Preparation method of high-substituted-ratio carboxyl methyl guar printing gum

A technology of carboxymethyl guar gum and printing paste, which is applied in the field of preparation of high-substitution carboxymethyl guar gum printing paste, can solve the problems of skyrocketing price of sodium alginate, hard fabric feel and long beating time And other problems, to improve the fabric feel, save time and effort to block the net, improve the effect of uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

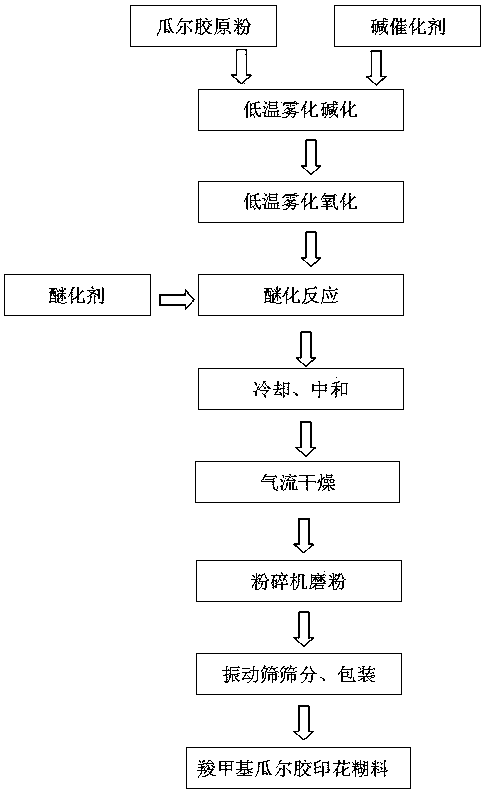

[0025] The preparation method of the high degree of substitution carboxymethyl guar gum printing paste of the present invention adopts the following process steps:

[0026] Atomize and spray 30Kg of alcoholic solution containing 8.5Kg of sodium hydroxide into 100Kg of guar collagen powder, alkalinize at 20°C for 30min; 25Kg of etherifying agent sodium chloroacetate, heated to 50°C, reacted for 3h, cooled after the reaction, neutralized with 1.5Kg of acetic acid for 30min, and controlled the pH value of the final product between 5-8. The neutralized crude product enters the airflow dryer and is dried at 105°C for 5 minutes with a moisture content of 10%. The intermediate product after drying and dehumidification is milled by a pulverizer and the fineness reaches 200 mesh, and is sieved by a vibrating sieve , to obtain a high degree of substitution of carboxymethyl guar gum printing paste (gua I).

Embodiment 2

[0028] The preparation method of the high degree of substitution carboxymethyl guar gum printing paste of the present invention adopts the following process steps:

[0029] Atomize and spray 40Kg of alcohol solution containing 13.0Kg sodium hydroxide into 100Kg of guar collagen powder, alkalinize at 30°C for 30 minutes; then atomize and spray 9Kg of hydrogen peroxide solution, oxidize at 30°C for 30 minutes; then add 35Kg The etherification agent sodium chloroacetate was heated to 70°C, reacted for 2.5 hours, cooled after the reaction, and neutralized with 2.0Kg acetic acid for 30 minutes, and the pH value of the final product was controlled between 5-8. The neutralized crude product enters the airflow dryer and is dried at 110°C for 6 minutes with a moisture content of 9%. The intermediate product after drying and dehumidification is milled by a pulverizer and the fineness reaches 200 mesh, and is sieved by a vibrating sieve , to obtain a high degree of substitution of carbox...

Embodiment 3

[0031] The preparation method of the high degree of substitution carboxymethyl guar gum printing paste of the present invention adopts the following process steps:

[0032] Atomize and spray 50Kg of alcoholic solution containing 16.0Kg of sodium hydroxide into 100Kg of guar collagen powder, alkalinize at 30°C for 30 minutes; then atomize and spray into 10Kg of hydrogen peroxide solution, oxidize at 30°C for 40 minutes; then add 45Kg The etherification agent sodium chloroacetate was heated to 80°C, reacted for 2.0 hours, cooled after the reaction, and neutralized with 3.0Kg acetic acid for 30 minutes, and the pH value of the final product was controlled between 5-8. The neutralized crude product enters the airflow dryer and is dried at 120°C for 8 minutes with a moisture content of 10%. The intermediate product after drying and dehumidification is milled by a pulverizer and the fineness reaches 200 mesh, and is screened by a vibrating sieve , to obtain high degree of substituti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of substitution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com