Patents

Literature

36 results about "Carboxymethyl guar gum" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Well Treatment Composition Crosslinkers and Uses Thereof

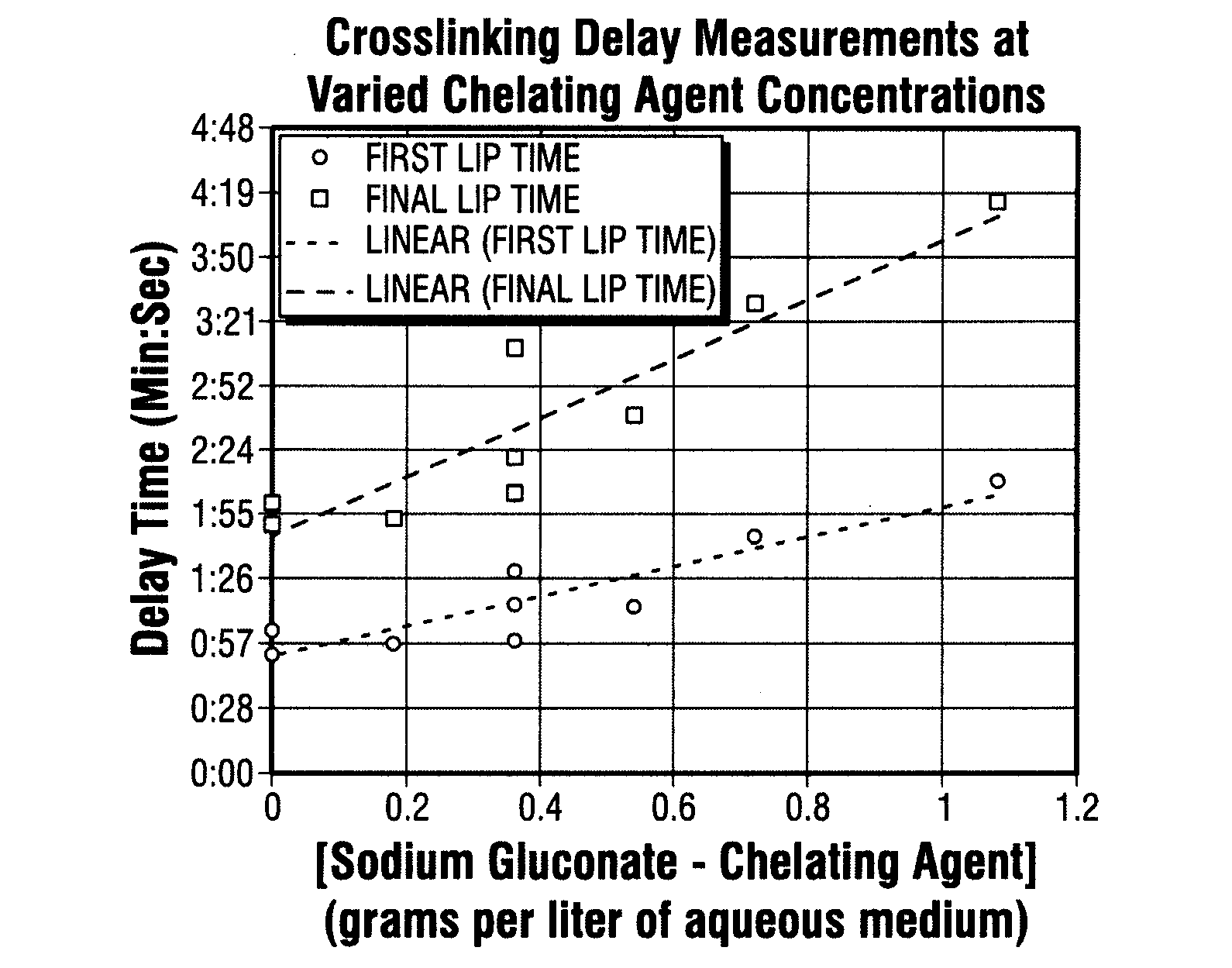

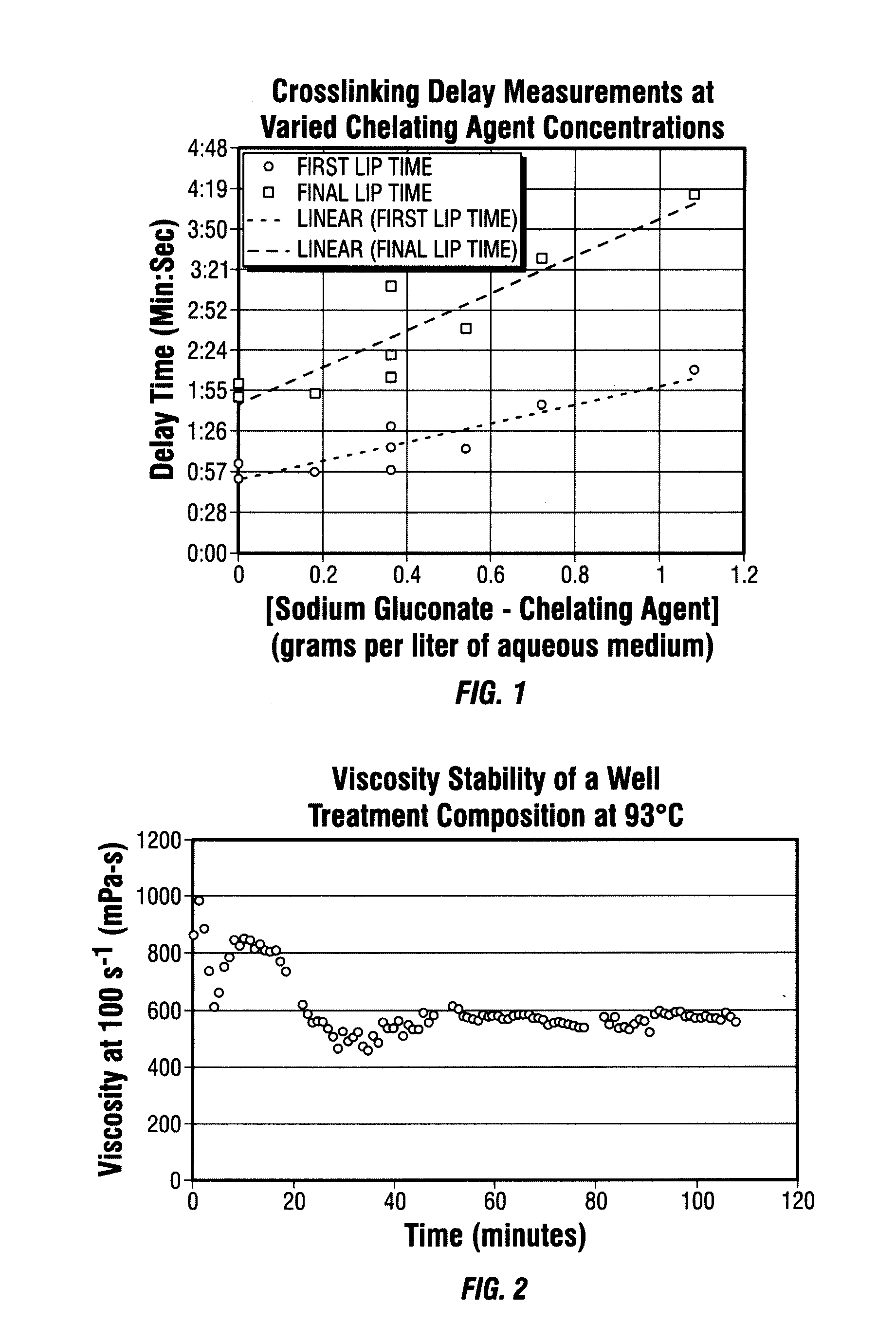

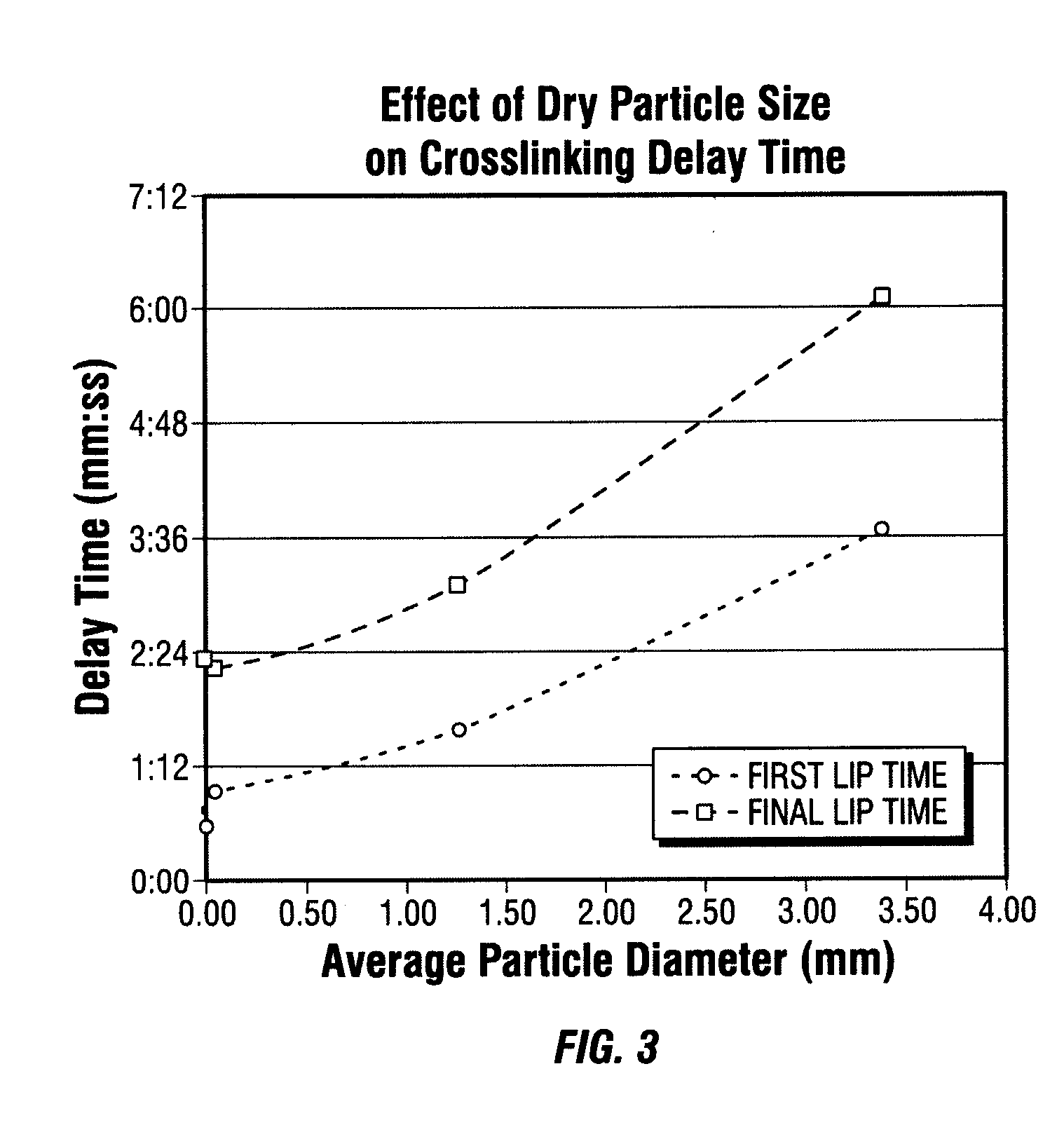

This invention relates to compositions used in treating subterranean formations, which include a hydrated polymer, and a dry blended multi-functional component. The hydrated polymer and dry blended multi-functional component are mixed at the ground surface of a wellsite, and subsequently injected into the formation providing controlled delay in crosslinking to achieve targeted fluid viscosity properties. The hydrated polymer may be a guar, hydroxypropyl guar, carboxymethyl guar, carboxymethylhydroxypropyl guar, synthetic polymers, and guar-containing compounds. The dry blended multi-functional component may include a crosslinker and a chelating agent, and the well treatment fluid may further include an activator mixed with the hydratable polymer. The chelating agent may be a polyols, gluconate, sorbitol, mannitol, carbonate, or any mixtures thereof. The crosslinker may be any source of boron, alkaline earth metal borates, alkali metal borates, zirconium compounds, titanium compounds, or any combination thereof, while the activator may be a caustic soda or magnesium oxide compound. The invention further provides methods for producing a well treatment composition including providing a hydrated polymer, and providing a dry blended multi-functional component. Also, methods of hydraulically fracturing a subterranean formation, as well as cleanup operations and gravel packing a wellbore are provided as well.

