Method for preparing optical fiber preform rod

An optical fiber preform and preform technology, applied in glass manufacturing equipment, manufacturing tools, glass fiber products, etc., can solve the problem of complex refractive index profile and Ge/F co-doping process in-tube method, and reduce the mechanical strength of quartz melt optical fiber , Destruction of the Si-O space network structure and other issues, to achieve the effect of improving mechanical strength, low environmental load, and high deposition efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

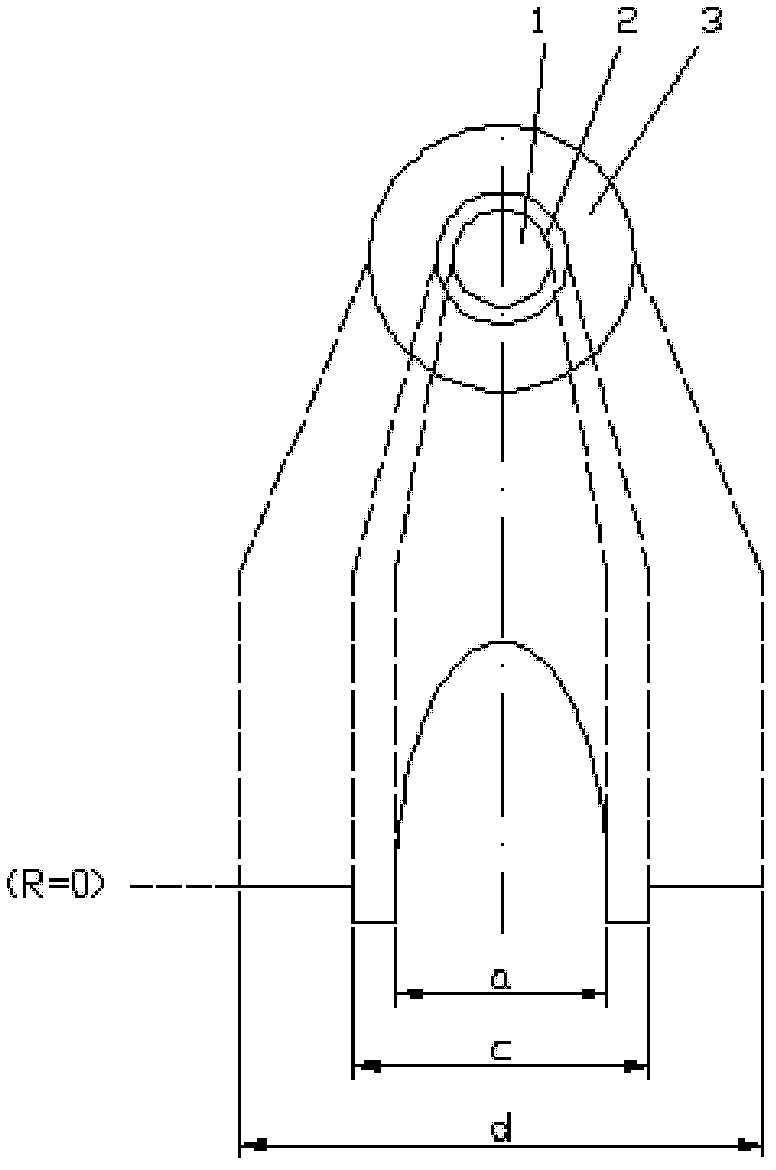

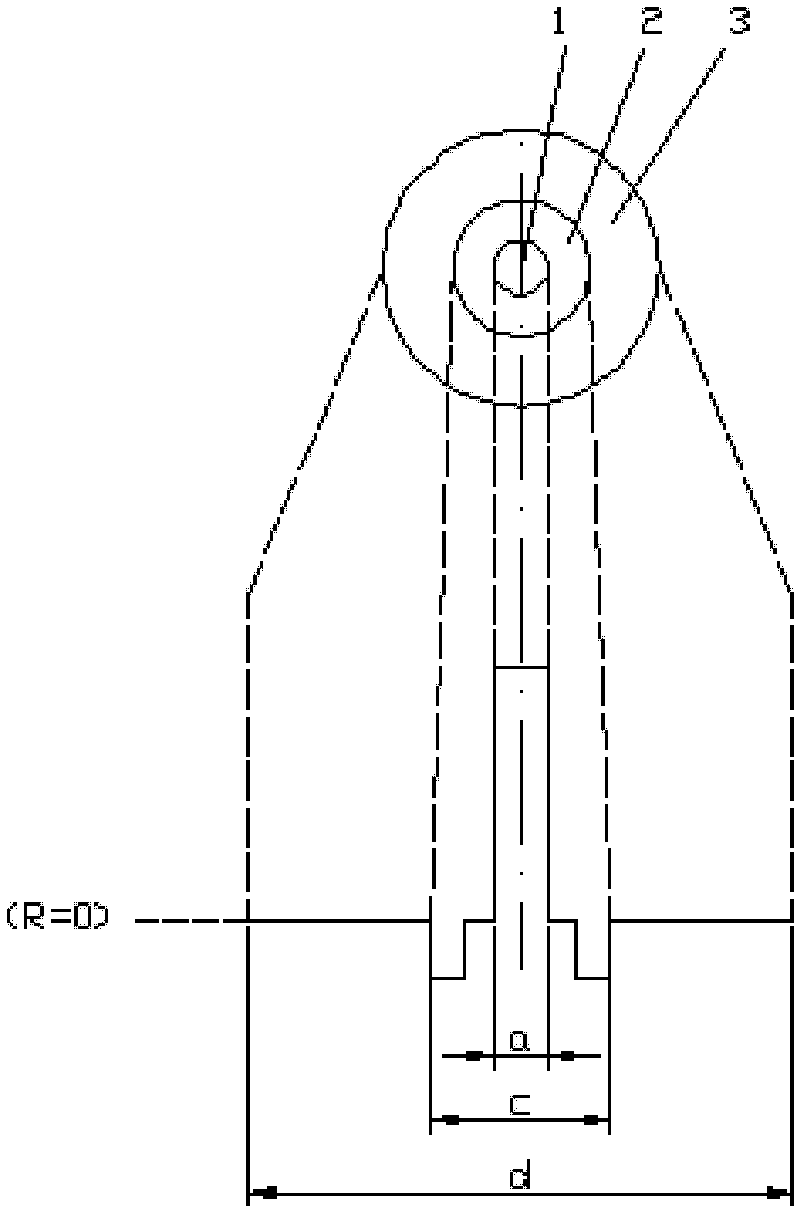

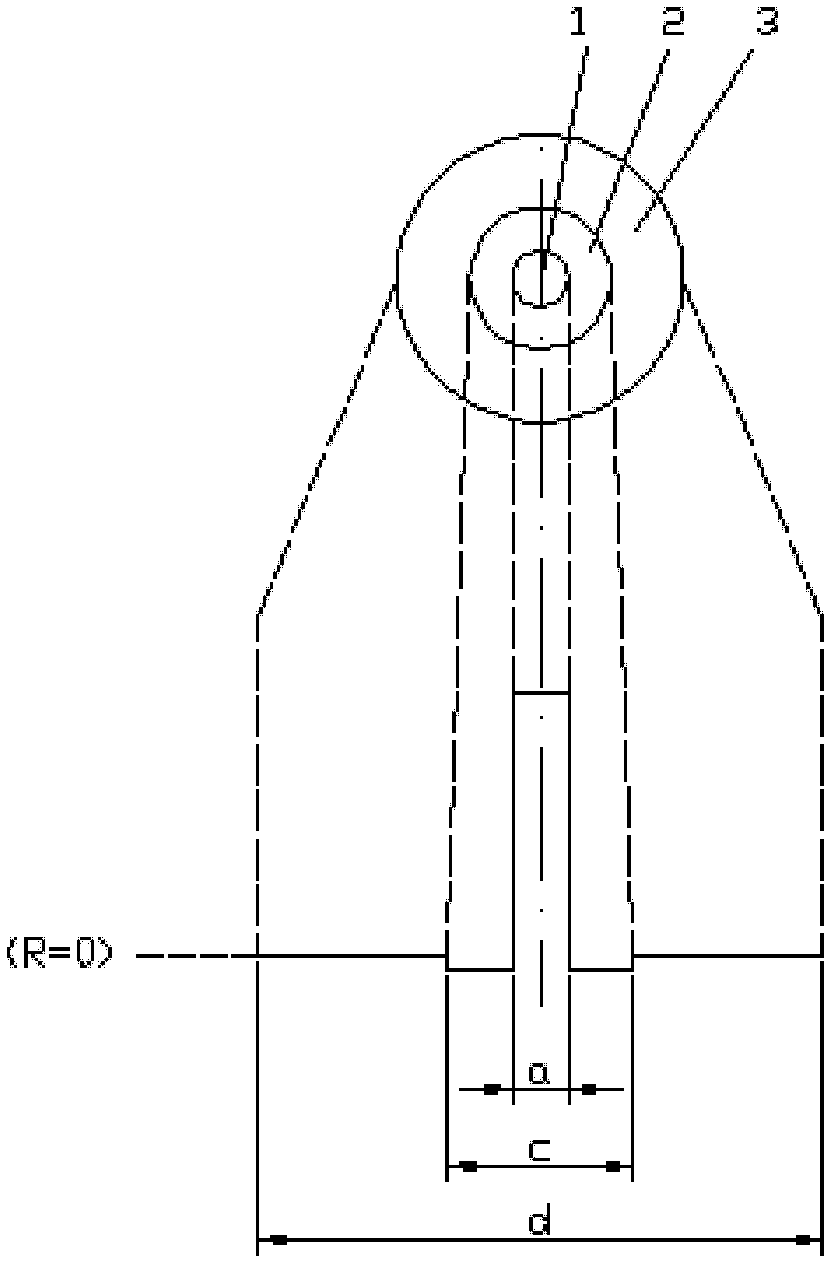

Image

Examples

Embodiment 1

[0038] Deposit a Ge / F co-doped core layer and part of the inner cladding material in a high-purity, low-hydroxyl quartz glass liner by chemical vapor deposition in a plasma tube. The hydroxyl content of the liner is required to be less than or equal to 1000ppb, and the further requirement is less than 100ppb. A further requirement is less than 10 ppb. A liner with an outer diameter of 36 mm is used, and a mixed gas flow of silicon tetrachloride vapor, germanium tetrachloride vapor and high-purity oxygen with a proportional