A deformation heat treatment method for improving the strength of α+β-type titanium alloy

A deformation heat treatment, titanium alloy technology, applied in heat treatment equipment, quenching devices, manufacturing tools, etc., can solve problems such as high energy consumption, low efficiency, and inability to mass production, to solve low efficiency, improve strength, and achieve continuous quenching processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

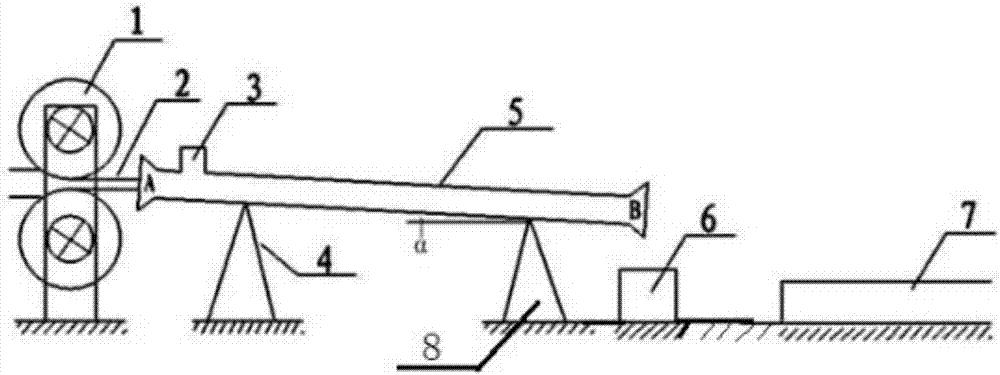

[0046] Using the present invention to carry out deformation heat treatment process to TC4 two-phase titanium alloy rod, first adopt two-roll mill 1 to roll TC4 two-phase titanium alloy to obtain the rolling piece 2 that specification diameter is Φ15mm, and rolling deformation is 91.6%; After quenching, the temperature of the rolled piece 2 is 820±5°C before quenching. Before quenching, the water inlet 3 is connected to make the flowing water fill the flowing water cooling pipe 5; (TC4) the rolled piece 2 is rolled from the two-roll mill 1. The feed port at one end of the flowing water cooling pipeline 5 enters and passes through the inside of the flowing water cooling pipeline 5 filled with cooling water, and enters the cooling bed 7 for air cooling after coming out from the discharge and water outlet at the other end of the flowing water cooling pipeline 5; The (TC4) rolled piece 2 above is subjected to low temperature stress relief heat treatment, and the heat treatment tempe...

Embodiment 2

[0048]Use the present invention to carry out deformation heat treatment process to TC20 (alpha+beta) type titanium alloy rod stock, at first two-roll mill 1 carries out rolling and obtains the rolled piece 2 that specification diameter is Φ 18mm, and rolling distortion is 85%; Carry out after rolling Quenching, the temperature of the rolled piece 2 before quenching is 845±5°C, before quenching, connect the water inlet 3, so that the flowing water is filled with the flowing water cooling pipe 5; The feed port at one end of 5 enters and passes through the flowing water cooling pipeline 5 inside that is full of cooling water, enters the cooling bed 7 air cooling after coming out from the discharge and water outlet at the other end of the flowing water cooling pipeline 5; TC20) Rolled piece 2 is subjected to low-temperature stress relief heat treatment, and the heat treatment temperature is 650°C. The mechanical properties of the TC20 material after deformation heat treatment were...

Embodiment 3

[0050] Use the present invention to carry out deformation heat treatment process to TC4ELI (alpha+beta) type titanium alloy rod stock, at first two-roll mill 1 carries out rolling and obtains the rolled piece 2 that specification diameter is Φ 20mm, and rolling distortion is 95%; Carry out after rolling Quenching, the temperature of the rolled piece 2 before quenching is 805±5°C, before quenching, connect the water inlet 3 (that is, pass water from the water inlet 3 to the flowing water cooling pipe), so that the flowing water fills the flowing water cooling pipe 5; (TC4ELI) After being rolled by the two-roll mill 1, the rolled piece 2 enters from the feed inlet at one end of the flowing water cooling pipe 5 and passes through the inside of the flowing water cooling pipe 5 filled with cooling water, and enters after coming out from the discharge and water outlet at the other end of the flowing water cooling pipe 5. The cooling bed 7 is air-cooled; finally, the (TC4ELI) rolled p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com