Method for evaporating sodium persulfate at low temperature

A sodium persulfate, low-temperature evaporation technology, applied in peroxyhydrate/peroxyacid, sustainable manufacturing/processing, climate sustainability, etc., can solve the problem of lack of substances, high specific energy consumption, and evaporator thermal efficiency Low problems, to achieve the effect of reducing evaporation temperature and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

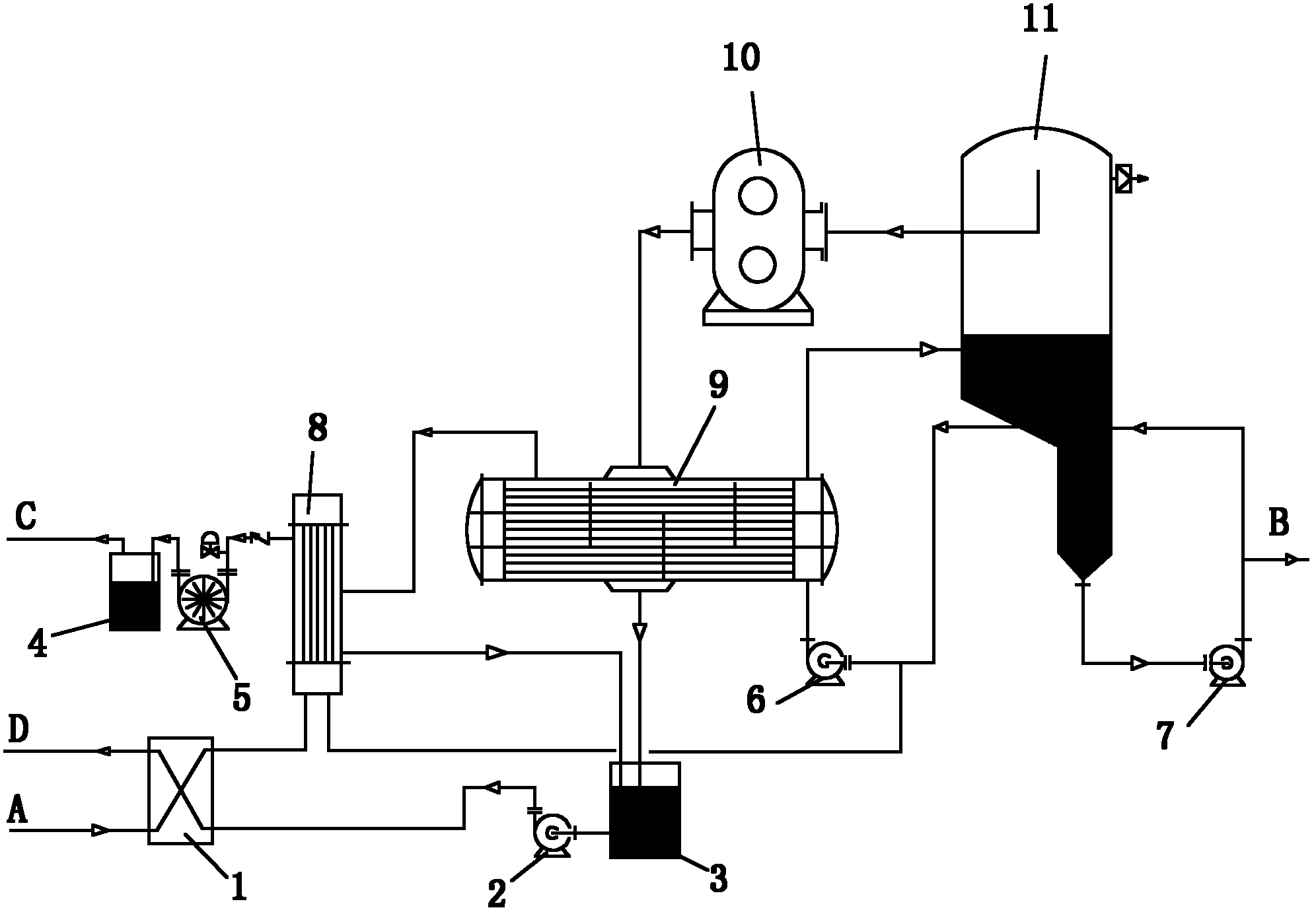

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments. Such as figure 1 Shown, the method for low-temperature evaporation sodium persulfate of the present invention may further comprise the steps:

[0016] 1. Feed material, the saturated sodium persulfate solution stock solution A at a temperature of 25°C is stored in the stock solution tank, and is pumped into the plate heat exchanger 1 by the feed pump, and the stock solution A in the plate heat exchanger 1 is evaporated with forced circulation Heat exchange with the secondary steam condensate in the vessel 9. After being preheated once, the stock solution A enters the tube-and-tube heat exchanger 8. In the tube-and-tube heat exchanger 8, the stock solution A, the steam non-condensable gas C from the forced circulation evaporator 9 and the steam non-condensable gas mixed in Secondary steam for heat exchange. After the second preheating, the tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com