Production method of high-gloss and high-covering-capability rutile titanium dioxide

A rutile-type titanium dioxide, production method technology, applied in the directions of titanium dioxide, titanium oxide/hydroxide, etc., can solve the problems of affecting gloss, low affinity, and insignificant improvement of gloss, and achieve gloss and cover. Power-enhancing, gloss-enhancing, high-hiding effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

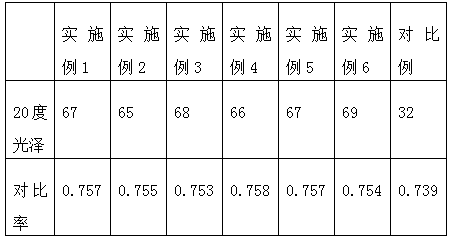

Examples

preparation example Construction

[0031] The preparation method of the high-gloss, high-covering titanium dioxide of the present embodiment comprises the following main steps:

[0032] (1) Prepare metatitanic acid slurry: weigh 2700g deionized water, add 1000g metatitanic acid, and stir evenly;

[0033] (2) Add 15.4g magnesium sulfate heptahydrate (MgO and TiO 2 The mass percentage is about 0.25%), stir evenly;

[0034] (3) Add 18.4g zirconium sulfate (ZrO 2 with TiO 2 The mass percentage is about 0.8%), stir evenly;

[0035] (4) Add 4.4g potassium carbonate (K 2 O and TiO 2 The mass percentage is about 0.3%), stir evenly;

[0036] (5) The metatitanic acid slurry treated above is subjected to pressure filtration and calcined at 950 degrees to obtain the primary titanium dioxide slurry, which is pulverized by a grinder, and 1190g of deionized water is added to make 700g / L Titanium dioxide slurry, and then sanded with a sand mill, so that the titanium dioxide reaches the original parti...

Embodiment 2

[0041] The preparation method of the high-gloss, high-covering titanium dioxide of the present embodiment comprises the following main steps:

[0042] (1) Prepare metatitanic acid slurry: weigh 2700g deionized water, add 1000g metatitanic acid, and stir evenly;

[0043] (2) Add 6.3g of magnesium carbonate (after adding MgO and TiO in the metatitanic acid slurry 2 The mass percentage is about 0.3%), stir evenly;

[0044] (3) Add 7.6g zirconium chloride (ZrO 2 TiO in metatitanic acid slurry 2 The mass percentage is about 0.4%), stir evenly;

[0045] (4) Add 2.4g potassium hydroxide (K 2 O and TiO in metatitanic acid slurry 2 The mass percentage is about 0.2%), stir evenly;

[0046] (5) The metatitanic acid slurry treated above is subjected to pressure filtration and calcined at 950 degrees to obtain the primary titanium dioxide slurry. The primary product is pulverized by a grinder, and 1190g of deionized water is added to make 700g / L titanium dioxide powde...

Embodiment 3

[0051] The preparation method of the high-gloss, high-covering titanium dioxide of the present embodiment comprises the following main steps:

[0052] (1) Prepare metatitanic acid slurry: weigh 2700g deionized water, add 1000g metatitanic acid, and stir evenly;

[0053] (2) Add 6g of magnesium oxide (after adding MgO and TiO in the metatitanic acid slurry 2 The mass percentage is about 0.6%), stir evenly;

[0054] (3) Add 16.5g zirconium nitrate (ZrO 2 TiO in metatitanic acid slurry 2 The mass percentage is about 0.6%), stir evenly;

[0055] (4) Add 4.8g potassium hydroxide (K 2 O and TiO in metatitanic acid slurry 2 The mass percentage is about 0.4%), stir evenly;

[0056] (5) The above-mentioned metatitanic acid slurry is filtered and calcined at 950 degrees to obtain the primary product of titanium dioxide, which is pulverized by a grinder, and 1190g of deionized water is added to make a 700g / L titanium dioxide slurry , and then sanded with a sand mil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com