Method for preparing kitchen waste anaerobic biogas residue biochar through ultrasonic-assisted hydrothermal carbonization

A technology of hydrothermal carbonization and kitchen waste, which is applied in the field of regeneration treatment and resource utilization of biogas residue and sludge, can solve problems such as carbonization of organic materials, and achieve the effects of increased moisture content, simple process, and easy process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

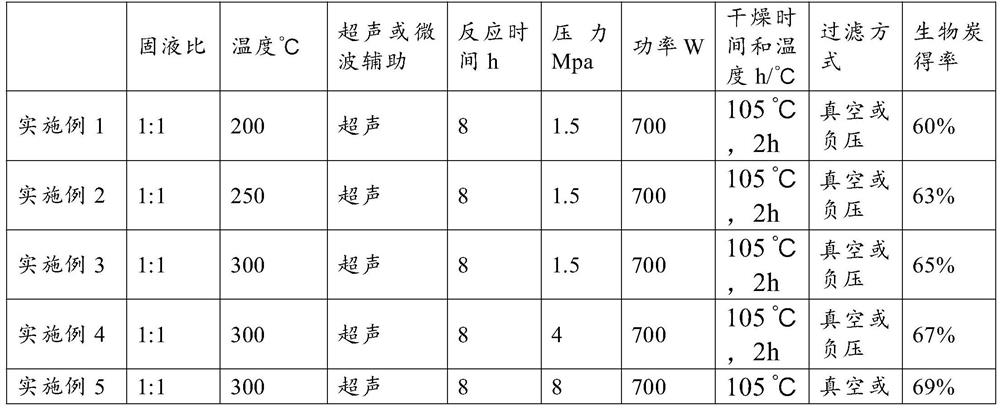

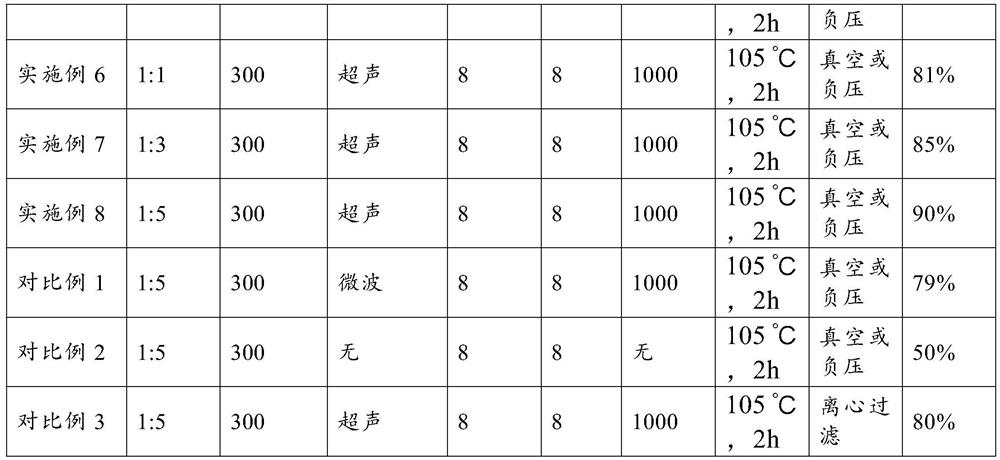

Embodiment 1

[0029] The kitchen waste anaerobic biogas residue and water are introduced into the ultrasonic-assisted hydrothermal carbonization reactor according to the solid-to-liquid ratio of 1:1 to react, the filling degree is 70%, the hydrothermal temperature is controlled at 200°C, and the internal pressure of the reactor is 1.5Mpa. Time 8h, ultrasonic power 700W, after the reaction, the product was cooled, vacuum or negative pressure filtered, dried (105°C, 2h), crushed and separated, and the yield of biochar was 60%.

Embodiment 2

[0031] The anaerobic biogas residue of kitchen waste and water are introduced into the ultrasonic-assisted hydrothermal carbonization reactor according to the solid-to-liquid ratio of 1:1 for reaction. The filling degree is 70%. Time 8h, ultrasonic power 700W, after the reaction, the product was cooled, vacuum or negative pressure filtered, dried (105°C, 2h), crushed and separated, and the yield of biochar was 63%.

Embodiment 3

[0033] The anaerobic biogas residue of kitchen waste and water are introduced into the ultrasonic-assisted hydrothermal carbonization reactor according to the solid-to-liquid ratio of 1:1 for reaction. The filling degree is 70%. Time 8h, ultrasonic power 700W, after the reaction, the product was cooled, vacuum or negative pressure filtered, dried (105°C, 2h), crushed and separated, and the yield of biochar was 65%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com