Water-soluble temporary plugging agent suitable for secondary fracturing and preparation method thereof

A secondary fracturing, water-soluble technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of rising water content of construction wells and limited influence, and achieve enhanced plugging capacity, mild reaction conditions, The effect of facilitating large-scale industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

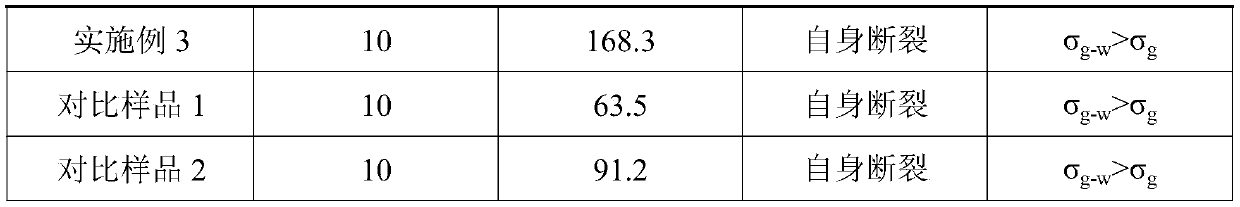

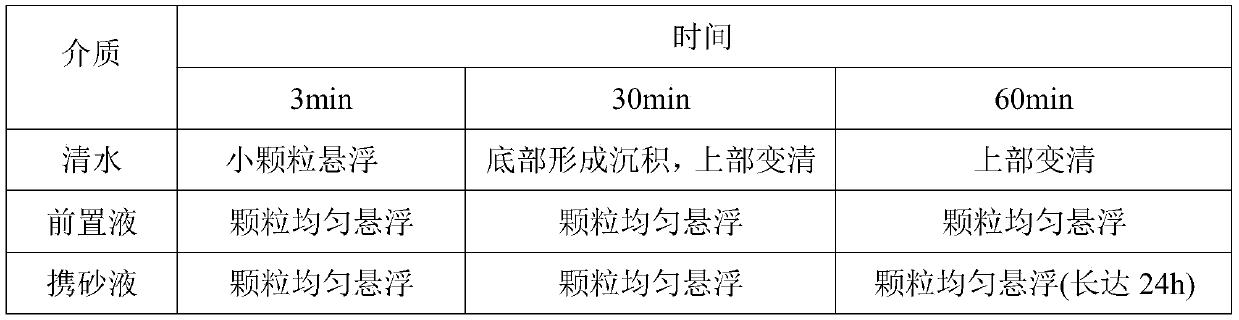

Examples

Embodiment 1

[0020] A preparation method of a water-soluble temporary plugging agent suitable for secondary fracturing, the steps are as follows:

[0021] S1. The raw material components were weighed according to the following mass percentages: 55% polylactic acid, 20% carboxymethyl guar gum, 15% butyl rubber powder, 7% bentonite, and 3% perfluorocetyl ammonium chloride.

[0022] S2. Add polylactic acid into a vacuum kettle, heat to 90°C, and keep the temperature constant. After the polylactic acid is softened, add carboxymethyl guar gum, and stir to mix evenly.

[0023] S3. Add fluorocarbon surfactant to the mixed material in step S1, and mix evenly; then add butyl rubber powder and bentonite, and stir for 2 hours.

[0024] S4. After the reaction is completed, cool and solidify, and pulverize to obtain a water-soluble temporary plugging agent.

Embodiment 2

[0026] A preparation method of a water-soluble temporary plugging agent suitable for secondary fracturing, the steps are as follows:

[0027] S1. The raw material components were weighed according to the following mass percentages: 65% polylactic acid, 21% carboxymethyl guar gum, 10% high-styrene styrene-butadiene rubber powder, 3% bentonite, and 1 perfluorohexadecyl ammonium chloride. %.

[0028] S2. Add polylactic acid into a vacuum kettle, heat to 95° C., and keep the temperature constant. After the polylactic acid is softened, add carboxymethyl guar gum, and stir to mix evenly.

[0029] S3. Add fluorocarbon surfactant to the mixed material in step S1, and mix evenly; then add high-styrene styrene-butadiene rubber powder and bentonite, and stir for 2 hours.

[0030] S4. After the reaction is completed, cool and solidify, and pulverize to obtain a water-soluble temporary plugging agent.

Embodiment 3

[0032] A preparation method of a water-soluble temporary plugging agent suitable for secondary fracturing, the steps are as follows:

[0033] S1. The raw material components are weighed according to the following mass percentages: 60% polylactic acid, 25% carboxymethyl guar gum, 11% mixture of butyl rubber powder and high styrene butadiene rubber powder by mass ratio, 3% bentonite, Perfluorocetyl ammonium chloride 1%.

[0034] S2. Add polylactic acid into a vacuum kettle, heat to 95° C., and keep the temperature constant. After the polylactic acid is softened, add carboxymethyl guar gum, and stir to mix evenly.

[0035] S3. Add a fluorocarbon surfactant to the mixed material in step S1, and mix evenly; then add a mixture of butyl rubber powder and high-styrene-styrene-butadiene rubber powder in an equal mass ratio, and bentonite, and stir for 2 hours.

[0036] S4. After the reaction is completed, cool and solidify, and pulverize to obtain a water-soluble temporary plugging ag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com