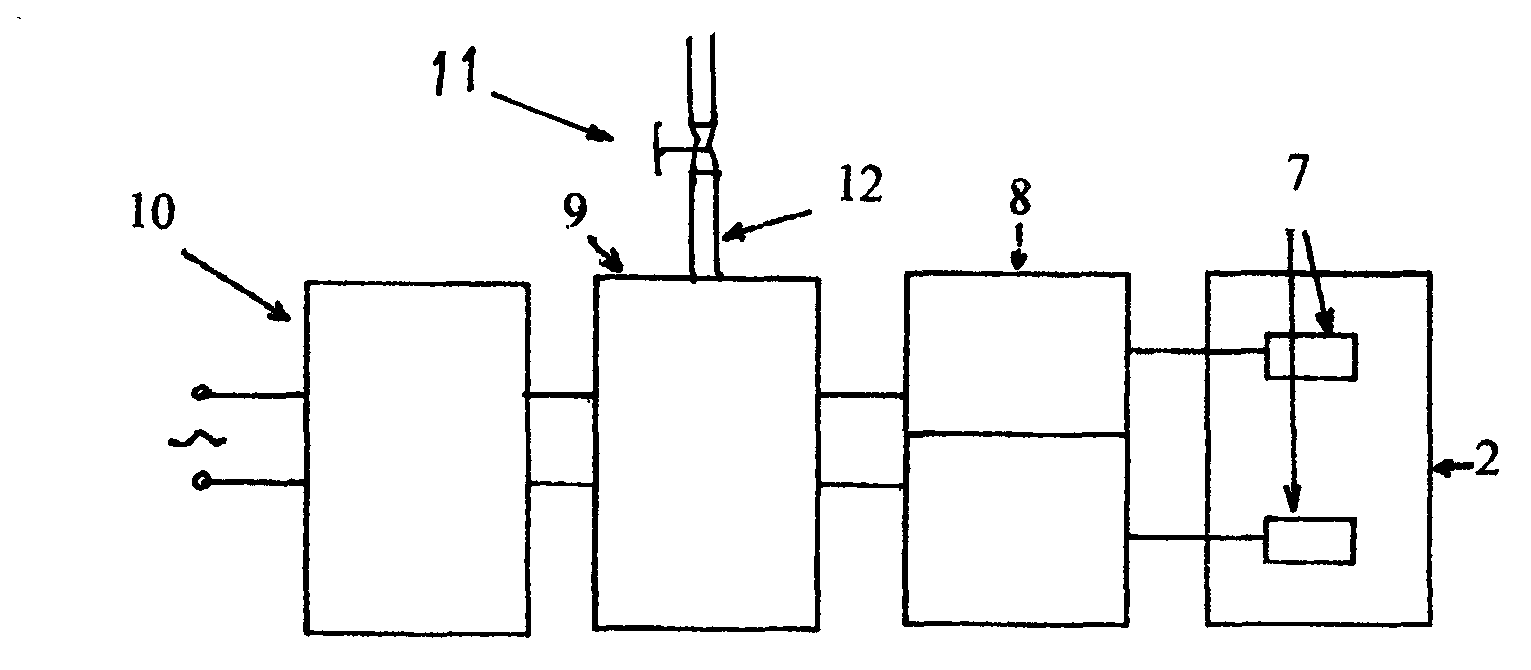

[0020] figure 2 In the shown embodiment, on the high-frequency high-voltage power supply (10), an AC...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com