Green and low-carbon intelligent group control method and system for oil extraction system

An oil production system and intelligent control unit technology, applied in control systems, energy industry, production fluids, etc., can solve problems such as failure to take into account the limitations of the well site power grid, achieve collaborative optimization of production goals, improve utilization, and improve system safety sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

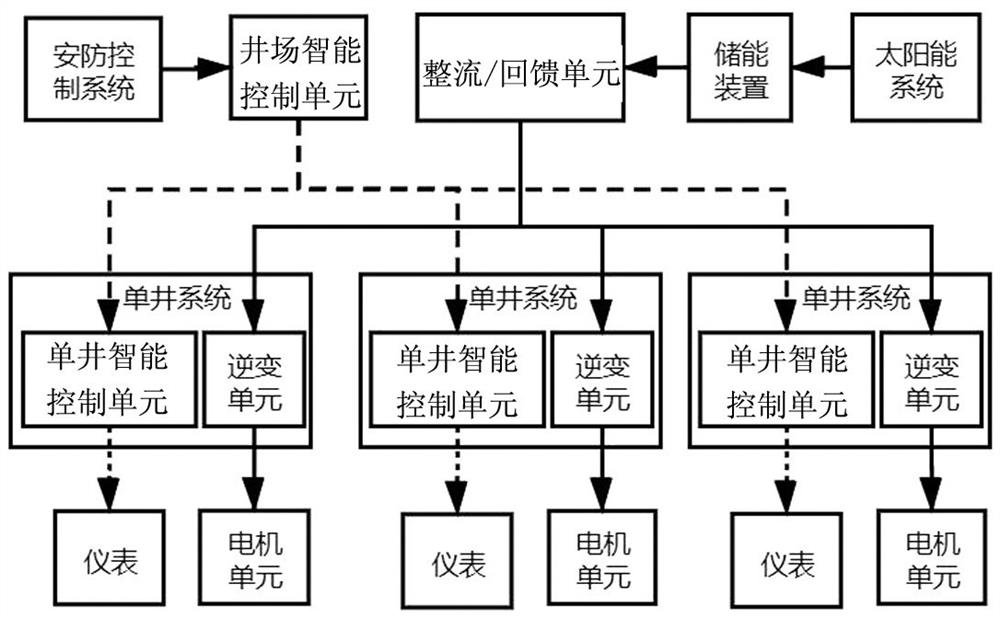

[0064] This embodiment discloses a green and low-carbon intelligent group control system for an oil production system, such as figure 1 As shown in the figure, it includes a well site intelligent control unit, a single well intelligent control unit and a security control system; the single well intelligent control unit includes multiple ones, which are arranged at each individual oil well; the security control system is the same as the aforementioned well site. The intelligent control units are electrically connected; the single-well intelligent control units are all electrically connected to the well site intelligent control unit; the intelligent group control system in this embodiment further includes a common DC bus device for oil wells, which consists of a rectifier / feedback unit, a common DC The busbar and the inverter unit are composed; the rectifier / feedback unit can be divided into the energy feedback method through the autotransformer. The energy feedback through the a...

