Flame-retardant pearl wool foam board

A technology of pearl cotton and foam board, used in coatings, fire-retardant coatings, polyurea/polyurethane coatings, etc., can solve problems such as the scope of blocking application and the general flame retardant performance of pearl cotton, and achieve good flame retardant effect, resistance to The effect of improving combustion efficiency and reducing local temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

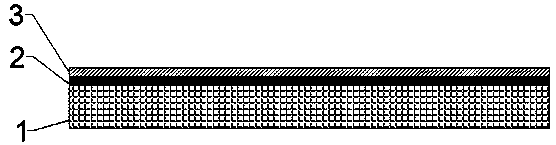

[0018] Such as figure 1 As shown, a flame-retardant pearl cotton foam board is composed of a main body 1, a flame-retardant layer 2 and an auxiliary layer 3, and the flame-retardant layer 2 and the auxiliary layer 3 are arranged on the main body 1 from inside to outside.

[0019] The main body 1 is prepared from the following raw materials according to the conventional process: 100 parts by mass of low-density polyethylene, 6 parts by mass of butane, 1 part by mass of monoglyceride, and 0.5 part by mass of talcum powder; wherein monoglyceride is a food with a content greater than 98wt% Grade monoglyceride, talc powder is superfine talc powder with a particle size above 5000 mesh.

[0020] The flame retardant layer 2 is composed of 100 parts by mass of polyacrylate, 12 parts by mass of aluminum sulfate octadecahydrate, 5 parts by mass of basic aluminum magnesium carbonate, 26 parts by mass of polycarbonate, and 2.5 parts by mass of a dispersant. The flame retardant layer 2 is ...

Embodiment 2

[0023] Such as figure 1 As shown, a flame-retardant pearl cotton foam board is composed of a main body 1, a flame-retardant layer 2 and an auxiliary layer 3, and the flame-retardant layer 2 and the auxiliary layer 3 are arranged on the main body 1 from inside to outside.

[0024] The main body 1 is prepared from the following raw materials according to the conventional process: 100 parts by mass of low-density polyethylene, 8 parts by mass of butane, 3 parts by mass of monoglyceride, and 1 part by mass of talcum powder; wherein monoglyceride is a food with a content greater than 98wt% Grade monoglyceride, talc powder is superfine talc powder with a particle size above 5000 mesh.

[0025] The flame retardant layer 2 is composed of 100 parts by mass of polyacrylate, 6 parts by mass of aluminum sulfate octadecahydrate, 3 parts by mass of basic aluminum magnesium carbonate, 35 parts by mass of polycarbonate, and 3 parts by mass of dispersant. The flame retardant layer 2 is prepar...

Embodiment 3

[0028] Such as figure 1 As shown, a flame-retardant pearl cotton foam board is composed of a main body 1, a flame-retardant layer 2 and an auxiliary layer 3, and the flame-retardant layer 2 and the auxiliary layer 3 are arranged on the main body 1 from inside to outside.

[0029] The main body 1 is prepared from the following raw materials according to the conventional process: 100 parts by mass of low-density polyethylene, 9 parts by mass of butane, 5 parts by mass of monoglyceride, and 1.5 parts by mass of talcum powder; wherein monoglyceride is a food with a content greater than 98wt% Grade monoglyceride, talc powder is superfine talc powder with a particle size above 5000 mesh.

[0030] The flame-retardant layer 2 is composed of 100 parts by mass of polyacrylate, 6 parts by mass of aluminum sulfate octadecahydrate, 12 parts by mass of basic aluminum magnesium carbonate, 15 parts by mass of polycarbonate, and 1 part by mass of a dispersant. The flame retardant layer 2 is p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com