A two-component water-based inorganic non-intumescent fireproof coating and its preparation method

A fire-retardant coating and inorganic non-technology, applied in the direction of fire-retardant coatings, coatings, etc., can solve the problems of short stability period of single-component coatings, the stability period is difficult to exceed 1 month, and the practicability is affected.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

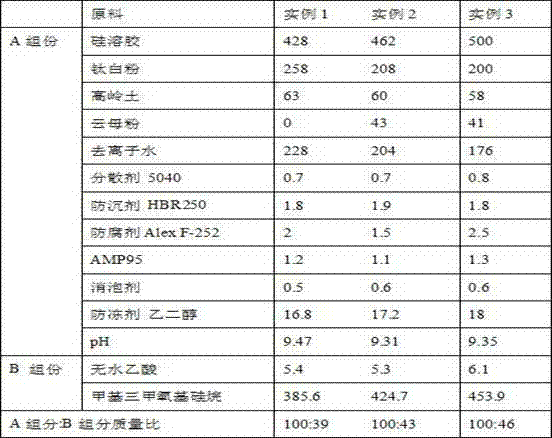

[0052] prepare first

[0053] A method for preparing the above-mentioned two-component water-based inorganic non-intumescent type fireproof coating: at first the sufficient amount of deionized water, antifreeze and anti-sedimentation agent as mentioned above are stirred under the condition of 200r / min for 8- 12 minutes, then add pigments and fillers, preservatives, half of the dispersant, half of the defoamer, and half of AMP95, and disperse at a high speed under the condition of 1800-2000r / min; stir the above materials for 30-40min Finally, reduce the stirring speed to 450-550r / min, and add silica sol and the remaining dispersant, the remaining defoamer and the remaining AMP95 to the above raw materials, and continue stirring for 50-70min to finally obtain a pH of 9.3 - Component A of 9.6;

[0054]Mix anhydrous acetic acid and organosilane monomers, stir evenly, and obtain component B.

[0055] Stir the prepared above-mentioned components A and B according to the mass ratio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com