Embodiment 2

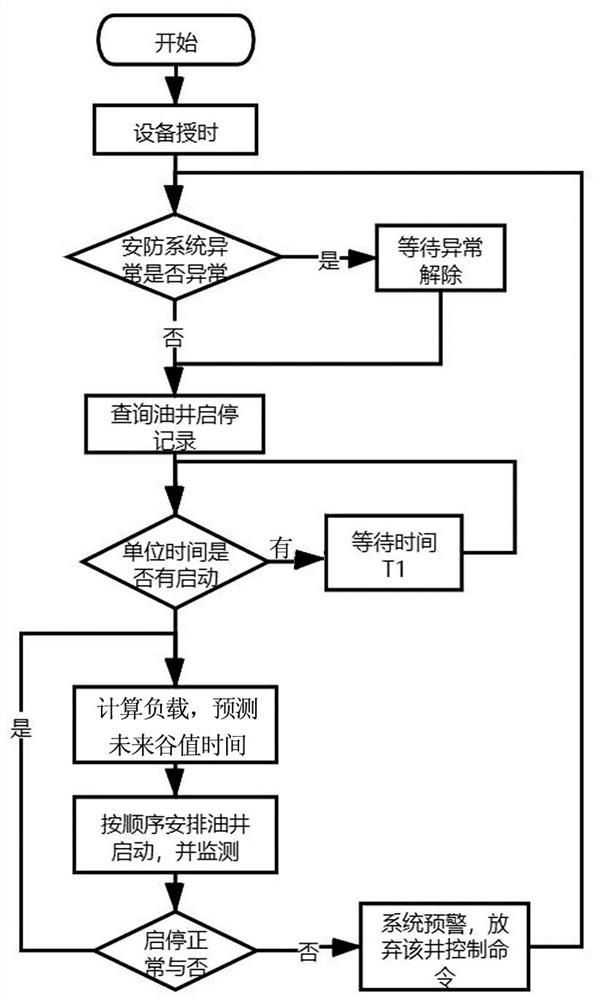

[0099] Based on the green and low-carbon intelligent group control system of the oil production system described in the first embodiment, the embodiment of the present disclosure discloses a green and low-carbon intelligent group control method of the oil production system, which includes the following steps of peak shifting optimization of oil wells:

[0100] 1) Analyze the average liquid production Q of the current oil well 0 ;

[0101] 2) Collect the energy consumption curve of the current well site equipment, and obtain the load rate F of the oil well motor in the system i , the pump efficiency η i ;

[0102] 3) Select the pump efficiency η among them i >η maxThe oil well, analyze and calculate its maximum safe frequency range, the frequency N corresponding to the high-efficiency load of the motor i to produce, where n max is the set maximum pump efficiency, η min is the set minimum pump efficiency;

[0103] 4) Select the pump efficiency η among them min i max the...

Embodiment 3

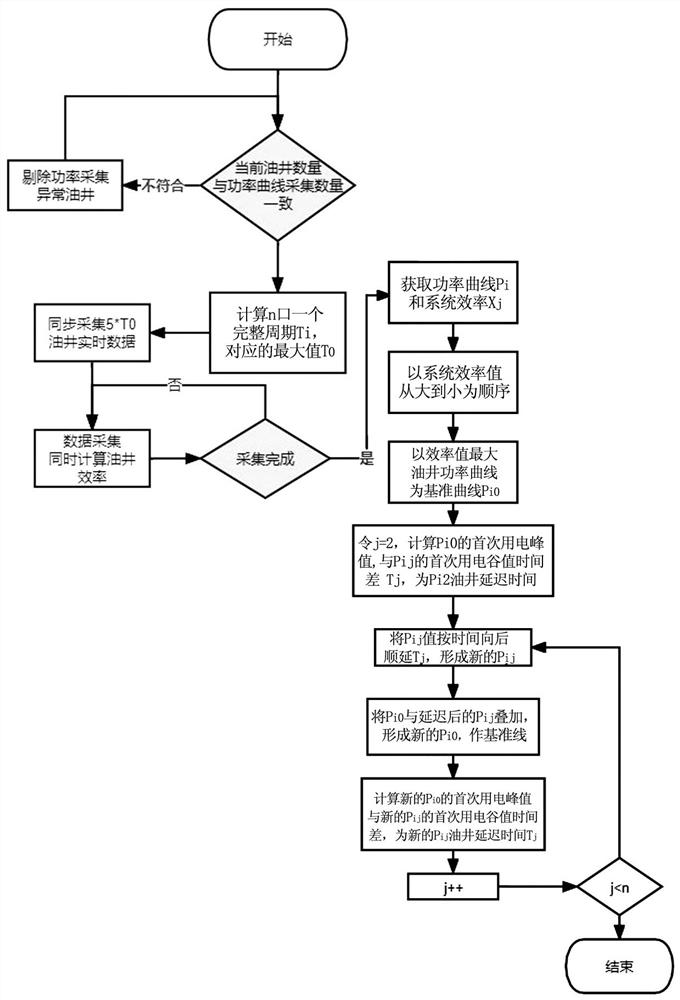

[0106] Based on the green and low-carbon intelligent group control system of the oil production system described in the first embodiment, the embodiments of the present disclosure disclose a green and low-carbon intelligent group control method of the oil production system, such as image 3 shown, including the following steps for off-peak operation of wells:

[0107] 1) Select the number n of oil wells with normal power acquisition;

[0108] 2) Calculate a complete cycle T of n ports i , the corresponding maximum value T 0 , set to T=5T 0 Carry out oil well data acquisition and obtain power curve P i and system efficiency X j (j=1,2,...,n);

[0109] 3) Wait for the acquisition to be completed, and calculate the delay time of oil well operation in the order of the system efficiency value from large to small;

[0110] 4) For the first time, the maximum oil well power curve of the efficiency value is used as the reference curve P i0 ; let j = 2;

[0111] 5) Calculate P ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com