Power cabinet with partitioning heat dissipation function

A technology for power cabinets and radiators, which is applied to output power conversion devices, cooling/ventilation/heating transformation, electrical components, etc. It can solve problems such as failure and high temperature of heat-sensitive devices, achieve high heat dissipation, improve heat dissipation efficiency, and avoid The effect of thermal influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

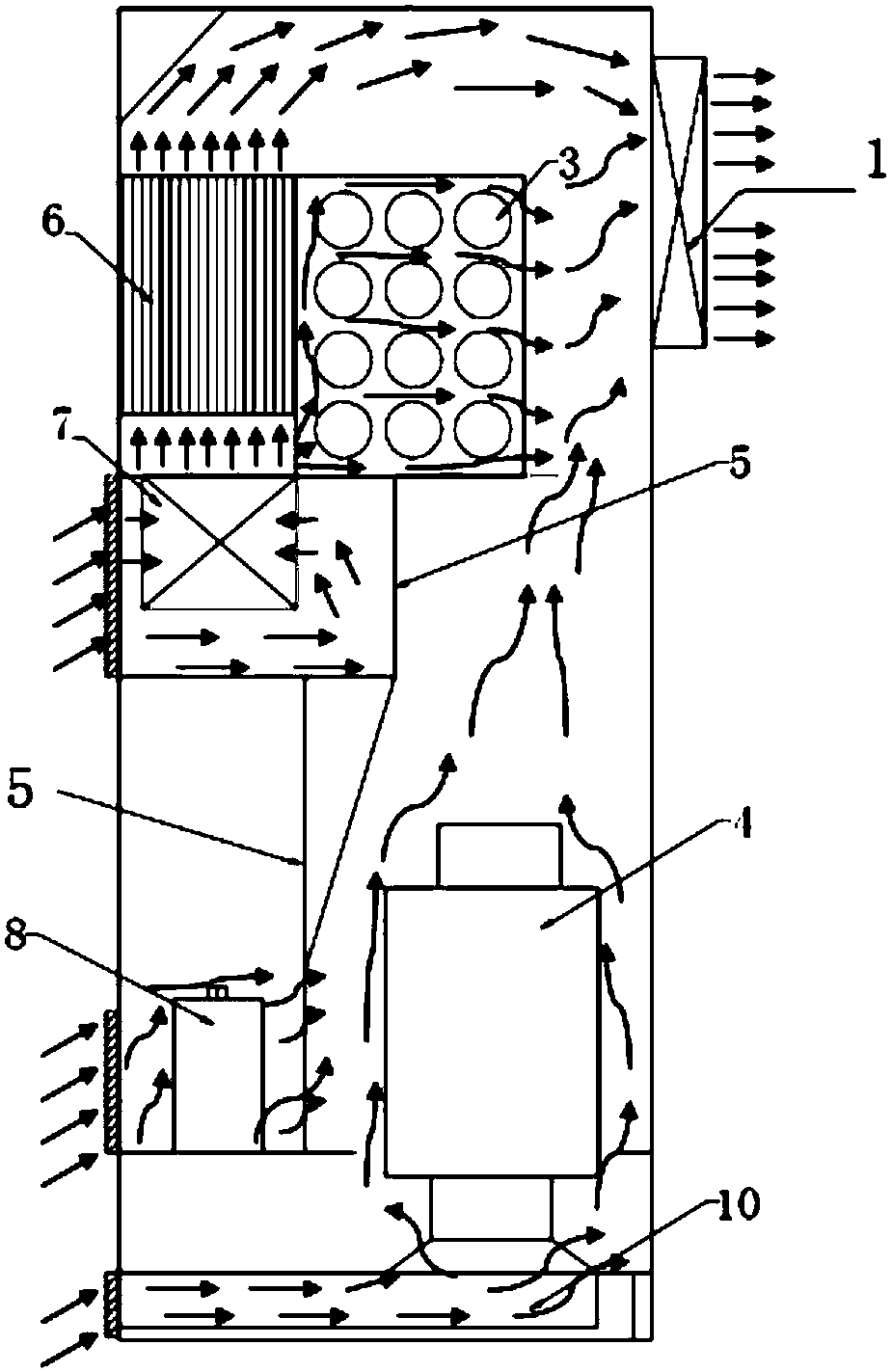

[0018] A power cabinet with zonal heat dissipation, such as figure 1 As shown, it includes the cabinet and the power module, reactor 4 and filter capacitor 8 arranged inside the cabinet, and also includes the air duct partition 5 arranged inside the cabinet. The air duct partition 5 and the front door panel of the cabinet will be The cabinet is divided into a first heat dissipation area and a second heat dissipation area, and the air duct partition 5 and the rear door panel of the cabinet form a third heat dissipation area; and the upper part of the first heat dissipation area and the second heat dissipation area;

[0019] A power module, a radiator 6, a film capacitor unit, and a double-inlet centrifuge 7 are arranged in the first heat dissipation area; the radiator 6 and the film capacitor unit are arranged side by side in sequence, and the double-inlet centrifuge 7 is arranged directly below the radiator , and the air outlet of the double air inlet centrifuge 7 is facing th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com