Cooling clothes

A technology for cooling clothing and clothing, applied in clothing, apparel, protective clothing, etc., can solve the problems of complex structure of cooling clothing, and achieve the effect of expanding the effective range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

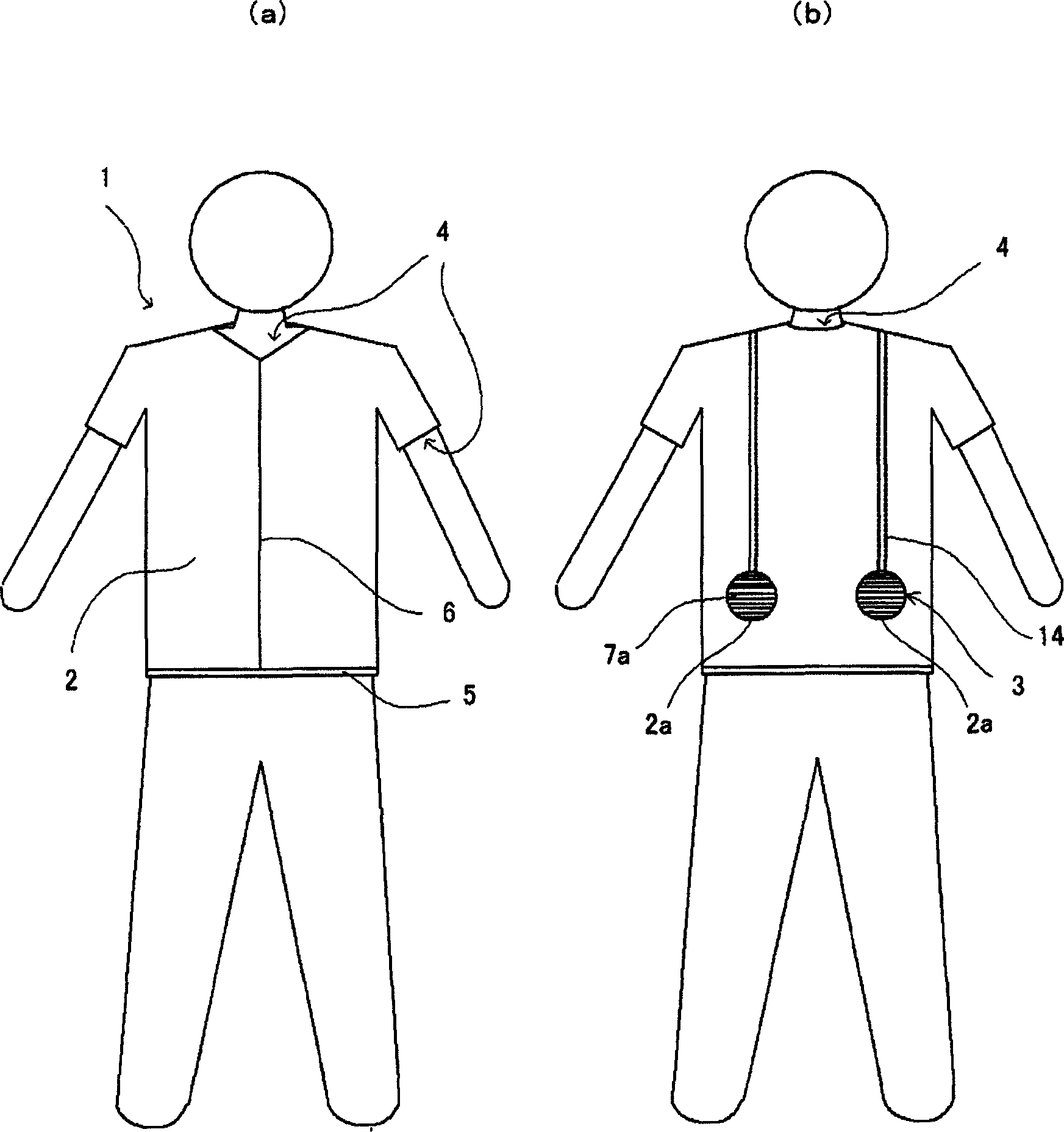

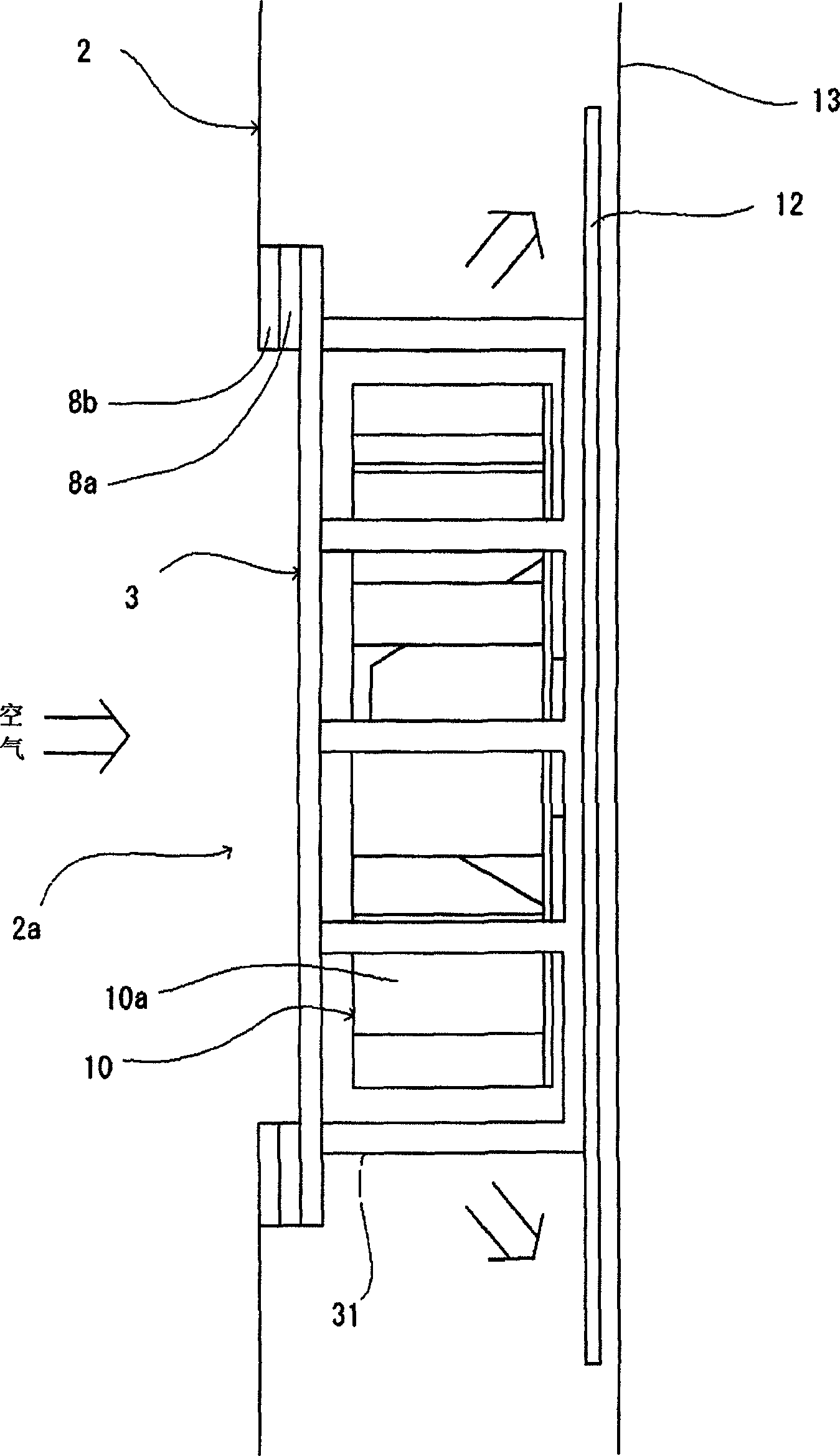

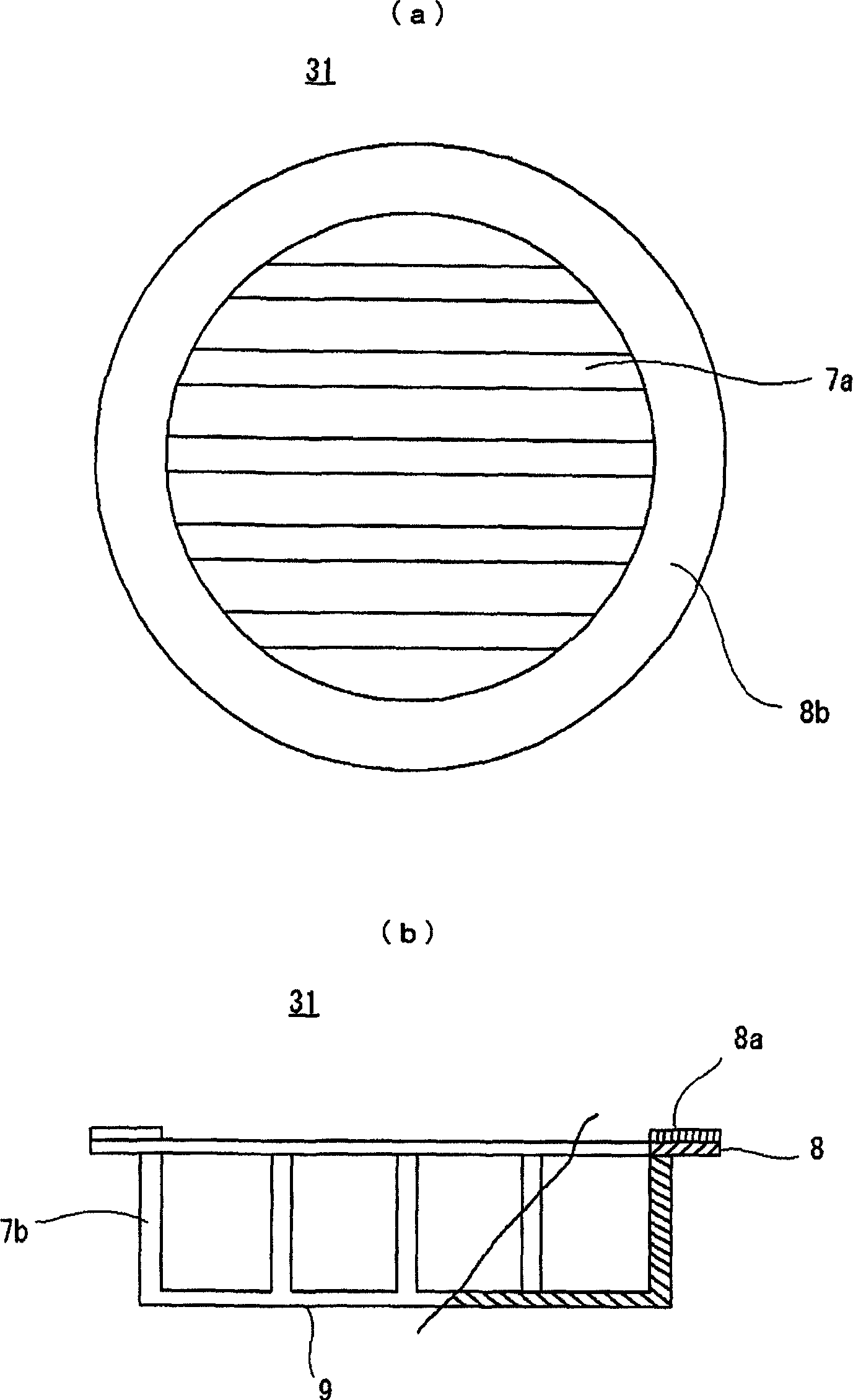

[0065] Hereinafter, the best mode for carrying out the present invention will be described with reference to the accompanying drawings. The first embodiment is an example in which the cooling suit of the present invention is applied to a half-sleeve top for work wear. figure 1 (a) is a schematic front view of the cooling suit according to the first embodiment of the present invention, and (b) is a schematic rear view thereof. like figure 1 As shown, the cooling suit 1 of the first embodiment includes: the garment 2 formed in the shape of a half-sleeve jacket, which has less air leakage and is also used as a flow guide cloth (the meaning of flow guide will be described later); The parallel wind generating device 3 on the left and