Film adhesive, dicing tape with film adhesive, method of manufacturing semiconductor device, and semiconductor device

一种切割胶带、胶粘剂的技术,应用在半导体/固态器件制造、薄膜/薄片状的粘合剂、胶粘剂等方向,能够解决焊盘污染、导电性下降、树脂糊剂厚度不均一等问题,达到防止热影响、抑制翘曲的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3 and comparative example 1~3

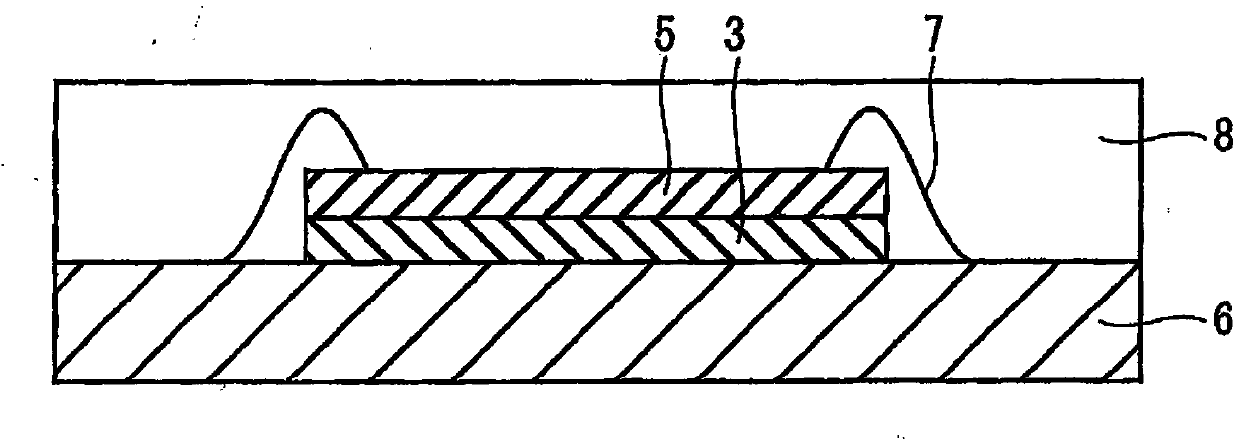

[0134] According to the proportions described in Table 1, the components and solvent (methyl ethyl ketone) described in Table 1 were put into the stirring tank of a mixing mixer (HM-500 manufactured by KEYENCE), and stirred and mixed for 3 minutes in the stirring mode. The obtained varnish was applied to a release treatment film (MRA50 manufactured by Mitsubishi Plastics Co., Ltd.) with a slit coater, and then dried to obtain a film-like adhesive.

