Method for preparing potassium hydrogen peroxymonosulfate composite salt

The technology of a potassium hydrogen peroxymonosulfate composite salt and potassium hydrogen sulfate is applied in the preparation field of designing a potassium hydrogen peroxymonosulfate composite salt, which can solve the problems of adverse effects on the human body and the environment, low vacuum concentration efficiency, and high product impurity content. , to achieve the effect of not easy to agglomerate, improve product stability, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

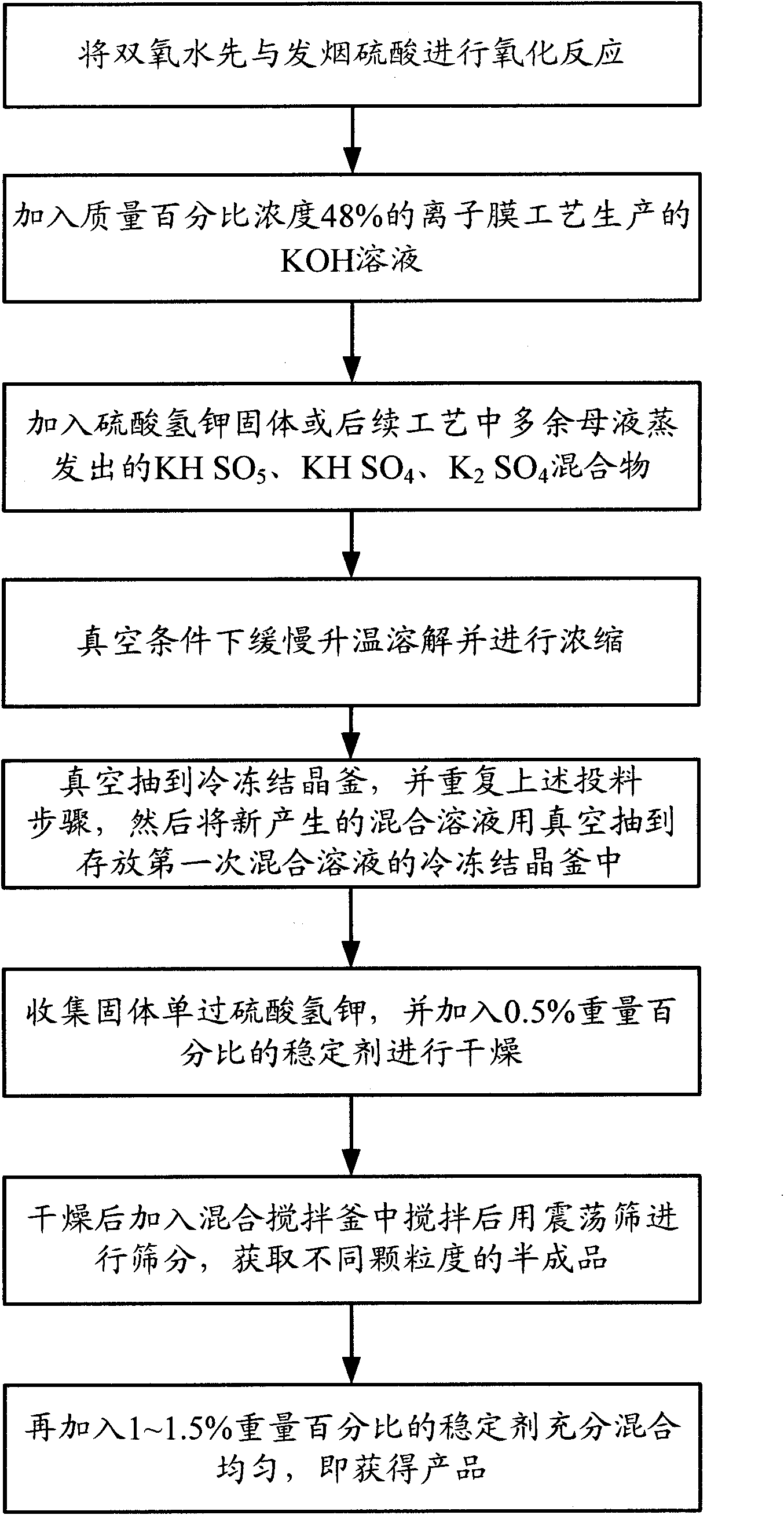

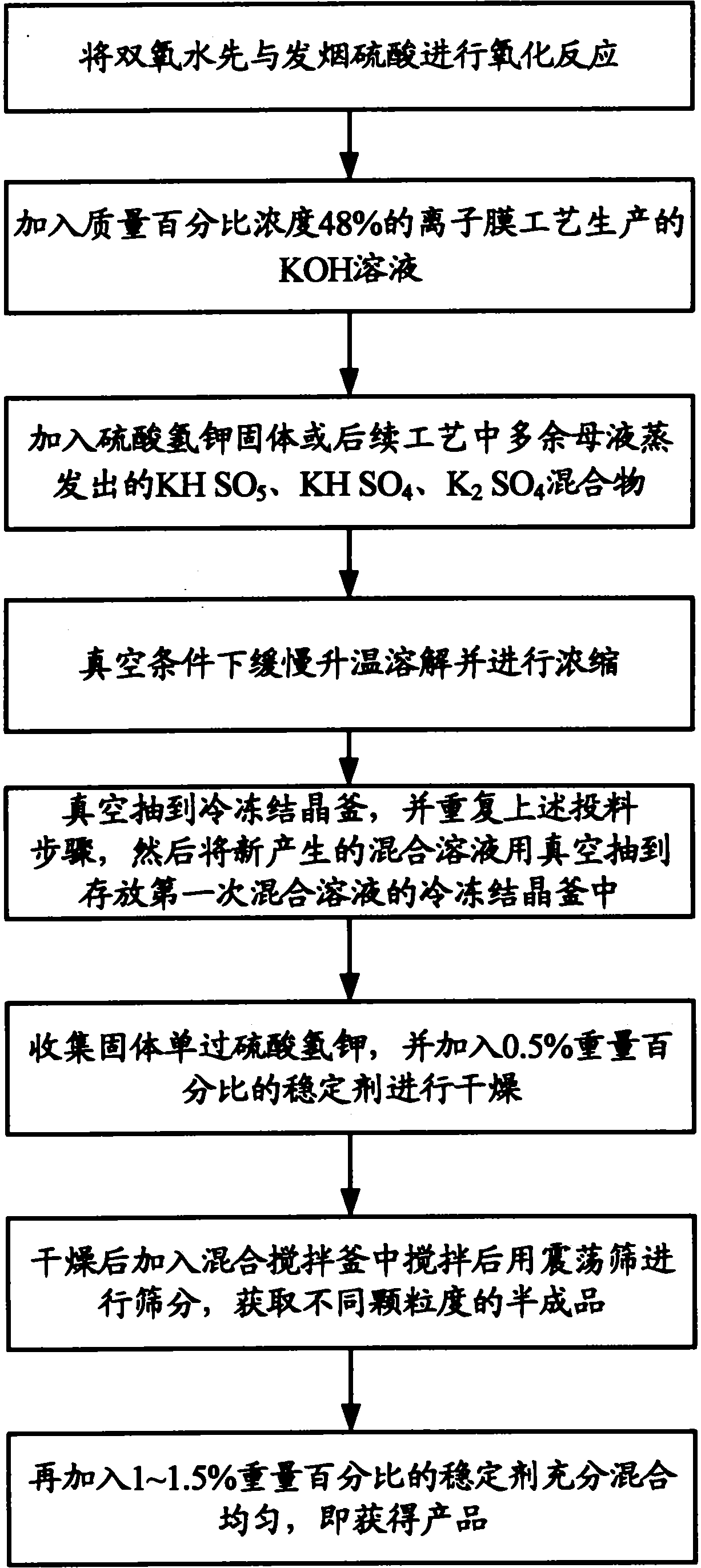

[0036] figure 1 It is the flow chart of the preparation method of potassium peroxymonosulfate composite salt, as shown in the figure. The method for preparing potassium peroxymonosulfate composite salt of the present invention has simple equipment, low investment, low process condition requirements, easy operation, safety, no process waste water pollution, high yield, low impurities, high quality, and low cost, which mainly include The following steps:

[0037] (1) The hydrogen peroxide is oxidized with fuming sulfuric acid to obtain a strong acid, also known as Caro’s acid. The reaction formula is:

[0038] H 2 O 2 +H 2 SO 4 =H 2 SO 5 +H 2 O;

[0039] The reaction temperature is 0-20°C, the best is 10°C, and the reaction time is 1 to 3 hours;

[0040] The molar ratio of hydrogen peroxide to fuming sulfuric acid is:

[0041] Hydrogen peroxide: oleum = 1:0.90~1.05;

