Treating solution for surface treatment of metal and a method for surface treatment

a surface treatment and metal technology, applied in the direction of electrolytic inorganic material coating, solid-state diffusion coating, coating, etc., can solve the problems of material which cannot be treated, and not being able to achieve sufficient corrosion resistance after coating, etc., to achieve excellent corrosion resistance and excellent corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

[0045] The effects of the treating solution for surface treatment of metal and the method for surface treatment of the present invention will be illustrated specifically in accordance with the Examples and Comparative Examples below. And a material to be treated, a degreasing agent and a coating used therein are arbitrarily selected from the materials which are on the market, and not intending to restrict the actual uses of the treating solution for surface treatment of metal and the method for surface treatment of the present invention.

[Test Plate]

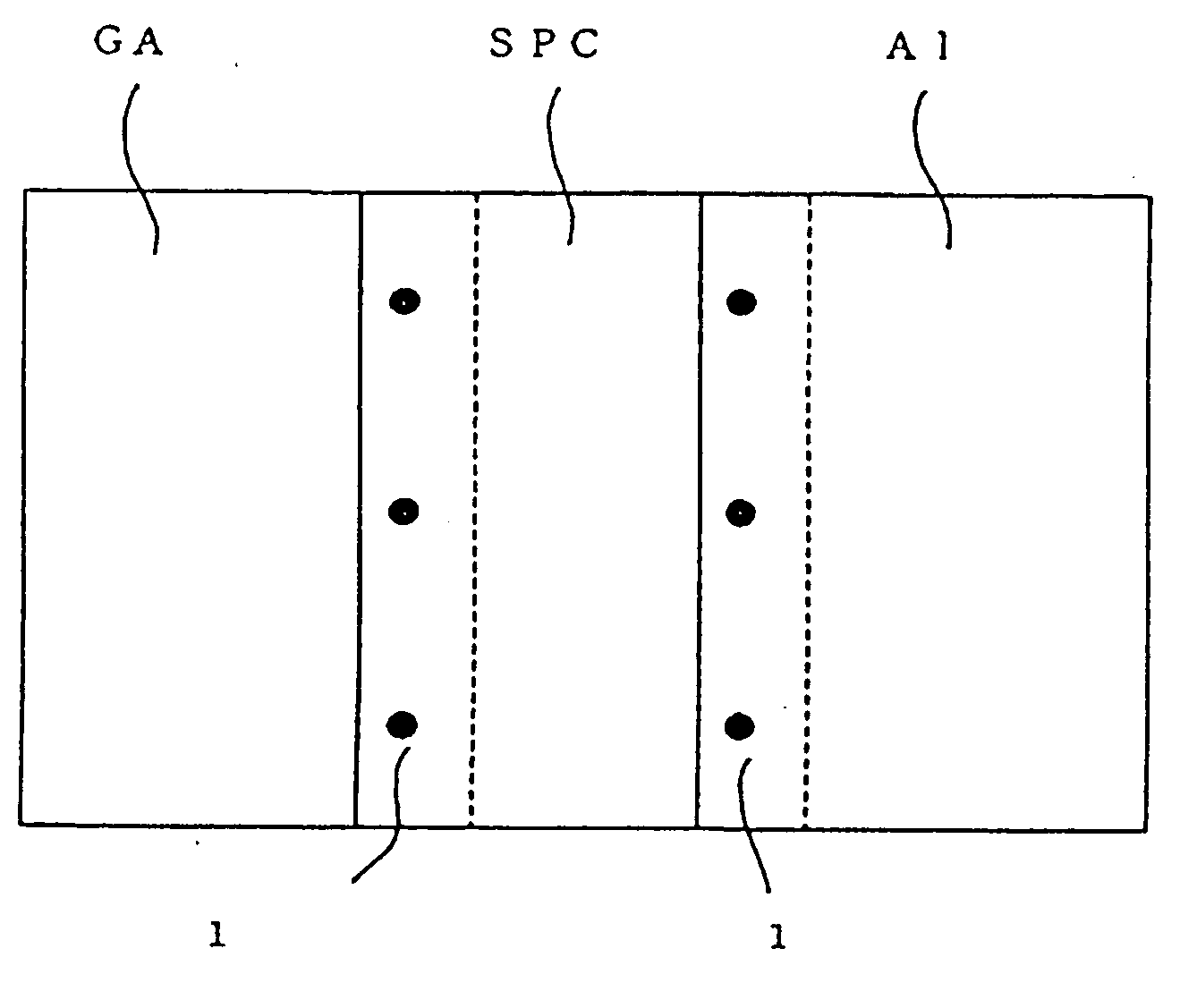

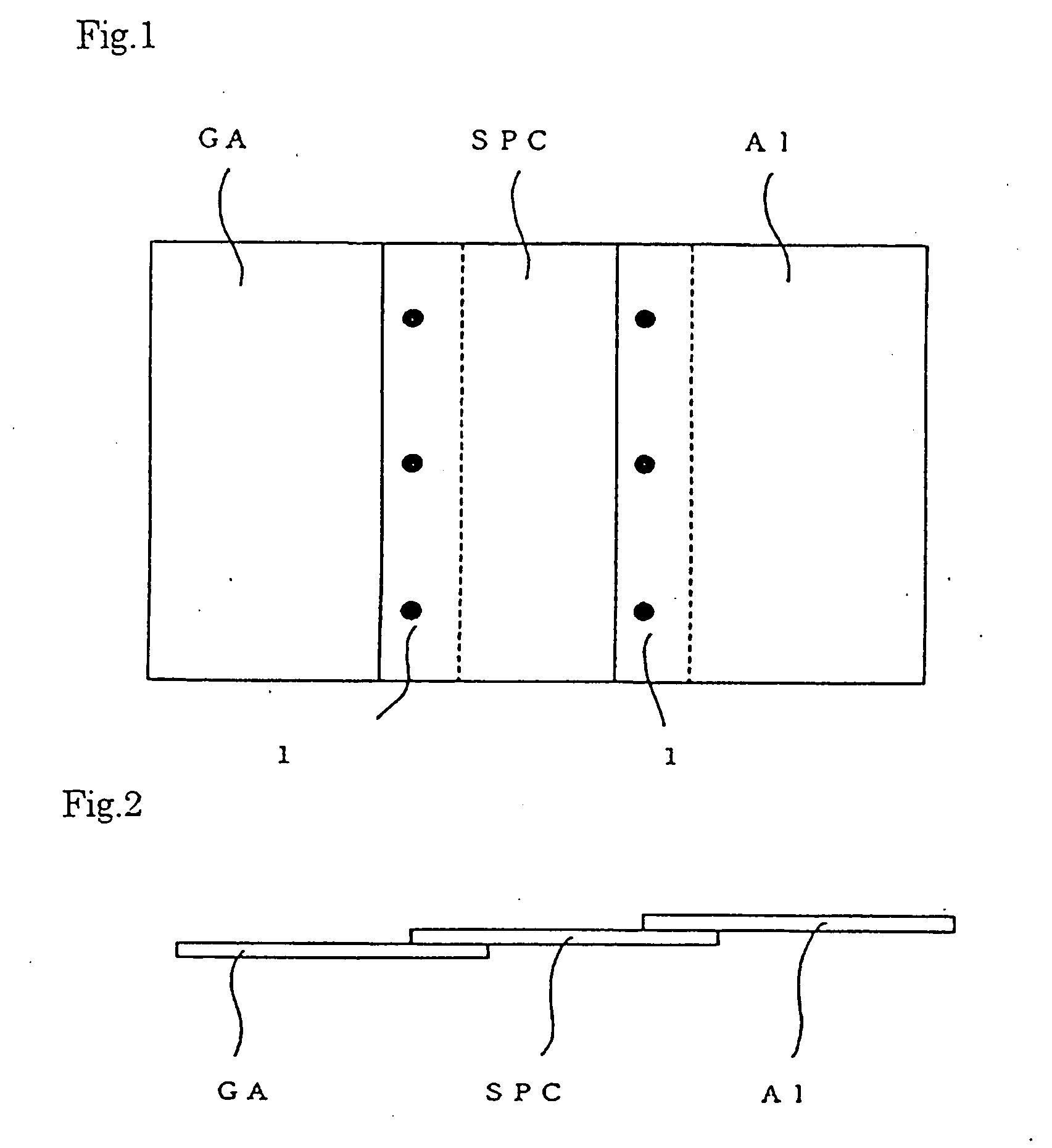

[0046] As the test plates, cold rolled steel plates, hot-dip zinc-coated steel plates, aluminum alloy plates and magnesium alloy plates are used in the Examples and Comparative Examples. The abbreviations and specifications of these test plates are shown below. For the evaluation of the appearance after surface treatment, the test plate prepared by joining three metal materials of SPC, GA and Al by a spot welding was used. For the evalu...

examples 1-4 , example 7

Examples 1-4, Example 7 and Comparative Examples 1-4: alkali degreasing→rinsing by water→film forming treatment→rinsing by water→rinsing by pure water→drying

