Guide rail straightness regulating device

A technology for adjusting device and straightness, applied in hoisting device, hoisting device, track, etc., can solve the problems of difficulty in controlling the accuracy of manual tapping method, affecting the guide rail and guide rail bracket, and difficult to control the adjustment amount, etc., to achieve a novel structure , Improve the quality and speed, and the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

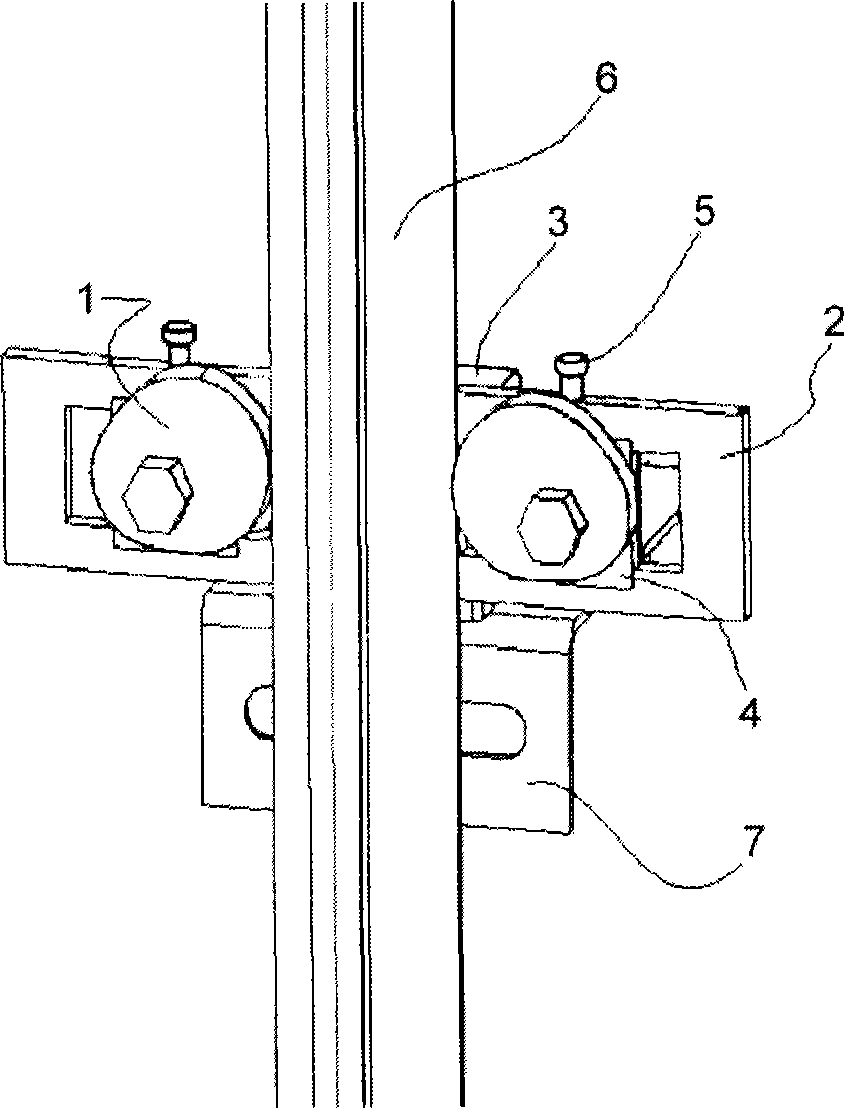

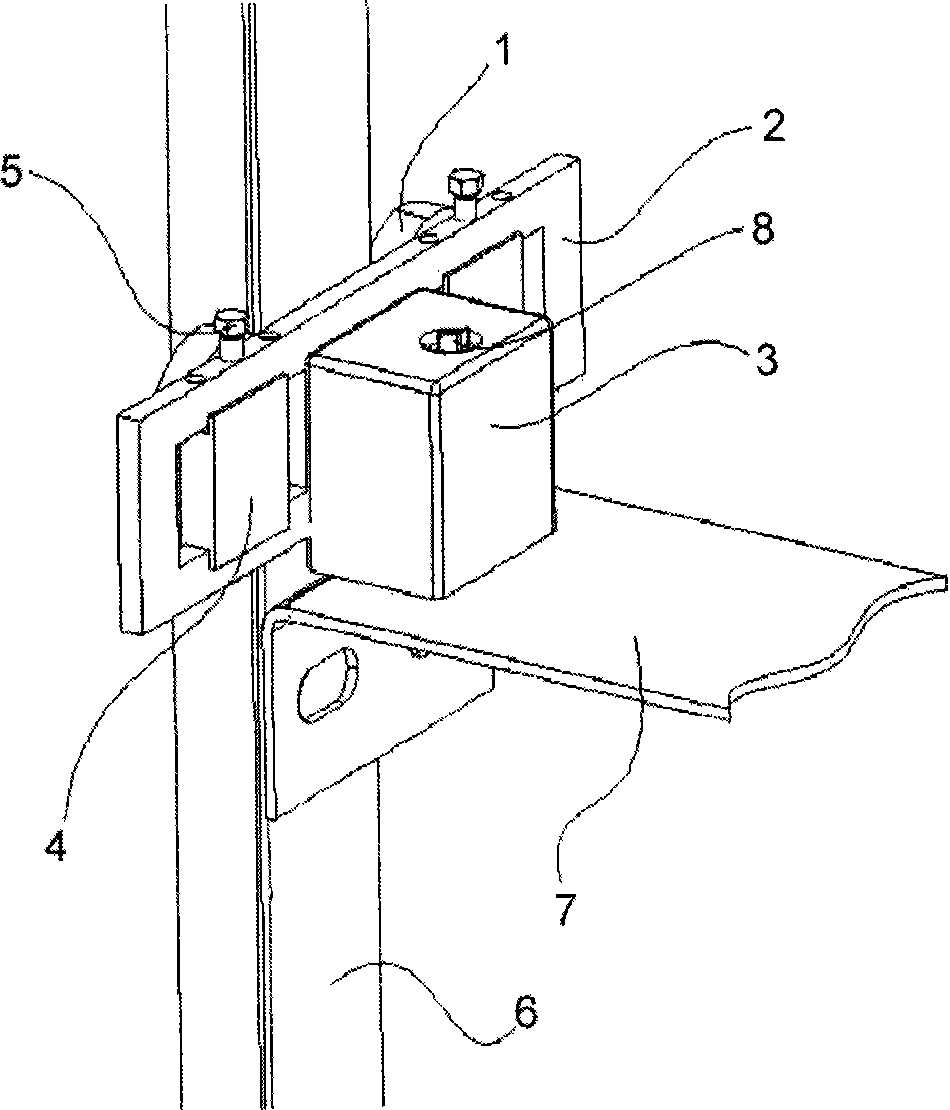

[0018] Example: such as figure 1 , figure 2 As shown, a guide rail straightness adjustment device includes a cam adjustment mechanism that can exert a stepless and continuous controllable extrusion force on the guide rail or beam, and an electromagnet fixing device for fixing the adjustment mechanism.

[0019] The cam adjustment mechanism includes a cam 1, a slider 4, a slider moving guide rail 2, and a set screw 5. The cam 1 can be rotatably mounted on the slider 4 around its wheel center, and the slider 4 can move on the slider moving guide rail. 2, the set screw 5 is used to fix the slider 4 in the slider moving guide rail 2.

[0020] A polygonal screw head is arranged on the cam 1, and the cam 1 can be easily rotated by clamping and rotating the polygonal screw head with a common wrench.

[0021] The cam adjustment mechanism is a cam adjustment mechanism with self-locking characteristics, and its self-locking characteristics are expressed as the friction coefficient of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com