Owner:DESSINGES MARIE NOELLE +1

Method of forming temporary blocking gel containing guar derivative

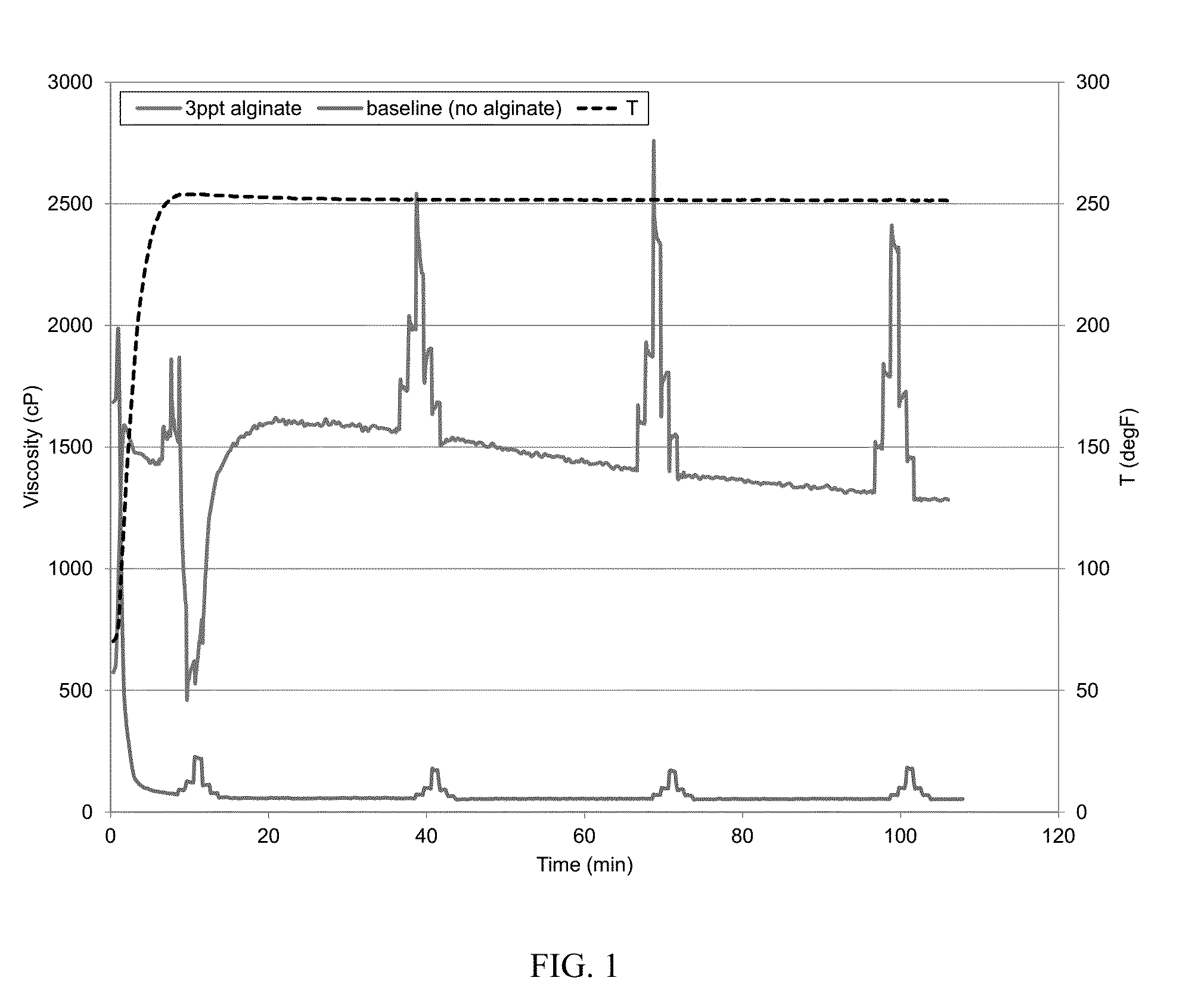

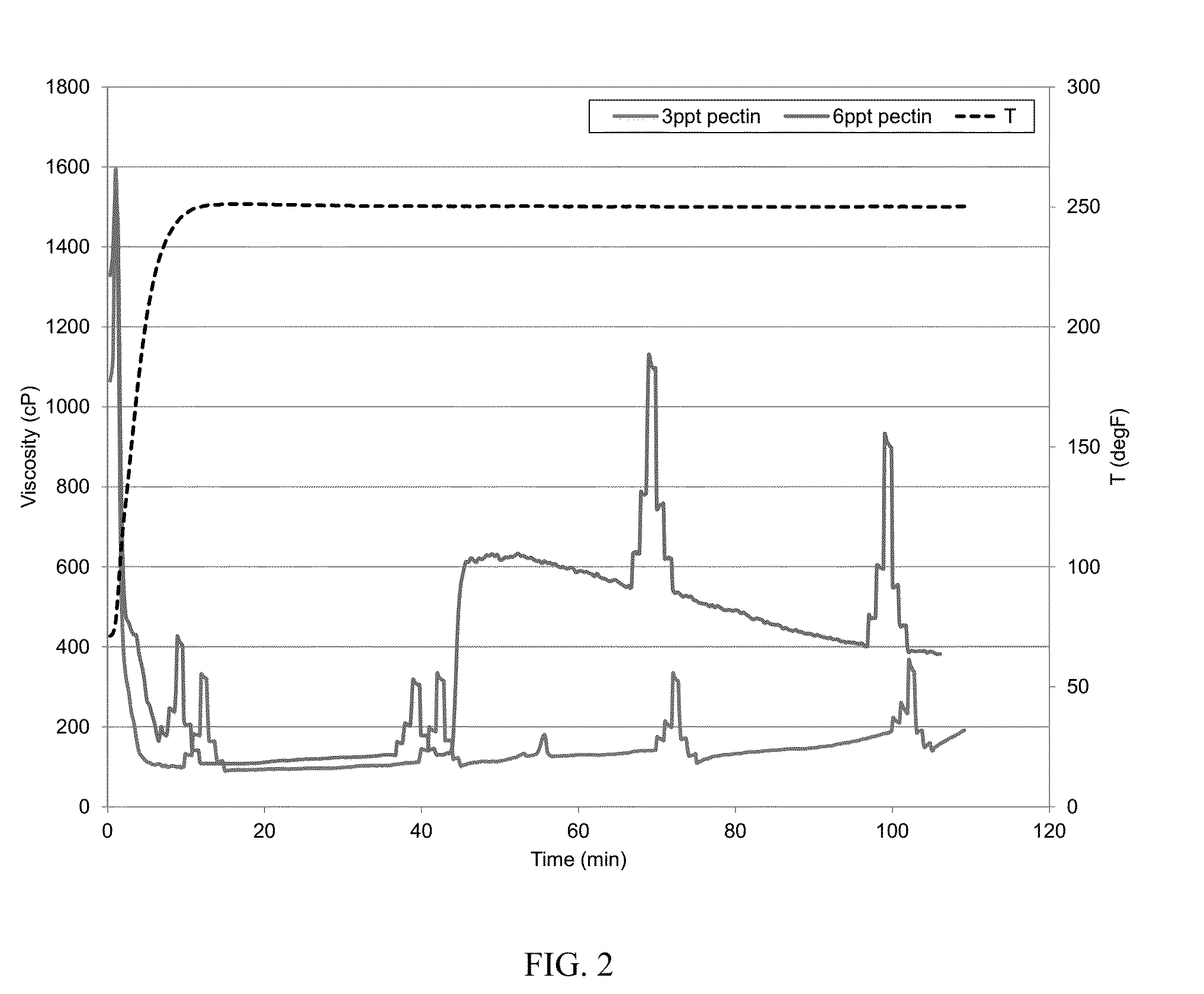

InactiveUS20050211435A1Minimizes friction pressureLow viscosityLiquid/gas jet drillingDrilling compositionCarboxymethyl guar gumViscosity

A high temperature blocking gel contains a blend of an aqueous fluid and carboxymethyl guar and a crosslinking agent. The gel exhibits excellent hydration capability in brines and positive viscosity generation and controls fluid loss from an oil well during drilling, completion and / or workover operations.

Owner:BAKER HUGHES INC

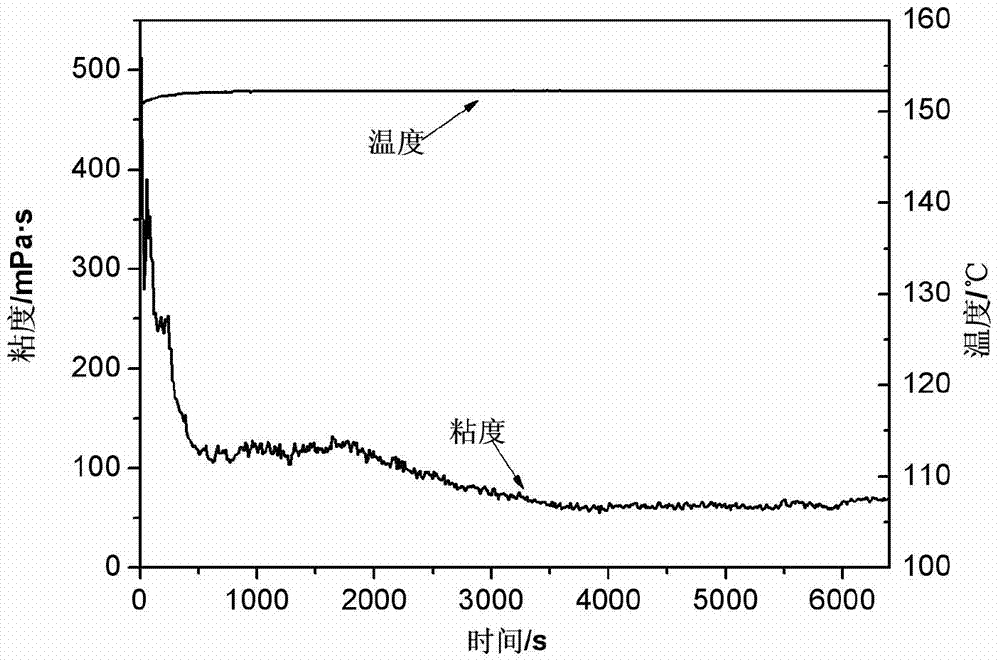

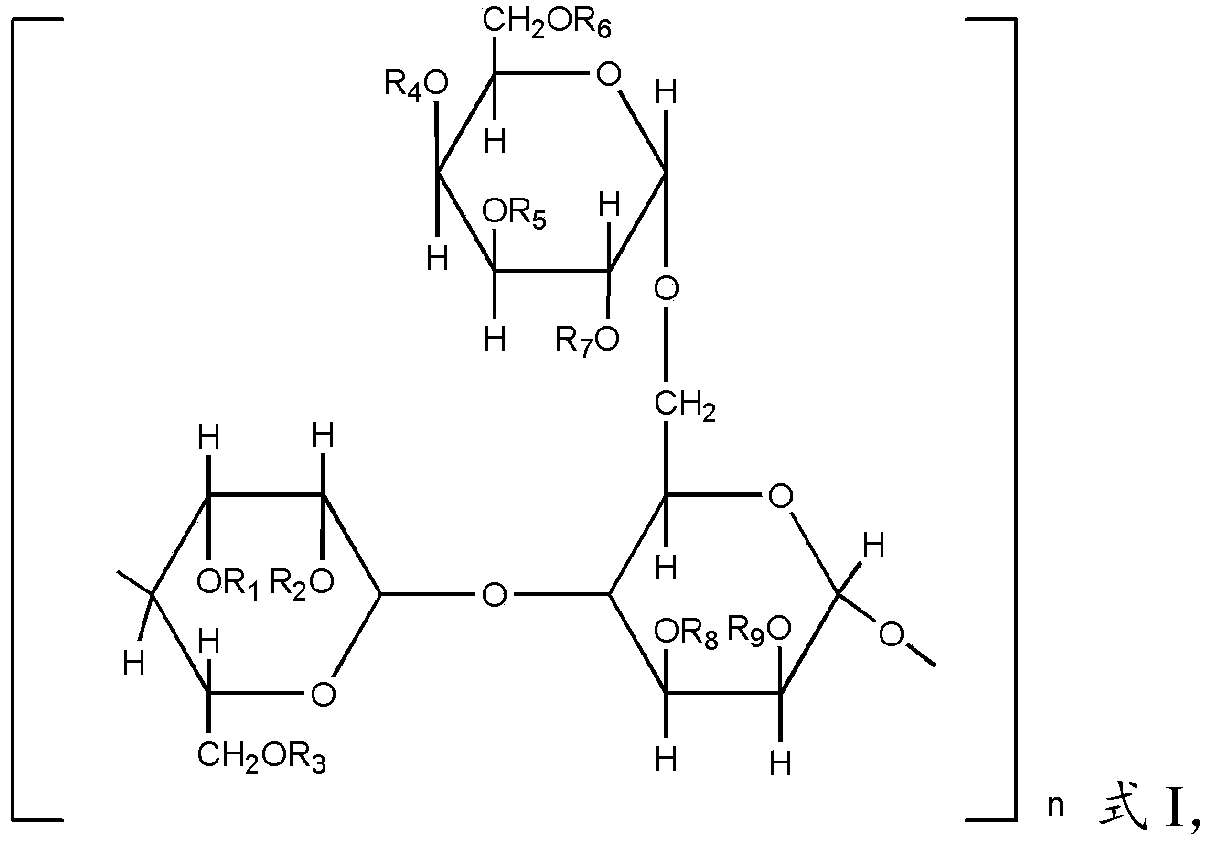

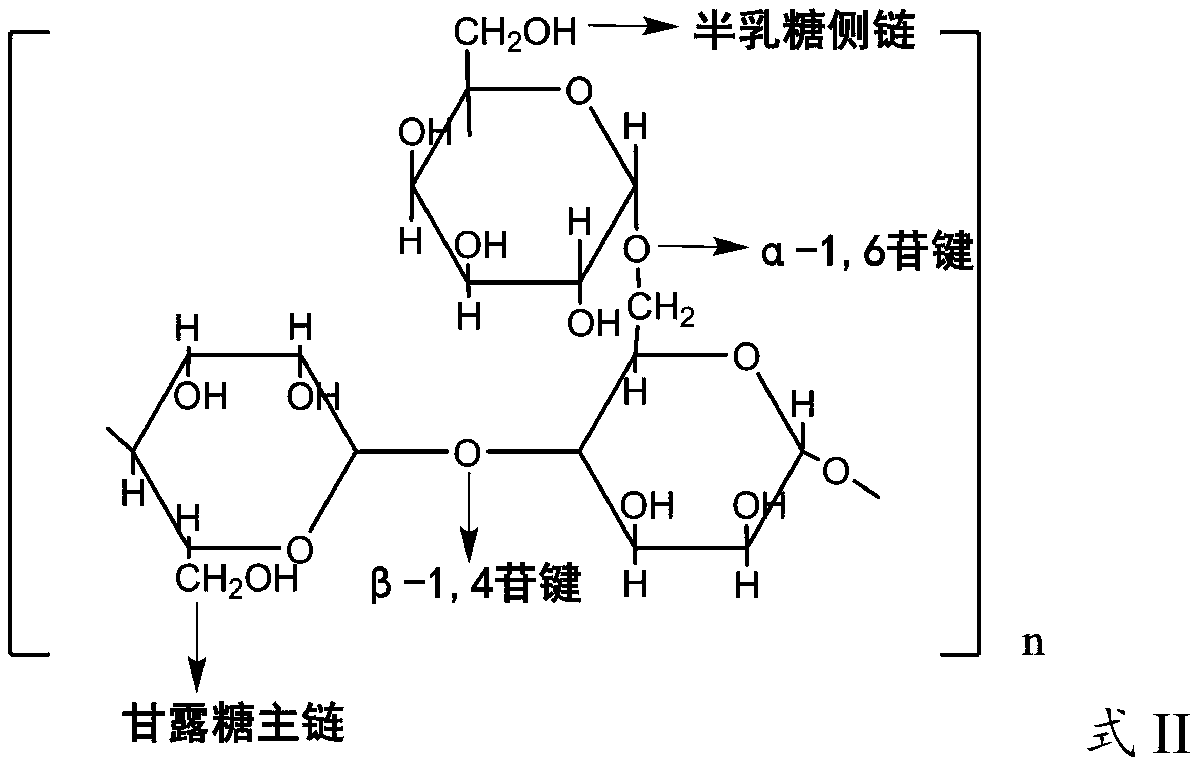

High-temperature hyper-salinity water-base fracturing fluid

ActiveCN103497754AShorten crosslinking timeDisperse completelyDrilling compositionWater basedCross-link

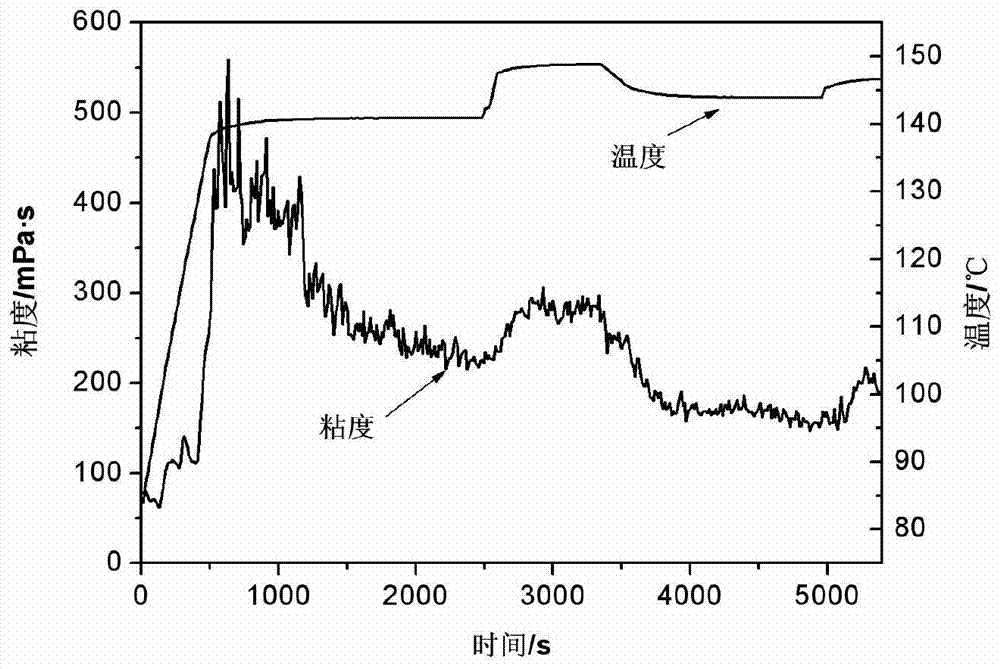

The invention discloses high-temperature hyper-salinity water-base fracturing fluid consisting of thickening liquid, a cross-linking agent and a gel breaker, wherein the thickening liquid comprises the following components in percentage by weight: 0.4-0.7% of a thickening agent, 0.1-0.8% of a cleanup additive, 0.01-0.1% of a sterilizing agent, 0.1-0.3% of a temperature stabilizing agent, and the balance of hyper-salinity seawater or stratum produced water; the thickening agent is sulfonyl hydroxypropyl guar gum, sulfonyl betaine amphoteric guar gum or sulfonyl carboxymethyl guar gum; the cross-linking agent is a stable complex formed from reaction of 9-18% of a zirconium compound, 3-40% of a boron compound, 9-18% of a chelating ligand and 5-19% of a bridging ligand by mass; the gel breaker is either ammonium persulfate or sodium persulfate. The fracturing fluid is directly prepared from hyper-salinity water and realizes effective utilization of seawater and hyper-salinity produced water from land, and is applicable to seaborne and terrestrial high-temperature oil-gas wells.