Example 5: alkali degreasing→rinsing by water→electrolysis formation treatment→rinsing by water→rinsing by Pure water→drying

Example 6: film formation treatment (used both as degreasing)→rinsing by water→rinsing by pure water→drying

Example 8: alkali degreasing→rinsing by water→film formation treatments→rinsing by water→after treatment→rinsing by pure water→drying

Example 9: film formation treatment (and degreasing)→rinsing by water→after treatment→rinsing by pure water →drying

Comparative Example 5: alkali degreasing→rinsing by water→surface conditioning→zinc phosphate treatment→rinsing by water→rinsing by pure water→drying

[0052] In above mentioned processes for Examples and Comparative Examples, alkali degreasing was carried out as follows. That is, Fine Cleaner L4460 (Trade Mark: Product of Nihon Parkerizing) was dilute...

example 1

[0053] Aqueous solution of zirconium with concentration of 200 ppm was prepared using zirconium oxynitrate reagent and nitric acid. After heating the aqueous solution to 45° C., the pH was adjusted to 3.0 using sodium hydroxide reagent and hydrofluoric acid, and the concentration of free fluorine ion measured by a fluorine ion meter (IM-55G; product of Toa Denpa Industries Co., Ltd) was adjusted to 1 ppm, thus obtaining the treating solution for surface treatment of metal. The total fluorine concentration in the treating solution for surface treatment of metal after adjusting free fluorine ion was 50 ppm.

[0054] The test plate rinsed by water after degreasing was immersed into the treating solution for surface treatment of metal for 120 seconds so as to carry out the surface treatment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pH | aaaaa | aaaaa |

| pH | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com