Method for preparing high-silicon coating on aluminum alloy surface

A technology of aluminum alloy surface and casting aluminum alloy, applied in metal material coating process, coating, solid-state diffusion coating, etc. The effect of improving, good wear resistance and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Under the protection of argon atmosphere, with 7 kW cross-flow CO 2 The laser strengthens the preset layer, and the laser cladding process parameters are: P=2 kW, scanning speed V=100 mm / min, and spot diameter D=4 mm, so as to prepare a silicon coating on the aluminum alloy surface.

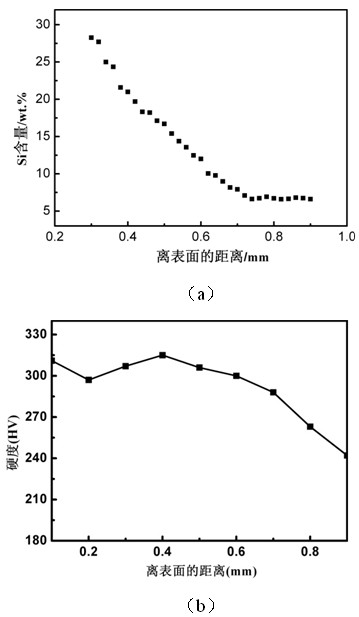

[0023] The laser-treated sample was placed in a conventional heat treatment furnace for diffusion heating treatment. The diffusion heating temperature was set at 450 °C and the holding time was set at 36 h, so as to prepare a high-silicon aluminum alloy with a gradient distribution of silicon content and microhardness, as shown in figure 1 As shown in a, the silicon content gradually decreases from the surface to the matrix; figure 1 As shown in b, the microhardness of the high-silicon coating is 250-320 HV, which is significantly higher than that of the substrate, and the cladding layer is well bonded to the substrate.

Embodiment 2

[0025] Under the protection of argon atmosphere, with 7 kW cross-flow CO 2 The laser strengthens the preset layer, and the laser cladding process parameters are: P=2.4 kW, scanning speed V=300 mm / min, and spot diameter D=4 mm, so that a silicon coating is prepared on the aluminum alloy surface.

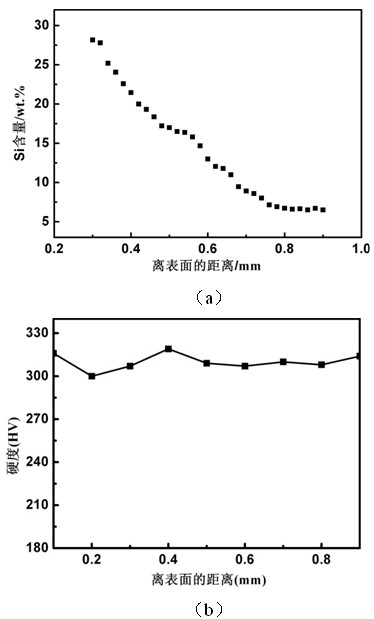

[0026] The laser-treated sample was placed in a conventional heat treatment furnace for diffusion heating treatment. The diffusion heating temperature was set at 500 °C, and the holding time was set at 36 h, so as to prepare a high-silicon aluminum alloy with a very small silicon content and a gradient distribution of microhardness, such as figure 2 As shown in a, the silicon content gradually decreases from the surface to the matrix; figure 2 As shown in b, the microhardness of the high-silicon coating is 300-320 HV, the hardness increase is the most obvious, and the cladding layer is well bonded to the substrate.

Embodiment 3

[0028] Under the protection of argon atmosphere, with 7 kW cross-flow CO 2 The laser strengthens the pre-set layer. The laser cladding process parameters are: P=2.8 kW, scanning speed V=500 mm / min, and spot diameter D=4 mm, so that a silicon coating is prepared on the aluminum alloy surface.

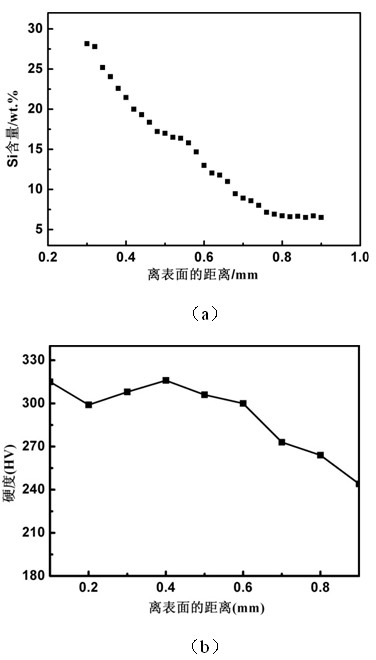

[0029] The laser-treated sample was placed in a conventional heat treatment furnace for diffusion heating treatment. The diffusion heating temperature was set at 550 °C and the holding time was set at 36 h, thereby preparing a high-silicon aluminum alloy with a very small silicon content and a gradient distribution of microhardness, as shown in image 3 As shown in a, the silicon content gradually decreases from the surface to the matrix; image 3 As shown in b, the microhardness of the high-silicon coating is 250-320 HV, which is significantly higher than that of the substrate, and the cladding layer is well bonded to the substrate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Microhardness | aaaaa | aaaaa |

| Microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com