Heating and refrigeration vortex type air source heat pump system

An air source heat pump, vortex technology, applied in the field of vortex air source heat pump systems, can solve the problems of increasing system complexity and manufacturing costs, only succumbing to thermal expansion valves, and system COP not being optimal , to achieve fast response and action speed, shortened defrosting time, and reduced complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

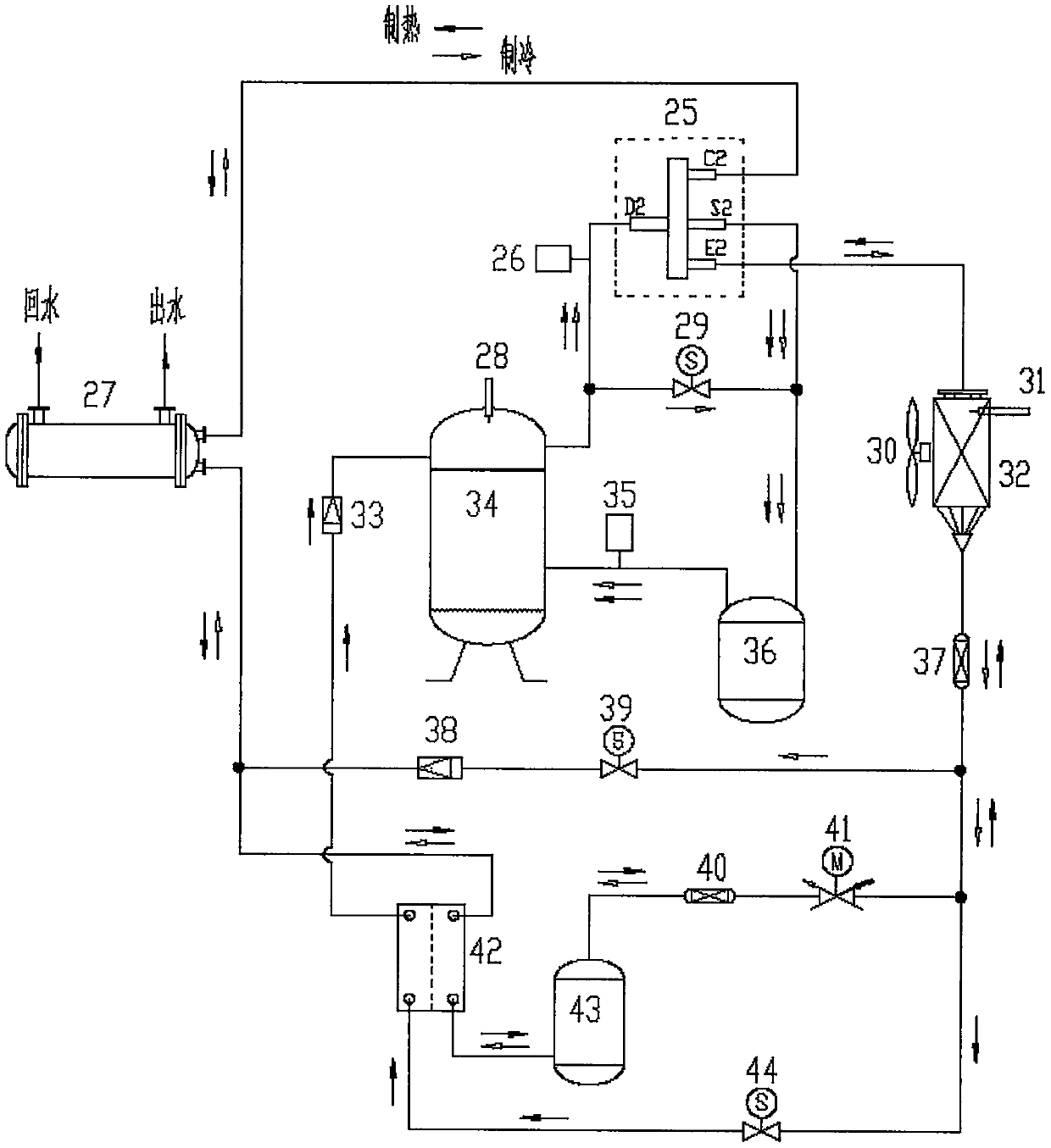

[0008]In the main heating (or cooling) circuit of the system, the exhaust port of the jet booster compressor B (34) is connected to the D2 pipe port of the four-way reversing valve B (25), and the high-pressure switch B ( 26). The C2 pipe mouth of the four-way reversing valve B (25) is connected with the air inlet when the water side shell and tube heat exchanger B (27) condenses. The liquid outlet of the water-side shell-and-tube heat exchanger B (27) when condensing is connected with the liquid inlet of the refrigerant subcooling chamber of the economizer B (42) when the system is heating. When the system is heating, the liquid outlet of the refrigerant subcooling chamber of the economizer B (42) is connected with the liquid inlet of the liquid storage tank B (43) when the system is heating. When the system is heating, the liquid outlet of the liquid storage tank B (43) is connected in series with the dry filter B (40), the electronic expansion valve (41), the pipeline filt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com