System and method for treating high-concentration organic waste liquid

A technology of organic waste liquid and treatment system, which is applied in the direction of combustion method, liquid fuel supply/distribution, lighting and heating equipment, etc. It can solve the problems of high operating cost, failure to achieve zero discharge, increase process cost, etc., and achieve the elimination of treatment process, reduced energy consumption, and short processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below with reference to the accompanying drawings and examples.

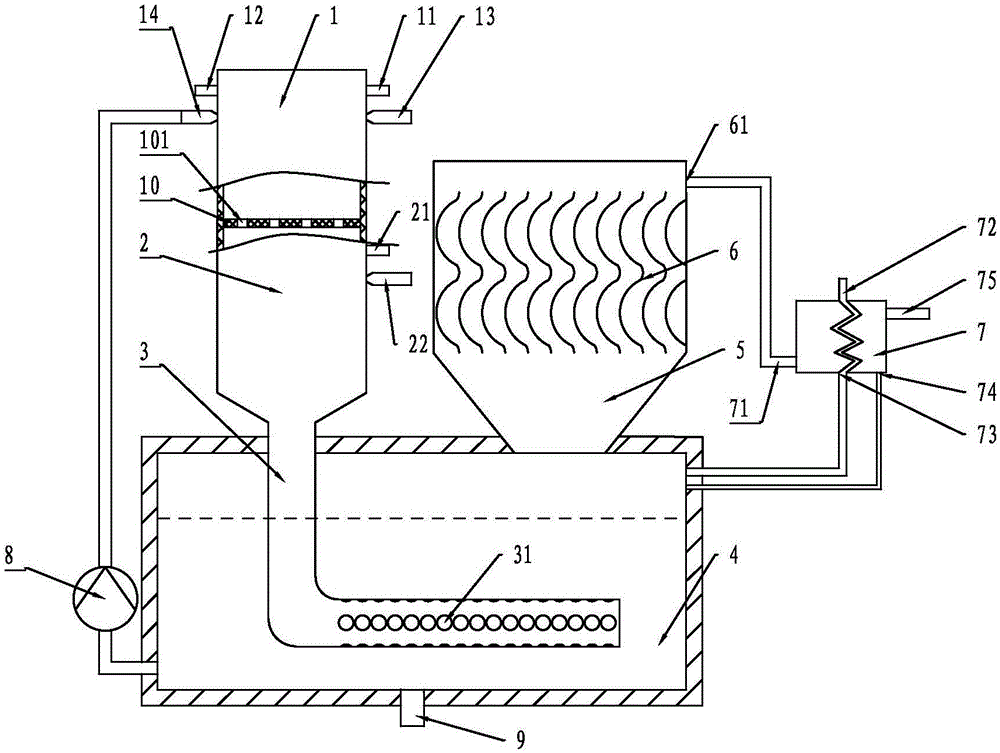

[0032] as attached figure 1As shown, the high-concentration organic waste liquid treatment system of the present invention includes a gasification chamber 1, a combustion chamber 2, a flue gas pipeline 3, a waste liquid pump 8, a waste liquid tank 4, a settling chamber 5, a defogging baffle 6, and a condenser 7. The gasification chamber is located on the top of the combustion chamber, and the two are integrally formed. A baffle 10 is installed between the gasification chamber 1 and the combustion chamber 2. A plurality of through holes 101 are arranged on the baffle. The baffle 10 is made of non-metallic refractory materials such as Made of refractory bricks.

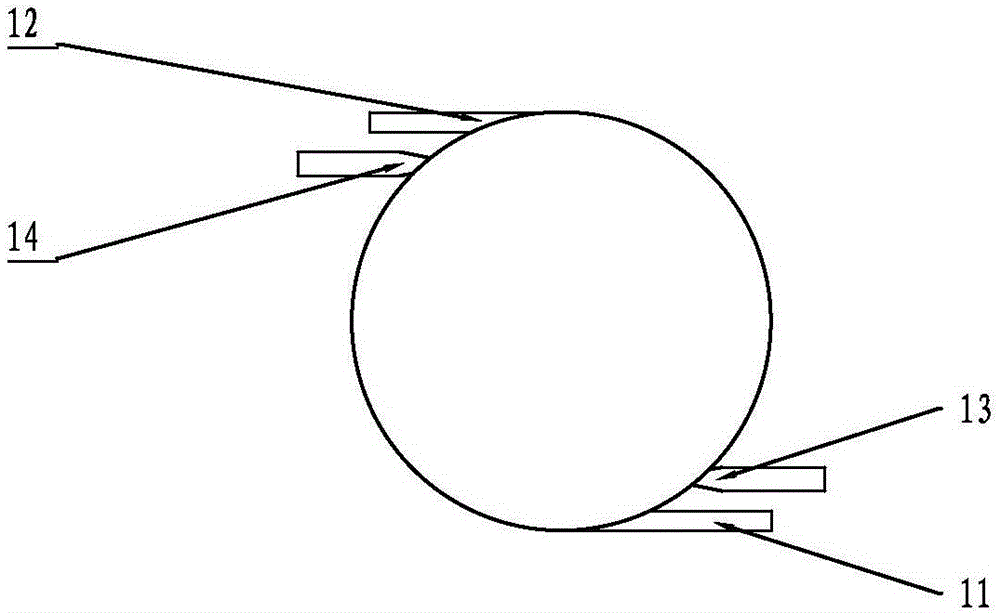

[0033] combine figure 2 As shown, the cross section of the gasification chamber 1 is circular, and the upper part of the side wall of the gasification chamber 1 is evenly provided with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com