On-line laser reinforcing device for hydraulic turbine blades

A technology of strengthening device and water turbine, which is applied in the field of local defect repair and strengthening of water turbine, can solve the problems of low degree of automation, inconvenient operation, and large thermal influence of the substrate, and achieves improved cladding accuracy, simple and convenient operation, and good bonding performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

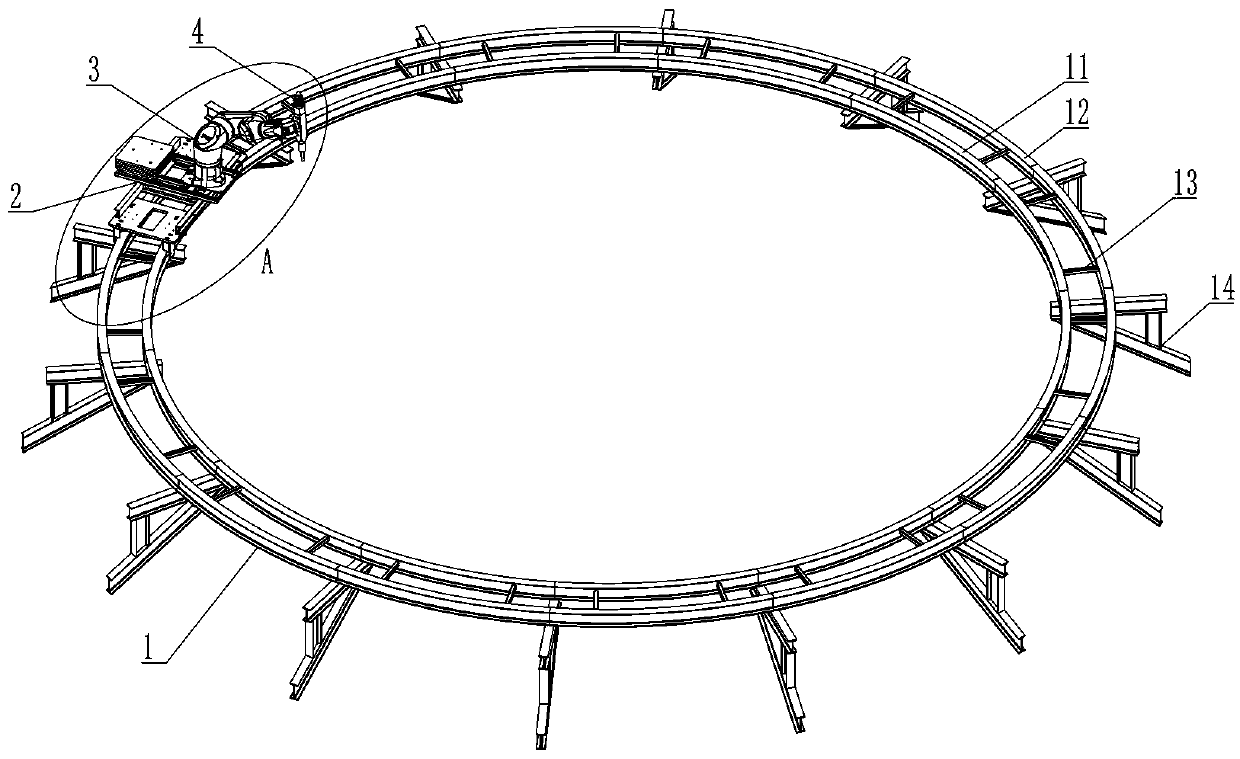

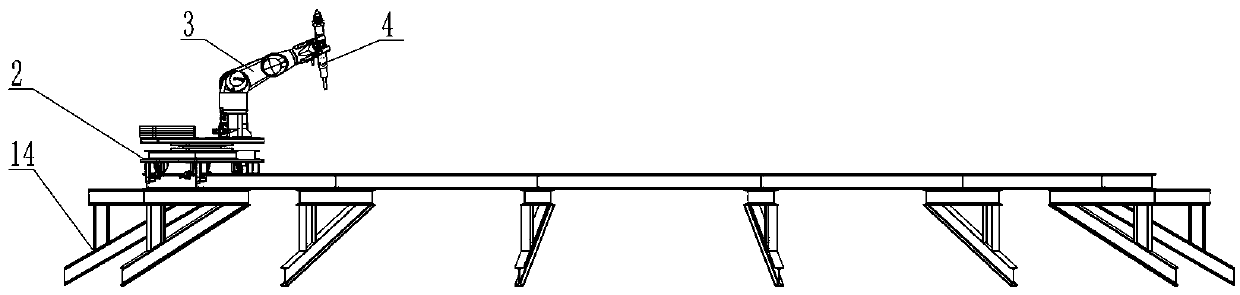

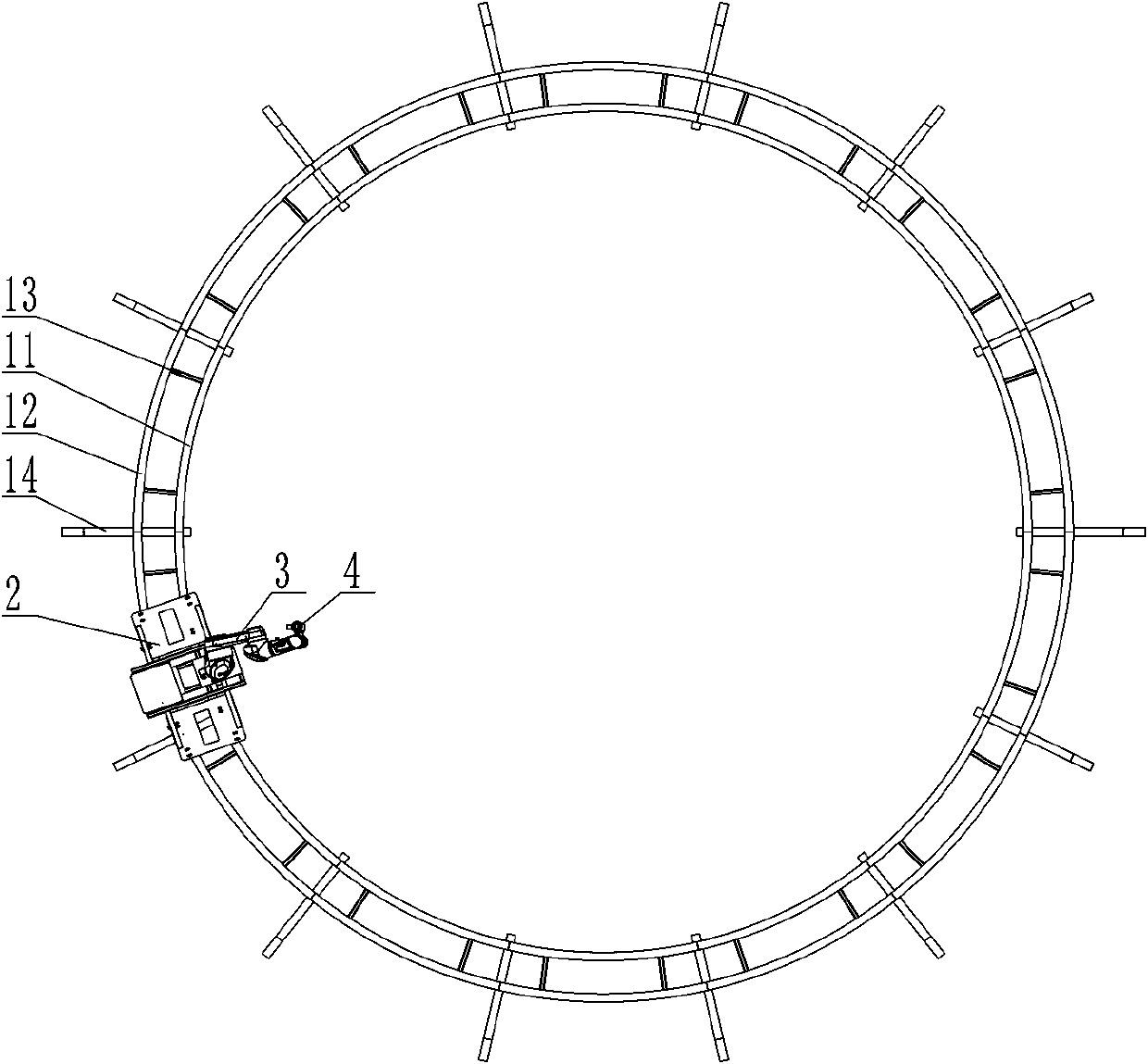

[0066] Such as Figure 1~Figure 20 Among them, an online laser strengthening device for water turbine blades, which includes a track 1, a running mechanism 2, a robot 3 and a complete set of laser cladding equipment 4; The complete set of cladding equipment 4 is connected with the robot 3. The walking mechanism 2 drives the robot 3 to move circularly along the track 1. The complete set of laser cladding equipment 4 emits laser beams to melt the surface of the substrate and the powder, and then solidify to repair the defects of the substrate. The structure is simple, by setting a ring-shaped track 1 in the water turbine runner chamber, and setting a running mechanism 2 on the track 1, the robot 3 is connected with the running mechanism 2, and the laser cladding complete set of equipment 4 is connected with the robot 3, and by pushing the running mechanism 2 along the track 1 The motion drives the robot 3 to reach the cladding area, and the robot 3 controls the complete set of l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com