Color printing printing ink supply device

A technology for feeding device and ink, which is applied in mixers with rotary stirring devices, transportation and packaging, mixers, etc. The effect of ink settling and avoiding ink breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The following is further described in detail through specific implementation methods:

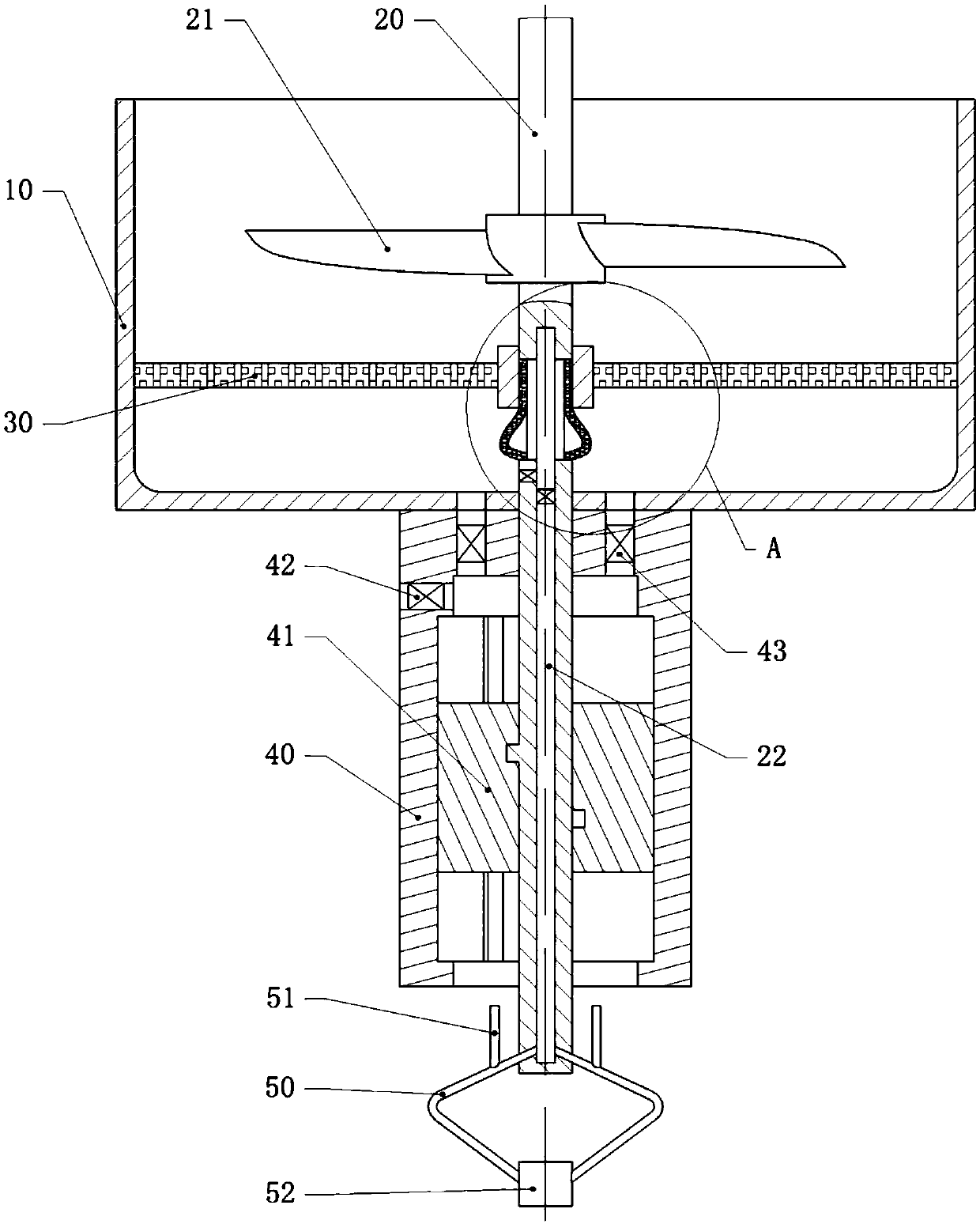

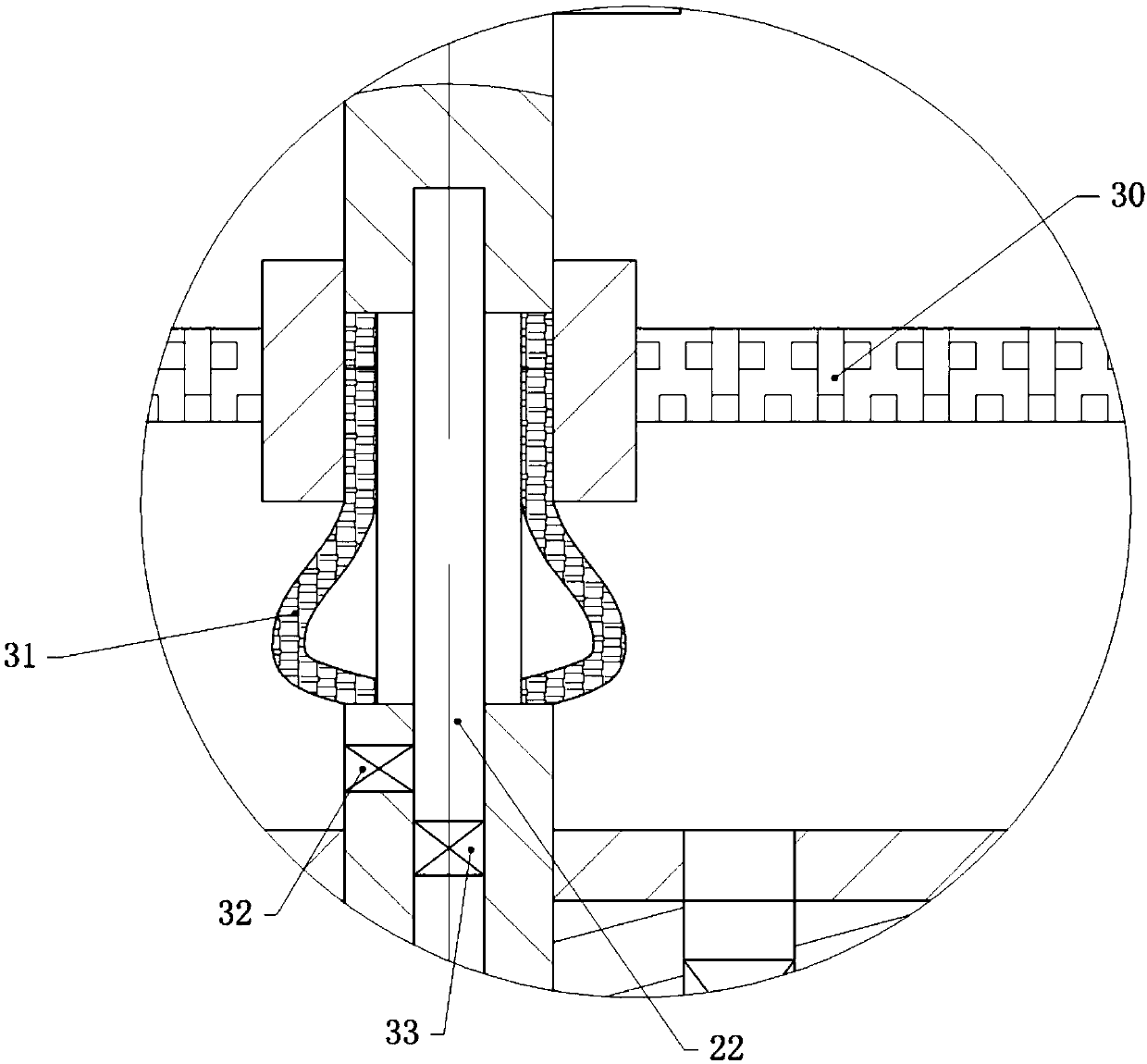

[0017] The reference signs in the accompanying drawings of the description include: ink tank 10, stirring shaft 20, stirring blade 21, ink channel 22, mesh plate 30, rubber bag 31, liquid inlet check valve 32, liquid discharge check valve 33, cylinder Body 40, piston 41, intake check valve 42, exhaust check valve 43, elbow 50, exhaust pipe 51, nozzle 52.

[0018] The embodiment is basically as attached figure 1 , figure 2 Shown:

[0019] The color printing ink supply device includes an ink tank 10, an agitating shaft 20 and a motor. The agitating shaft 20 is driven to rotate by the motor. The agitating shaft 20 penetrates the ink tank 10 and extends downward in the vertical direction. The upper end is connected to drive the stirring shaft 20 to rotate. The upper end of stirring shaft 20 is provided with stirring blade 21 and net plate 30, and stirring blade 21 is positioned at t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com