Dewatered sludge bio-drying apparatus

A technology of dewatering sludge and biological drying, which is applied in dehydration/drying/concentrated sludge treatment, biological sludge treatment, etc. It can solve the problems of poor air permeability and uneven drying of sludge, and achieve good sealing performance and high treatment efficiency. The effect of maximizing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

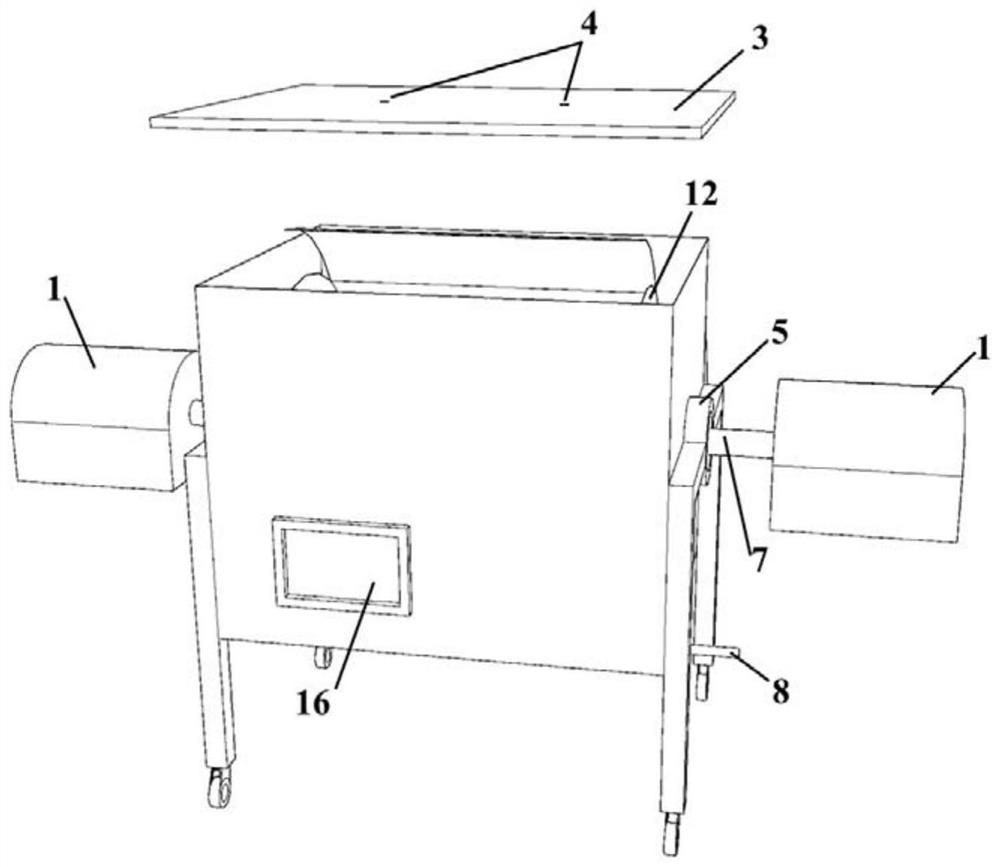

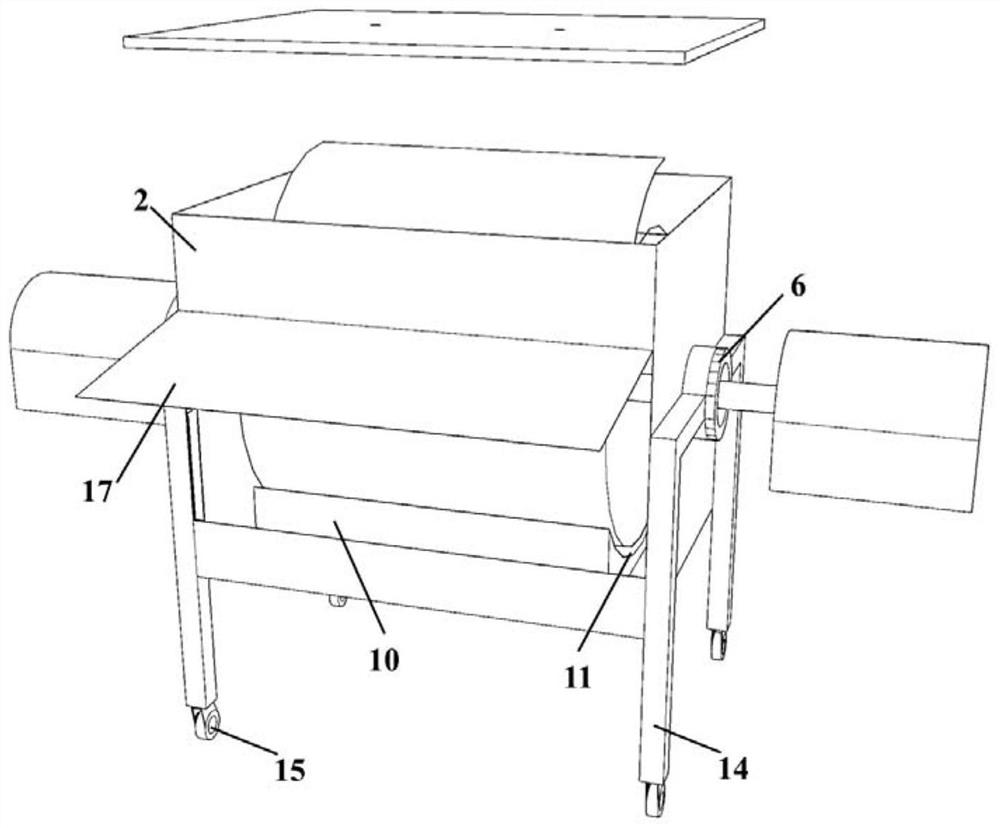

[0040] A biological drying device for dewatered sludge, such as Figure 1-2 , the device includes a reactor main body, the reactor main body includes: a drum inner shell 12 for filling dewatered sludge to be dried; The air distribution chamber 10 is connected to the ventilation pipe 