Communicated composite inlet channel system for four-valve diesel engine

A diesel engine and intake port technology, which is applied in the field of four-valve diesel engine intake ports, can solve the problems affecting the mixing effect of mixed intake air and diesel oil and gas, shorten the mixing time and process of tangential air flow and spiral air flow, and achieve good oil and gas Mixing effect, little change in casting process, full combustion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

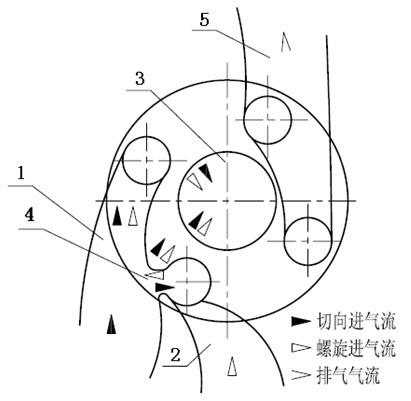

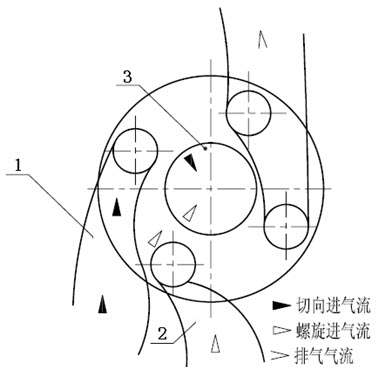

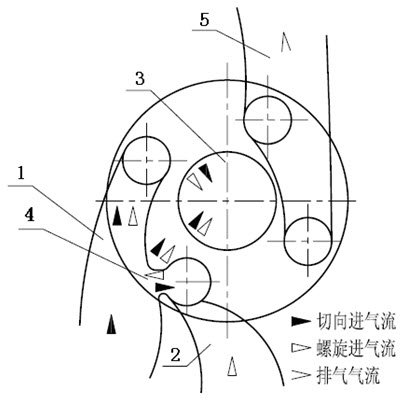

[0009] The structural principles of the present invention will be further described below in conjunction with the accompanying drawings and through embodiments. The four-valve diesel engine connected compound intake port system mainly includes a tangential intake port 1, a spiral intake port 2 and a cylinder 3. A connecting air inlet 4 is provided on the partition wall between the tangential air inlet 1 and the helical air inlet 2, so that the air flow in the two air inlets of the tangential air inlet 1 and the helical air inlet 2 is communicated. The entrance cross-sectional areas of the tangential air inlet 1 and the helical air inlet 2 are equal. The design of the connected air intake structure is also applicable to the intake port of the two-valve diesel engine.

[0010] The entrance cross-sectional area of the tangential air inlet 1 and the spiral air inlet 2 of the present embodiment is equal to 1496mm 2 , the communication port 4 is simultaneously cast on the partit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com