Owner:SOUTHWEST PETROLEUM UNIV

Method of forming temporary blocking gel containing guar derivative

InactiveUS7347265B2Low viscosityMinimizes friction pressureLiquid/gas jet drillingDrilling compositionCarboxymethyl guar gumViscosity

A high temperature blocking gel contains a blend of an aqueous fluid and carboxymethyl guar and a crosslinking agent. The gel exhibits excellent hydration capability in brines and positive viscosity generation and controls fluid loss from an oil well during drilling, completion and / or workover operations.

Owner:BAKER HUGHES INC

Seed coatings, coating compositions and methods for use

ActiveUS20180251654A1Promote seedling establishmentEasy to grow plantsBiocideCellulose coatingsPolyethylene oxidePotato starch

A seed or seedling is coated with underivatized guar, cationic hydroxypropyl guar, polyacrylamide, poly(methacrylic acid), poly(acrylic acid), polyacrylate, polyethylene glycol), polyethyleneoxide, poly(vinyl alcohol), polyglycerol, polytetrahydrofuran, polyamide, hydroxypropyl guar, carboxymethyl guar, carboxymethylhydroxypropyl guar, underivatized starch, cationic starch, corn starch, wheat starch, rice starch, potato starch, tapioca, waxy maize, sorghum, waxy sorghum, sago, dextrin, chitin, chitosan, xanthan gum, carageenan gum, gum karaya, gum arabic, pectin, cellulose, hydroxycellulose, hydroxyalkyl cellulose, hydroxyethyl cellulose, carboxymethylhydroxyethyl cellulose, or hydroxypropyl cellulose, the coated seed or seedling having a shelf-life at room temperature in ambient conditions in an unsealed container to at least two months.

Owner:RHODIA OPERATIONS SAS

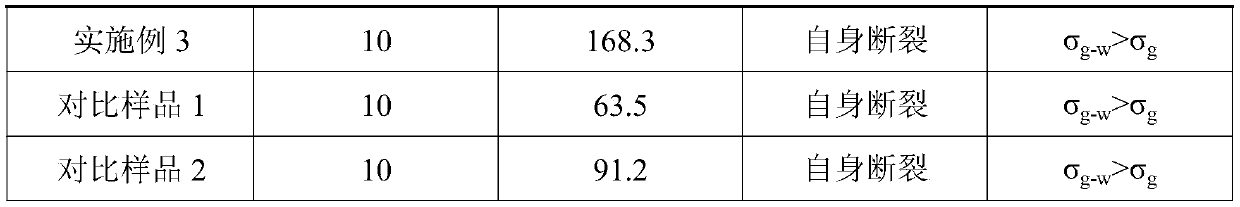

Preparation method of carboxymethyl guar gum

The invention relates to a preparation method of carboxymethyl guar gum. The method comprises the steps of: alkalization of guargum raw powder: conducting alkalization at a temperature of 60-70DEG C for 90min, with the guargum raw powder and sodium hydroxide in a mass ratio of 1:0.3, and the guargum raw powder and a bactericide in a mass ratio of 1:0.02; etherification of guargum raw powder: adding chloroacetic acid at a temperature of 50DEG C, with the guargum raw powder and chloroacetic acid in a mass ratio of 1:0.5, carrying out etherification at a temperature of 60-70DEG C for 15min, then adding epoxypropane for thermostatic reaction at a temperature of 60-70DEG C for 2h, with the guargum raw powder and epoxypropane in a mass ratio of 1:0.1; and when the reaction is over, performing washing for 3 times with a washing medium at a mass concentration of 80%, then implementing centrifugation and drying at a temperature of 85DEG C, with the washing medium chosen from methanol, ethanol or isopropanol. The carboxymethyl guar gum prepared by the solvent method of the invention has good fracture-making and sand-carrying functions, and has low broken gum residual content in a fracturing fluid system of the densifier as well as less damage to stratums.

Owner:PETROCHINA CO LTD

Method for preparing flocculating agent for water treatment

InactiveCN101519238AGood water solubilityGood thickening effectWater/sewage treatment by flocculation/precipitationWater bathsOrganic acid

The invention discloses a method for preparing a flocculating agent for water treatment, which comprises the following steps of: by weight percent, weighing 40 to 60 percent of guar gum, 20 to 40 percent of chloroacetic acid, and 20 to 35 percent of alkaline catalyst, placing weighed organic acid into a reactor; adding 80 percent of organic solvent till the organic acid dissolves uniformly and adding an excess amount of 30 percent alkaline catalyst; pouring the guar gum into the reactor, and stirring the mixture in the reactor at room temperature for 5 to 30 minutes till the mixture is uniform; after the material is in a semidry state, crushing the material and passing the crushed material through a sieve; placing the material in an reactor, and heating the reactor in a water bath for promoting the reaction, wherein the water bath temperature is kept between 50 and 80 DEG C, and the reaction lasts for 10 to 60 minutes; after reaction, obtaining carboxyl methylated guar gum by grinding and sieving.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

Silica microcapsules and methods of preparing same

Disclosed is a microcapsule containing: (i) a microcapsule core having an active material, and (ii) a microcapsule wall formed of a first polymer and second polymer. The first polymer is a sol-gel polymer. The second polymer is gum arabic, purity gum ultra, gelatin, chitosan, xanthan gum, plant gum, carboxymethyl cellulose, sodium carboxymethyl guar gum, or a combination thereof. The weight ratiobetween the first and second polymer is 1:10 to 10:1. Also disclosed are processes for preparing the microcapsule and uses of the microcapsules in consumer products.

