Automatic precise electrochemistry etching method and automatic precise electrochemistry etching equipment

An etching equipment and electrochemical technology, applied in the field of automatic precision electrochemical etching equipment, can solve the problems of large influence on the quality of the processed workpiece, difficult to control the corrosion accuracy, high labor intensity, etc., to achieve high equipment control accuracy, perfect process adaptability, Easy to operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be further described below in conjunction with the accompanying drawings.

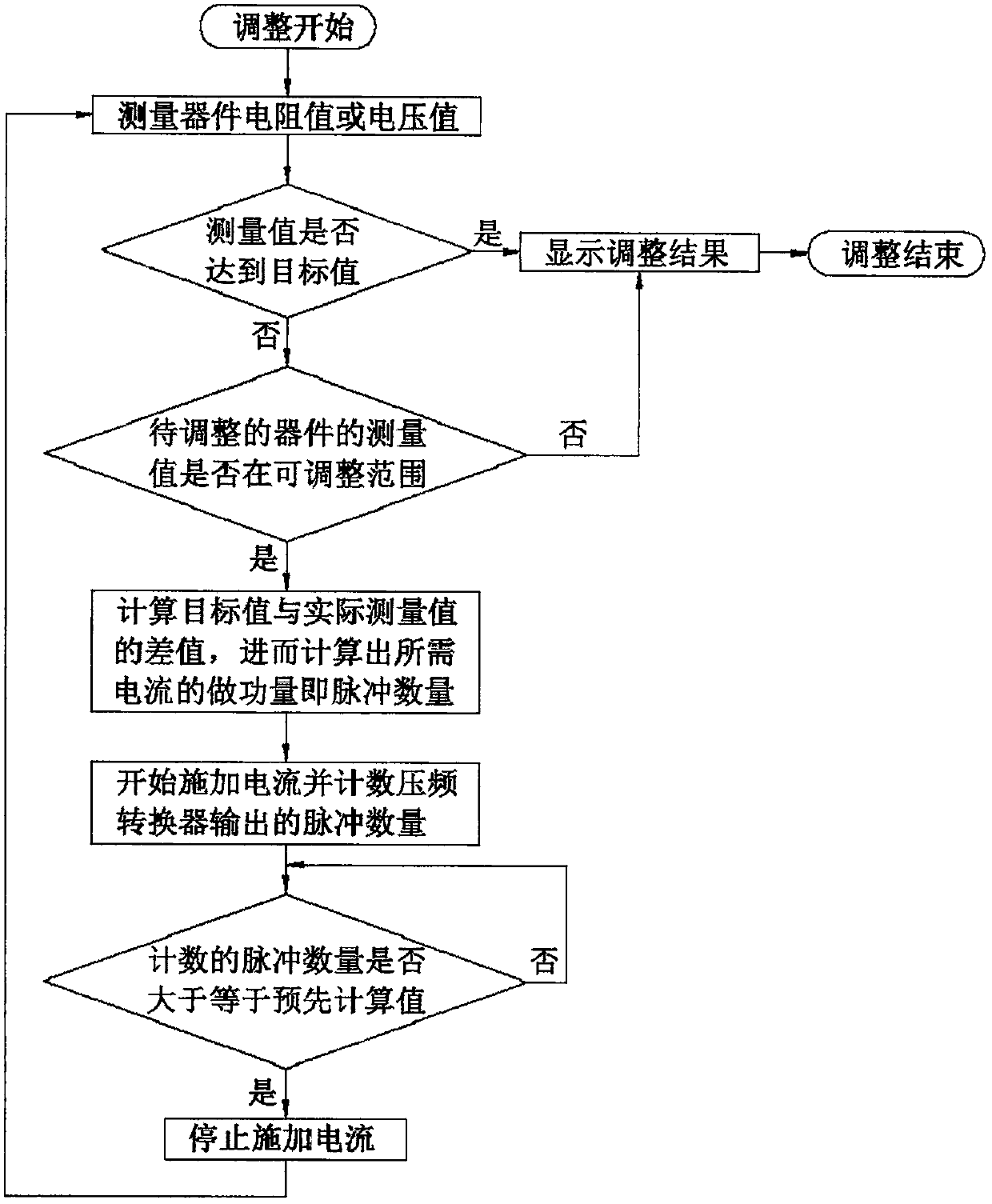

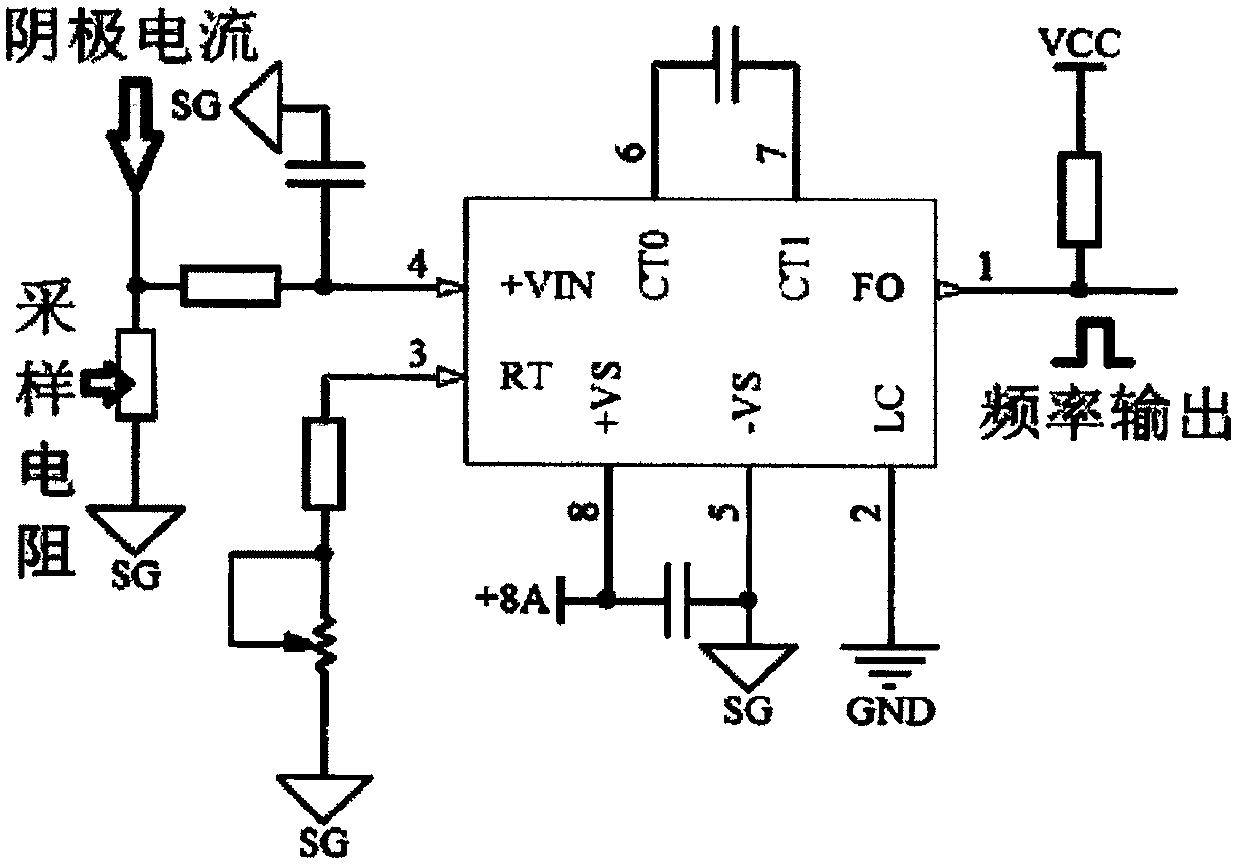

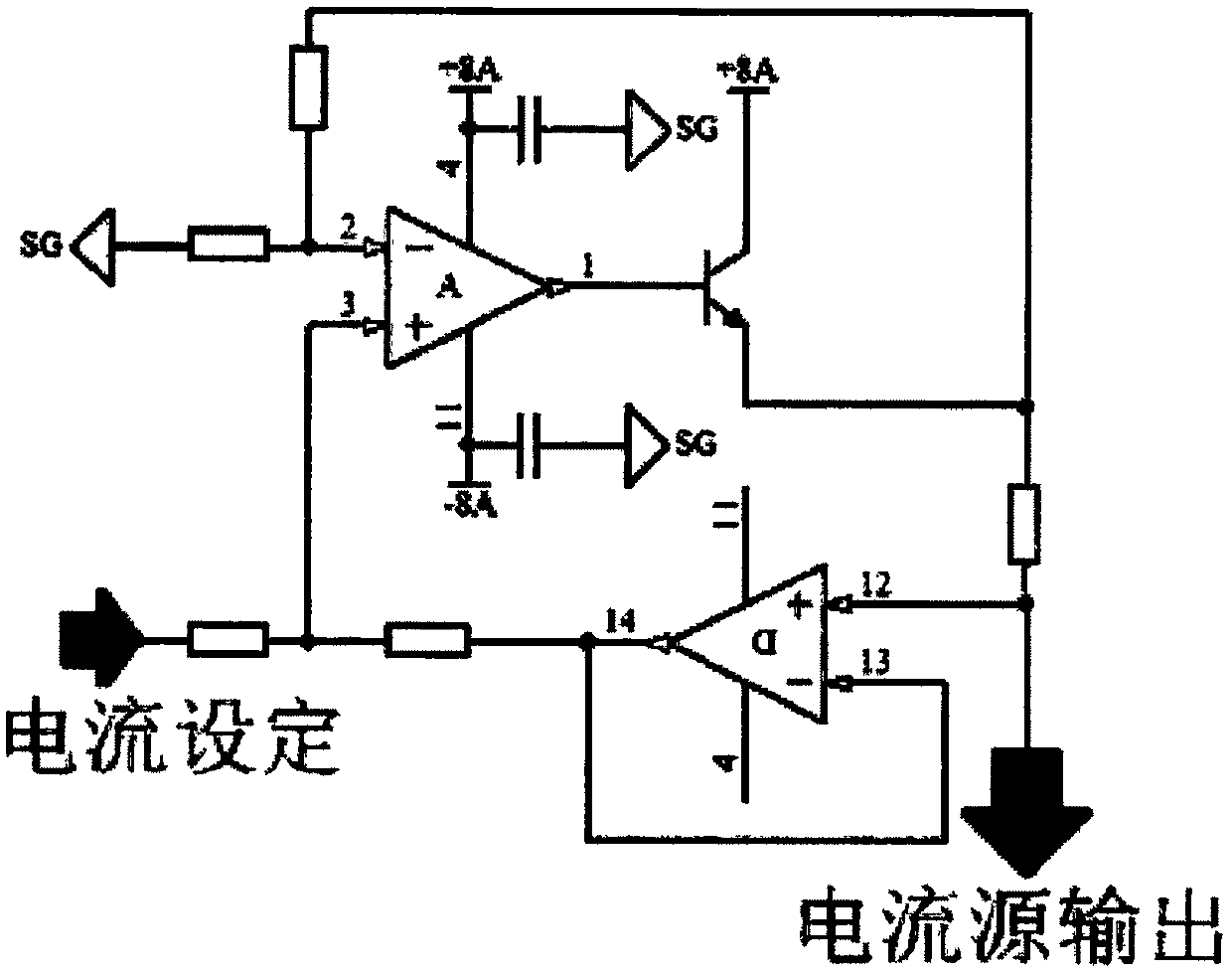

[0052] refer to Figure 1-12 , the automatic precise electrochemical etching method provided by the invention, it comprises the following steps:

[0053] Parameter setting: set the adjustment parameters of the workpiece according to the shape and requirements of the workpiece; set the calibration parameters of the mechanical structure according to the displacement deviation calibration of the mechanical structure; set the shape parameters according to the shape of the workpiece.

[0054] Workpiece positioning: place the workpiece with reserved positioning holes on the workpiece placement platform 6, make the reserved holes on the workpiece placement platform 6 coincide with the positioning holes on the workpiece, and pass through according to the preset position offset of the etching device Control the X-axis electric shift table 2 and the Y-axis electric shift table ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com