Quenching device

A technology of quenching device and quencher, which is applied in the direction of quenching device, furnace type, furnace, etc., can solve the problems of low work efficiency and unstable treatment effect, and achieve the effect of simple structure, changing the effect of heat treatment, and easy realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

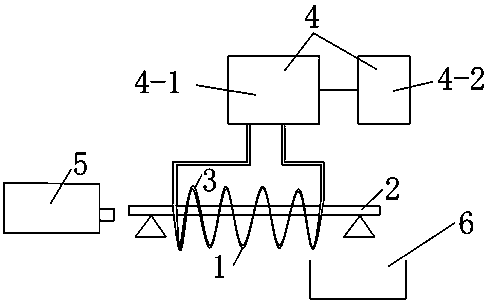

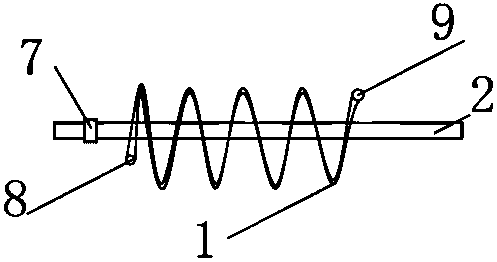

[0017] Embodiment, a kind of quenching device, see figure 1 , including a helical coil quencher 1 surrounded by a hollow copper tube 3, one end of the helical coil quencher 1 is a feed end 8, and the other end is a discharge end 9, and the helical coil quencher 1 is provided with The track 2 for the workpiece to pass through, the hollow copper tube 3 is provided with a resistance wire and the two ends are connected with the heater 4 . The feeding end 8 is provided with an oil cylinder 5, and the push rod of the oil cylinder 5 can expand and contract in the horizontal direction.

[0018] The heater 4 includes a connected intermediate frequency outdoor heater 4-1 and an indoor heater 4-2. Track 2 is two parallel steel pipes, see figure 2 .

[0019] A pool 6 is provided below the discharge end of the helical coil quencher 1 .

[0020] The tray 7 is provided with a side wall and one side facing the discharge end 8 is open, and the push rod of the oil cylinder 5 is connected w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com