Owner:INTERNATIONAL FLAVORS & FRAGRANCES

Low-concentration carboxymethyl fracturing fluid and preparation method thereof

Owner:西安长庆化工集团有限公司 +1

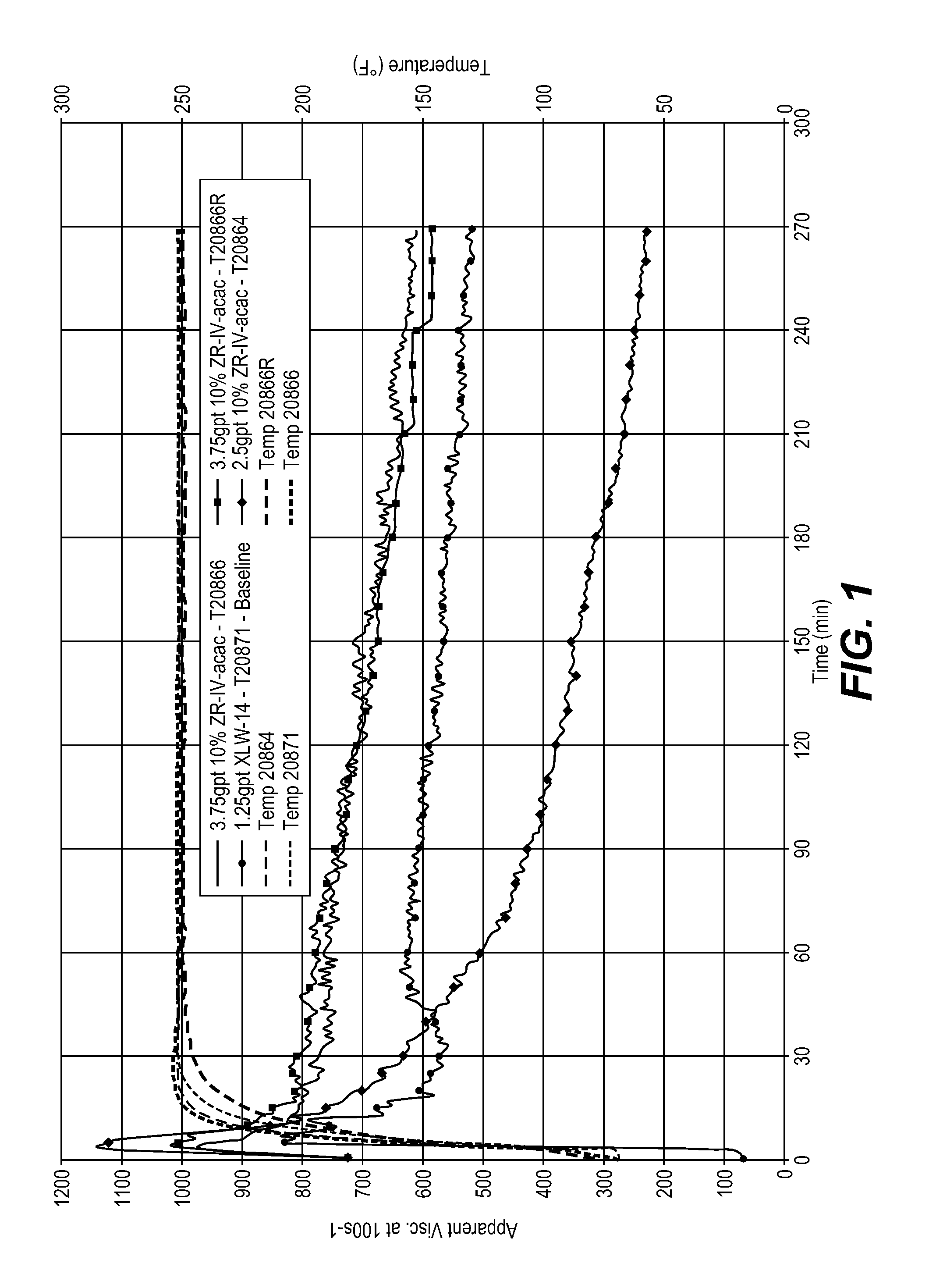

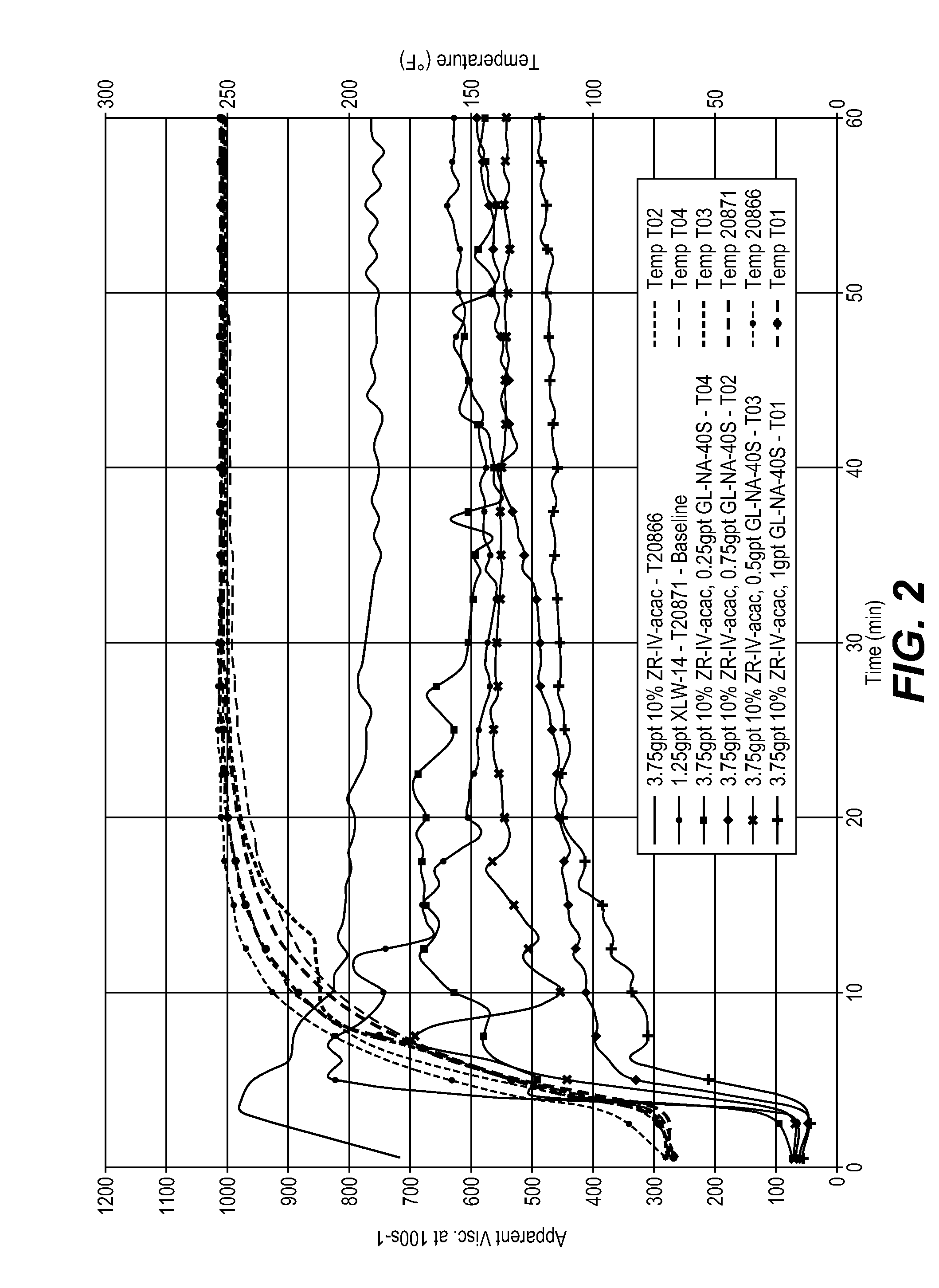

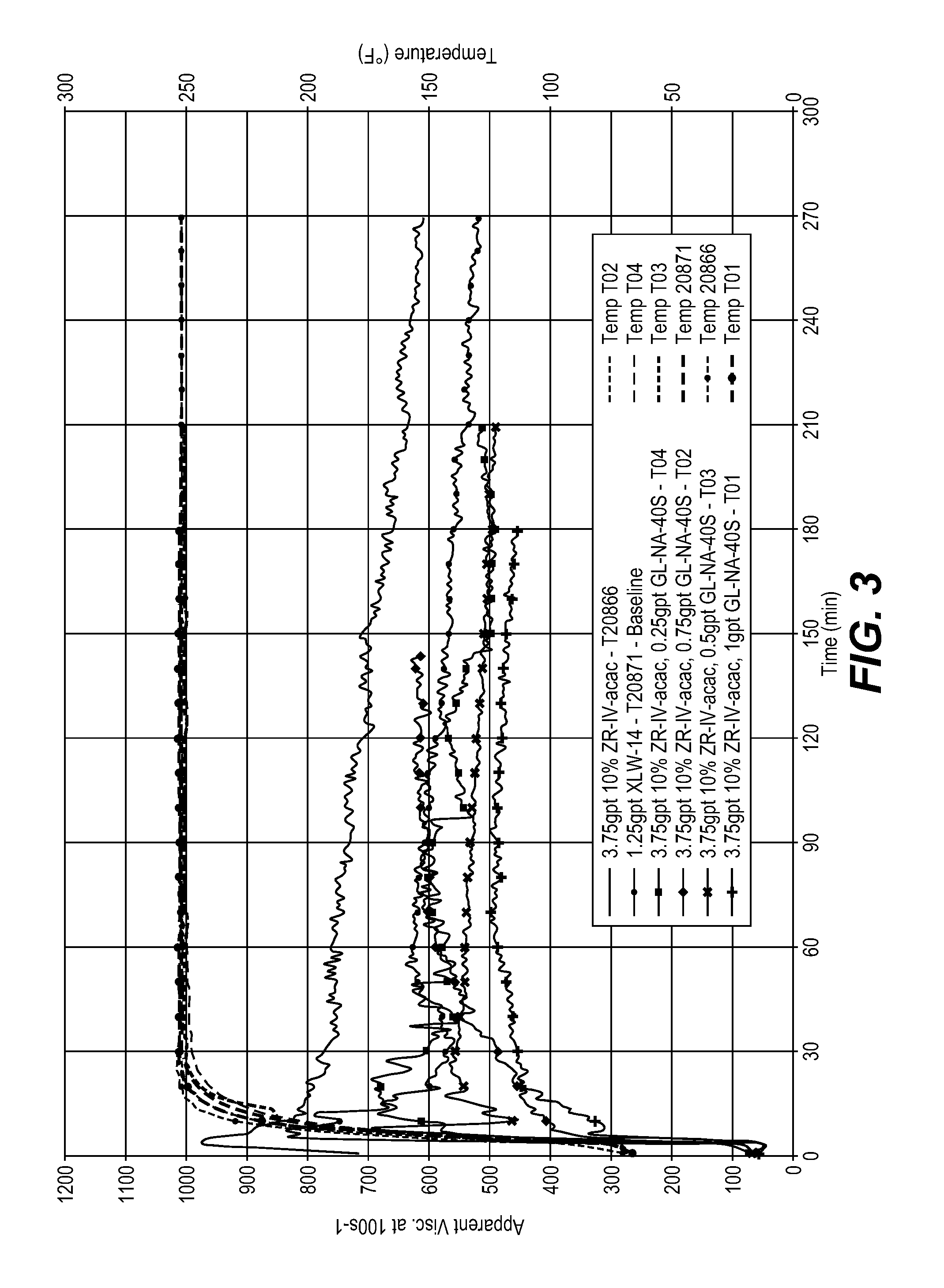

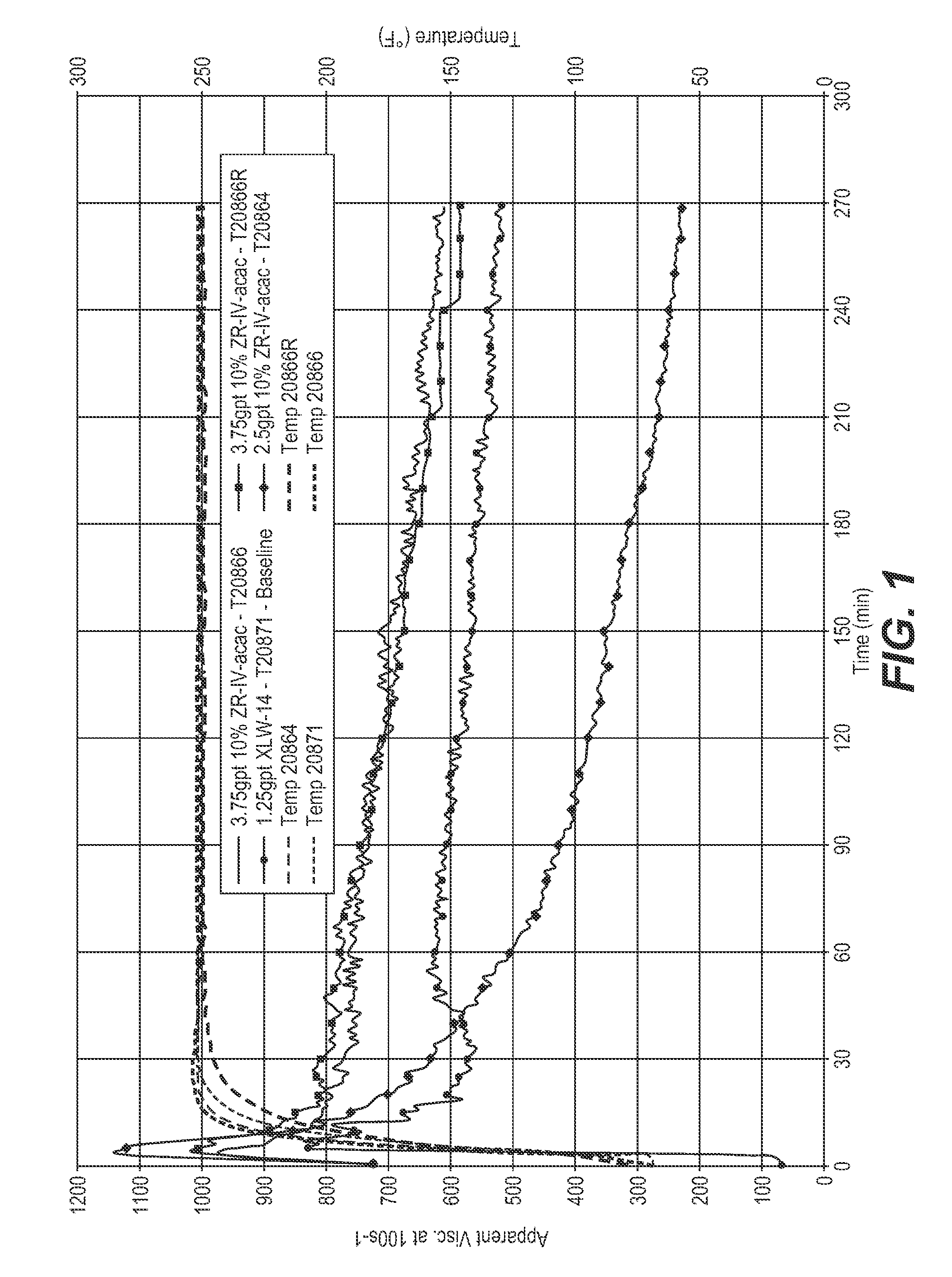

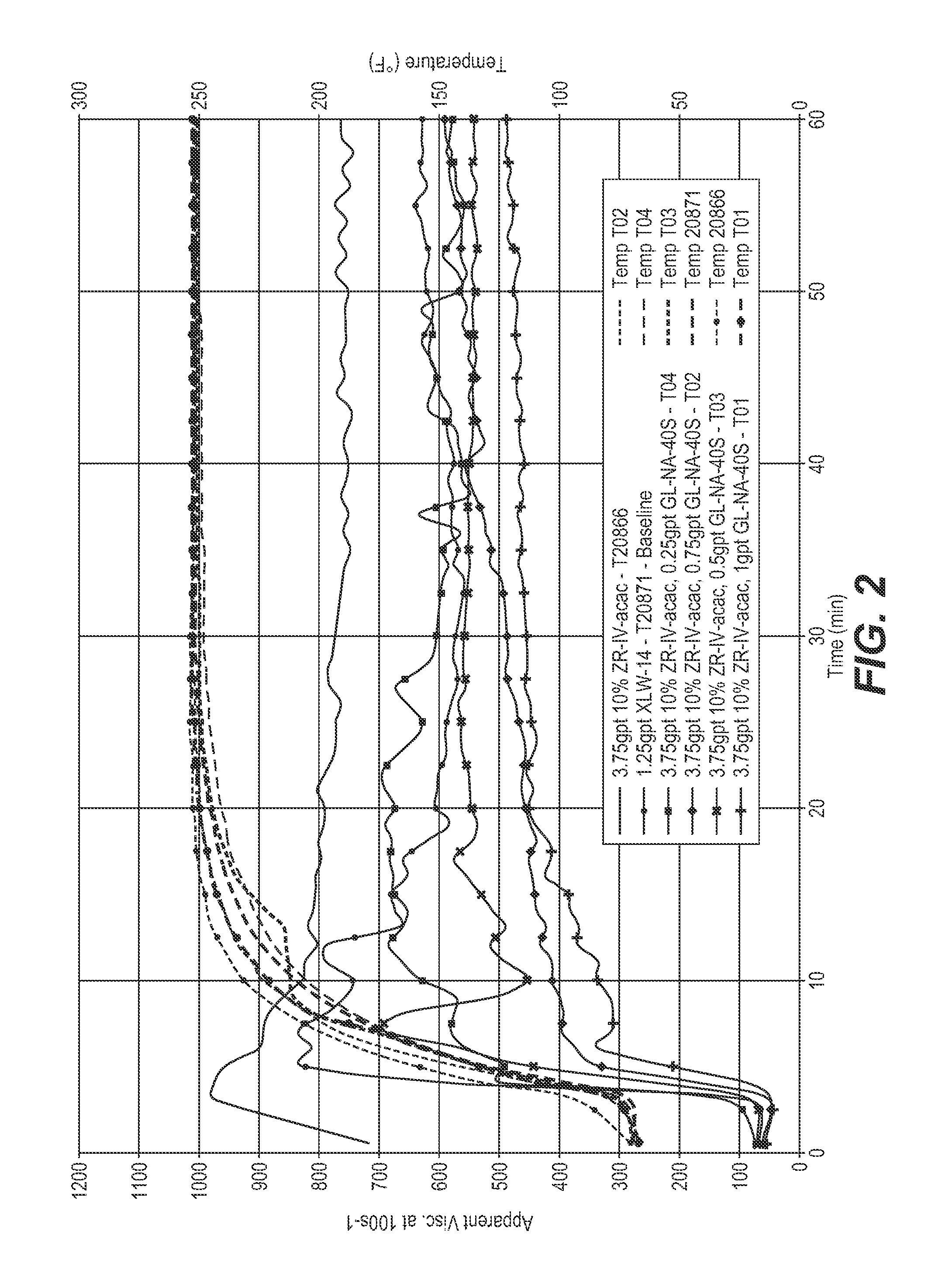

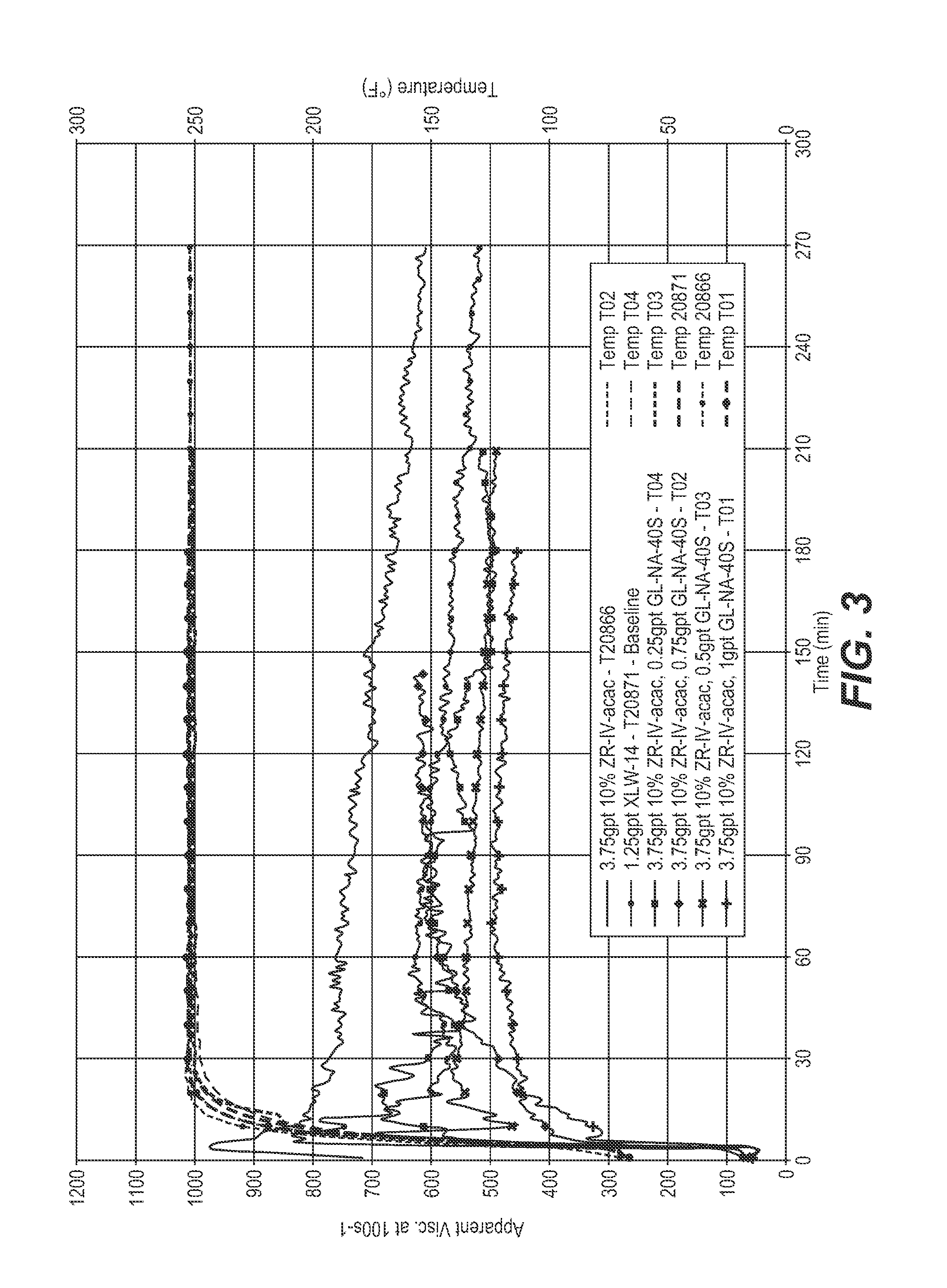

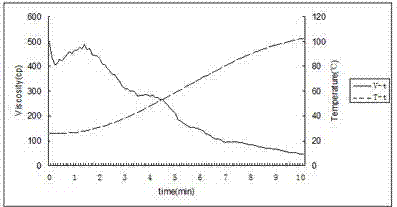

Method of delaying crosslinking in well treatment operation

Crosslinking of a crosslinkable viscosifying agent and a crosslinking agent may be delayed in a well treatment fluid by incorporated within the fluid a glutamic-N,N-diacetic acid salt, such as a glutamic-N,N-diacetic acid sodium salt like tetrasodium glutamate diacetate. The crosslinking agent may be a zirconium containing crosslinking agent like zirconium (IV) acetyl acetonate. The viscosifying agent may be guar or a guar derivative such as carboxyalkyl guars and hydroxyalkylated guars like carboxymethyl guar, hydroxypropyl guar, hydroxyethyl guar, hydroxybutyl guar and carboxymethylhydroxypropyl guar.