change is introduced into the tube from one end, and a chemical reaction is induced on the inner wall of the liner by low-pressure plasma. Thousands of thin layers of quartz glass with a thickness of micron order are formed. The above-mentioned liner containing the deposited layer is placed at a high temperature of 1900°C-2200°C to melt and shrink into a solid glass rod, which is a core rod. The deposited layer constitutes the corresponding core portion and...

Embodiment 2

[0041] Quartz glass is deposited inside a fluorine-doped quartz tube with a relative refractive index of -0.30% and an outer diameter of 50 mm by vapor deposition. Among them, the contribution of fluorine-doped refractive index in the core layer is -0.08%, and the contribution of F-doped refractive index in the sunken cladding prepared by the in-tube method is -0.15%. In order to improve the production capacity of the mandrel, a large-size liner and a high-rate deposition process are preferred, and the length of the mandrel is 1200mm. The hydroxyl content of the liner is less than 100 ppb. From one end of the liner, a mixed gas flow of silicon tetrachloride vapor, germanium tetrachloride vapor, and high-purity oxygen that changes in proportion according to the program is introduced into the tube, and thousands of thin layers of quartz glass with a thickness of micron are formed on the inner wall of the liner. . The above-mentioned liner containing the deposited layer was pla...

Embodiment 3

[0044] Quartz glass is deposited inside a fluorine-doped quartz tube with a relative refractive index of -0.30% and an outer diameter of 50 mm by vapor deposition. The contribution of fluorine-doped refractive index in the core layer is -0.10%, and the contribution of F-doped refractive index in the inner cladding prepared by the in-tube method is -0.11%. In order to improve the production capacity of the mandrel, a large-size liner and a high-rate deposition process are preferred, and the length of the mandrel is 1200mm. The hydroxyl content of the liner is less than 100 ppb. From one end of the liner, a mixed gas flow of silicon tetrachloride vapor, germanium tetrachloride vapor, and high-purity oxygen that changes in proportion according to the program is introduced into the tube, and thousands of thin layers of quartz glass with a thickness of micron are formed on the inner wall of the liner. . The above-mentioned liner containing the deposited layer was placed at a high...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com