[0042] It is best to use hydrogen peroxide with a weight concentration of 50 to 70%;

[0043] The sulfuric acid can be ol...

Embodiment 1

[0068] (1) Oxidize 140 kg of hydrogen peroxide with a weight concentration of 70% and 250 kg of fuming sulfuric acid with a concentration of 65% at a reaction temperature of 10°C and a reaction time of 120 minutes; add 15% by weight potassium hydrogen sulfate solution 480KG

[0069] (2) React 405 kg of 48% potassium hydroxide solution with the product obtained in step (1) to obtain an aqueous solution of potassium monopersulfate. The reaction temperature is 23°C and the reaction time is 70 minutes; the reaction is in a vacuum The vacuum is 0.1 MPa;

[0070] (3) Add 30kg of potassium hydrogen sulfate to the concentration kettle, add the aqueous solution of potassium monopersulfate in a vacuum, and slowly (15 minutes) at a vacuum of 0.1 MPa to warm up to a temperature of 28 ℃ for 15 minutes. ;

[0071] (4) Cool to 5°C to crystallize. Repeat steps (1), (2), (3) (this time step (3) only raises the temperature without adding potassium hydrogen sulfate), and add the resulting mixed solu...

Embodiment 2

[0078] Using the same method as in Example 1, the difference is that the process water used in step (1) is the mother liquor produced in Example 1, and the additive in step (3) is the concentrated product of the mother liquor in Example 1, with a yield of 800 kg. The results are as follows:

[0079] The purity of the product is: active oxygen ≥4.75%.

[0080] The content of potassium persulfate is 0.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com