Owner:BAKER HUGHES INC

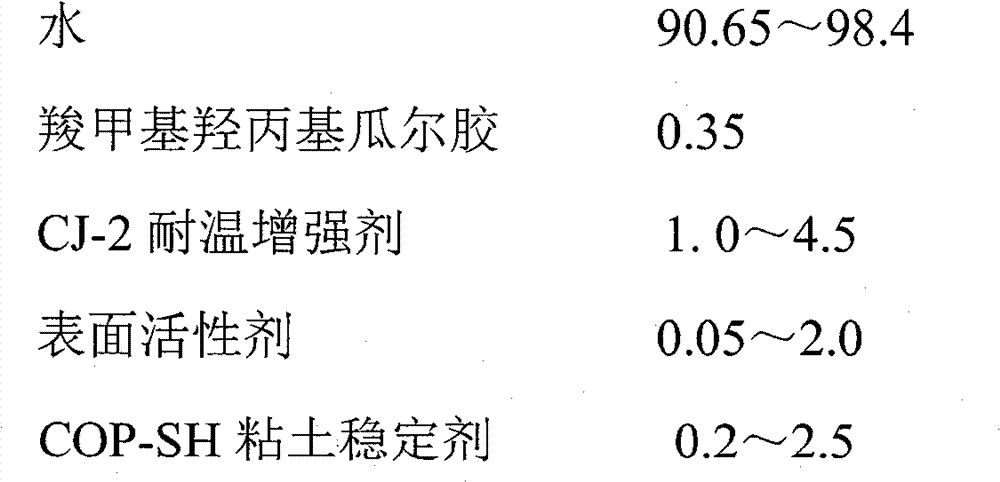

Carboxymethyl guar gum acid fracturing fluid

ActiveCN102102014AReduce performanceNot easy to generate adsorptionDrilling compositionAluminium chloridePolymer science

The invention relates to carboxymethyl guar gum acid fracturing fluid, which is prepared from the following components of water, carboxymethyl hydroxypropyl guar gum, a CJ-2 heat-resistant reinforcing agent, a surfactant, a COP-SH clay stabilizer, and a JL-12 crosslinking agent, wherein the JL-12 crosslinking agent is prepared by complexing aluminium chloride and C3-C7 straight chain organic ketone; the COP-SH clay stabilizer is (C4-C8) small cationic quaternary ammonium salt; the CJ-2 heat-resistant reinforcing agent is a mixture of sulfuric acid and citric acid or ethylic acid, which has the pH value of 1-3; the surfactant is a non-ionic fluorocarbon surfactant; a thickening agent of a fracturing fluid system can be used under the acid condition, and the content of water insolubles is more than 5 percent lower than that of the conventional hydroxypropyl guar gum; the matched additives are non-cationic additives, and are difficult to adsorb after entering stratum, so that the wettability of stratum rocks cannot be changed and the performance of the additives cannot be reduced; and the gum-breaking residue of the fracturing fluid system is a little and the damage to the stratum islow.

Owner:PETROCHINA CO LTD

Preparation method of carboxymethyl guar gum

The invention relates to a novel preparation method of carboxymethyl guar gum, which comprises the following three steps: alkalization reaction, etherification reaction and after-treatment. The carboxymethyl guar gum is prepared from the raw material guar gum raw powder by using ethanol as a reaction solvent and sodium hydroxide as a catalyst; and the viscosity of the prepared carboxymethyl guar gum is 3600 mPa.s, and the substitution degree is 0.68. The carboxymethylation reaction of the guar gum is performed in the ethanol solution, so that the carboxymethyl guar gum prepared by the reaction between the chloroacetic acid and guar gum has the advantages of high substitution degree, high viscosity, high solubility and low content of water-insoluble substances. The raw material and process route related in the reaction process conform to the green chemical requirements, and can not generate pollutants, and thus, the reaction process is economic and environment-friendly and has high adaptability. The method has the advantages of short preparation route and simple technique, and is convenient to operate and suitable for large-scale industrial production.

Owner:LANZHOU UNIVERSITY

Biopolymer-based seed coatings compositions and methods for use

ActiveUS20190150354A1Promote seedling establishmentEasy to keepAmylose/amylopectin coatingsDextran coatingsCross-linkCellulose

A seed or seedling is coated with a cross-linked biopolymer and, optionally, a second binder selected from underivatized guar, cationic hydroxypropyl guar, polyacrylamide, poly(methacrylic acid), poly(acrylic acid), polyacrylate, poly(ethylene glycol), polyethyleneoxide, polyamide, hydroxypropyl guar, carboxymethyl guar, carboxymethylhydroxypropyl guar, underivatized starch, cationic starch, corn starch, wheat starch, rice starch, potato starch, tapioca, waxy maize, sorghum, waxy sarghum, sago, dextrin, chitin, chitosan, xanthan gum, carageenan gum, gum karaya, gum arabic, pectin, cellulose, hydroxycellulose, hydroxyalkyl cellulose, hydroxyethyl cellulose, carboxymethylhydroxyethyl cellulose, or hydroxypropyl cellulose. The seed coating composition is characterized by a dust value, as measured using a Heubach dustmeter device, which is lower by at least 30% as compared to an analogous composition that does not contain the crosslinked biopolymer.

Owner:RHODIA OPERATIONS SAS

Hydrophobic group and hydroxypropyl group-contained guar gum

InactiveCN102329396AReduce dosageHigh temperature resistanceDrilling compositionAdjuvantPolymer science

The invention relates to a method for preparing a hydrophobic group and hydroxypropyl group-contained guar gum. At present, the viscosifying agents used for compression fracture on an oilfield are mainly the three varieties, namely hydroxypropyl guar gum, carboxymethyl guar gum and carboxymethyl hydroxypropyl guar gum, the three viscosifying agents have single performance, fracturing fluid systems respectively formed by the three viscosifying agents all require stabilizing agents, cleanup additives, corrosion inhibitors and other varieties of adjuvants, the preparation of fracturing fluids is complicated, and the cost of fracturing construction is increased to a certain extent. According to the method provided by the invention, by taking guar gum pieces as a starting raw material and adopting a kneading method, the hydrophobic group and hydroxypropyl group-contained guar gum is synthesized through etherification and chain scission and grafting, and has the function of a surface active agent, the use amount of the surface active agent is reduced during the usage, the cost is reduced, at the same time, the temperature resistance of the guar gum is stronger than that of the single hydroxypropyl guar gum, and the temperature resistance of a deep well is strengthened.

Owner:西安长庆化工集团有限公司

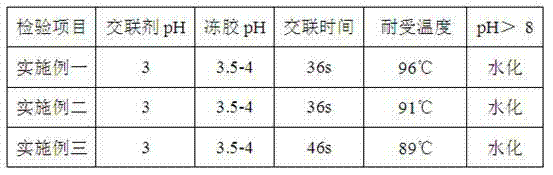

Preparation method of acidic crosslinking agent applied to carboxymethyl guar gum

InactiveCN102757779AHigh temperature resistanceGood sand carryingDrilling compositionCarboxymethyl guar gumZirconium oxychloride

The invention relates to a preparation method of an acidic crosslinking agent applied to carboxymethyl guar gum. An acid technology is usually carried out in a hydraulic fracturing process, which causes secondary damage to a reservoir stratum. The preparation method comprises the following steps of: uniformly mixing 3 parts by weight of citric acid, 57-82 parts by weight of water and 10-20 parts by weight of micromolecular polyhydroxy compound and heating, after the temperature reaches 50 DEG C, slowly adding 5-20 parts by weight of zirconium oxychloride; and keeping the temperature to be 50-55 DEG C, reacting for 3-4 hours, cooling a product to reach room temperature to obtain the acidic crosslinking agent. The cidic crosslinking agent provided by the invention is suitable for an acidic system, and jelly formed by crosslinking is higher in temperature tolerance and is well in sand carrying property, and can be applied to an alkaline-sensitive stratum; a small quantity of citric acid is added in a synthesis process, so that the pH of the whole reaction system is kept constant, the operation step during production is simplified; and the consumption of the organic zirconium crosslinking agent is 0.8 percent, the concentration of a carboxymethyl guar gum water solution is 0.4 percent, and the quantity of residue after crosslinking gelout is 160mg / L.

Owner:SHAANXI UNIV OF SCI & TECH

Seed coatings, coating compositions and methods for use

ActiveUS10745578B2Promote plant growthImprove adhesionBiocideCellulose coatingsPolymer sciencePotato starch

A seed or seedling is coated with underivatized guar, cationic hydroxypropyl guar, polyacrylamide, poly(methacrylic acid), poly(acrylic acid), polyacrylate, polyethylene glycol), polyethyleneoxide, poly(vinyl alcohol), polyglycerol, polytetrahydrofuran, polyamide, hydroxypropyl guar, carboxymethyl guar, carboxymethylhydroxypropyl guar, underivatized starch, cationic starch, corn starch, wheat starch, rice starch, potato starch, tapioca, waxy maize, sorghum, waxy sorghum, sago, dextrin, chitin, chitosan, xanthan gum, carageenan gum, gum karaya, gum arabic, pectin, cellulose, hydroxycellulose, hydroxyalkyl cellulose, hydroxyethyl cellulose, carboxymethylhydroxyethyl cellulose, or hydroxypropyl cellulose, the coated seed or seedling having a shelf-life at room temperature in ambient conditions in an unsealed container to at least two months.

Owner:SPECIALTY OPERATIONS FRANCE

Method of delaying crosslinking in well treatment operation

InactiveUS20150101818A1Delayed formationFluid removalDrilling compositionAcetic acidCarboxymethyl guar gum

Crosslinking of a crosslinkable viscosifying agent and a crosslinking agent may be delayed in a well treatment fluid by incorporated within the fluid a glutamic-N,N-diacetic acid salt, such as a glutamic-N,N-diacetic acid sodium salt like tetrasodium glutamate diacetate. The crosslinking agent may be a zirconium containing crosslinking agent like zirconium (IV) acetyl acetonate. The viscosifying agent may be guar or a guar derivative such as carboxyalkyl guars and hydroxyalkylated guars like carboxymethyl guar, hydroxypropyl guar, hydroxyethyl guar, hydroxybutyl guar and carboxymethylhydroxypropyl guar.

Owner:BAKER HUGHES HLDG LLC

Carboxymethyl guar gum cross-linking agent and preparation method and application thereof

The invention discloses a carboxymethyl guar gum cross-linking agent and a preparation method and application thereof. The technical scheme is characterized in that the carboxymethyl guar gum cross-linking agent comprises the following raw materials in percentage by weight: 8-12% of crystalline aluminum chloride, 20%-22% of additives and the balance of water, wherein the additives are at least two of formaldehyde, glyoxal, ethanediol, propanetriol and glacial acetic acid. The invention also discloses the preparation method of the carboxymethyl guar gum cross-linking agent and the application of the carboxymethyl guar gum cross-linking agent in a carboxymethyl guar gum fracturing fluid system. The carboxymethyl guar gum cross-linking agent prepared through the method disclosed by the invention has the advantages of wide applicability, good cross-linking property and low integrated cost; after added with the carboxymethyl guar gum cross-linking agent, the carboxymethyl guar gum fracturing fluid system becomes weakly acidic and has a pH value of 3-4, and has the functions of effectively inhibiting the expansion migration caused by the electronegativity of a clay surface, thus playing a role in stabilizing clay.

Owner:HENAN NORMAL UNIV

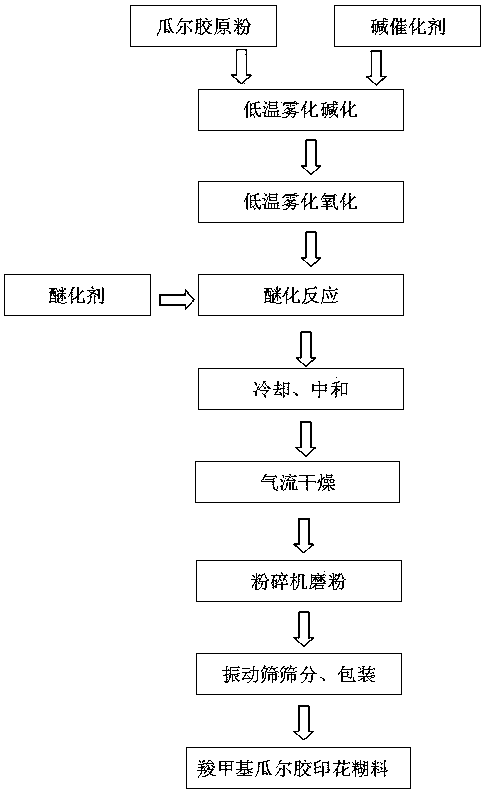

Preparation method of high-substituted-ratio carboxyl methyl guar printing gum

ActiveCN102720073BImprove finenessGood water solubilityDyeing processSolubilityCarboxymethyl guar gum

The invention discloses a preparation method of high-substituted-ratio carboxyl methyl guar printing gum, which belongs to the technical field of modified guar. The preparation method comprises the steps of performing the procedures of atomizing alkalization, atomizing oxidization, etherification, cooling neutralization, drying, crushing screening and packaging on raw guar powders to obtain the high-substituted-ratio carboxyl methyl guar printing gum. According to the preparation method, the uniformity of a grafting group is ensured by virtue of high-efficiency atomizing and spraying; the high substituted ratio of a final product is ensured by virtue of semi-dry etherification, so that the difficulties of poor uniformity and low substituted ratio of the conventional carboxyl methyl vegetable glue are solved; and simultaneously, compared with the conventional wet processing, the preparation method is more environment-friendly and more economical. The product, namely the high-substituted-ratio carboxyl methyl guar printing gum, disclosed by the invention can partly or wholly replace sodium alga acid to be applied to printing of activated dyes and the printing process of other anionic dyes, and is equivalent to the sodium alga acid in the aspect of application effects of water solubility, color fastness, color yield, vividness, handfeeling and the like, thus serving as a good substitute of the sodium alga acid.

Owner:无锡金鑫科技有限公司

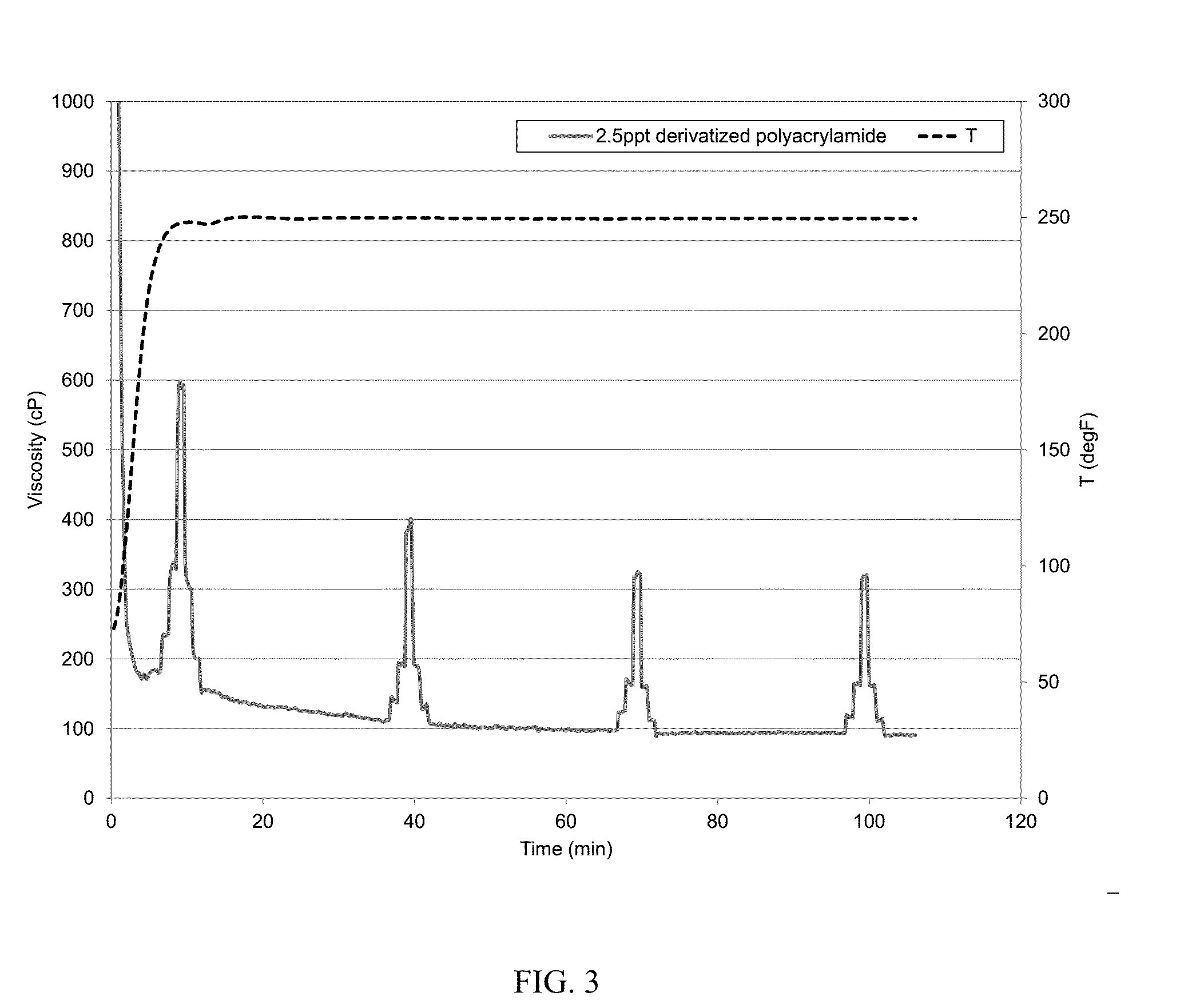

Method of stabilizing viscosifying polymers in well treatment fluid

InactiveUS20150284624A1Improve productivityFluid removalFlushingCarboxymethyl celluloseProduction rate

Productivity from a subterranean formation is enhanced by pumping into a well penetrating the formation after the well has been drilled a hard water aqueous fluid containing a polymeric stabilizer and a crosslinkable viscosifying polymer such as carboxymethyl guar or carboxymethyl cellulose.