8; in other words, the main body of the reactor is a double-layer shell structure, the outer shell is a cuboid, and the inner shell is a drum; the inner shell 12 of the drum is provided with a feed inlet , The side of the reactor shell 2 is provided with a discharge port; the device also includes a rotating mechanism for controlling the rotation of the drum inner shell 12 . The upper surface of the air distribution chamber 10 is a porous plate shell 11, and the material of the drum inner shell 12 is a steel plate with a porous structure.

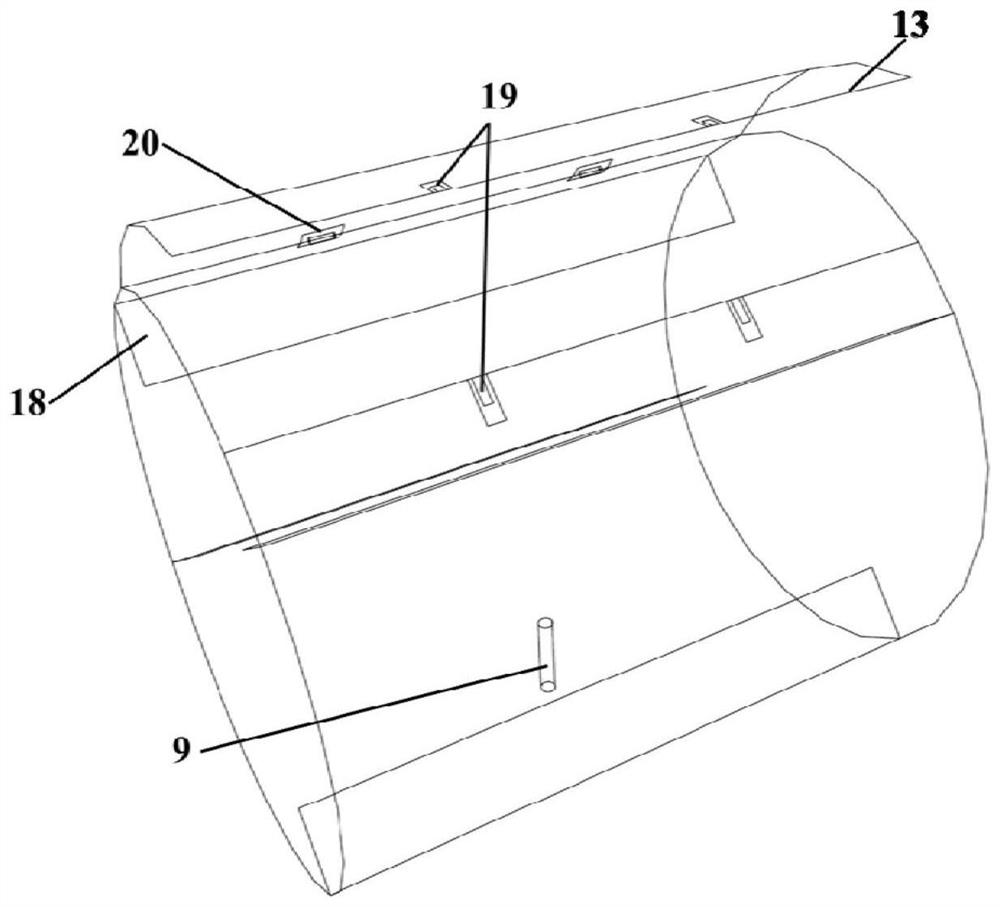

[0041] Such as image 3, The drum inner shell 12 is provided with a baffle plate 18 perpendicular to the rotation direction of the drum inner shell 12 . The s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com