Processing method of Hainan white pine nuts

A processing method and technology of sunflower pine, applied in the field of food processing, can solve the problems of low efficiency, no provision, complicated operation, etc., and achieve the effects of improving the use efficiency, increasing the extrusion force, and being convenient to operate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below by means of specific embodiments:

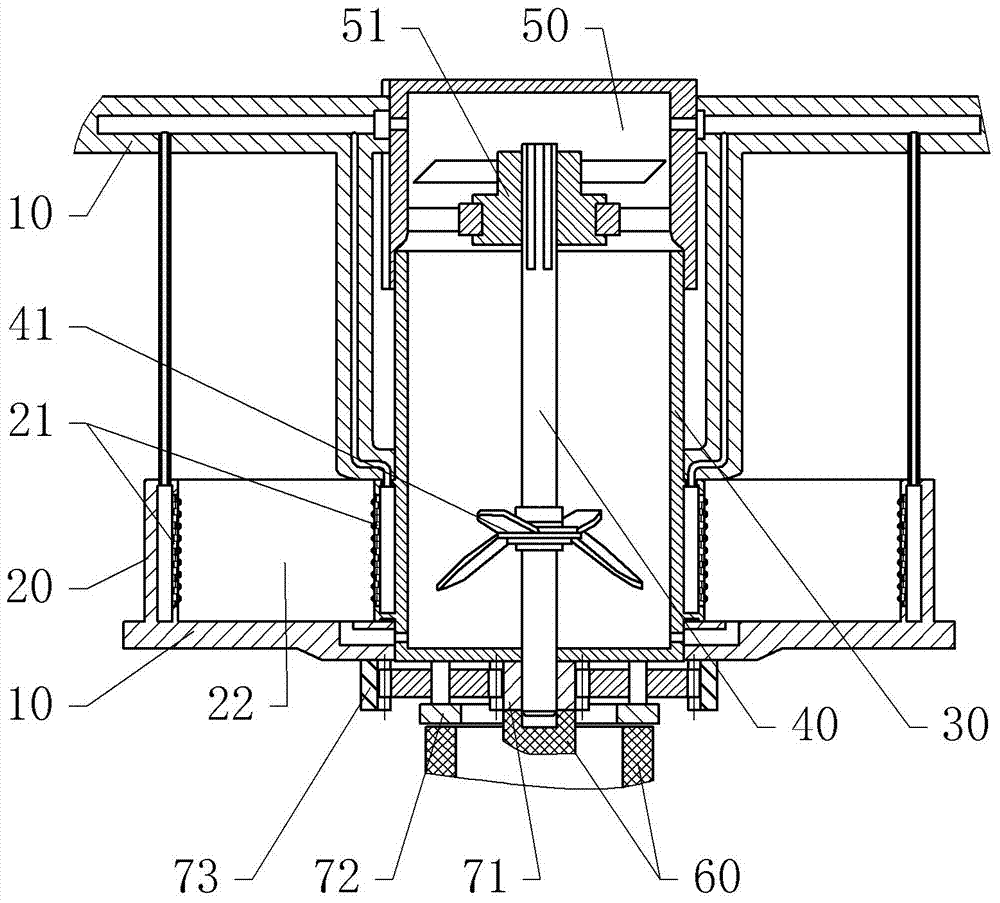

[0029] The reference signs in the accompanying drawings of the specification include: base 10, outer cylinder 20, flexible layer 21, microdermabrasion chamber 22, inner cylinder 30, crushing material shaft 40, crushing material blade 41, booster cylinder 50, turbine 51, clutch 60, sun gear 71, planet carrier 72, ring gear 73.

[0030] The processing method of the sunflower pine nut of the present embodiment adopts a kind of pine nut skin grinding device to process the pine nut, as figure 1 As shown, the pine nut microdermabrasion device includes a base, an outer cylinder, an inner cylinder, a crushing shaft and a planetary gear transmission mechanism. The outer cylinder, the inner cylinder and the crushing shaft are arranged in sequence from the outside to the inside, and the outer cylinder is fixed on the base. Both the inner cylinder and the scrap shaft are rotatably c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com