Side wall concrete construction method employing side wall trolley

A construction method and technology of a wall trolley, which are applied in the fields of formwork/formwork/work frame, on-site preparation of building components, construction, etc., can solve the problem of slow formwork assembly speed, high labor intensity of workers, and lap jointing of steel pipe brackets. major problems, to achieve the effect of improving overall stability and construction quality, improving stability and construction speed, and improving stability and construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The specific implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

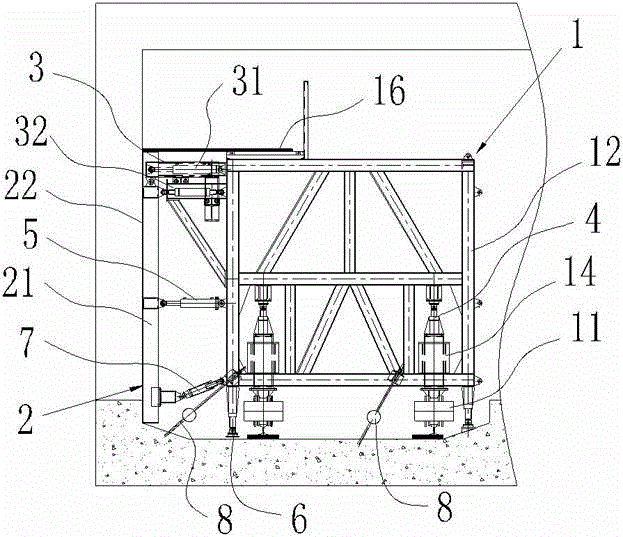

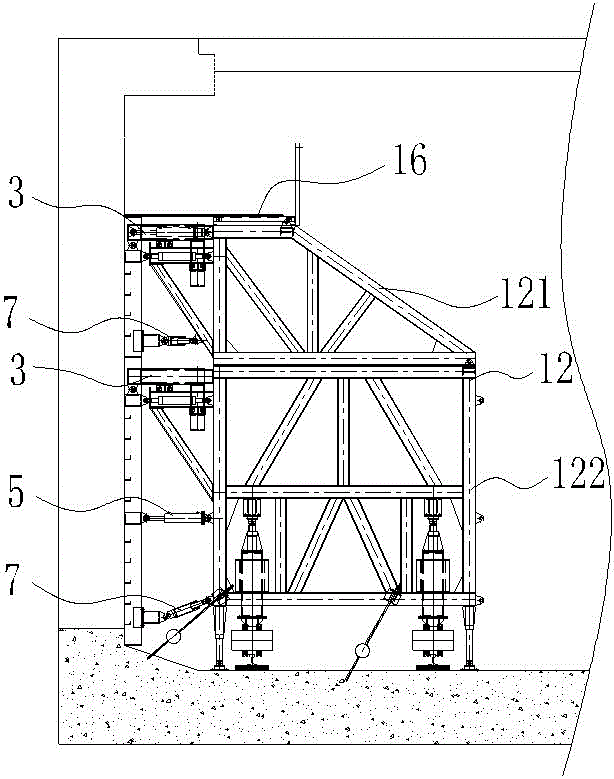

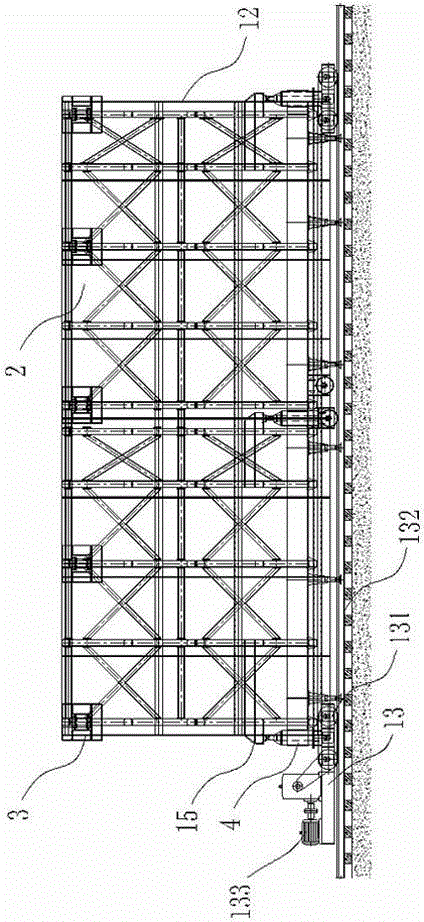

[0044] see also Figure 1~4 As shown, an embodiment of a side wall concrete construction method using a side wall trolley, wherein the applied side wall trolley is a side wall trolley unit or a longitudinal splicing of several side wall trolley units. The wall trolley unit includes a trolley moving and fixing system 1, and a steel formwork connection positioning system 2. In the embodiment, the designed length of the side wall trolley is 12m. In order to meet certain construction conditions, it can be split into two 6m side wall trolleys for use. The following are all described with the embodiment of the side wall trolley with a length of 12m after splicing.

[0045] The trolley moving and fixing system 1 includes a base 11 provided with a steel column 14 , a beam frame assembly 12 movably connected to the steel column ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com