Owner:BAKER HUGHES INC

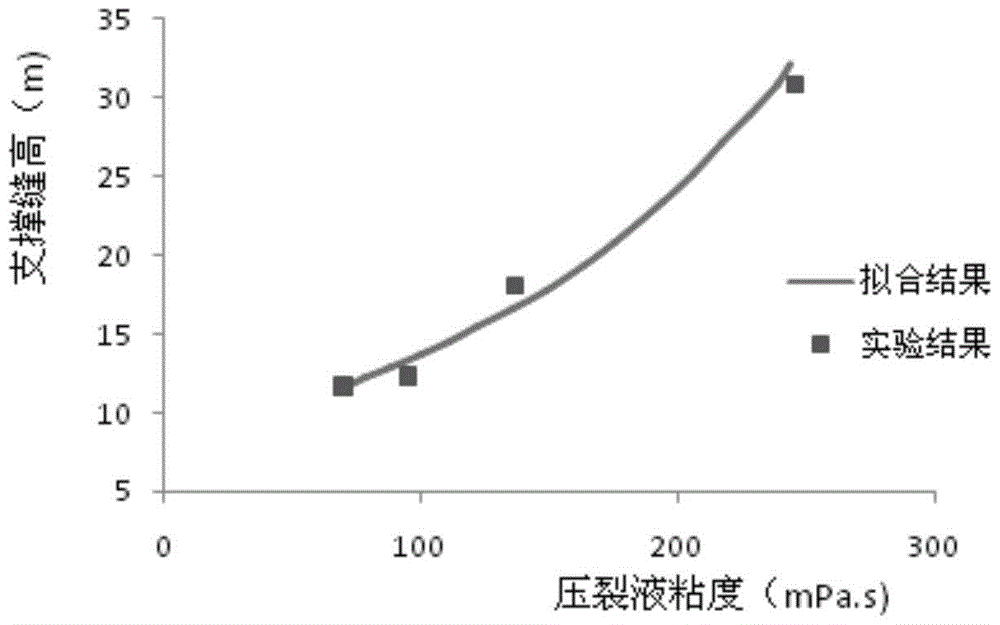

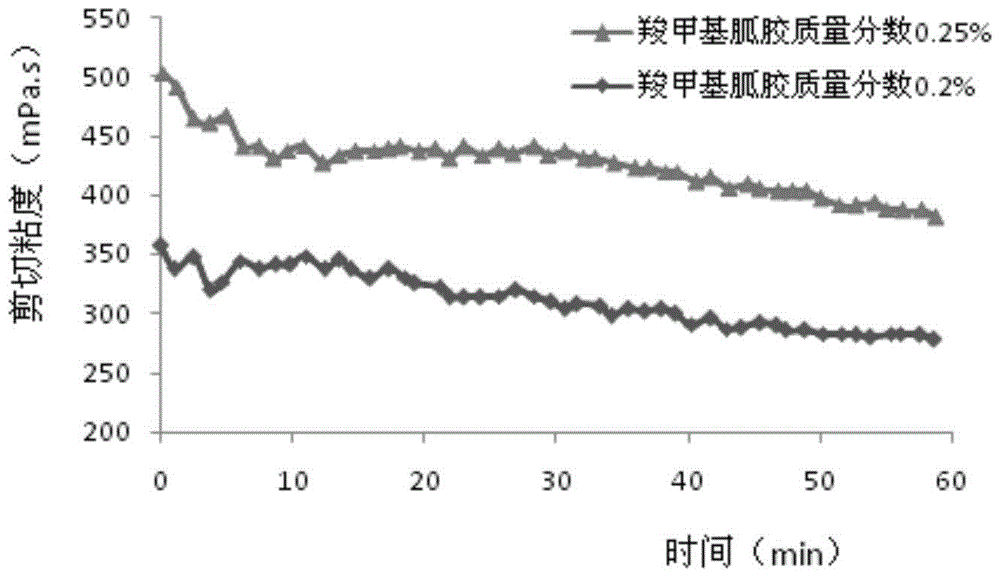

Low-concentration carboxymethyl fracturing fluid and preparation method thereof

The invention discloses a low-concentration carboxymethyl fracturing fluid and a preparation method thereof. At present, a hydraulic fracturing mode is adopted for reconstructing a reservoir bed, but a fracturing fluid system has high gel breaking residue content; when the reservoir bed is reconstructed, the using amount of a gel breaking agent is high, and the average increment reaches about 0.03 percent; after the fracturing fluid is subjected to gel breakage at formation temperature and flow-back fluid reaches ground, a certain cross-linking back condition exists due to reduction in temperature. The fracturing fluid consists of 96.15-98.85 parts of water, 0.25-0.3 part of carboxymethyl guar gum, 0.15-0.25 part of JL-11 cross-linking agent, 0.30-1.0 part of surfactant, 0.20-1.0 part of clay stabilizer, 0.05-0.5 part of bactericide and 0.2-0.8 part of temperature-resistant intensifier. Prepared solution A and L-11 cross-linking agent are mixed according to a volumetric ratio of 100:0.15-100:0.25 to form the fracturing fluid. In the water-based fracturing fluid cross-linked under an alkaline condition, due to low concentration of a thickening agent, low gel breakage residue and high flow guide capacity, the damage caused to the reservoir bed by the fracturing fluid is reduced, and production increasing and reconstruction effects are improved.

Owner:西安长庆化工集团有限公司 +1

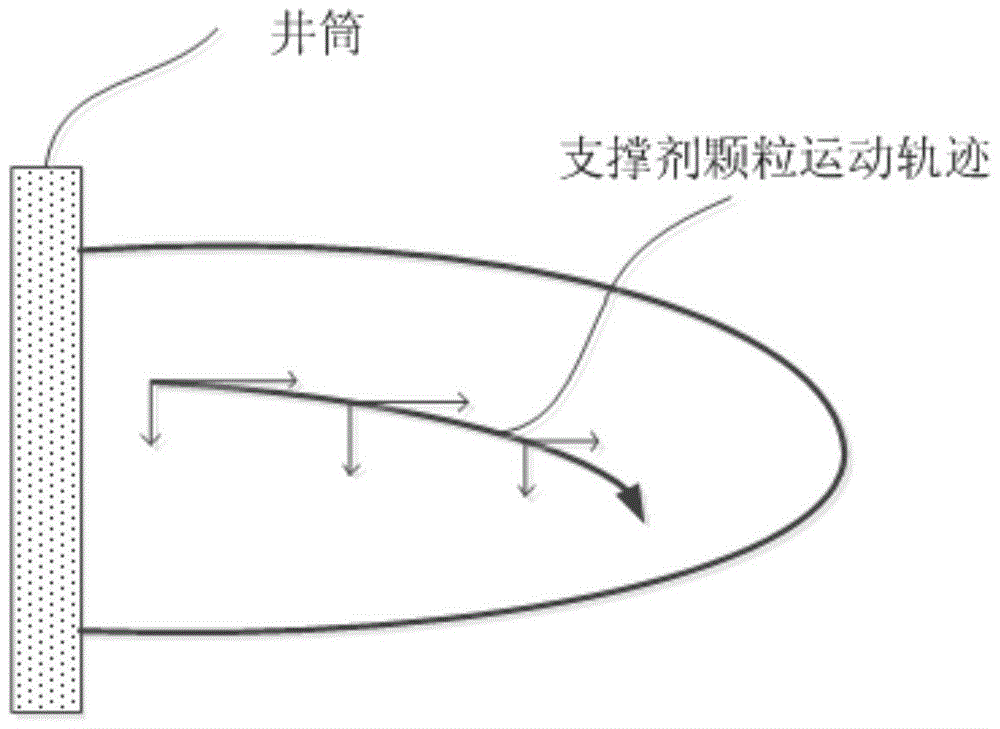

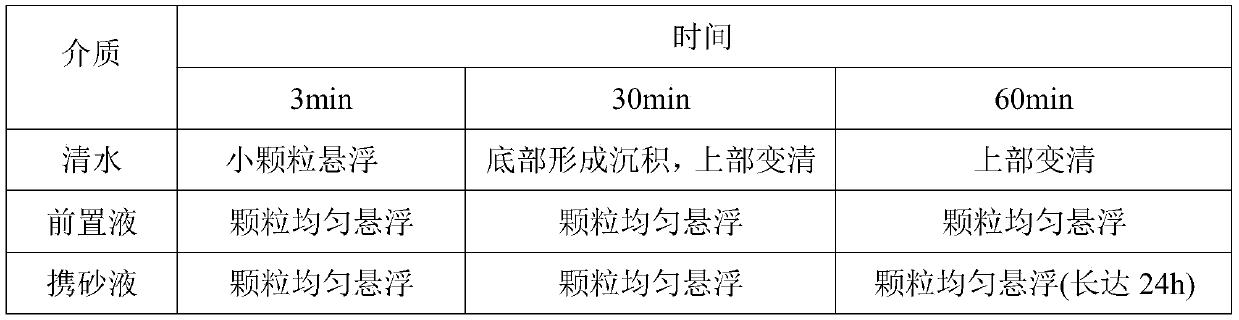

A method for hydraulic fracturing of coalbed methane

ActiveCN104088616BEfficient miningReduced fracturing costsFluid removalDrilling compositionCarboxymethyl guar gumFracturing fluid

The invention relates to a hydraulic fracturing method for coal bed gas. Active water fracturing fluid is used as the front fluid and the displacement fluid, and carboxymethyl guaridine fracturing fluid is used as the sand-carrying fluid; four kinds of quartz sands with different particle size ranges are selected as the proppant 100-70 mesh silt sand and 70-40 mesh fine sand are used as proppant in the pre-fluid, and 40-20 mesh medium sand and 20-14 mesh coarse sand are used as proppant in the sand-carrying liquid; the proppant selection is different The ratio of the amount of sand added to the particle size sand; the concentration of the clay stabilizer KCl in the active water fracturing fluid and the carboxymethyl guar gum fracturing fluid is based on the natural gamma ray log expressed in API units of the logging data of the fracturing target interval Intensity GR averages are determined. The invention greatly improves the effect of coal bed methane recovery increase, effectively prevents swelling and at the same time reduces the configuration cost of fracturing fluid to the greatest extent.

Owner:INST OF ROCK & SOIL MECHANICS CHINESE ACAD OF SCI

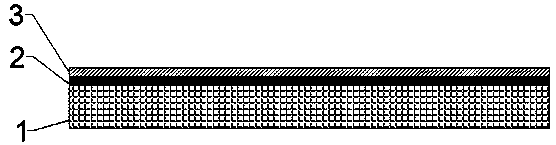

Flame-retardant pearl wool foam board

InactiveCN110157028AImprove flame retardant performanceReduce the temperatureFireproof paintsPolyurea/polyurethane coatingsFiberCarboxymethyl guar gum

The invention relates to a flame-retardant pearl wool foam board which consists of a main body, a flame-retardant layer and an auxiliary layer, wherein the flame-retardant layer consists of polyacrylate, aluminum sulfate octadecahydrate, basic magnesium aluminum carbonate, polycarbonate and a dispersant; and the auxiliary layer consists of waterborne polyurethane, polyacrylamide, carboxymethyl guar gum, carboxymethyl cellulose, an activated carbon fiber, porous latex and a dispersant. The flame-retardant pearl wool foam board provided by the invention has a flame-retardant layer, both the aluminum sulfate octadecahydrate and the basic magnesium aluminum carbonate can emit moisture when being combusted, then an ambient temperature can be reduced, and functions of fire extinguishing and flame retardancy can be achieved. Meanwhile, due to adoption of the auxiliary layer consisting of dilution materials, moisture in the environment can be absorbed by the auxiliary layer at normal time, andthe absorbed moisture can be released in combustion or at a high temperature; and partial humidity of the environment can be increased, partial temperatures of the environment can be reduced, then combustion can be prevented or retarded, the flame-retardant layer is assisted, and the flame retardancy effect of the pearl wool foam board can be improved.

Owner:张家港市禾守环保科技有限公司

Methyl carboxymethyl guar gum as well as preparation method and application thereof

ActiveCN111574637AFlexible adjustment of water solubilityImprove rheologyDyeing processSolubilityCarboxymethyl guar gum

The invention provides methyl carboxymethyl guar gum as well as a preparation method and application thereof, and belongs to the technical field of active printing and dyeing paste. The invention provides methyl carboxymethyl guar gum. The aqueous solution of the methyl carboxymethyl guar gum has high viscosity, good rheological property and high permeability, and the methyl carboxymethyl guar gumis used as a paste material in reactive printing and dyeing, has good water solubility, is easy to elute, has good rheological property when passing through a printing screen, and does not react withreactive dye and a fabric chemically, so that the hand feeling of the fabric is not influenced; and methyl has certain hydrophobicity, so that the dispersion of the dye in the paste is facilitated, and the paste removal rate is high.

