Methyl carboxymethyl guar gum as well as preparation method and application thereof

A technology of methyl carboxymethyl guar gum and carboxymethyl guar gum, which can be used in dyeing, textiles and papermaking, and can solve the problems of long beating time, easy leakage, water solubility, fluidity and permeability. Good and other questions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

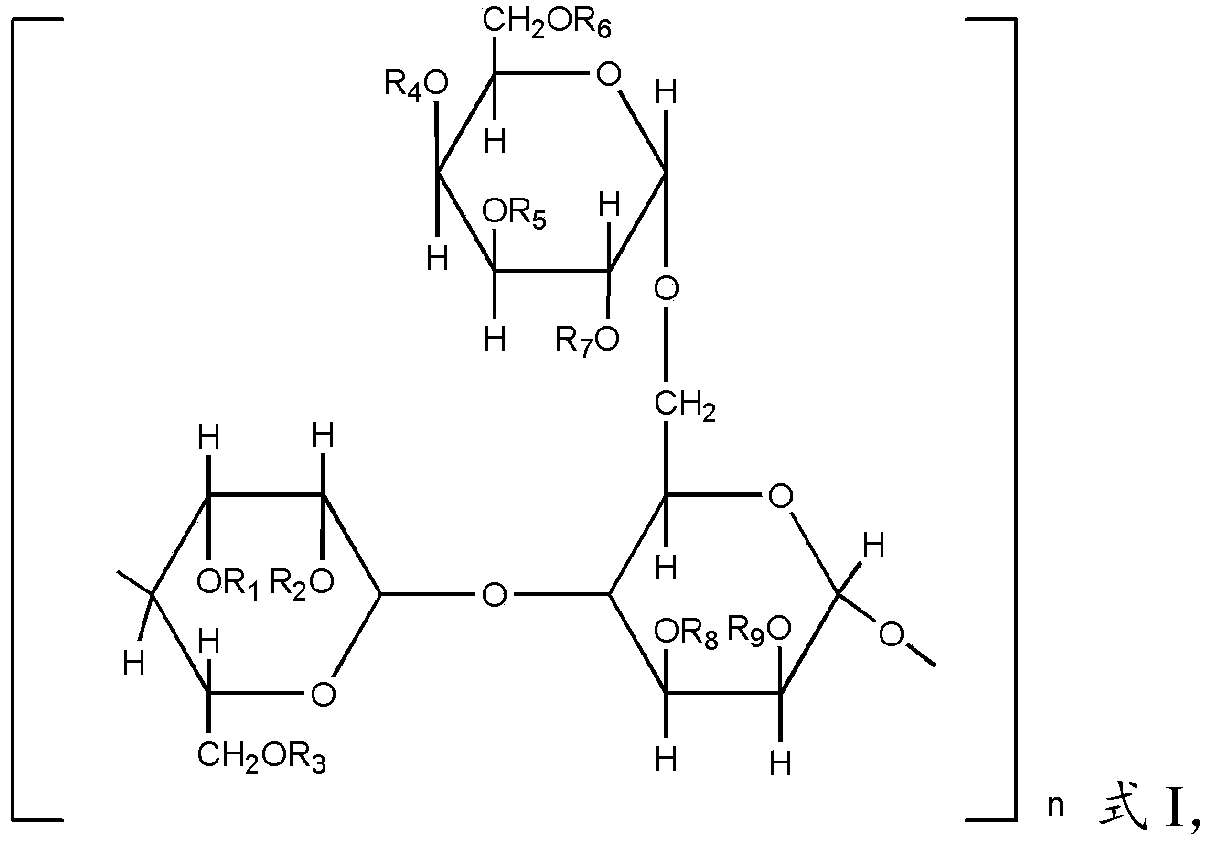

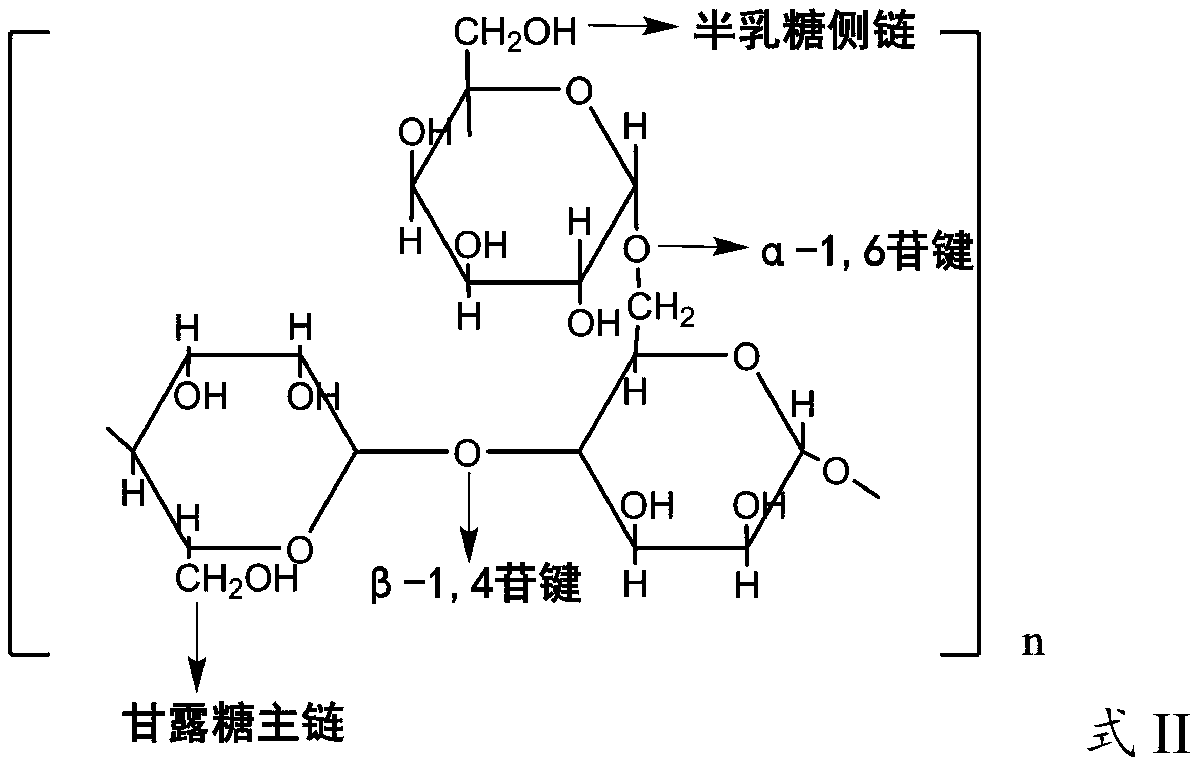

[0030] The present invention also provides the preparation method of the methyl carboxymethyl guar gum described in above-mentioned technical scheme, comprises the following steps:

[0031] Carboxymethyl guar gum, inorganic alkaline substance and water are mixed to carry out alkalization reaction to obtain alkalization product;

[0032] Under vacuum conditions, the alkalized product is mixed with methyl chloride to carry out etherification reaction to obtain the methyl carboxymethyl guar gum.

[0033] The present invention mixes carboxymethyl guar gum, inorganic alkaline substances and water for alkalization reaction to obtain alkalization products. In the present invention, the inorganic alkaline substance is preferably sodium hydroxide, and the mass ratio of the sodium hydroxide to carboxymethyl guar gum is preferably 0.3 to 0.6:1, and the alkalized inorganic alkaline substance The role is to activate the hydroxyl group. The present invention preferably mixes sodium hydrox...

Embodiment 1

[0053] (1) Alkalization reaction

[0054] At room temperature, add 100g of ethanol and 300g of water into the reaction kettle, then add 45g of sodium hydroxide into the reaction kettle, stir to dissolve evenly, raise the temperature of the kettle to 40°C, add 48g of guar gum powder, and stir for 15 minutes ;