right of the lower back is used for inhaling external air and generating an airflow parallel to the body between the clothing 2 and the underwear or the body; the air outlet 4 as an air outlet; the function formed on the clothing 2 An air suction por...

no. 2 approach

[0086]Next, a second embodiment of the present invention will be described with reference to the drawings. In the second embodiment, the present invention is applied to work clothes having a higher cooling capacity than the cooling clothes of the first embodiment. The air supply capacity of the second embodiment is double that of the first embodiment, ie 20m 3 / H or so. The main difference between the second embodiment and the first embodiment is that in the second embodiment, as the blade of the parallel wind generating device, a propeller is used instead of the impeller; A new air outlet part of the sheet; and a fixing unit, ie, a fixing belt, is provided to prevent the large fan from shaking due to body movements. Other structures are the same as those of the first embodiment. Therefore, in the second embodiment, the same reference numerals are attached to parts having the same functions as those of the first embodiment, and detailed descriptions thereof will be omitted....

no. 3 approach

[0095] Next, a third embodiment of the present invention will be described. The third embodiment differs from the first and second embodiments in that not only a fan but also a power supply (battery) and a lead wire are attached to the fixing belt. The other points are the same as those of the second embodiment. Therefore, in this embodiment, the same reference numerals are attached to parts having the same functions as those of the first and second embodiments, and detailed descriptions thereof will be omitted. Fig. 10(a) is a schematic view showing a state in which the fixing band 160 of the present embodiment is unfolded. The width of the fixing band 160 of the present embodiment is larger than the diameter of the fan 3 , and the two fans 3 , the lead wire 32 for power supply, and the power source 33 are detachably mounted thereon. Therefore, it can be said that the fixing belt 160 has removed the baffle (clothing) from the cooling suit. FIG. 2(b) is an enlarged schemati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com