Ink-jet recording medium and method of improving moisture resistance of same

A technology for ink-jet recording medium and ink-receiving layer, which is applied in the field of ink-receiving layer and ink-jet recording medium, can solve the problems of enhanced moisture resistance and no advantages mentioned, and achieve excellent moisture resistance, excellent water resistance and ink absorption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

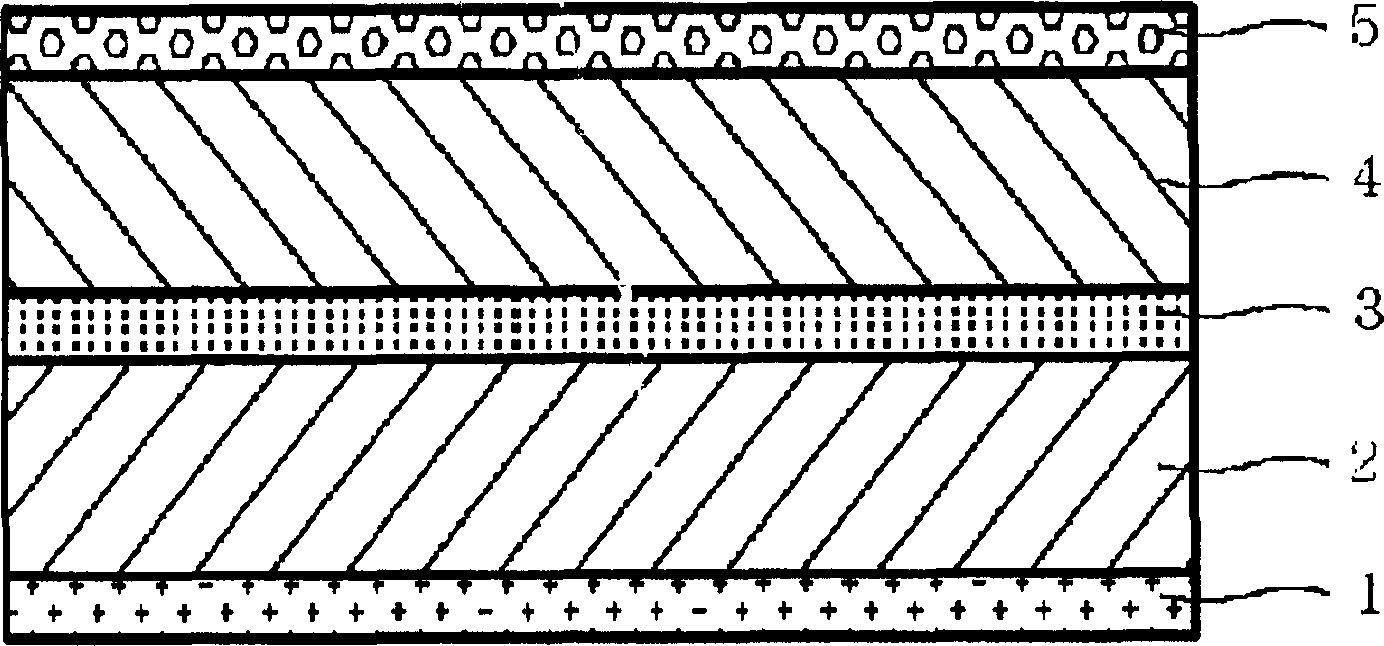

Image

Examples

Embodiment 1

[0070] The ink receiving layer composition was prepared by the following formulation.

[0071] Components of the ink receiving layer Content (parts by weight)

[0072] Alumina (ALUMINIUMOXID C, Degussa, Germany) 87.5

[0073] Polyvinyl alcohol (PVA 224E, Kuraray, Japan) 7.0

[0074] Cationic core-shell latex (TruDot DPX-8015-87, Westvaco, America) 1.8

[0075] Zirconium oxychloride (Junsei, Japan) 2.1

[0076] Leveling agent (Flow 425, Tego, Germany) 1.0

[0077] Fluorescent dye (SW5274F, Samone Corp.) 0.5

[0078] Boric acid (Samchun Co., Ltd.) 0.1

[0079] Mixed solvent (distilled water:ethanol:dimethylformamide=75:10:15, weight ratio) 400

[0080] The ink-receiving layer composition was coated on paper with a basis weight of 200 g / m 2 The upper surface of the gelatin-treated resin-coated paper (also known as barium paper) coated with a bar coater, and then dried at 110 ° C for 3 minutes to obtain a thickness of about 35 μm. layered inkjet recording medium.

Embodiment 2

[0082] An ink jet recording medium was prepared according to the method of Example 1, except that the ink receiving layer composition was prepared according to the following formulation.

[0083] Components of the ink receiving layer Content (parts by weight)

[0084] Alumina sol (PG 003, Cabot, America) 85.0

[0085] Polyvinyl alcohol (PVA 117, Kuraray, Japan) 10.0

[0086] Cationic core-shell latex (TruDot DPX-8087-06, Westvaco, America) 1.3

[0087] Zirconium oxychloride (Junsei, Japan) 1.5

[0088] Glyoxal (Samchun Co., Ltd.) 0.65

[0089] Leveling agent (Flow 425, Tego, Germany) 1.0

[0090] Fluorescent dye (SW5274F, Samone Corp.) 0.5

[0091] Borax (Samchun Co., Ltd.) 0.05

[0092] Mixed solvent (distilled water:ethanol:dimethylformamide=70:10:20, weight ratio) 400

Embodiment 3

[0094] An ink jet recording medium was prepared according to the method of Example 1, except that the ink receiving layer composition was prepared according to the following formulation.

[0095] Components of the ink receiving layer Content (parts by weight)

[0096] Alumina sol (SS 30, HANA Chemicals) 76.9

[0097] Alumina (ALUMINIUMOXID C, Degussa, Germany) 8.5

[0098] Polyvinyl alcohol (PVA P-17, Dongyang Chemical.Co.) 8.0

[0099] Cationic core-shell latex (TruDot DPX-8087-06, Westvaco, America) 1.5

[0100] Zirconium oxynitrate (Aldrich, America) 3.5

[0101] Leveling agent (Flow 425, Tego, Germany) 1.0

[0102] Fluorescent dye (SW5274F, Samone Corp.) 0.5

[0103] Boric acid (Samchun Co., Ltd.) 0.1

[0104] Mixed solvent 400

[0105] (distilled water:ethanol:dimethylformamide:dimethylsulfoxide=70:10:15:5, weight ratio)

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com