Preparation method for extracting amino acids from alfalfa

An amino acid and alfalfa technology, applied in fermentation and other directions, can solve the problems of inedible stems and leaves of alfalfa, low value of creation, and low economic benefits, and achieve the effect of filling the technical gap, facilitating cleaning, and improving agricultural benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

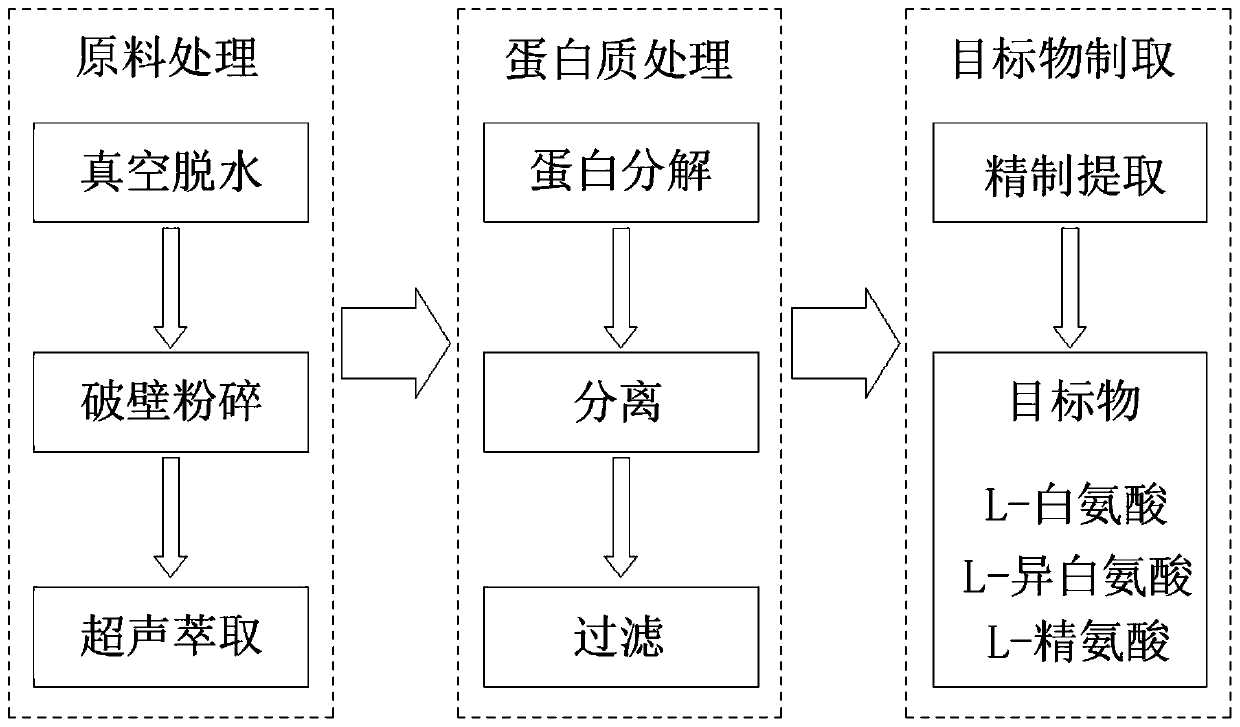

[0044] see figure 1 , a preparation method for extracting amino acid from alfalfa, comprising the following steps:

[0045] Step 1. Vacuum dehydration: Put 1 kg of fresh non-edible alfalfa stem and leaf part A into vacuum dehydration equipment for vacuum dehydration and drying to obtain dry matter. The time is 2 hours.

[0046] Step 2, wall breaking and pulverizing: the dry matter in step 1 is broken and pulverized to obtain a pulverized product, and the particle size of the pulverized product is 150 mesh.

[0047] Step 3. Ultrasonic extraction: Add the pulverized material in step 2 to the ultrasonic extraction equipment. The extraction temperature is 40°C, and three consecutive extractions are performed to obtain the non-target product crude fiber and extract. The ultrasonic extraction equipment uses ultrasonic extraction The protein in the pulverized matter, if the protein is extracted by conventional stirring method, can rarely reach 30% of the total protein content, but...

Embodiment 2

[0056] see figure 1 , a preparation method for extracting amino acid from alfalfa, comprising the following steps:

[0057] Step 1, vacuum dehydration: put 1 kilogram of fresh alfalfa stem and leaf part B with no edible value into vacuum dehydration equipment for vacuum dehydration and drying to obtain dry matter; in step 1, the vacuum degree in vacuum dehydration is -0.2MPa, and the temperature is 50°C, the drying time is 3 hours.

[0058] Step 2, wall breaking and pulverizing: the dry matter in step 1 is broken and pulverized to obtain a pulverized product; further, in step 2, the particle size of the pulverized product is 500 mesh.

[0059] Step 3. Ultrasonic extraction: Add the pulverized material in step 2 to the ultrasonic extraction equipment. The extraction temperature is 50°C, and the continuous extraction is carried out to obtain the non-target product crude fiber and extract. The ultrasonic extraction equipment uses ultrasonic waves to extract the pulverized mater...

Embodiment 3

[0068] see figure 1 , a preparation method for extracting amino acid from alfalfa, comprising the following steps:

[0069] Step 1, vacuum dehydration: put 1 kilogram of fresh non-edible alfalfa stem and leaf part C into vacuum dehydration equipment for vacuum dehydration and drying to obtain dry matter; in step 1, the vacuum degree in vacuum dehydration is -0.15MPa, and the temperature is 45°C, drying time is 2.5 hours.

[0070] Step 2, wall-breaking and pulverizing: the dry matter in step 1 is broken and pulverized to obtain a pulverized product; further, in step 2, the particle size of the pulverized product is 300 mesh.

[0071] Step 3. Ultrasonic extraction: Add the pulverized material in step 2 to the ultrasonic extraction equipment. The extraction temperature is 45°C, and continuous extraction is performed to obtain non-target product crude fiber and extract. The ultrasonic extraction equipment uses ultrasonic waves to extract the pulverized material For the protein ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com