Owner:昆山京昆油田化学科技有限公司

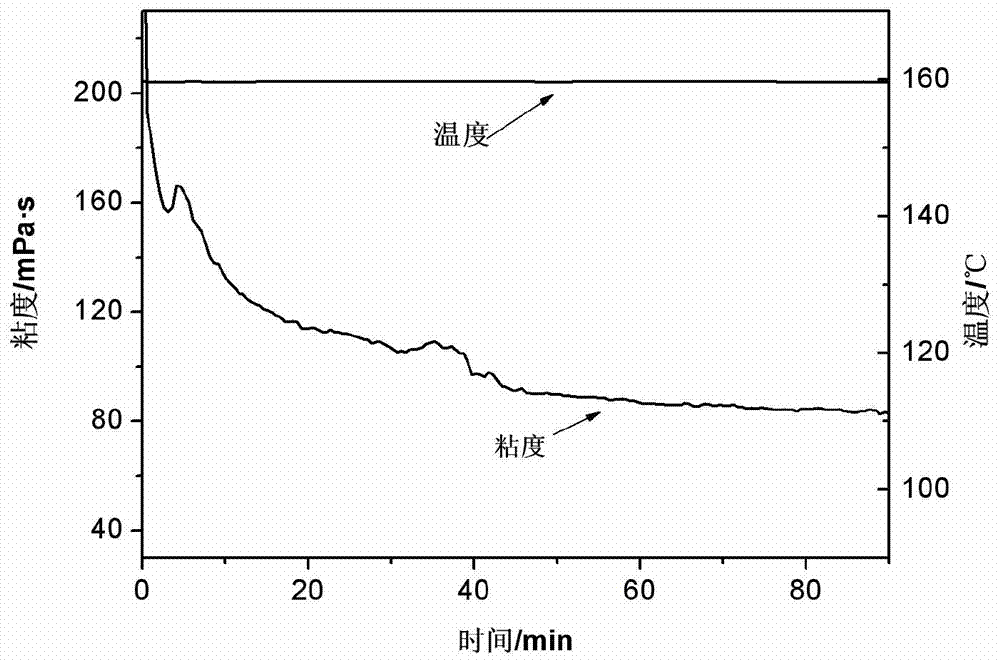

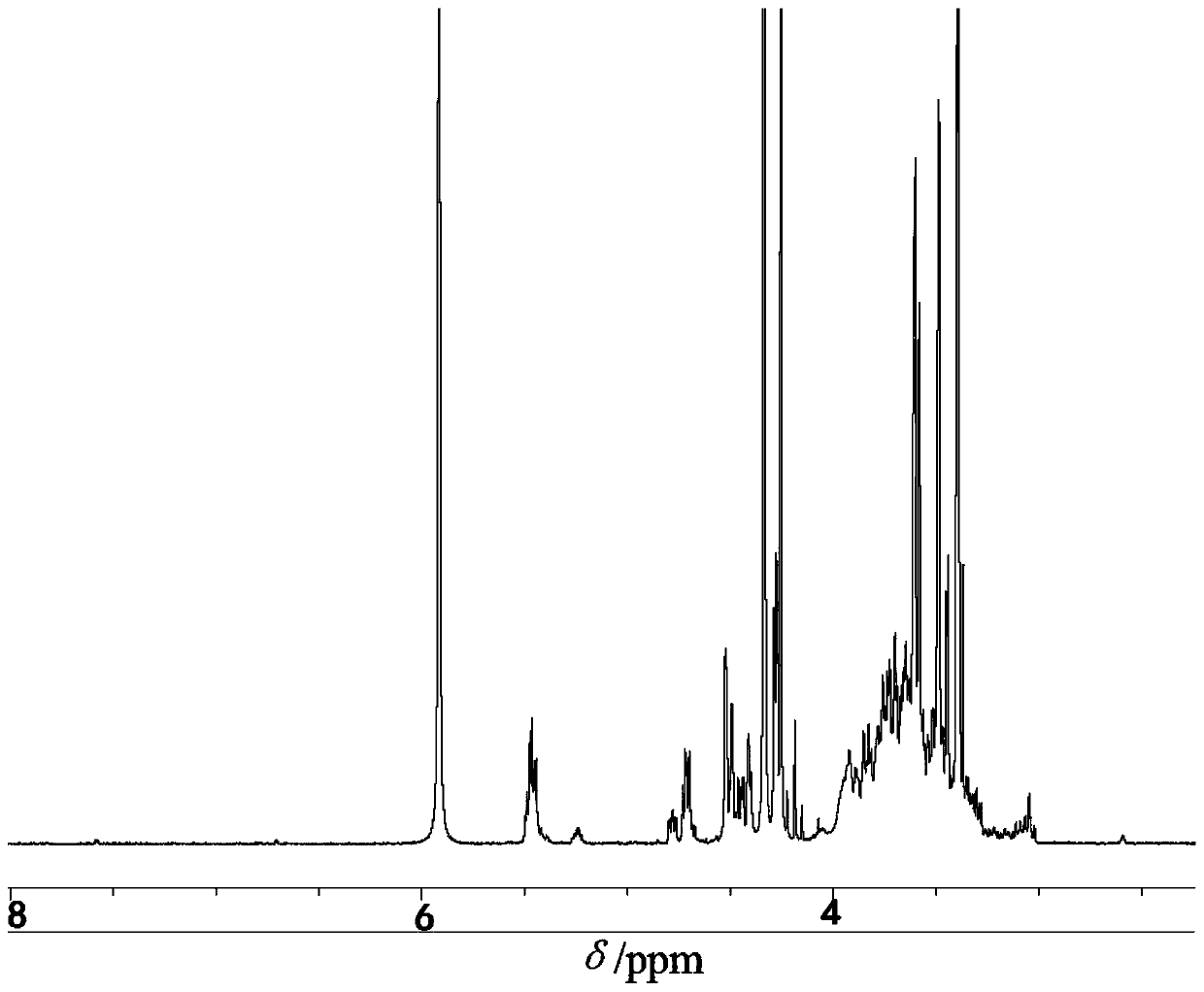

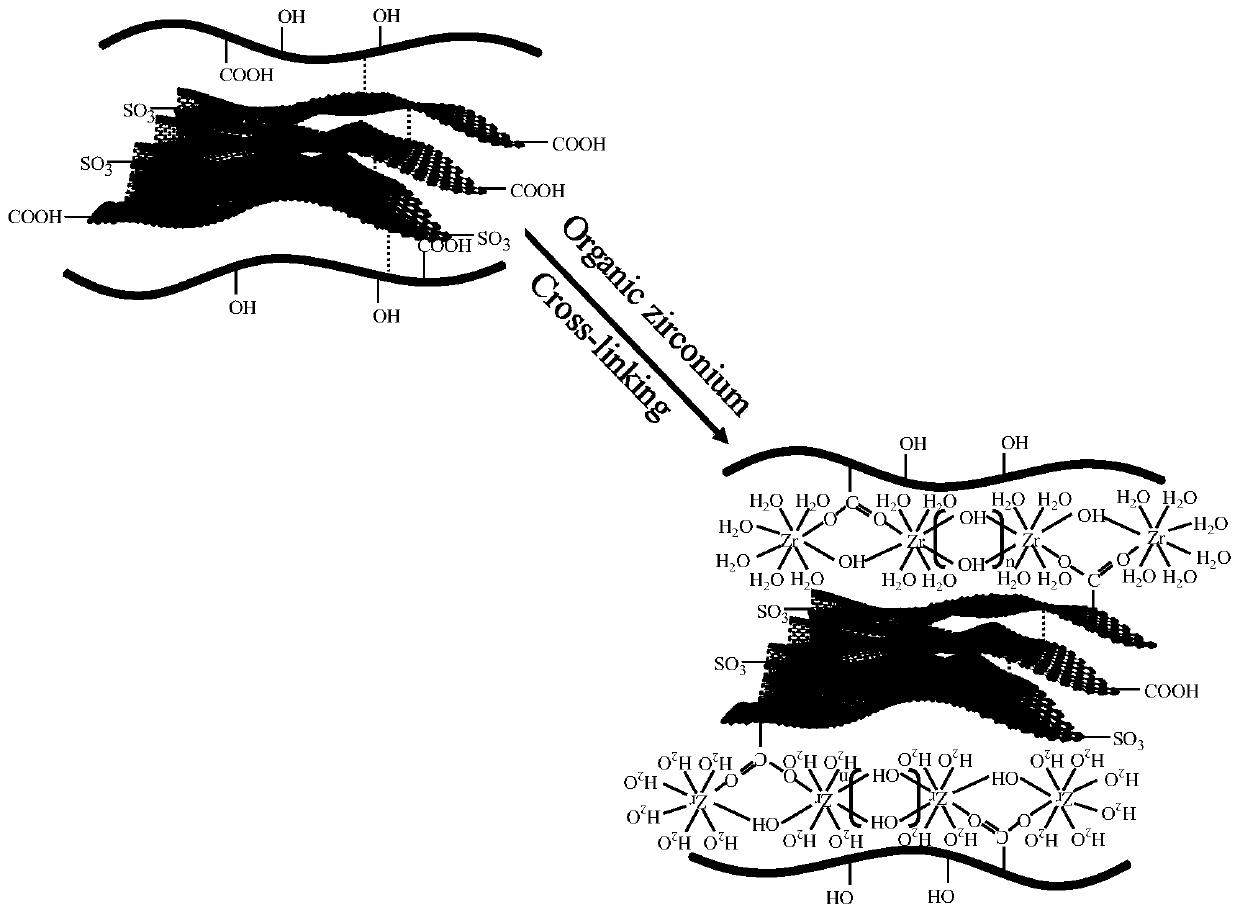

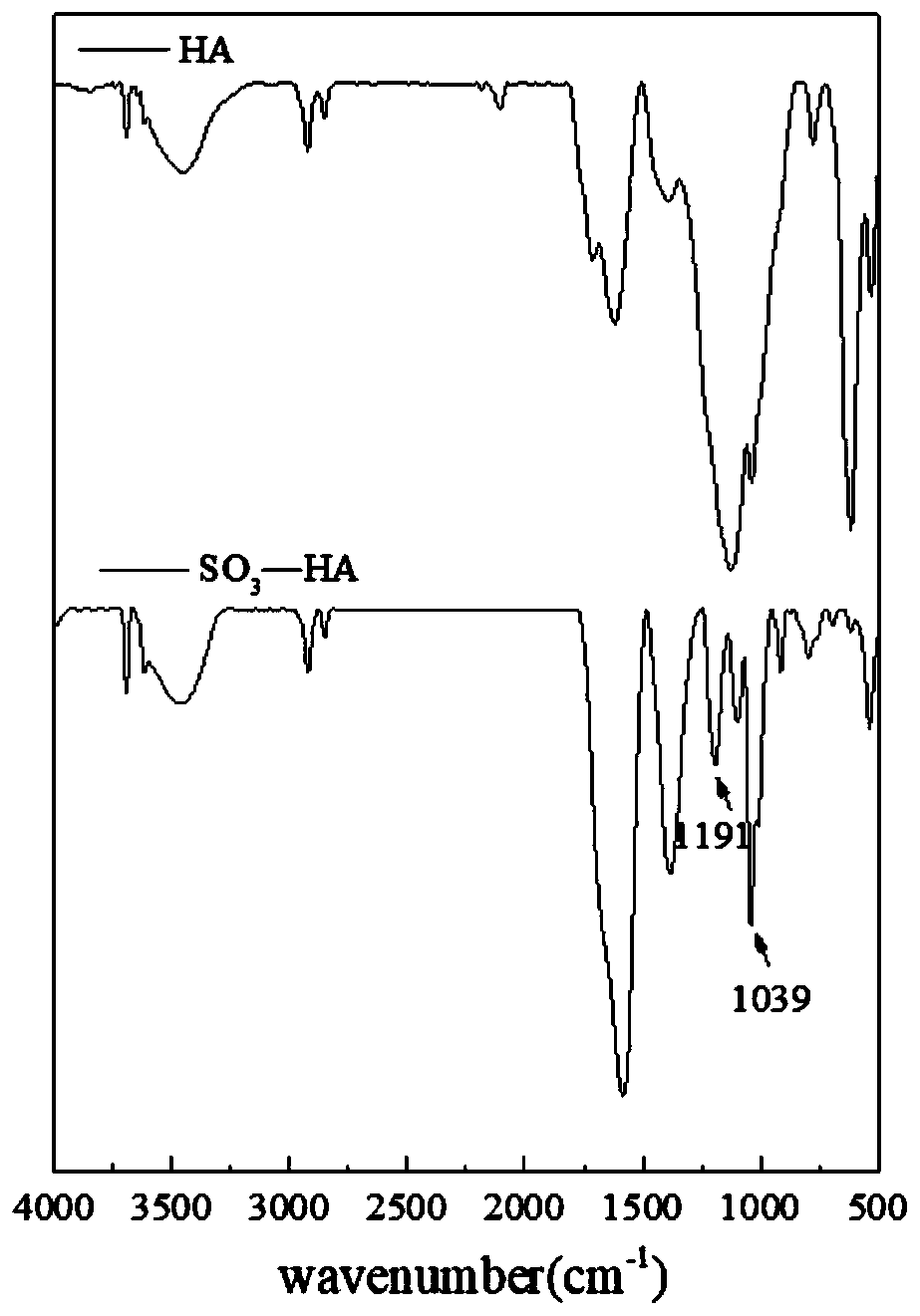

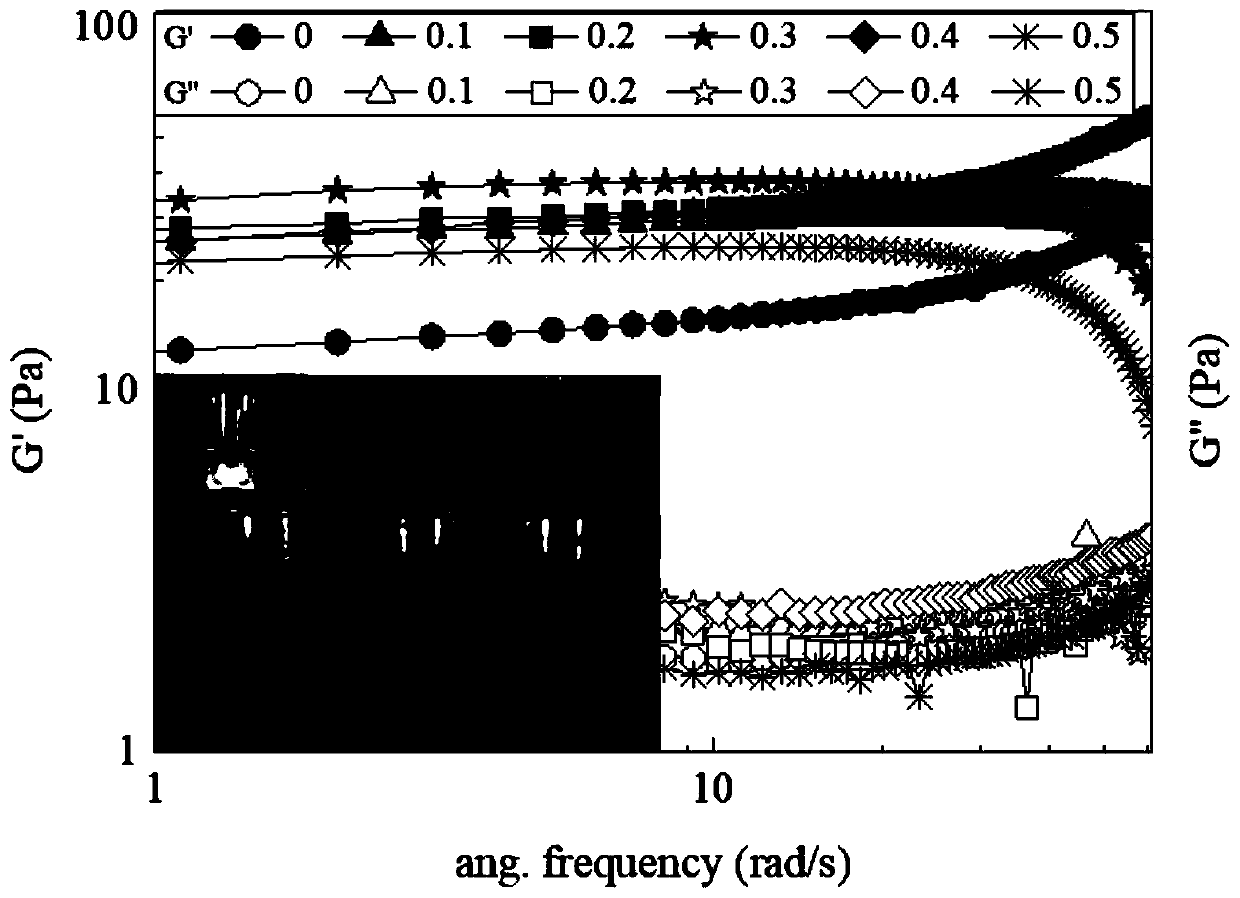

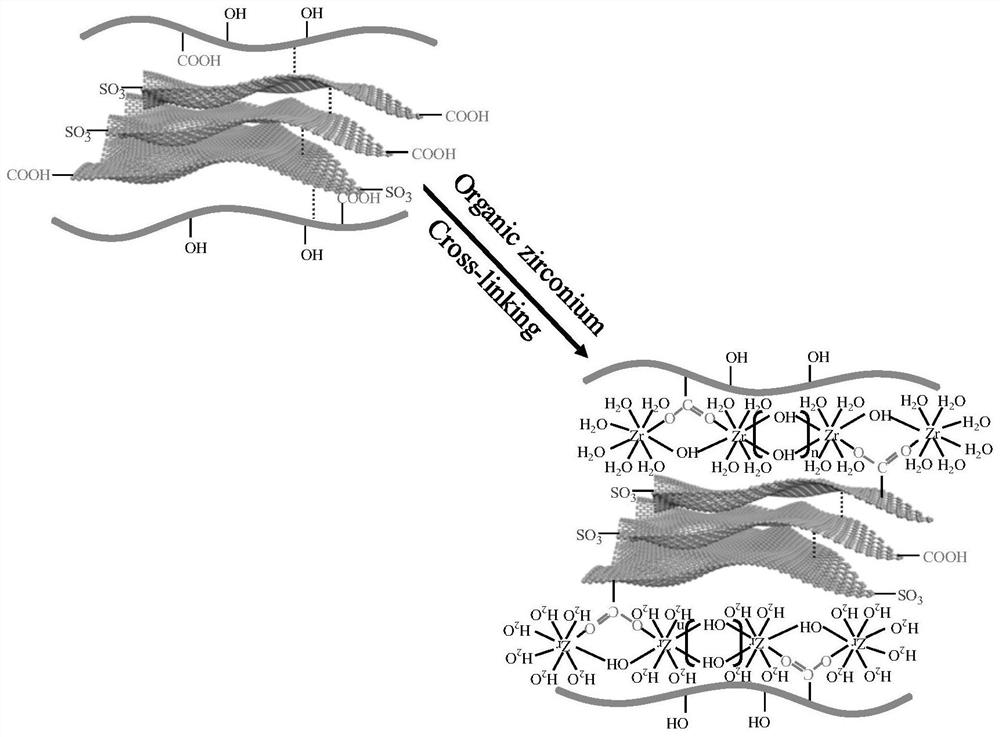

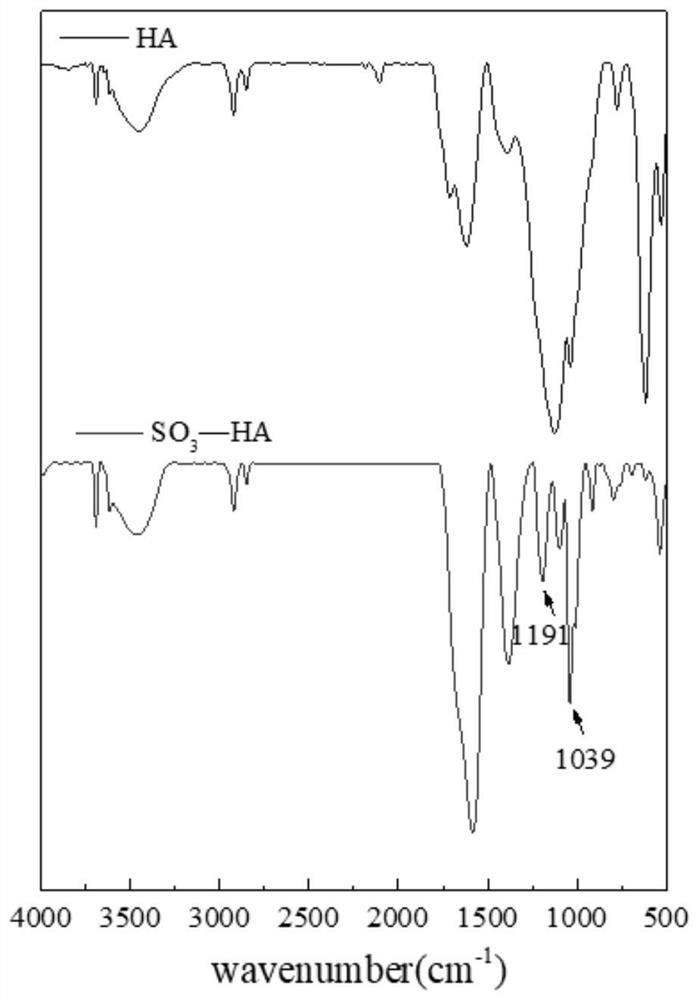

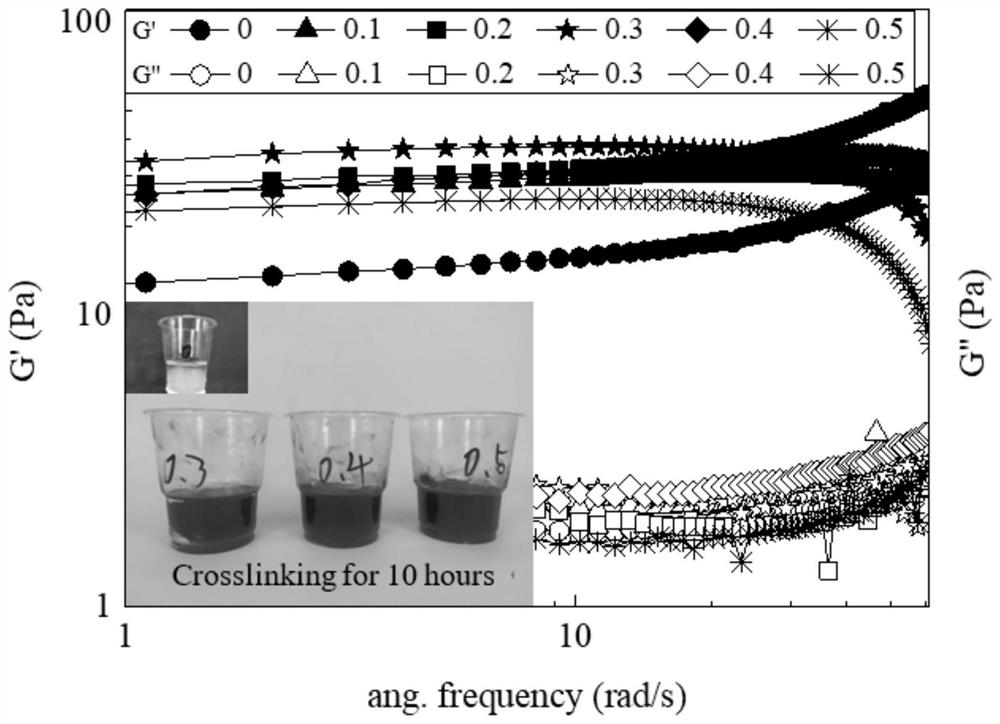

Sulfonated humic acid fracturing fluid and preparation method thereof

ActiveCN111334278AImprove water retentionHigh viscoelasticityDrilling compositionCarboxymethyl guar gumSulfite salt

The invention discloses a sulfonated humic acid fracturing fluid and a preparation method thereof. The method comprises the steps of: 1) completely dissolving humic acid in a sodium hydroxide solution, then adding sodium sulfite, conducting heating and stirring continuously, and then adding a hydrochloric acid solution dropwise until brown and black pasty precipitates are generated; purifying thebrownish black slurry to obtain sulfonated humic acid; 2) dissolving zirconium oxychloride and ammonium chloride in water, then adding ethylene glycol and lactic acid, then adding a potassium hydroxide solution dropwise until the pH value is neutral, and continuously performing heating and stirring to obtain a colorless and transparent organic zirconium binder; 3) preparing a carboxymethyl guar gum solution; adding sulfonated humic acid into the carboxymethyl guar gum solution, and stirring the substances uniformly, and then adding an organic zirconium cross-linking agent to obtain the sulfonated humic acid fracturing fluid. According to the novel fracturing fluid obtained by the invention, the water-retaining properties are improved, the viscoelasticity is also improved, and the salt tolerance is very considerable due to the adding of sulfonic acid group.

Owner:SHAANXI UNIV OF SCI & TECH

Carboxymethyl guar gum acid fracturing fluid

ActiveCN102102014BReduce contentReduce performanceDrilling compositionAluminium chloridePolymer science

The invention relates to carboxymethyl guar gum acid fracturing fluid, which is prepared from the following components of water, carboxymethyl hydroxypropyl guar gum, a CJ-2 heat-resistant reinforcing agent, a surfactant, a COP-SH clay stabilizer, and a JL-12 crosslinking agent, wherein the JL-12 crosslinking agent is prepared by complexing aluminium chloride and C3-C7 straight chain organic ketone; the COP-SH clay stabilizer is (C4-C8) small cationic quaternary ammonium salt; the CJ-2 heat-resistant reinforcing agent is a mixture of sulfuric acid and citric acid or ethylic acid, which has the pH value of 1-3; the surfactant is a non-ionic fluorocarbon surfactant; a thickening agent of a fracturing fluid system can be used under the acid condition, and the content of water insolubles is more than 5 percent lower than that of the conventional hydroxypropyl guar gum; the matched additives are non-cationic additives, and are difficult to adsorb after entering stratum, so that the wettability of stratum rocks cannot be changed and the performance of the additives cannot be reduced; and the gum-breaking residue of the fracturing fluid system is a little and the damage to the stratum islow.

Owner:PETROCHINA CO LTD

A kind of sulfonated humic acid fracturing fluid and preparation method thereof

ActiveCN111334278BImprove water retentionHigh viscoelasticityDrilling compositionCarboxymethyl guar gumSulfite salt