[0055] (2) guar gum and sodium chloroacetate etherification reaction

[0056] The reaction temperature was raised to 70°C, 80g of 15wt% sodium chloroacetate solution was added to the system, the reaction was continued to stir for 60 minutes, and the temperature was lowered to 30°C;

[0057] (3) Alkalization reaction

[0058] Add 45g of sodium hydroxide solution with a mass concentration of 40% into the above reaction kettle, and stir for 15 minutes;

[0059] (4) etherification reaction of carboxymethyl guar gum and methyl chloride

[0060] Vacuumize the reactor, add 25g of methyl chloride, raise the temperature to 50°C at the same time, keep the temperature and stir ...

Embodiment 2

[0064] (1) Alkalization reaction

[0065] At room temperature, add 100g of ethanol and 300g of water into the reaction kettle, then add 45g of sodium hydroxide into the reaction kettle, stir to dissolve evenly, raise the temperature of the kettle to 40°C, add 48g of guar gum powder, and stir for 15 minutes ;

[0066] (2) guar gum and sodium chloroacetate etherification reaction

[0067] The reaction temperature was raised to 70°C, 100g of 15wt% sodium chloroacetate solution was added to the system, the reaction was continued to stir for 60 minutes, and the temperature was lowered to 30°C;

[0068] (3) Alkalization reaction

[0069] Add 45g of sodium hydroxide solution with a mass concentration of 40% into the above reaction kettle, and stir for 15 minutes;

[0070] (4) etherification reaction of carboxymethyl guar gum and methyl chloride

[0071] Vacuumize the reactor, add 25g of methyl chloride, raise the temperature to 50°C at the same time, keep the temperature and stir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com