Tea drying device

A technology of tea drying device and drying barrel, which is applied in tea treatment before extraction, solid separation, chemical instruments and methods, etc., which can solve the problems of weak tea taste, over-drying and insufficient drying of tea, and achieve control The structure is simple and the effect of improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below by means of specific embodiments:

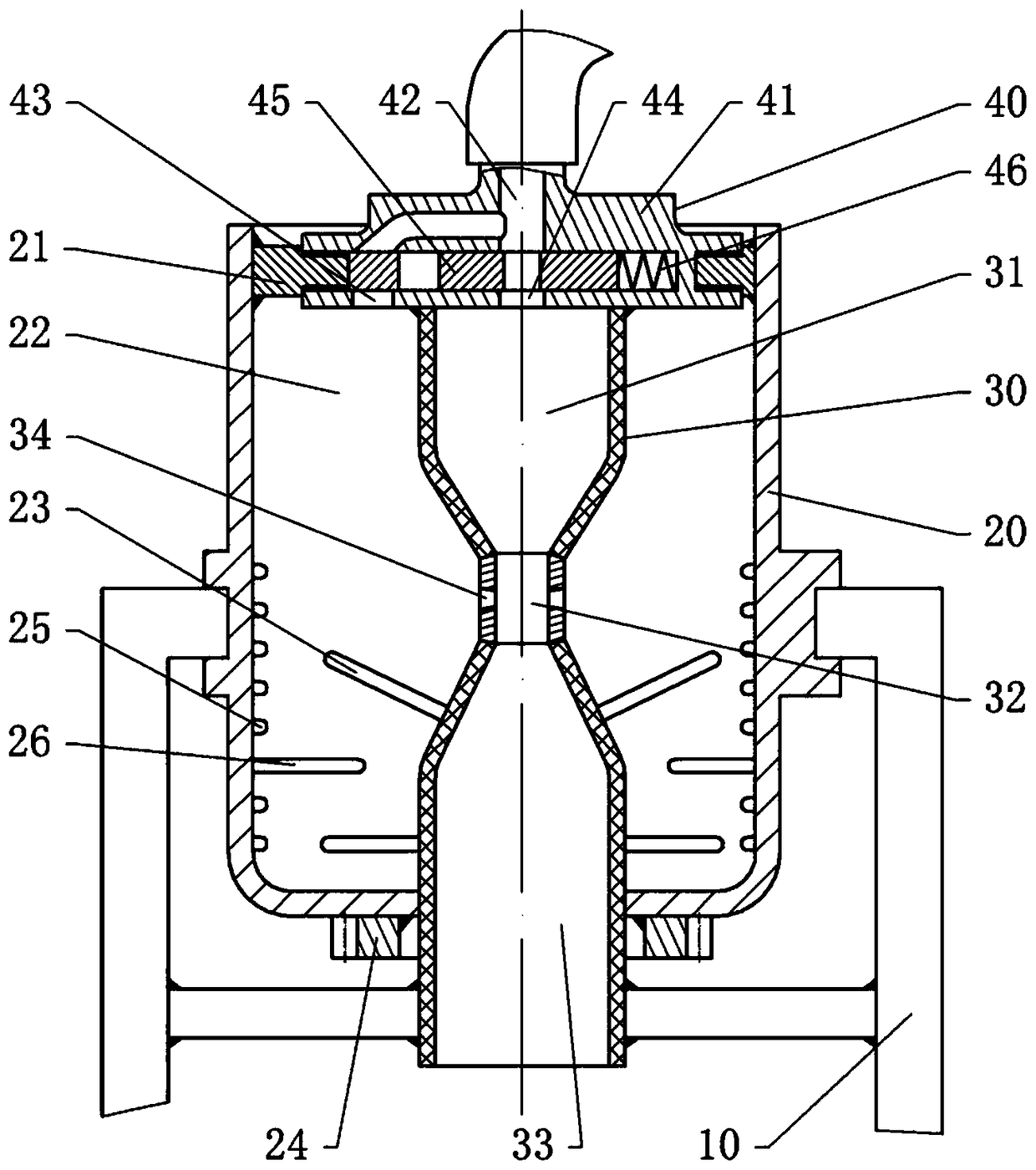

[0021] The reference signs in the accompanying drawings of the description include: frame 10, drying barrel 20, cam 21, drying chamber 22, second stirring rod 23, driving gear 24, protrusion 25, first stirring rod 26, discharge pipe 30. Inlet section 31, throat 32, diffuser section 33, suction hole 34, two-position three-way reversing valve 40, valve seat 41, air inlet 42, second exhaust port 43, first exhaust port 44 , spool 45, stage clip 46.

[0022] The embodiment is basically as figure 1 Shown:

[0023] The tea drying device of the present embodiment comprises a frame 10, a discharge pipe 30, a drying barrel 20 sleeved on the periphery of the discharge pipe 30, a driving motor for driving the rotation of the drying barrel 20, and a drying barrel to the discharge pipe 30 and the drying barrel. 20 hot air mechanism for air supply and DC power supply for generating e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com