The invention discloses a sulfonated humic acid fracturing fluid and a preparation method thereof. The method comprises: 1) completely dissolving humic acid in sodium hydroxide solution, then adding sodium sulfite, continuously heating and stirring, and then adding dropwise hydrochloric acid solution until brown and black paste precipitates are produced; the brown-black slurry is purified to obtain sulfonated humic acid; 2) dissolving zirconium oxychloride and ammonium chloride in water, then adding ethylene glycol and lactic acid, and then Add potassium hydroxide solution dropwise until the pH value reaches neutral, continue heating and stirring to obtain a colorless and transparent organic zirconium crosslinking agent; 3) configure carboxymethyl guar gum solution; add sulfonated humic acid to carboxymethyl Stir evenly in the guar gum-based solution; then add an organic zirconium cross-linking agent to obtain sulfonated humic acid fracturing fluid. The novel fracturing fluid obtained by the present invention not only improves the water retention, but also improves the viscoelasticity, and the addition of the sulfonic acid group makes the salt resistance very considerable.

Owner:SHAANXI UNIV OF SCI & TECH

A kind of carboxymethyl guar gum crosslinking agent and its preparation method and application

Owner:HENAN NORMAL UNIV

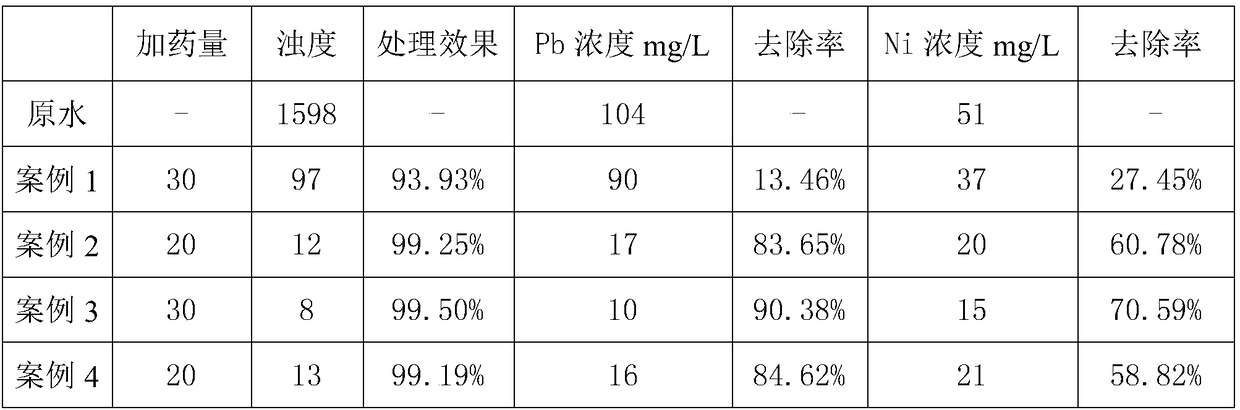

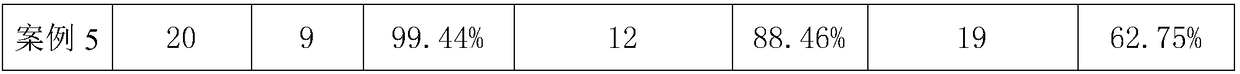

Nanoparticle structure magnetic water purifier and preparation method thereof

InactiveCN108483552ASmall particle sizeLarge specific surface areaWater contaminantsWater/sewage treatment by sorptionEpoxyCarboxymethyl guar gum

The invention discloses a nanoparticle structure magnetic water purifier and a preparation method thereof. The nanoparticle structure magnetic water purifier is high in treatment speed and good in water purification effect. According to the technical scheme, guar gum is modified, carboxyl methyl guar gum epoxy chloropropane polymer is synthesized, ferrous, ferric iron and the polymer are placed into the same reaction system and grafted to the surface of a nanometer ferroferric oxide particle through a coprecipitation method, and the magnetic nano-particle wrapped by the carboxyl methyl guar gum epoxy chloropropane polymer is manufactured, and the water purifier is applicable to the field of industrial wastewater treatment.

Owner:广州小众环保科技有限公司

Water-soluble temporary plugging agent suitable for secondary fracturing and preparation method thereof

ActiveCN110283578AExcellent viscoelastic propertiesExcellent plugging strengthDrilling compositionPolymer scienceSodium Bentonite

The invention discloses a water-soluble temporary plugging agent suitable for secondary fracturing. The agent is prepared from the following raw material components in percentage by mass: 55-65% of polylactic acid, 20-25% of carboxymethyl guar gum, 10-15% of rubber powder, 3-8% of bentonite, and 0.5-3% of a fluorocarbon surfactant. The rubber powder is butyl rubber powder or high styrene styrene butadiene rubber powder. The preparation method of the water-soluble temporary plugging agent comprises the following steps: adding the polylactic acid into a decompression kettle, heating to 85-95 DEG C, preserving constant temperature, adding the carboxymethyl guar gum after the polylactic acid softens, and stirring and mixing evenly; adding the fluorocarbon surfactant into a mixed material, and mixing evenly; then adding the rubber powder and the bentonite, and stirring for reacting for 2 hours; cooling and solidifying after the reaction is completed, and smashing to obtain the water-soluble temporary plugging agent. Compared with a conventional temporary plugging agent of the same type, the water-soluble temporary plugging agent disclosed by the invention is higher in plugging strength, adhesion performance and suspension stability than the conventional temporary plugging agent, and the requirements of site construction can be met.

Owner:SOUTHWEST PETROLEUM UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com