Preparation method of ammonium persulfate crystal

A technology of ammonium persulfate and crystals, which is applied in the field of preparation of ammonium persulfate crystals, can solve the problems of small particle size and poor fluidity, and achieves the effects of low equipment requirements, simple operation and process cost saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The invention provides a kind of preparation method of ammonium persulfate crystal, comprising the following steps:

[0025] Provide a mixed material liquid of ammonium persulfate and ammonium sulfate, the mass concentration ratio of ammonium persulfate and ammonium sulfate in the mixed material liquid is 1: (2~3);

[0026] Add ammonium persulfate seed crystals when controlling the temperature of the mixture liquid at 20-25°C, and then cool down to -2-6°C at a cooling rate of 5-15°C / h to obtain ammonium persulfate crystals.

[0027] The invention provides a mixed material liquid of ammonium persulfate and ammonium sulfate, the mass concentration ratio of ammonium persulfate and ammonium sulfate in the mixed material liquid is 1:(2~3), preferably 1:(2.2~2.8), more Preferably it is 1:(2.4-2.6). In the present invention, the concentration of ammonium persulfate in the mixture liquid is preferably 180-220 g / L, more preferably 190-210 g / L. In the present invention, the pH ...

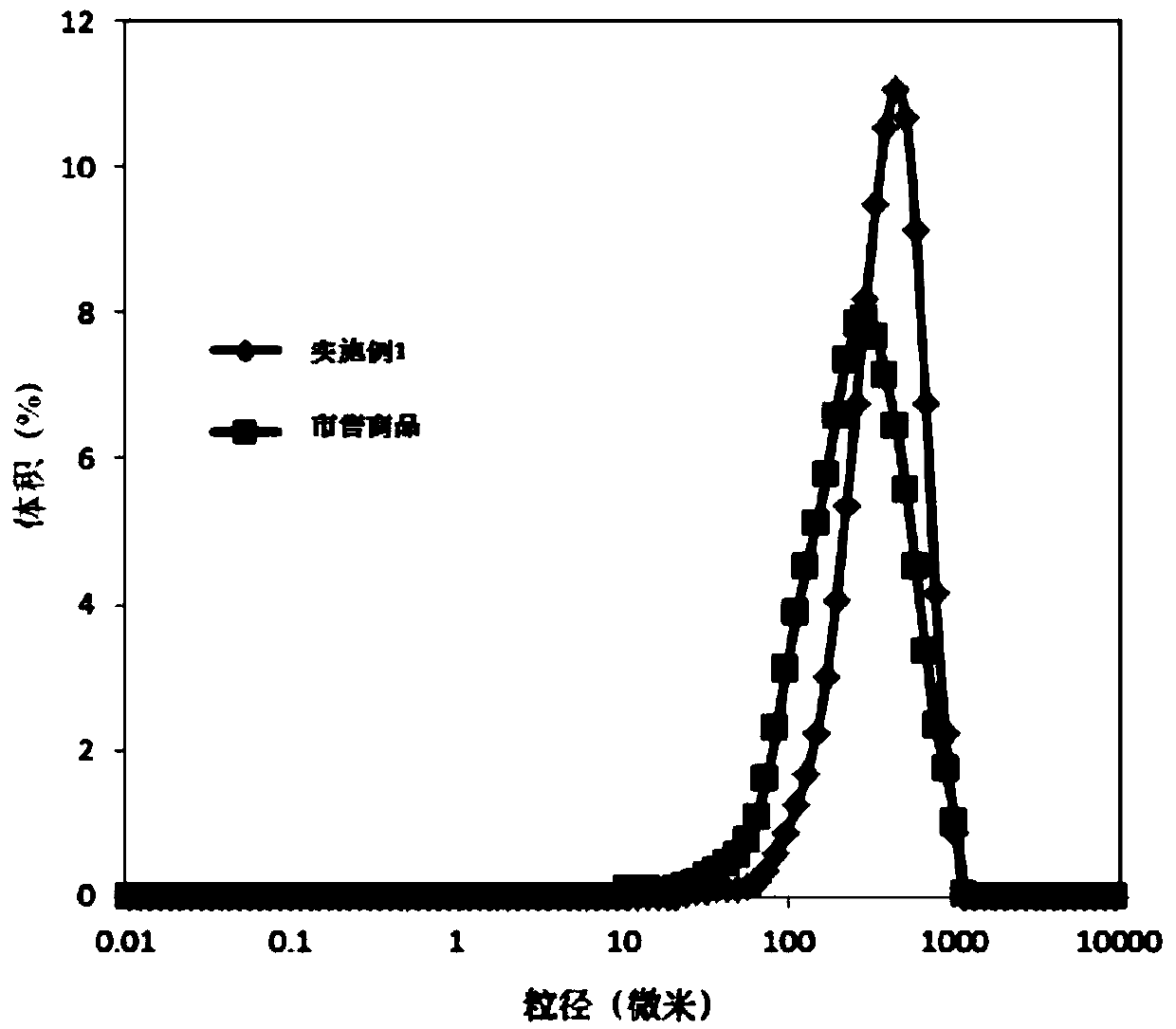

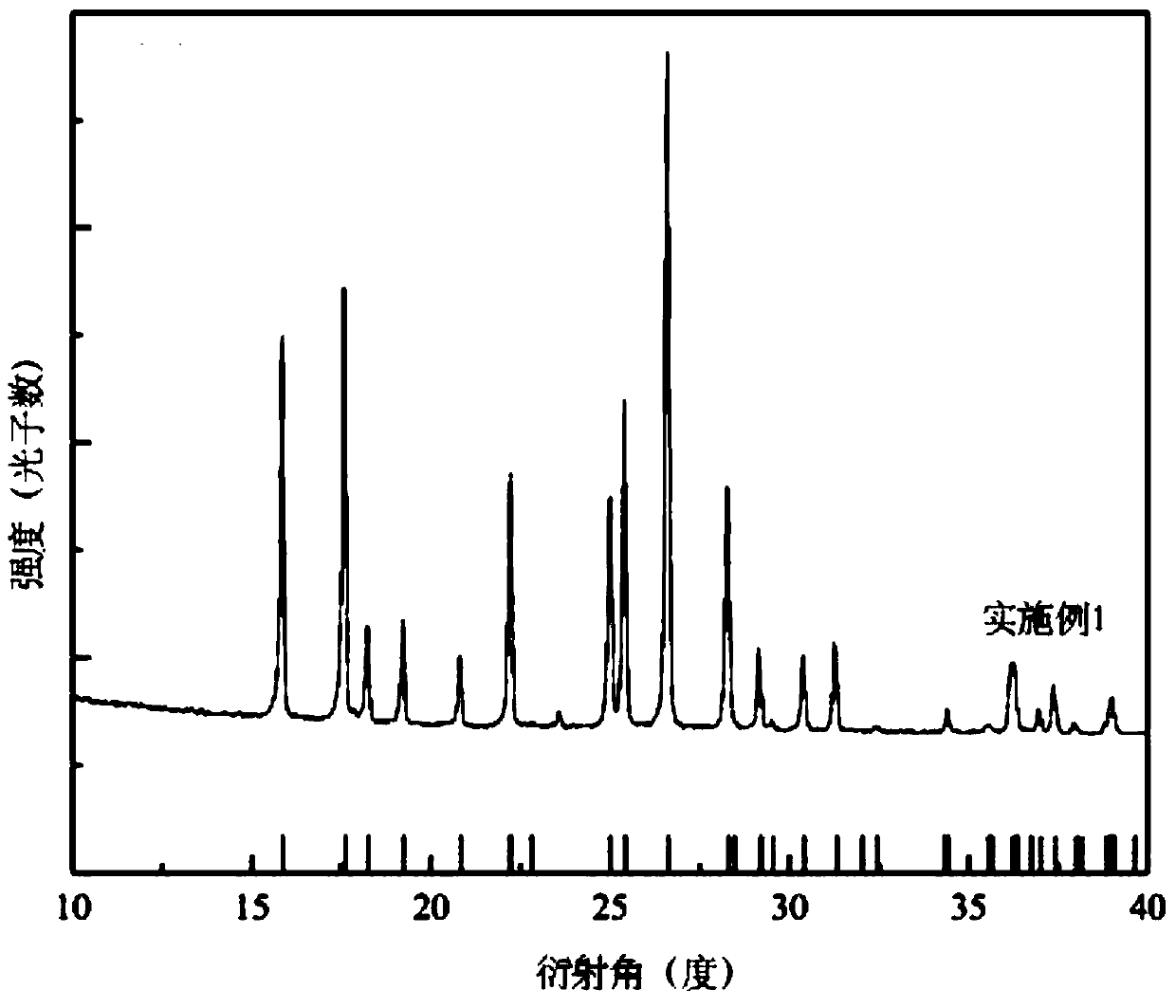

Embodiment 1

[0045] Provide 6000L of mixed material liquid of ammonium persulfate and ammonium sulfate, wherein the pH value is adjusted to 7.0 with ammonia gas;

[0046] Pass the mixed material liquid into the crystallization tank (initial temperature is 26°C), set the stirring speed and cooling speed, and carry out uniform cooling, then add ammonium persulfate seed crystals to the system, and continue to proceed at the same cooling rate. Cool down; when the temperature is lowered to the termination temperature at a uniform rate, grow crystals at the termination temperature for 20 minutes, then centrifuge the obtained system at a speed of 5000 r / min for 15 minutes, and dry the obtained solid at 80°C for 30 minutes to obtain ammonium persulfate crystals. Other operating parameters are listed in Table 1 along with the average particle size and purity of the resulting ammonium persulfate crystals.

Embodiment 2~12

[0048] Ammonium persulfate crystals were prepared according to the method of Example 1, and the average particle size and purity of some operating parameters and the obtained ammonium persulfate crystals are listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com