Method for desulfurizing exhaust gas

A technology for desulfurization of waste gas and waste gas, which is applied in separation methods, chemical instruments and methods, lighting and heating equipment, etc., can solve the problems of high equipment investment, operation cost and energy consumption, avoid equipment scaling and fouling, and achieve good absorption effect. , the effect of reducing SO2 emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A method for exhaust gas desulfurization, including heat exchange, absorption, oxidation and circulation parts.

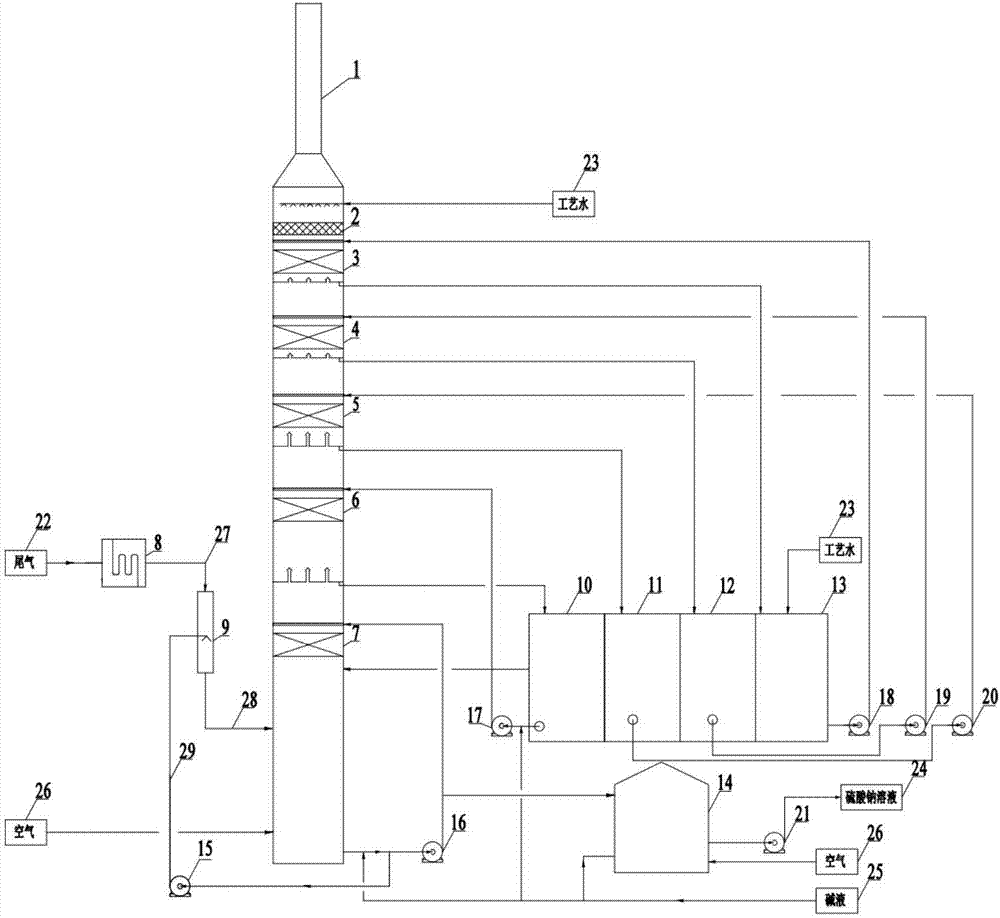

[0027] figure 1 In , the direction of the arrow indicates the flow direction of gas or liquid. like figure 1 As shown, the heat exchange is mainly carried out in the flue gas heat exchanger 8 and the quenching section 9 . High SO from sulfur recovery 2 Concentrated high-temperature waste gas 22 first passes through the flue gas heat exchanger 8 for heat exchange, and the waste gas is reduced from 300°C to 220°C. The exhaust gas 27 after cooling enters from the top of the quenching section 9, which is a vertical spray pipe, and the absorption liquid at the bottom of the tower is transported to the quenching section 9 by the quenching circulating pump 15 as the quenching circulating liquid 29 for spraying, and the gas-liquid two-phase Countercurrent contact, adiabatic saturation cooling of high-temperature exhaust gas, the exhaust gas is absorbed by adiaba...

Embodiment 2

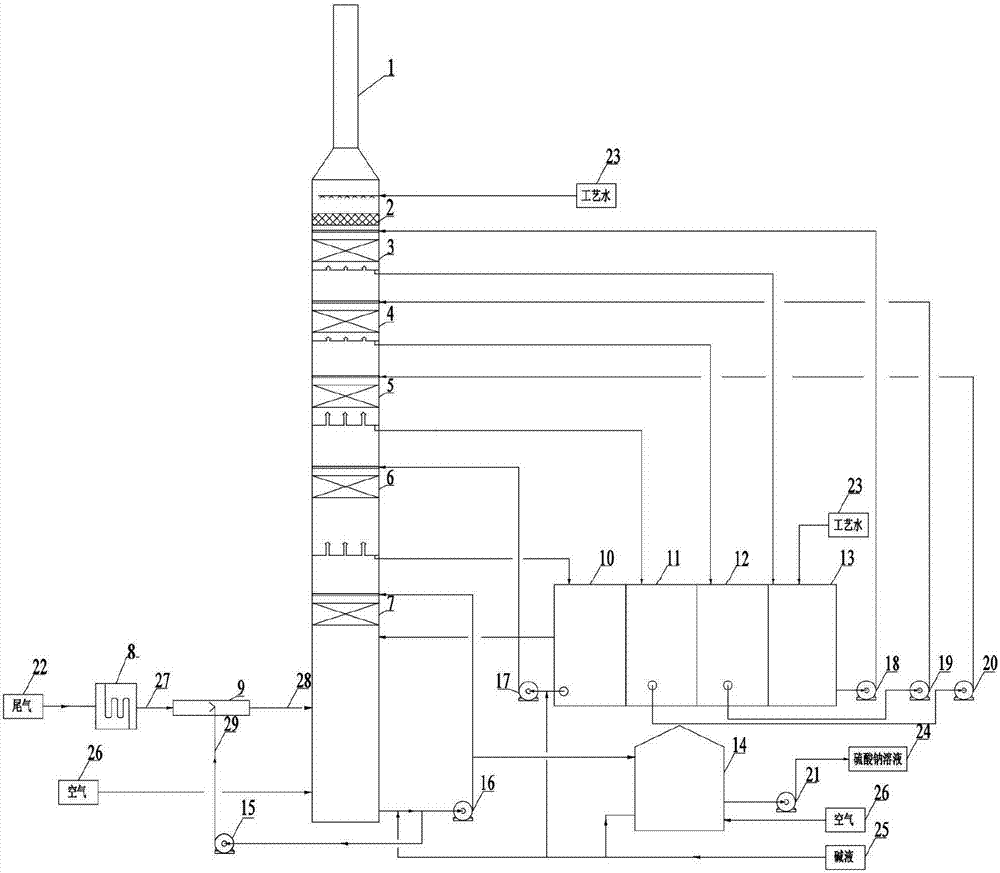

[0045] like figure 2 As shown, in addition to replacing the vertical spray pipe as the quenching pipe 9 with a horizontal spraying pipe in embodiment 1, the gas-liquid in the quenching pipe 9 is countercurrently contacted, and the absorption liquid circulation tank 10, the primary water circulation tank 11, Except that the secondary water circulation tank 12 and the tertiary water circulation tank 13 are arranged separately, the rest is the same as that of Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com