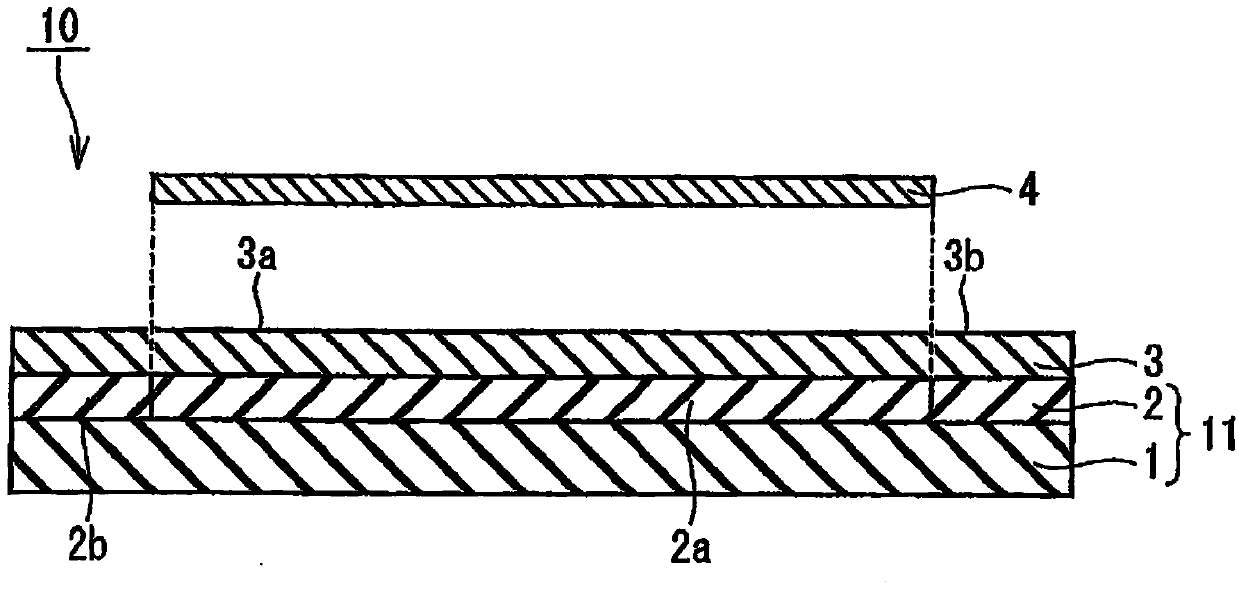

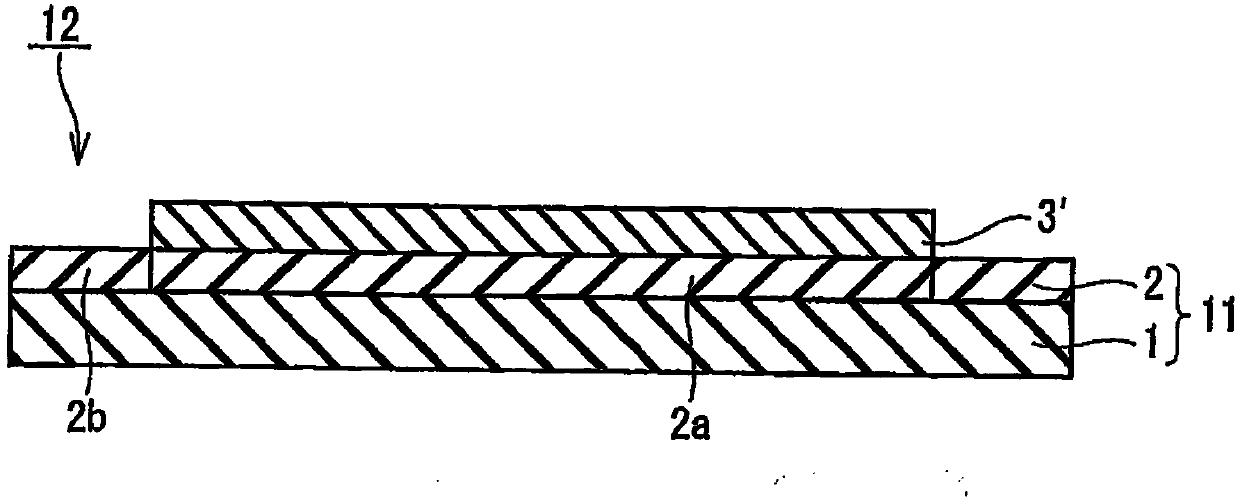

[0135] The obtained film adhesive was cut out into a circle with a diameter of 230 mm, and stuck to the adhesive layer of a dicing tape (P2130G manufactured by Nitto Denko Co., Ltd.) at 25°C to prepare a film adhesive. Cut the tape.

Embodiment 4~6 and comparative example 4~6

[0137] According to the proportions described in Table 2, put the ingredients described in Table 2 into the stirring tank of a planetary mixer (T.K.HIVIS MIX "P-03" manufactured by PRIMIX Co., Ltd.), and stir and mix at 90°C 20 minutes. Through a forming press (Kitagawa Seiki Co., Ltd. VH1-1572) at 120°C and a pressure of 1kg / cm 2 The resulting mixture is pressurized to form a film-like adhesive.

[0138] The obtained film adhesive was cut out into a circle with a diameter of 230 mm, and stuck to the adhesive layer of a dicing tape (P2130G manufactured by Nitto Denko Co., Ltd.) at 25°C to prepare a film adhesive. Cut the tape.

[0139] [Production of Mirror Silicon Wafer]

[0140] A silicon wafer (manufactured by Shin-Etsu Chemical Co., Ltd., thickness 0.6 mm) was ground to a thickness of 0.05 mm using a wafer back grinder (DFG-8560 manufactured by DISCO Co., Ltd.) to produce a mirror-surfaced silicon wafer.

[0141] [evaluate]

[0142] The following evaluations were perf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| tensile modulus | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com