Exhaust passage control valve

a control valve and exhaust passage technology, applied in the direction of functional valve types, machines/engines, transportation and packaging, etc., can solve the problems of vibration between the opening state and closing state of the valve element, high cost, and large spring siz

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

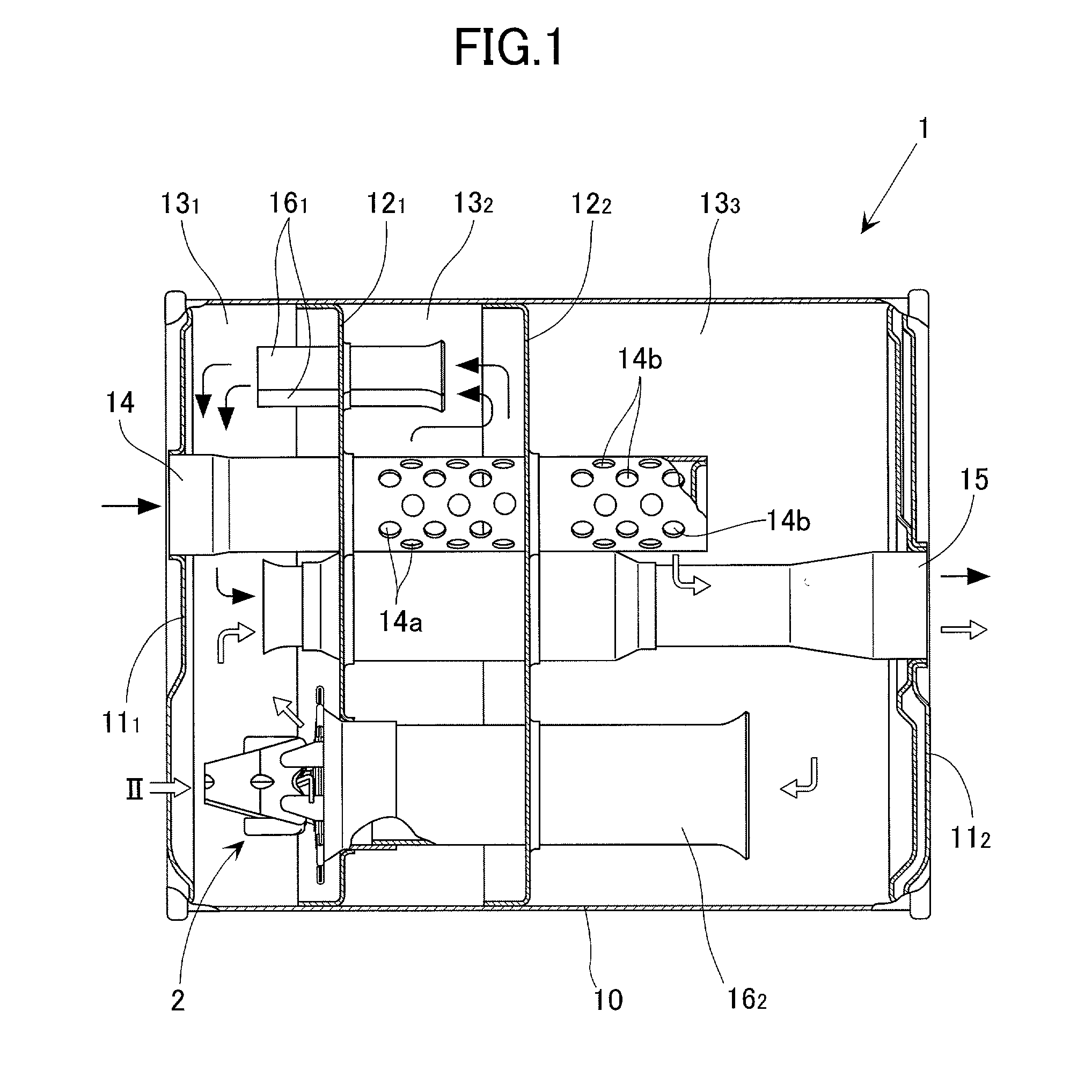

[0020] With reference to FIG. 1, numeral 1 denotes a silencer which is interposed in an exhaust system of an engine. The silencer 1 is made up of a cylindrical shell 10 and end walls 11.sub.1, 11.sub.2 which close one end and the other end, respectively, of the shell 10. Inside a main body of the silencer 1, there are provided a pair of first and second separators (partition walls) 12.sub.1, 12.sub.2 to thereby separate the space inside the main body of the silencer 1 into the following chambers: i.e., a first silencer chamber 13.sub.1 between the end wall 11.sub.1 on said one end and the first separator 12.sub.1; a second silencer chamber 13.sub.2 between the first separator 12.sub.1 and the second separator 12.sub.2; and a third silencer chamber 13.sub.3 between the second separator 12.sub.2 and the other end wall 11.sub.2. The silencer 1 is further provided with: an exhaust inlet pipe 14 which extends from said one end wall 11.sub.1 to the third silencer chamber 13.sub.3 through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com